Professional Documents

Culture Documents

WPS FS Prazen

WPS FS Prazen

Uploaded by

Boris KozjanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS FS Prazen

WPS FS Prazen

Uploaded by

Boris KozjanCopyright:

Available Formats

POPIS VARILNEGA POSTOPKA WELDING PROCEDURE SPECIFICATION

Varilni postopek / Welding proces

Poloaj varjenja / Welding position

WPS N:

Rev.:

WPAR N: Datum: Nart t./ Drawing N:

Naronik: Customer Oblika zvara / Joint design Podloga: Backing: Vrsta priprave in ienja Seam preparation: Oznaka zvara: Weld mark: Oblika zvarnega leba / Weld joint form: Sequence: Debelina ploevine / Plate thickness: Ploevina/Blech Tip / Type: Osnovni material / Base material:

Premer cevi / Pipe diameter Opombe: Remarks:

Zgradba zvara / Welding sequence:

Dodajni material / Fillermaterial: Description EN Pass

Koren/Root: Polnilni/Fill: Temenski/Cover

Plini / Gas:

AWS oznaka AWS Class

SFA specif.

Znamka Trade:

Zaitni plin: Shielding: EN 439:

Pretok: Flow rate: Pretok: Flow rate:

l/min

Zaita korena: Backing: Toplotna obd. zvarov

l/min

Topl. Obd. Zvarov / Post weld heat treatment: Nain predgrevanja: Preheating process: Varek: Layer: Postopek: Process:

dod. mat. filler

Temp. predgrevanja: Preheating temp: Vrsta toka Type of current Varilni tok Current

Suenje elektrod: Redrying: Napetost Voltage Pomik ice Wire feed Vnos topl. Heat input

C

Hitrost varj.

min as varjenja

Travel speed Welding time

Potezni ali nihajni varek / String or weawe bead:

Zaetno in medvarkovno ienje / Initial and interpass cleaning:

Nihanje: Oscilation: Medvarkovna temp.

Veslojni var / Single or Multiple pass per side:

Razdalja med kont. obo in varjencem / Contact tube to work distance:

/

oba za za. plin Orifice or gas cup size

Interpass temp: Pokovanje / Peening:

leblenje: Gauging: Kontrola / Inspections: Opombe / Remarks: Wolfram elektroda Tungsten electrode dia:

ienje: Cleaning:

/

Stopnja / Scope:

Keramina oba: Ceramic nozzle:

Pripravil / Prepared by:

Preizkuevalec / Approver:

Datum: Datum:

C: pokrivni varek / cover pass

Klasifikacija napak/ Quality range:

Posebnosti / Others:

R:korenski varek / root pass F: polnilni varek / filler pass

SIST EN 25817:

WPS_FS_prazen.xls

You might also like

- Spoljni VodovodDocument43 pagesSpoljni VodovodMile MilojevicNo ratings yet

- WPS PDFDocument1 pageWPS PDFMirza SinanovicNo ratings yet

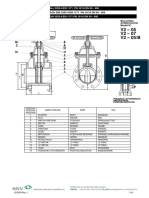

- Zasuni EV Zasun MIVDocument29 pagesZasuni EV Zasun MIVblago956No ratings yet

- Obrazec Za Izdelavo PWPS 311 - 2020Document1 pageObrazec Za Izdelavo PWPS 311 - 2020Marija IvanovskaNo ratings yet

- Kategorija I Wps-111 PCDocument1 pageKategorija I Wps-111 PCnenadtabNo ratings yet

- Obrazec Za Izdelavo WPS 135 - 2020 - KDocument1 pageObrazec Za Izdelavo WPS 135 - 2020 - KMarija IvanovskaNo ratings yet

- Obrazec Za Izdelavo PWPS 135 - 2020Document1 pageObrazec Za Izdelavo PWPS 135 - 2020Marija IvanovskaNo ratings yet

- Tlačni Djelovi Kotla: Welding, Heat Treatment and Testing Plan (WHTP) Schweiss, Glüh Und Prüfung Plan (WHTP)Document2 pagesTlačni Djelovi Kotla: Welding, Heat Treatment and Testing Plan (WHTP) Schweiss, Glüh Und Prüfung Plan (WHTP)Born ToSinNo ratings yet

- P80802-14 INSTITUT (BWSSNB, T 12mm, S355J2+N, 135) - OdobritevDocument1 pageP80802-14 INSTITUT (BWSSNB, T 12mm, S355J2+N, 135) - OdobritevMarija IvanovskaNo ratings yet

- WPS 1-2018Document5 pagesWPS 1-2018Igor RaicNo ratings yet

- Spisak I ATD Final 24.05.2022.Document129 pagesSpisak I ATD Final 24.05.2022.Nikola LopacaninNo ratings yet

- Gasni VentilDocument3 pagesGasni VentilDragan MarkovicNo ratings yet

- P80802-14 INSTITUT (BWSSNB, T 12mm, S355J2+N, 135) - PVPDocument2 pagesP80802-14 INSTITUT (BWSSNB, T 12mm, S355J2+N, 135) - PVPMarija IvanovskaNo ratings yet

- Elasticna SpojnicaDocument12 pagesElasticna SpojnicaAnelVeky23No ratings yet

- Q Techna 16 4 2005Document38 pagesQ Techna 16 4 2005NinoPrelecNo ratings yet

- Jahac ZiceDocument12 pagesJahac ZiceJosip Babic100% (1)

- Katalog HidropneumatikaDocument84 pagesKatalog HidropneumatikaJosjedankorisniknaskribiduNo ratings yet

- Elementi Locljivih in Nelocljivih ZvezDocument17 pagesElementi Locljivih in Nelocljivih ZvezFeelxxNo ratings yet

- PBPS 01-2015, Rev.1Document1 pagePBPS 01-2015, Rev.1brunizzaNo ratings yet

- 8 MMDocument6 pages8 MMCRISTIAN SILVIU IANUCNo ratings yet

- 10 MMDocument7 pages10 MMCRISTIAN SILVIU IANUCNo ratings yet

- Popisi KompletDocument5 pagesPopisi KompletIvan KoličNo ratings yet

- 1-0-Uvod Zasuni MIVDocument3 pages1-0-Uvod Zasuni MIVblago956No ratings yet

- Nvo Končar PDFDocument20 pagesNvo Končar PDFAmarK90No ratings yet

- FORTIS MARIBOR Brosura Okt 2014 SLODocument2 pagesFORTIS MARIBOR Brosura Okt 2014 SLOBoris KozjanNo ratings yet

- Sapio Sapio Laserski PliniDocument1 pageSapio Sapio Laserski PliniBoris KozjanNo ratings yet

- Fotonapetostni Modul 540W CompressedDocument1 pageFotonapetostni Modul 540W CompressedBoris KozjanNo ratings yet

- Proizvodnja Peletov V SlovenijiDocument3 pagesProizvodnja Peletov V SlovenijiBoris KozjanNo ratings yet