Professional Documents

Culture Documents

En-Standards For Copper Tube and Fittings

En-Standards For Copper Tube and Fittings

Uploaded by

starykltCopyright:

Available Formats

You might also like

- BS en 12952-7-2012Document46 pagesBS en 12952-7-2012Mokhammad Fahmi IzdiharrudinNo ratings yet

- En 13480-3 Mechanical Calculation of Straight PipesDocument10 pagesEn 13480-3 Mechanical Calculation of Straight PipeskhaireddinNo ratings yet

- BS en 442-1-2014Document42 pagesBS en 442-1-2014AleksanderNo ratings yet

- Din 8077-8078 & Iso 15874-2Document7 pagesDin 8077-8078 & Iso 15874-2Filip100% (4)

- BS en 10255-2004 (2007)Document28 pagesBS en 10255-2004 (2007)david13andrei100% (2)

- Globe Stop and Check Valve - en 13709Document4 pagesGlobe Stop and Check Valve - en 13709Nemanja PapricaNo ratings yet

- BS en 1057 - Copper Pipework TablesDocument2 pagesBS en 1057 - Copper Pipework TablespaulnwhiteNo ratings yet

- BS en 01254-6-2012Document52 pagesBS en 01254-6-2012lunatic2000No ratings yet

- En DIN Standards in Pipeline ConstructionDocument2 pagesEn DIN Standards in Pipeline ConstructionJohn Smith67% (3)

- ISOStandardDocument3 pagesISOStandardlady soto chNo ratings yet

- En 12165Document7 pagesEn 12165lijojose10% (1)

- BS en Iso 5155-1996Document46 pagesBS en Iso 5155-1996AnoyNo ratings yet

- Steel Tubes BS 1387 (EN 10255) PDFDocument5 pagesSteel Tubes BS 1387 (EN 10255) PDFraduono0% (1)

- En 14 511-2Document14 pagesEn 14 511-2Daniel MilosevskiNo ratings yet

- Iso 559 PDFDocument22 pagesIso 559 PDFsenthilNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- EN1092Document18 pagesEN1092le wang83% (6)

- BSI Standards Publication BS EN ISO 15494 - 2015Document10 pagesBSI Standards Publication BS EN ISO 15494 - 2015Kevin AlmeidaNo ratings yet

- Iso 10294 2 1999 PDFDocument8 pagesIso 10294 2 1999 PDFhoang nguyenNo ratings yet

- BS en 13547-2013Document30 pagesBS en 13547-2013Ahmed HassanNo ratings yet

- En 1057 PDFDocument37 pagesEn 1057 PDFdeea19sNo ratings yet

- Cen TR 13480-7 (2002) (E)Document6 pagesCen TR 13480-7 (2002) (E)g9g9No ratings yet

- En 10051Document2 pagesEn 10051sskamalakannanNo ratings yet

- Stainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthDocument15 pagesStainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthOctavio Cotillo LubiánNo ratings yet

- En 10217-1Document40 pagesEn 10217-1BaneMarkovic100% (2)

- Din en 13789-2003Document14 pagesDin en 13789-2003karuna346No ratings yet

- BS en 558 2017Document38 pagesBS en 558 2017Anonymous HPlNDhM6ejNo ratings yet

- BS en 01506-2007Document24 pagesBS en 01506-2007Dzana KadricNo ratings yet

- BS4504 16 DimensionsDocument2 pagesBS4504 16 DimensionsalfonscarlNo ratings yet

- Pipes StandardDocument2 pagesPipes StandardEsmail GandhiNo ratings yet

- BS en 1057 Tube Sizes - Crane Copper TubeDocument2 pagesBS en 1057 Tube Sizes - Crane Copper TubestarykltNo ratings yet

- Din 8074 Pehd PipesDocument20 pagesDin 8074 Pehd PipesAli MkawarNo ratings yet

- CEN-TR 13480-7-2002-OtklDocument28 pagesCEN-TR 13480-7-2002-OtklVasko Mandil100% (2)

- EN 10255 2004+A1 2007 SpecificaitonDocument27 pagesEN 10255 2004+A1 2007 Specificaitonsanjaig100% (1)

- DIN 2527-1972, Blank FlangesDocument6 pagesDIN 2527-1972, Blank FlangesalfredopinillosNo ratings yet

- BS en 1515-2Document22 pagesBS en 1515-2Angelo MinatiNo ratings yet

- DIN 8077-2008 EnglishDocument34 pagesDIN 8077-2008 EnglishquochunguicNo ratings yet

- BS en 12201 3 PDFDocument32 pagesBS en 12201 3 PDFCorciu Valentin33% (3)

- En 14511-1-2011Document12 pagesEn 14511-1-2011BorisNo ratings yet

- BS en 1515 2 PDFDocument22 pagesBS en 1515 2 PDFCristian G. Ciocoi100% (1)

- German Standard DIN 477 Cylinder Valve ConnectionsDocument2 pagesGerman Standard DIN 477 Cylinder Valve Connections2bjornNo ratings yet

- BS en 1254 6Document52 pagesBS en 1254 6Hsaam Hsaam100% (1)

- BS en 12237-2003-Ventilation For Buildings Ductwork Strength and Leakage of Circular Sheet Metal DuctsDocument14 pagesBS en 12237-2003-Ventilation For Buildings Ductwork Strength and Leakage of Circular Sheet Metal DuctsKhizerNo ratings yet

- Din 3357-1Document7 pagesDin 3357-1gm_revankar39420% (1)

- BS 143 & 1256: 2000Document30 pagesBS 143 & 1256: 2000thanh_79No ratings yet

- En 12237 (2003) (E)Document3 pagesEn 12237 (2003) (E)dilic7No ratings yet

- BS en 13141-7 2004 Ventilation For Buildings PDFDocument24 pagesBS en 13141-7 2004 Ventilation For Buildings PDFRamiAl-fuqahaNo ratings yet

- Guided Cantilever MethodDocument12 pagesGuided Cantilever MethodDan PastorNo ratings yet

- BS en 12449 2016Document46 pagesBS en 12449 2016engr.sshoaibrazaNo ratings yet

- Dinen 10079 - 200706 - enDocument46 pagesDinen 10079 - 200706 - enAnonymous dvrhf5No ratings yet

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1Document42 pagesISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1markosdistefanoNo ratings yet

- En 13371Document11 pagesEn 13371med4jonok100% (1)

- BS en 1074-4-2000Document18 pagesBS en 1074-4-2000Mohammed khaleelNo ratings yet

- Hepworth ProfileDocument19 pagesHepworth Profilediljamchris100% (1)

- All About PipingDocument46 pagesAll About PipingRakesh RanjanNo ratings yet

- Copper Pressure Piping SystemsDocument2 pagesCopper Pressure Piping SystemsstarykltNo ratings yet

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- PIPE Material SpecDocument12 pagesPIPE Material SpecRana PrathapNo ratings yet

- Pipes HandbookDocument13 pagesPipes HandbooksauroNo ratings yet

- Pipe and Tube SizeDocument32 pagesPipe and Tube Sizehothanhdung2002No ratings yet

- Aluminium Layer Standards - IsO7599 - 1983Document12 pagesAluminium Layer Standards - IsO7599 - 1983Ashish TanejaNo ratings yet

- Swimming Pools Design 2011 Rev3 PDFDocument97 pagesSwimming Pools Design 2011 Rev3 PDFAshish Taneja100% (2)

- 1 Mech Malleable Iron Fittings Catalogue PDFDocument12 pages1 Mech Malleable Iron Fittings Catalogue PDFAshish TanejaNo ratings yet

- KOHLER Retail BookDocument212 pagesKOHLER Retail BookNeeraj RawatNo ratings yet

- Roughness DataDocument4 pagesRoughness DataAshish TanejaNo ratings yet

- 14Document424 pages14Kheiro SantosNo ratings yet

- BS en 1254 3Document16 pagesBS en 1254 3Ashish Taneja0% (1)

- IS8008 8reducing TeeDocument5 pagesIS8008 8reducing TeeAshish TanejaNo ratings yet

- IS8008 8reducing TeeDocument5 pagesIS8008 8reducing TeeAshish TanejaNo ratings yet

- Chap - 6 - Fire Fighting SystemsDocument23 pagesChap - 6 - Fire Fighting Systemsundertaker55No ratings yet

En-Standards For Copper Tube and Fittings

En-Standards For Copper Tube and Fittings

Uploaded by

starykltOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En-Standards For Copper Tube and Fittings

En-Standards For Copper Tube and Fittings

Uploaded by

starykltCopyright:

Available Formats

EN STANDARDS FOR COPPER TUBE AND FITTINGS

EN

standards have been written to harmonise copper tube and fitting standards throughout the 18 member nations of the European Committee for Standardisation. Tube standard EN 1057 Copper and copper alloys Seamless round copper tubes for water and gas in sanitary and heating applications, is one of a series of European Standards for copper and copper alloy tubes that are in the course of adoption. It specifies the requirements for copper tubes from 6mm up to 267mm diameter for: distribution pipework for hot and cold water; hot water heating systems, including under-floor heating systems; domestic gas and liquid fuel distribution; waste water sanitation. The tube standard gives details of nominal cross-sectional dimensions in millimetres (nominal outside diameter x nominal wall thickness) and material temper. It also gives product designation details and sets out tests that are carried out by the manufacturer to ensure that the tube supplied is free from defects and meets the requirements of the standard. With 46 recommended combinations of diameter and wall thickness, available from the 26 different diameters and 12 different wall thicknesses, together with a further (non-recommended) 57 other combinations, and 12 other combinations included for a limited period, ordering copper tube might not be quite the simple task it is today! The main combinations of diameter and wall thickness are set out in Table 1. In the table, 'R' indicates a European recommended dimension, 'X' indicates

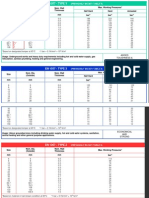

Table 1

Tube size 6 8 10 12 14 15 16 18 22 25 28 35 40 42 54 64 66.7 70 76.1 80 88.9 108 133 159 219 267 0.5 X X X X X

EN 1057 Outside diameters and wall thicknesses (mm)

0.6 R R R R 0.7 0.8 R R R R X R X R X X X X X 0.9 Nominal Wall thickness 1.0 1.1 1.2 1.5 2.0 R R R R X R X X X X R X X R X R R X X X R R R X X R R X X X X R R X X R R R X R X R X X X X R R X X R X R X R X X R 2.5 3.0

R X X R

X X X X

X R

X X X X X R X X R R R R

R = European recommended dimensions

X = indicates other European dimensions Tensile strength Rm, MPa min. 220 250 250

Material temper Designation in accordance with EN 1173 R220 R250 R250

Nominal outside diameter d, mm

Hardness indicative

Common term annealed half hard half hard

min. 6 6 6

max. 54 66.7 159

HV5 (40 to 70) (75 to 100) (75 to 100)

NOTE 1: Hardness figures are given for guidance only. NOTE 2: Minimum elongation values range from 40% to 20% for annealed and half hard tempers.

Table 3 Form of delivery

Form of Tube dia. (mm) Length Material delivery from up to & inc. (m) temper Coils Straight lengths 6 6 6 28 267 267 10-50 3-6 3-6 R220 R250 R290

Fittings standard The EN 1254 standard has five separate parts for the specifications of the fitting ends: EN 1254-1 covers capillary ends for copper tube; EN 1254-2 covers compression ends for copper tube; EN 1254-3 covers compression for plastic tube; EN 1254-4 covers male and female threaded ends; EN 1254-5 covers short cup ends (for brazing only). Ordering fittings The main change that we, as installers, are likely to notice is in the method of designating the particular fitting we require. To be certain the following information should be quoted: either the manufacturers catalogue number or common name (elbow, tee, coupling); the number and part of the standard, (for example EN 1254-1 would specify a capillary fitting); the size of the connecting ends (see below for sequence) or, in the case of fittings with threaded connections in accordance with EN1254-4, or other threads, by the thread designation; if a 'slip' fitting is required this will have to be stated; if dezincification resistance is required this will have to be stated; if required, the type of plating will have to be stated. Sequence for specifying ends In the UK we have ordered tees (and crosses) using the following sequence: run-run-branch(-branch).This will be the non-preferred method. The preferred method will be to order using the sequence: run-branch-run(-branch). This could cause confusion. If the order does not make it clear that the non-preferred sequence was used the supplier will assume that the run-branch-run sequence is required, (see Figure 1).

other European dimensions, whilst the shaded boxes indicate our current BS 2871: Part 1 tube sizes. The 'R' marked dimensions have been chosen as a first step towards a rationalised standard with not more than three wall thicknesses for each diameter together with a restricted number of diameters.Table 2 sets out the mechanical properties of the tube in its three states of temper whilst Table 3 gives details of the recommended form of delivery, in terms of straight lengths and coils. Ordering the product When requesting prices or ordering tube it will be important to correctly state a number of items of information to be certain of receiving correct information and then delivery of the particular tube required. The standard sets out the following items of information that should be supplied: quantity of material required, (in metres); denomination of the product, (copper tube); number of the European standard, (EN 1057); temper designation, (see Table 2); nominal cross-sectional dimensions: outside diameter x wall thickness, (see Table 1); form of delivery, (see Table 3). An example: Ordering details for 150m of copper tube conforming to the standard, in temper R250 (half-hard), outside diameter 15mm, wall thickness 0.7mm, in 3m straight lengths. (In other words our tried and trusted 15mm Table X tube.) This should be identified as follows: 150m copper tube EN 1057 - R250 - 15 x 0.7 - 3m straight lengths. Quite a mouthful, I think you'll agree! But, necessary if you are to be certain of receiving the particular type of copper tube you require.

Confused! There is no need to be confused or in any way intimidated by the new terminology. Some of us still remember metrication in 1971 with the change from inches to, the then alien, millimetres. However, usage becomes second nature and expressions such as "15mm Table X" are now familiar to all of us. As one would expect, copper tube and fittings manufacturers are fully conversant with the European standards and, if you have any doubts regarding the new terminology, cross reference can be made to the former standard and the manufacturer will do the rest. For example that old favourite 15mm Table X could be ordered by requesting 15mm tubing to EN1057 aligning with the former Table X. It will be just as easy to order fittings by quoting EN1254 in conjunction with the manufacturers catalogue number or common name (e.g. elbow, tee, etc.).

28mm 22mm 15mm

Old ordering system: tee specified as 28 x 15 x 22mm. New standard: tee specified as 28 x 22 x 15mm.

Figure 1 Specifying Tees

You might also like

- BS en 12952-7-2012Document46 pagesBS en 12952-7-2012Mokhammad Fahmi IzdiharrudinNo ratings yet

- En 13480-3 Mechanical Calculation of Straight PipesDocument10 pagesEn 13480-3 Mechanical Calculation of Straight PipeskhaireddinNo ratings yet

- BS en 442-1-2014Document42 pagesBS en 442-1-2014AleksanderNo ratings yet

- Din 8077-8078 & Iso 15874-2Document7 pagesDin 8077-8078 & Iso 15874-2Filip100% (4)

- BS en 10255-2004 (2007)Document28 pagesBS en 10255-2004 (2007)david13andrei100% (2)

- Globe Stop and Check Valve - en 13709Document4 pagesGlobe Stop and Check Valve - en 13709Nemanja PapricaNo ratings yet

- BS en 1057 - Copper Pipework TablesDocument2 pagesBS en 1057 - Copper Pipework TablespaulnwhiteNo ratings yet

- BS en 01254-6-2012Document52 pagesBS en 01254-6-2012lunatic2000No ratings yet

- En DIN Standards in Pipeline ConstructionDocument2 pagesEn DIN Standards in Pipeline ConstructionJohn Smith67% (3)

- ISOStandardDocument3 pagesISOStandardlady soto chNo ratings yet

- En 12165Document7 pagesEn 12165lijojose10% (1)

- BS en Iso 5155-1996Document46 pagesBS en Iso 5155-1996AnoyNo ratings yet

- Steel Tubes BS 1387 (EN 10255) PDFDocument5 pagesSteel Tubes BS 1387 (EN 10255) PDFraduono0% (1)

- En 14 511-2Document14 pagesEn 14 511-2Daniel MilosevskiNo ratings yet

- Iso 559 PDFDocument22 pagesIso 559 PDFsenthilNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- EN1092Document18 pagesEN1092le wang83% (6)

- BSI Standards Publication BS EN ISO 15494 - 2015Document10 pagesBSI Standards Publication BS EN ISO 15494 - 2015Kevin AlmeidaNo ratings yet

- Iso 10294 2 1999 PDFDocument8 pagesIso 10294 2 1999 PDFhoang nguyenNo ratings yet

- BS en 13547-2013Document30 pagesBS en 13547-2013Ahmed HassanNo ratings yet

- En 1057 PDFDocument37 pagesEn 1057 PDFdeea19sNo ratings yet

- Cen TR 13480-7 (2002) (E)Document6 pagesCen TR 13480-7 (2002) (E)g9g9No ratings yet

- En 10051Document2 pagesEn 10051sskamalakannanNo ratings yet

- Stainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthDocument15 pagesStainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthOctavio Cotillo LubiánNo ratings yet

- En 10217-1Document40 pagesEn 10217-1BaneMarkovic100% (2)

- Din en 13789-2003Document14 pagesDin en 13789-2003karuna346No ratings yet

- BS en 558 2017Document38 pagesBS en 558 2017Anonymous HPlNDhM6ejNo ratings yet

- BS en 01506-2007Document24 pagesBS en 01506-2007Dzana KadricNo ratings yet

- BS4504 16 DimensionsDocument2 pagesBS4504 16 DimensionsalfonscarlNo ratings yet

- Pipes StandardDocument2 pagesPipes StandardEsmail GandhiNo ratings yet

- BS en 1057 Tube Sizes - Crane Copper TubeDocument2 pagesBS en 1057 Tube Sizes - Crane Copper TubestarykltNo ratings yet

- Din 8074 Pehd PipesDocument20 pagesDin 8074 Pehd PipesAli MkawarNo ratings yet

- CEN-TR 13480-7-2002-OtklDocument28 pagesCEN-TR 13480-7-2002-OtklVasko Mandil100% (2)

- EN 10255 2004+A1 2007 SpecificaitonDocument27 pagesEN 10255 2004+A1 2007 Specificaitonsanjaig100% (1)

- DIN 2527-1972, Blank FlangesDocument6 pagesDIN 2527-1972, Blank FlangesalfredopinillosNo ratings yet

- BS en 1515-2Document22 pagesBS en 1515-2Angelo MinatiNo ratings yet

- DIN 8077-2008 EnglishDocument34 pagesDIN 8077-2008 EnglishquochunguicNo ratings yet

- BS en 12201 3 PDFDocument32 pagesBS en 12201 3 PDFCorciu Valentin33% (3)

- En 14511-1-2011Document12 pagesEn 14511-1-2011BorisNo ratings yet

- BS en 1515 2 PDFDocument22 pagesBS en 1515 2 PDFCristian G. Ciocoi100% (1)

- German Standard DIN 477 Cylinder Valve ConnectionsDocument2 pagesGerman Standard DIN 477 Cylinder Valve Connections2bjornNo ratings yet

- BS en 1254 6Document52 pagesBS en 1254 6Hsaam Hsaam100% (1)

- BS en 12237-2003-Ventilation For Buildings Ductwork Strength and Leakage of Circular Sheet Metal DuctsDocument14 pagesBS en 12237-2003-Ventilation For Buildings Ductwork Strength and Leakage of Circular Sheet Metal DuctsKhizerNo ratings yet

- Din 3357-1Document7 pagesDin 3357-1gm_revankar39420% (1)

- BS 143 & 1256: 2000Document30 pagesBS 143 & 1256: 2000thanh_79No ratings yet

- En 12237 (2003) (E)Document3 pagesEn 12237 (2003) (E)dilic7No ratings yet

- BS en 13141-7 2004 Ventilation For Buildings PDFDocument24 pagesBS en 13141-7 2004 Ventilation For Buildings PDFRamiAl-fuqahaNo ratings yet

- Guided Cantilever MethodDocument12 pagesGuided Cantilever MethodDan PastorNo ratings yet

- BS en 12449 2016Document46 pagesBS en 12449 2016engr.sshoaibrazaNo ratings yet

- Dinen 10079 - 200706 - enDocument46 pagesDinen 10079 - 200706 - enAnonymous dvrhf5No ratings yet

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1Document42 pagesISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1markosdistefanoNo ratings yet

- En 13371Document11 pagesEn 13371med4jonok100% (1)

- BS en 1074-4-2000Document18 pagesBS en 1074-4-2000Mohammed khaleelNo ratings yet

- Hepworth ProfileDocument19 pagesHepworth Profilediljamchris100% (1)

- All About PipingDocument46 pagesAll About PipingRakesh RanjanNo ratings yet

- Copper Pressure Piping SystemsDocument2 pagesCopper Pressure Piping SystemsstarykltNo ratings yet

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- PIPE Material SpecDocument12 pagesPIPE Material SpecRana PrathapNo ratings yet

- Pipes HandbookDocument13 pagesPipes HandbooksauroNo ratings yet

- Pipe and Tube SizeDocument32 pagesPipe and Tube Sizehothanhdung2002No ratings yet

- Aluminium Layer Standards - IsO7599 - 1983Document12 pagesAluminium Layer Standards - IsO7599 - 1983Ashish TanejaNo ratings yet

- Swimming Pools Design 2011 Rev3 PDFDocument97 pagesSwimming Pools Design 2011 Rev3 PDFAshish Taneja100% (2)

- 1 Mech Malleable Iron Fittings Catalogue PDFDocument12 pages1 Mech Malleable Iron Fittings Catalogue PDFAshish TanejaNo ratings yet

- KOHLER Retail BookDocument212 pagesKOHLER Retail BookNeeraj RawatNo ratings yet

- Roughness DataDocument4 pagesRoughness DataAshish TanejaNo ratings yet

- 14Document424 pages14Kheiro SantosNo ratings yet

- BS en 1254 3Document16 pagesBS en 1254 3Ashish Taneja0% (1)

- IS8008 8reducing TeeDocument5 pagesIS8008 8reducing TeeAshish TanejaNo ratings yet

- IS8008 8reducing TeeDocument5 pagesIS8008 8reducing TeeAshish TanejaNo ratings yet

- Chap - 6 - Fire Fighting SystemsDocument23 pagesChap - 6 - Fire Fighting Systemsundertaker55No ratings yet