Professional Documents

Culture Documents

Nicola Tesla (US Pat. 1209359)

Nicola Tesla (US Pat. 1209359)

Uploaded by

GaleriaTechniki.PLOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nicola Tesla (US Pat. 1209359)

Nicola Tesla (US Pat. 1209359)

Uploaded by

GaleriaTechniki.PLCopyright:

Available Formats

UNITED STATES PATENT OFFICE.

JrI][OLA. !rar..&. 01' JrSW YOaJ[, Jr. Y., A8SIO.O. TO WAL'l'JUl( W.t.TCJI COXP.t.JI'Y, 01' W.t.I.'l'JUX, ....... CJr'C7..rrII, .t. COUO .... TIO. 01' X·.AClIl78Z'1"1'B.

IIPZZD-nrDIC.t.TO ..

1,109,359.

Ip..u.Uo. of I.ettera hte.t.

Patented Dec. 19, 1916.

A"UoaU •• 11e4 .. ,. _, ltl6. IertalJfo.Ml,'I'M.

10 all1DMm it may COtICM"ft.: latter, especially so when the specific gravity

Be it known that I, NJJtOLA T7.8LA, B citi- or the viscosity of the liquid IS great.

zen of the United States, residing ·at New Having determined the conditions under York, in the county and State of New York, which the law of proportionality of torque have invented certain new and useful Im- to speed (rather than to the square 'of the provements in Speed-Indicators, of which speed or to some hizher exponential functhe following is a full, clear, and exact de- bon of the same) holds good, I have appUed scription. . my discoveries in the production of new de-

In the provision of speed indicators, that vices essentially indicators of speed but give direct readings of rate of motion,- having wider fields of US&-whicn are, in for example shaft speeds in terms of revolu- many aspects, superior to other forms of tions per minute or vehicle speeds in miles speedometers.

per hour-it is obviously important that the Specifically I have devised rate-of-motion Instrument be simple, Inexpensive and du- indicators which comprise driving and rabIe, and that its indications be correct driven members with 'confronting, .cloeely-

, throughout a wide range of speed. Likewise adjacent, noncontacting, smooth, annular it is very desirable that its operation, shall" surfaces of large area, coacting in ~e transbe subject to little or no appreciable devia- mission of torque through the viscosity and tion hom accuracy under normal or ex- adhesion of interposed thin films of air,pected extraneous changes, such as those of mechanical structures offering' numerous atmospheric density, tentperatute, or mag- constructive and operative advantages. netic influence, in order that the stru~u~ Furthermore, by pro~rly designing and ~ may be free from any complications InCI- -ordinating theessentJal elements of suc~ m-, dent to the employment of specific means struments I have secured substantiaf linear compensating for such varying conditions. proportionality between the deflections of

My present invention supplies a speed the indicating or secondary element and the measunnE appliance amply satisfying com- rate of rotation of the driving or 'primary

mercial demands as above stated, in a strue- member.. '

tor:e wherein the adhesion and viscosity of The conditions more or leas indispensable a gaseous medium, preferlllbly air, is utilized for this most perfect embodiment 01 my infor torque-transnussion between the driving vention-that is to say, embodiment· in a and driven members. speed indicator approximating rigorous

More particularly, my invention provides linearproportiona..1ityof de1lection tc)speeda rotatable primary and a mechanically re- are:

sistant or biased pivoted secondary element,' I. The arrangement· should be such that coOperating. through an intervening fluid the exchange of fluid acting on the 8yIItem medium to produce, inherently, without the' is effectively prevented or minimized. If U8fI of compensating instrumentalities, new fluid were permitted to pass freely beangular· displacements of the secondary ele- tween the elements there would be, as in a ment in linear proportion to the rate of rota- pump, with the rise and' fall of mooty,

,tion of the primary, 80 that the readinft corresponding changeS of quantity and the IIC&le may be uniformly graduated. ThIs torque would not vary directly as the speed, latter advantage is secured through the ap- but as an exponential 'function of the same. . plication of novel principles, discovered by Broadly speaking, such provision u is com-

me, which. will be presently elucidated. . monlv made in hydraulic brakes for free eir-

In investigating the effects of fluids in cuIation of fluid with ~. to the rotative

'motion upon rotative B}'stems I have ob- syatem, with the attendailt aeceleratioD and served that under certain conditions to be retardation of the, ftow, will generally prohereafter defined, the drag or . turning duee a torque varying u the square of the e40rt exerled by the fluid is exactly pro- speed, subject however; iD. practice, to in-

'portiona~ to its- velocity relative to the fluenees which may cause it to 'change aesyStem. This· I . h~:ve' found to be true of cording to still hIgher powera. For thia p880us and liquid .media, with the distinc- reason confinement of the fluid interveiling tion however, that the limits withiil. which between the primary and secondary elements the law hold. good are narrower for the of the sy~ 80 that BUM active, torque-

transmitting medium may remain resident, and not be constantly renewed, is vital to complete attainment of the desired linear

pro~rtionality. .,

2. The spaces or channels inclosing the acti ve medium should be as narrow as practicable: although within limits this is relative, tnernnge of. effective separation increasing with the diameter of the juxtaposed rotative surfaces. My observations have established that when the spacing is so wide as to accommodate local spiral circulation in the resident fluid between the 'confronting areas, marked departures from...rigorous proportionality of torque to speed occur. Therefore in small instruments withprimary members of but few inches diameter, it is desirable that the channels should be as narrow as is mechanically feasible with due regard to the importance ofmaintaining the noncontacting relation of the rotative parts ..

3. The velocity of the fluid relative to the system should be as small as the circumstances of the case will permit. When a gas such as air is the active medium, it may be 10.0. feet per second or even more, but with Iiquids speeds of that order cannot be used WIthout detriment.

4. The bodies exposed to the action of the fluid should be symmetriCally shaped and with smooth surfaces, devoid of corners or projections which give rise to destructive eddies that are partIcularly hurtful.

5. The system should be so shaped and disposed that no part of the moving fluid except that contained in the spaces or channels can effect materially the torque. If this rule is not observed the' accuracy of the instrument may be impaired to an appreciabledegree, for even though torque transmission between. the confronting surfaces is proportional, there may yet be a component of the rotary effort (through the fluid coacting with the external surfaces) proportional to an. exponential function of the speed. Hence' It IS desirable that by a closely investing casing, or other means, the torque-transmitting effect of fluid outside of the' channels between the rotative parts be

minimized. .

6. In general the flow of the medium should be calm and entirely free from 8.11 turbulent action. As soon as there is & break of continuity the law above stated is violated and the indications of the device cease to be rigorously precise.

These requirements can be readily fulfilled and the above discoveries applied to a great many valuable uses, as for indicating the speed of rotation or translation, respectively, of a shaft, or a vehicle, such as an automobile. locomotive, boat or aerial vessel; for determining the velocity of a fluid in motion; for measuring the quantity of flow in steam, air, gas, water or oil supply; for

1,209,SlS9

ascertaining the frequency of *hanical and electrical impulses or. oscillations; for determining . physical constants; and for numerous other purposes of scientific and practical importance.

The nature and object of the invention will be clearly understood from the succeeding description with reference to the aceompanying drawings in which:

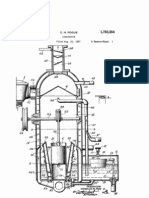

Figure 1 represents a vertical cross section of a speed indicator or hand tachome~l' embodying t~e above principles ; Fig. 2 IS It horizontal view of the instrument disclosing part of the scale, and Figs. 3 and 4 are diagrammatic illustrations showing modified constructions of the main parts in a similar device.

Referring to Fig. 1, 1 is apulley-shaped metal disk from three to four Inches In diameter constituting the .freely-rotatable primary element. It is fastened to a driveshaft 2 which is turned to fit a hole in the central hub 3 of the Casting 4. A ball bearing 5 set in a· recess of the .former, serves to take up the thrust against the shoulder 6 of the shaft and insures free running _ of the same. In Close J?roximity to the disk 1 is. the thin shell 7 In the form of a cup, this being the secondary element of the system. It IS made of stift' and light material, as hard aluminum, and is fixed to a spindle 8, supported in nearly frictionless bearings or PIVots 9 and 10.. As . before remarked the spacing between the two elements, (1 and 7), should best be as small as manufacturing conditions may make feasible. By way of example, a' separation,-in an instrument of the diameter suggested,-of say .0.15" to .025" will be found effective for working purposes and also within a reasonable range of inexpensive mechanical attainment. Still smaller spacing' is, however, theoretically desirable. One of the' bearings. aforesaid is screwed into the end of the shaft 2 and the other into allug 11 in . a slotted tubular extension 12 0 a casting

13. The running bearing in the shaft, though not of perceptible influence on. the indications, may be replaced by a stationary support behind and close to shell 7, as at 8. A torsional spring 14 is provided, for biasing the pivoted element 7, having its ends held' in collars 15 and 16, which can be clamped, as by the set screws shown, the one to the spindle 8 and the other to the plug 11. The bearin~s 9 and 10. are capable of longitudina.l adjustment and can be locked in any position by check nuts 17, and 18, but this refinement is generally unnecessary. The castings 4 and 13, in the construction specifically shown, when screwed together form a casing that closely invests the rotative system. This casing forms one available means for preventing communication of torque from the primary element 1 to the

B

secondary member 7 through the medium cations will not be true to scale, even though contacting with the ·external surfaces of the instrument be prefect: in other respects. both] to any extent sufficient for mllterially In order that the torque should vary rigormodifying the torque due to the films be- ously as the speed, the fluid particles in the tween the elements, but Other means to this minute channels between the rotating and end ·may be subsdtuted. The chamber in- pivoted members should move in circles and closed within the casting should be air- not in· spirals, as necessarily would be the tight for .highest accuracy in order that the case in II. device in which pumping action density of the contained medium. may re- could take place, snd. either by making main constantt . although . in the .vast. major- both the primary and Iiecondary elements ity ofca.ses wn:et"e air is used as the active .etrectively-iinrrforate to prevent central agent, the slight e1fects of ordinary changes admission 0 .. airl or otherwise 80 eonof tempenture anCt:density of the external structed and conditioned that air may not atmosphere can be ignored, as. they· are in freely pass from center to periphery beI measure neutralized by the concommitant tween the elements of the movin~ sJstem. variations in the resilience of the torsional .• unchanging residence of a definite body spring and as they do not seriously atrect o( the active medium within the SY8- the proportionality of deflections observed. .~ is insured. Where pumping action,However, when great precision is essential, that. is to sa.y, acceleration or retardation a seal. 19 of suitable paCking, paste or amal- of. fluid movement other than circularly rm may be employed. Obviously the work- with the primary element,-tak~ place mg parts may be contained in a eeparate,the deftectionsincrease more rapidly than perfectly tight reservoir filled. with fluid the speed. It follows that centrifugal force, of any desired character, the rotating memo which is the essential active principle in b;er or ~ 1 being driven by a magnet o~t- pumping, must be negligible to avoid comside, Th18 expedient has been adopted m pression of t~e air at. the periphery which numerous instanc~ and is quite familiar. might result In a sensibly increased torque. The casting 4 has a window or opening .20, To appreciate this, it should be borne in closed by a piece of transparent substance, mind that the resistance of a circular strip such as celluloid, for enabling the readings of the active area would, under such eonto be made on the scale which is engraved ditions, be proportionate to the fourth power upon or glued to the rim of 'the indication- of the diameter so that a slight compression controlling element or shell To The shaft 2 and attendant" increase of density of. the is armed with a. steel or rubber tip 21, and a medium in the peripheral portion would handle 22 of fiber or other material is .fas- cause a noticeable departure from rigorous tenedto the central hub of.casting 13, com- proportionality. Experience has demonpleting the hand tachometer.· .strated that when the space is· very narrow,

. Fig. 2· in which like numbers designate as is indispensable for the fullest attaincorresponding parts is self-explanatory. ment of the desired proportionality, the cen. Attention may be called to the pointed in- trifugal etrect of the active fluid, be it gasedex 23 placed jn the opening 20 and mark- ous or liquid. is SO small as to be unobserving, when the instrument is not in use, zero able. The inference is that the actions in the on the scale. The latter can be readily put narrow space between the rotative members in proper position by turning the collar 16 are. capillary or molecular and wholly difto the desired angle. ferent in principle from those taking' place

As . described the device is adapted for ' in a pumping device in which the fluid use in the manner of an ordinary hand masses are. alternately retarded and acceletachometer. In taking the revolutions of a rated .. The scale, which, as will be apparent shaft, the tip 21 is placed firmly into the from the preceding, is uniform in an instrucentral cavity of the.former! as usual, with ment best embodying my invention, may th~ result of entraining the disk 1 and bring. be so graduated that each degree corresponds ing it to full speed by friction. The active to a certain number of revolutions per unit medium, preferably air, in the narrow chan. of time, and for convenience, (in shaft-speed nels between the rotating and pivoted mem- indicators as herein shown), the constant bers, by virture of its adhesion and vis- is made & round number, as 100. The escosity, 18 set in circular motion by the pri- tablishment of this relation through the admary element, and, giving up the momentum justment of the torsional spring is faciliimparted to it on the light secondary shell 7, tated by varying the distance between the causes the latter to turn until the torque parts 1 and 7, thus modifying the torque exerted is balanced by the retractile force of and consequently the deflection, (the torque spring 14. Care should be taken to em- varying inversely as the distance) while alploy a Spring the resistance of . which in- ways keeping within the range throughout creases linearly with displacement, so that. which linear proportionality is attainable. the detlections are exactly proportionate to In calibrating it is necessary to make but the torsional etrect, as otherwise the indio one observation comparative with some posi-

tive standard and to plot the balance-of the scale accordingly. The conditions above set forth being renlized, the reading will be accnrntely pl'0l)ortionnte to the speed and the constant wil he correct thro\1~h the whole runge eontemplatedin the design, Therein lies.l\ very Important advantage bearing Oil uuinnfnct.iire nnd introduction of devices of this character over those now in use which a1'6 bused on' an empirical scale, tedi.0\1S to prepare, and unreliable ... When desired, the instrument may be rendered dead bent through magnetic or mechanical dumping, but by making the torque very great, and the inertia of the secondary element very small, such objectionable complication mny be avoided. With a given separation the turning effort is proportionate to the product of the velocity of rotation, the density of the fluid and the aggregate area of the active surfaces, hence by increasing either of these factors the torsion can be augmented at will. It obviously follows that the pull exerted on a circular disk will be I\S the third power of the diameter and one way of attaining the object is to use Ii. large plate, Other and better ways areillustrated in Figs. 8 and 4 in which the rotating and pivoted elements are composed of interleaved disks or cylinders. The first arrangement permits an indefinite increase of the torque, the second commends itself throu~h the facility of adjustment of the force oy varying the active area.

For many reasons it is decidedly advantageous to employ air as the agent ill an instrument 'intended for popular purposes, especially those involving rough use and inexpert handling, since thereby the cost of manufacture may be kept low, the need for ensealing minimized and susceptibility of the parts to easy disassembling and re:plncement attained. It is, therefore, desirable that the annular confronting surface of the elements,-whether of disk or cylindrical form,-be sufficiently extensive for securing ample torque to make the instrument approximately dead beat and to minimize the percentage of error due to mechanical im-

perfections.· .

The foregoing description contains, I Delieve, all tlie information necessary for enabling an expert to carry my invention into successful practice. When using the indicator in the manner of an ordinary vehicle speedometer, as in an automobile, the shaft 2 is rigidly or flexibly geared to the driving axle or other suitable part and readings are made in miles per hour, as is customary. As will be apparent many other valuable uses may be served, since the primary element may be connected in suitable electrical or mechanical manner with any rotating part, the speed of which may be translated through a linearly proportionate constant

1,209,869

into the desired terms of time and qUantitl' and the rending scale may be calibrated lD such terms. It will also be evident that by accurate workmanship, following the teachings of my ill vention,· instruments at once simple, rugged, and scientifically accurate may be constructed for 0. very wide range of uses in either huge or tiny sizes; and, since the eommercinl requirements of accuracy in mnn~ ~elds ,:ti ves I~ l'ellson~ble ran~e of pernnssive e1'1'01', manufncturing considerations may lend to deviations from strict observance of some of the conditions that I ha ve indicated as best attaining a. rigorous proportionality of reading. The provision of simple mechanical elements, cooperating primarily only through the viscosity and adhesiveness of the air films intervening therebetween and substantially free from need for enseuling and from error caused by changes of extraneous conditions, especially temperature, affords striking commercial advantages unattainable in any form of speedometer of which I am aware. Therefore while I have described in detail for the purpose of full disclosure a specific and highly advantageous embodiment of my invention, it will be understood that wide variations in the mechanical development thereof mal be made without departure from its spirit within the scope of the appended claims,

. What I claim is:

1. In combination, fixed supporting means, disconnected alined drivlDg and driven shaftsrotatably mounted in said supporting means, relatively thin spaced rigid pieces of material rigidly connected to and arranged coaxially about said driven shaft with broad surfaces opposite each other, and other relatively thin spaced rigid pieces of material rigidly connected to and arran~ed coaxially with the driving shaft, and being alternated with the first-mentioned pieces between them and having their broad surfaces adjacent to and spaced . from the broad surfaces of said other pieces, said pieces all arranged in air, through which torque is frictionally transmitted from the secondmentioned pieces to those first-mentioned.

2. In combination, in a speedometer, disconnected alined driving and driven sha.fts, a fixed support,· said shafts being mounted in said support, a coiled spring having one end secured to said fixed support and the other end secured to said driven shaft, relatively thin spaced rigid pieces of material rigidly connected to and arranged coaxially about said driven shaft with their broad

. surfaces opposite each other, other relatively thin spaced rigid pieces of material riw.d1y connected to and arranged coaxially WIth tbe driving shaft, and being alternated between said first-mentioned pieces and spaced therefrom, and an air body filling

a

the spaces between said pieces and consti- non-con~ relation, relatively ut.euift tuting the ·torque-t.i·anamitting frid.ion· friCtion aurfacea, and an interpo8ed gu&oua medium therebetween.' ' body, through which the dri!ing member

3. In combination, in a speedometer, dis- frictionally drags the driven element. 'connected alined driving and driven shafts, ',8, "In a speedometer, the combination with a frnme hft ving bearings for .id shafts, a supporting means, eeparatel.y-rOtata.,le drivcoiled syring whose inner ~nd .is secured to ing and driven shafts mounted therein, biasSlud driven shaft andhaving lts outer end ~ m~ns for the ~ven shaft, and D!ean8 secured to said frame, spaced rigid pieces of to mdicate rotary dJBPlacement of the biaaed material rigidly connected to and arranged abaft in terms of speed, of pieces rotativ~y about said driven shaft, and other spaced c..ned by said respeCtive shafts, having rigid pieces of material rigidly connected to relative1y-extensi.ve, non-contacting, cloeelynnd arranged about said driving shaft, the adjacent surfaces arrannd to confront each fonnerpieces being alternated between the other, an~ & gasoous ~e<Iium interveni.Dit belatter, PIeces in spaced relation with their tween said conirontmg surfaces to coact broad surfaces 'in close juxtaposition, and therewith frictioruilly to transmit torque with the interspaces between. _id8J.>a~d from the driving shaft to the biased. driven PIeces formmg a convoluted ur-contammg shaft.

channel therebetween open to the surround- 9. In a speedometer, the combination of

ing air. " a primary element rotatable' at v~

, ~.In comb~ation! disconnected alined speeds, having a plurality of spaced annuli, driving and driven shafts, a fixed support.] a biased secondary element, arranged' for bearings therefor in said support, a coiled separate rotary movement and adapted and spring having one end secured to the driven arranged to indicate speed variationaby the shaft and its other end Secured. to said fixed extent of its displacement, said secondary support, a cup-shaped body secured W ,one element having a plurality of spaced, thin, ~~ of sai~ dr~~ shaft coaxialJy, sp~~d light annuli, the annuli of said two elements rigid relatively thin ~lates secured to said interleaved in non-contacting, closely-adjabody in parallel relation to each other, an- cent relation always to present toward each other cup-shaped body secured coaxiBlly to other extensive friction surfa~ and an said driven shaft and inclosing said plates air body, through the films of which, interat their outer edges in spaced. relation there- vening between said annuli, rotation of the to, other spaced rigid relatively thin plates primary 'element may induce speed-indicatsecured. to the second-mentioned body and ing displacement of the secondary element. ~xtend.ing betw~ the first-mention~ plates 10. A speedometer wherein a Pl'imarr, m spaced relation thereto, and an' &ll' body' variable-speed element, and a biased, speedfilling the spaces between said pieces fric- indication-controlling secondary' element, tionally to transmit torque from the driving that·. are 'suitably supported for ieparate structure to the driven structure. movement, have opposed extensive friction

5. The combination with means f9r sup- surfaces in non-contacting juxtaposition for port and driving and driven shafts rotata- frictional communication of power from the bll supported thereby, of means to trans- primary element to the secondal1 element mlt torque from the driving shaft to the through a gaseous medium that mtervenes driven shaft comprising opposed material- between said friction surfaces.

pieces respectively connected with the driv- ll . .An air drag speedometer, wherein, a mg shaft and the driven shaft and arranged primary, variable-~ element and a to present tpward each other relatively-ex- 'biased speed-indication-controlling secondtensive, non-contacting, closely-adjacent sur- ary element, that are suitably mounted for faces, and a gaseous medium in which said separate rotary movement in an air-containpieces work, said gaseous medium serving ing casing, have opposed, extensive fricfrictionally to connect the said opposed ina.;. tion-surfaces in non-contact~ juxtapositerial-pieoesfor transmission of torque from tion, for frictional communication of torque the driving shaft to, the driven shaft. from the primary element. to the secondary

6. In combination, driv.ing and driven ele- element through the medium of the casing-

'meats sUitably supported and having con':' contained air. .

fronted annuli always presenting to each 12. .In a speedometer, the combination of other relatively-extensive, non-contacting, an air containing casing, a primary element closely-adjacent surfaces, said 'Surfaces dis- and a secondary element mounted in Said PGSed in a ~us friction medium, where- casing for separate movement, said elements by the driving member, by its rotation, in- having, extensive surfaces exposed. toward duces rotary motion of the driven member each other in closely, conti$Uous but nonthrough the dl"ag of the gaseous medium in- contacting relation for frictional communitervening between said annuli cation' of power to one hom' the other

7. In combination, driving and driven ele-through the intervening air, means resili.ments having in opposed, closely adjacent, ently to resist displacement of the second-

l,909,slS9

ary element, and means to indicate displace- transmitting fluid medium, sa.id surfaces bement of the secondary element in terms of ing so closely proximate that the .torque speed. . transmitted from the driving to the driven

18. In' combination, in a speedometer, member is substantially proportional to the

disconnected shafts respectively carrying rate of rotation of the former. .

driving and driven elements that have an- 19. A. speed indicator comprising} in null a.ftording continuous extensive frio- : combination, a rotatable body, a second. antion surfaces in always confronting non- 'gularly movable body, means to resist dbtconta~ closel'y - spaced relation, the placement o-f the .latter propOrtionately. to driven element bemg light and biased by a the torque applied thereto,' and a fluid melight spring, for ready response to torque dium interpOSed between them, I!&id bodies tr&nSJnltted frictionally by air, and the !Lir having opposed annular surfacee in such .film-spaces between the elements constitut- close proxunity that pumping 'of the.meing an open tortuous channel] and an air dium therebetween is prevented and the de. conta.ining casin~ inclosing th~ driving and flections o! the .seoond body are made prodriven elements, lts contained air body form- portionate to the speed of the other. .

in~ the sole effective means of torque trans- 20. A speed indicator,· comprising,· in

mission between the elements. combination, a rotatable va.ria.ble. speed pri-

14. In a speedometer% ~he combination of mary element, and a light, pivoted, torrotatable driving and driven elements hav- sionally-reeisted, indication-contro~ seeing in opposed, closely-adjacent non-con- ondary element, suitably mounted for seJ?atacting relation, relatively extensive friction rate movement and operatively linked WIth surfaces, means to bias the driven element! the former through an. interposed gaseous means to indicate rotary displacement 01 medium, said elements having opposed, ansaid driven element in terms of speed, a cas- nular non-contacting surfaces so extensive ing inclosing said elements and containing and closelY proximate that the whirling meair, said contained air body extending in dium exerts a, strong and steady turning films between the friction surfaces, and effort upon the secondary element, substanforming the sole effective means of torque tially. in linear proportion to the speed of

transmission between the driving and the primary. . .

driven elements. 21. The combination, in a rate indicator,

15. In combination, driving and driven of a freely rotatable primary and a torelements having in opposed non-contacting sionally-resisted indication controlling secrelation relatively extensive friction sur- ondary member mounted for separate movefaces so closely adjacent that through an in- ment, with their opposed non- contacting terposedgaseous body the driving member symmetrical surfaces confining therebe-· frictionally drags the driven member with tween a resident fluid body and arranged in a torque linearly proportionate to the speed such close :proximity that the fluid, enof the former. . tra.ined in. CIrcles by the rotating primary

16 .. A. rate indicator wherein a freely-ro- exerts a torque on the secondary member tatableprimary and a biased, indication- in substantially linear proportion to the

controlling secondary member, suitably sup- speed of the former. .

ported for separ~te movemen.t,have op- 22. In eombination, in a speed-~dicatol", posed, non-contacting surfaces In such close a rotatable pnmary element, a biased secproximity that through an intervening vis-. ondaryelement, a fluid body between and COWl fluid medium torque is transmitted to around them., said elements having opposed the secondary member in linear proportion non-contacting extensive surfaceS in such to the-speed of the primary. close proximity that the resident fluid body

11. A. rate indicator wherein a freely ro- therebetween transmits torque to the seCondtatable primary and . a biased, indication- ary in substantia.lly linear proportion to the . controlling secondary element, suitably sup- speed of the primary element, and means ported for separate movement are opera- for minimizing the rotary effort transmitted tively linked through an intervening vis- through the fluid around the elements.

eous and adhesive air body, said elements 23. A. rate indicator comprising a strucha.ving opposed extensive non-contacting ture confining a substantially unchanging surfaces SO closeiy adjacent that the torque body of fluid and including' an extensive transmitted to· the secondary element annular surface of a freely rotatable memthrough said air body is substantially in ber, arranged to impart CIrcular motion to !;near proportion to the speed of the pri- the fluid, and a confronting annular surmary element. . . '. .. f~ce of an indication-controlling angularly-

18. In a speed indicator the combination displaeeable member, arran~ed. to take up of two rotatively movable driving and momentum of the fluid, said surfaces bedriven members having opposed non-con- ing SO closely proximate that the torque tacting extensive surfaces confining between transmitted through the fluid is .proporthem a practically constant body of torque- tional to the speed of the rotatable meniber.

U. A speed indicator comprising two ele- for reading its displacement in terms of ments mounted for separate movement in a speed, said two members having opposed, fluid medium} one' of the elements being non-contacting imperforate annular surfaces freely rotatab e at varying speeds, and the in such close proximity as to confine thereother pivoted and biased against angular between a film of fluid through which torque displacement, said elements having opposed is transmitted to the resistant member in non-contacting extensive symmetrical sur- linear proportionality to the speed of the faces in such close proximity that torque is rotatable member.

transmitted through the intervening fluid 29.· The combination with a closed fluid

body in substantially lineal' proportion to containing casing, of a plurality of sym-. the speed of the 'primary" element, and a metrical bodies with smooth surfaces rotamember surrounding said elements and tably mounted therein, means for torminimizing the flow of the fluid' along the sionally restraining some of said bodies, and exterior surfaces of said secondary element. means for rotating the others, said bodies

25. In u device of the character described, being placed with their surfaces in such close the combination of II. rotatable primary ele- proximity to each other and to the walls of ment, It spring-biased secondary element, a the casing that the rotating bodies will cause casing surrounding the same and It fluid an even and undisturbed circular motion of body filling the casmg, said elements having the fluid and transmit torque to the torsionopposed non-contacting annular surfaces in ally restrained bodies in proportion to the such close proximity that the rotary effort speed of the others.

exerted through the fluid body on the sec- 30. In a speed measuring instrument the ondary element is proportionate to tpe combination of driving and driven mem'b;rs speed of the primary element, some parts of having in opposed closely udjacentnon-consaid casing being so closely proximate to said tacting relation relatively extensive smooth elements as to minimize torque-transmitting friction surfaces, and an interposed gaseous flow of the fluid along the exterior surfaces body through which the driving member

of the secondary element. frictionally drags the driven member.

20. An air d,'sg speedometer wherein a 31. A tachometer comprising, in combi-

rotatable primary variable-speed element nation, a rotatably mounted shaft, a smooth and, a biased pivoted secondary element, annular body fixed thereto, a similar pivoted mounted fOl' separate movement in an air- body, .a torsion spring for the latter, indicontaining casing,have opposed extensive eating means movable with said pivoted smooth annular surfaces in such close juxta- bodv, and 'an air-containing caSin~, said position that torque is transmitted through bodies having their annular surfaces m such the air intervening between said surfaces in close, non-contacting proximity that the insubstantially linenr proportion to the speed tervening air transmits torque to the pivoted of the rotatable primary element. body in substantially linear proportion to

27. A speed indicator comprising a closed the speed of the rotatable body.

fluid-filled casing, primary and secondary 32. A tachometer comprising, in combielements mounted therein, the one for rota- ,nation, 1\ rotatably mounted shaft~ a primary tion and the other .for torsionally resisted element carried thereby, a pivotea secondary unguln displacement, said elements having element, a torsion spring therefor permitopposed non-contacting extensive annular ting its 'an~lar displacement substantiAlly surfaces forming therebetween 1\ smooth in- in, proportion to the torque, indicating tervening channel wherein confined fluid means operated by the pivoted element and may move in circles under the influence of gradullted with substllntial uniformity, nnd the primary member, Rnd between them and a fluld-eontaining cuBing closely investing the Interior surfaces of the CASing '81lrrouncl- part of said rotative system, the opposed iug channels wherein fluid conti","lolls to the ,surfaces of the elements being 80 closely secondary element may receive circular proximate to each other and to part of the movement from the primary element, said ('~Ising that the fluid- transmitted torque surfaces being. II? closely ss: .. thl~t ('.tUlsing .deflections o! the pivoted body ill i?rque tra.nsnlU~uori throll 1 the fluid IS RuhstllntlRJly proportionate to the speed 'of hneady proportionate to t ie speed of the tht\ ll1"imnl'Y element.

primary element. In testimony whereof I "flix my Biptature

28. The combination, in a speed indicator, in the presence of two subscribing Wltn8B8e8.

of ,~ closed casing, a fluid bocly a'.ld two ro- NIKOLA TESLA.

tatlvely-movable members therein, means

for rotating one of the members, means for resisting d~splacement of the other, and means ~troI1ed by the last named member

·Witnesses :

M. LA. WSON DTu, TnoxA8 J. U"NIl.

N. TESLA.

SPEED INDICATOR.

APPLICATION FILED MAY 29.1914.

1,209,359.

Patented Dec. 19, ]916.

Feg . .3.

Fig . ...!.

Eeg.4.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Franklin B. Mead Jr. (US Pat. 5590031)Document15 pagesFranklin B. Mead Jr. (US Pat. 5590031)GaleriaTechniki.PLNo ratings yet

- US Pat. 3693731Document10 pagesUS Pat. 3693731GaleriaTechniki.PLNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- Thomas Galen Hieronymous (US Pat. 2482773)Document6 pagesThomas Galen Hieronymous (US Pat. 2482773)GaleriaTechniki.PL100% (1)

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- Canada Patent - 30.142Document10 pagesCanada Patent - 30.142GustavBlitzNo ratings yet

- Canada Patent - 29.537Document24 pagesCanada Patent - 29.537GustavBlitzNo ratings yet

- Canada Patent - 135.174Document12 pagesCanada Patent - 135.174GustavBlitzNo ratings yet

- Canada Patent - 142.352Document18 pagesCanada Patent - 142.352GustavBlitzNo ratings yet

- Canada Patent - 24.033Document12 pagesCanada Patent - 24.033GustavBlitzNo ratings yet

- United Kingdom Patent - 6502Document5 pagesUnited Kingdom Patent - 6502GustavBlitzNo ratings yet

- United Kingdom Patent - 6481Document9 pagesUnited Kingdom Patent - 6481GustavBlitzNo ratings yet

- United Kingdom Patent - 8575Document6 pagesUnited Kingdom Patent - 8575GustavBlitzNo ratings yet

- United Kingdom Patent - 2975Document9 pagesUnited Kingdom Patent - 2975GustavBlitzNo ratings yet

- United Kingdom Patent - 2812Document7 pagesUnited Kingdom Patent - 2812GustavBlitzNo ratings yet

- United Kingdom Patent - 2801Document5 pagesUnited Kingdom Patent - 2801GustavBlitzNo ratings yet

- United States Patent - 685.957Document5 pagesUnited States Patent - 685.957GustavBlitzNo ratings yet

- Nicola Tesla (US Pat. 1655114)Document8 pagesNicola Tesla (US Pat. 1655114)GaleriaTechniki.PL100% (1)

- Nicola Tesla (US Pat. 685955)Document7 pagesNicola Tesla (US Pat. 685955)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (US Pat. 787412)Document6 pagesNicola Tesla (US Pat. 787412)GaleriaTechniki.PLNo ratings yet