Professional Documents

Culture Documents

Trainingpathway L3

Trainingpathway L3

Uploaded by

bmrajah0 ratings0% found this document useful (0 votes)

7 views1 pagetp

Original Title

trainingpathway_L3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttp

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageTrainingpathway L3

Trainingpathway L3

Uploaded by

bmrajahtp

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

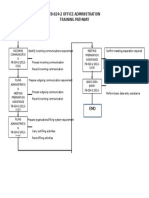

TRAINING PATHWAY H-176-3 SENIOR AUTOMATION TECHNICIAN

START H-176-3

PREPARE REPOERT

12.01 1/4

VERIFY PART LIST REQUISITION

Ensure Tools, Jigs And Fictures Functionality 4.05 1/1 12.02 2/4

MECHANICAL EQUIPMENT H-176-3 (M01)

DECTECTION SYSTEM H-176-3 (M04)

CARRY OUT DETECTION SYSTEM PARAMETER SETUP

ADMINISTRATIVE SKILL H-176-3 (M07)

CARRY OUT INVENTORY CONTROL 12.03 3/4

7.05

1/1

ADMINISTER SYSTEM PROCEDURES 12.04 4/4

TOTAL PREVENTIVE MAINTENANCE H-176-3 (M02)

TROUBLESHOOT ROBOTS MALFUNCTION CARRY OUT PREVENTIVE MAINTENANCE SCHEDULING 09.03

1/5 PREPARE WORK SCHEDULE

11.02

2/2

VERIFY PREVENTIVE MAINTENANCE ACTIVITIES 11.03 3/2

INDUSTRIAL ROBOTIC H-176-3 (M05)

CARRY OUT ROBOTS FAULTY PARTS REPLACEMENT 09.04 2/5

EFFECTIVE SUPERVISION H-176-3 (M08)

13.01

1/5

MONITOR WORK 13.02 2/5

ENSURE ROBOTS FUNCTIONALITY 09.05 3/5

CONDUCTING IN HOUSE TRAINING 13.03 3/5

CARRY OUT OPERATION AND NETWORK CONDITION CHECK Configure Programmable Logic Controller (PLC) 10.01 1/3 13.04

CONDUCT MEETING

4/5

PLC SYSTEM H-176-3 (M03)

5.04 1/2

CARRY OUT NETWORK FUNCTIONALITY CHECK

NETWORK SYSTEM H-176-3 (M06)

ENSURE SAFE WORKING ENVIROMENT 13.05 5/5

10.02

2/3

Monitor Process parameters

5.05

2/2

MONITOR NETWORK OPERATION AND FUNCTIONALITY

END

H-176-3

10.03

3/3

(ix)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PM Checklist Puma PK 20Document1 pagePM Checklist Puma PK 20bmrajah100% (1)

- m1 Basic Working CommunicationDocument8 pagesm1 Basic Working CommunicationbmrajahNo ratings yet

- Automation Lab Inventory 1Document1 pageAutomation Lab Inventory 1bmrajahNo ratings yet

- T.pathway FB-024-2Document1 pageT.pathway FB-024-2bmrajahNo ratings yet

- Trio Manual51Document252 pagesTrio Manual51bmrajahNo ratings yet

- MC-091 L3 KK 1 6Document6 pagesMC-091 L3 KK 1 6bmrajahNo ratings yet

- Test Paper Eng ManagementDocument3 pagesTest Paper Eng ManagementbmrajahNo ratings yet

- Assignment Hydraulic & PneumaticDocument3 pagesAssignment Hydraulic & PneumaticbmrajahNo ratings yet

- Lab Equipment Request FormDocument1 pageLab Equipment Request FormbmrajahNo ratings yet

- MC 091 Worksheet BreakdownDocument12 pagesMC 091 Worksheet BreakdownbmrajahNo ratings yet

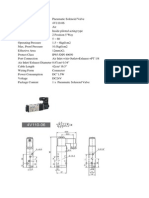

- Airtac Single Solenoid Datasheet PDFDocument1 pageAirtac Single Solenoid Datasheet PDFbmrajahNo ratings yet

- Workplan TemplateDocument1 pageWorkplan TemplatebmrajahNo ratings yet

- PM Checklist Junair 6 25Document1 pagePM Checklist Junair 6 25bmrajahNo ratings yet

- Standard Practice (Numbering)Document4 pagesStandard Practice (Numbering)bmrajahNo ratings yet

- Case Study Lp03 TeoriDocument1 pageCase Study Lp03 TeoribmrajahNo ratings yet

- 99 Examples Pneumatic Applications PDFDocument120 pages99 Examples Pneumatic Applications PDFAndres RodriguezNo ratings yet