Professional Documents

Culture Documents

Thermal Expansion (1) .PDV

Uploaded by

culwavesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Expansion (1) .PDV

Uploaded by

culwavesCopyright:

Available Formats

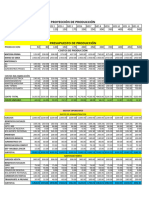

BEARING CONE BORE GROWTH EXPANSION RATES DUE TO THERMAL CHANGES

Calculations based on an ambient temperature of 20 degrees Celcius

Thermometer Temperature Reading in Degrees Celsius

Cone Bore in (mm)

~~~~~~~

25

50

75

100

125

150

175

200

225

250

275

300

325

350

375

400

425

450

475

500

525

550

575

600

625

650

675

700

725

750

775

800

825

850

875

900

925

75 C

~~~~~~~~

0.0150

0.0300

0.0450

0.0600

0.0750

0.0900

0.1050

0.1200

0.1350

0.1500

0.1650

0.1800

0.1950

0.2100

0.2250

0.2400

0.2550

0.2700

0.2850

0.3000

0.3150

0.3300

0.3450

0.3600

0.3750

0.3900

0.4050

0.4200

0.4350

0.4500

0.4650

0.4800

0.4950

0.5100

0.5250

0.5400

0.5550

100 o C

~~~~~~~~

0.0218

0.0436

0.0655

0.0873

0.1091

0.1309

0.1527

0.1745

0.1964

0.2182

0.2400

0.2618

0.2836

0.3055

0.3273

0.3491

0.3709

0.3927

0.4145

0.4364

0.4582

0.4800

0.5018

0.5236

0.5455

0.5673

0.5891

0.6109

0.6327

0.6545

0.6764

0.6982

0.7200

0.7418

0.7636

0.7855

0.8073

125 o C

~~~~~~~~

0.0286

0.0573

0.0859

0.1145

0.1432

0.1718

0.2005

0.2291

0.2577

0.2864

0.3150

0.3436

0.3723

0.4009

0.4295

0.4582

0.4868

0.5155

0.5441

0.5727

0.6014

0.6300

0.6586

0.6873

0.7159

0.7445

0.7732

0.8018

0.8305

0.8591

0.8877

0.9164

0.9450

0.9736

1.0023

1.0309

1.0595

150 o C

~~~~~~~~

0.0355

0.0709

0.1064

0.1418

0.1773

0.2127

0.2482

0.2836

0.3191

0.3545

0.3900

0.4255

0.4609

0.4964

0.5318

0.5673

0.6027

0.6382

0.6736

0.7091

0.7445

0.7800

0.8155

0.8509

0.8864

0.9218

0.9573

0.9927

1.0282

1.0636

1.0991

1.1345

1.1700

1.2055

1.2409

1.2764

1.3118

Guidelines:

- Recommended Mode of Heating is by Induction Heater or by Oil Bath method.

- In an oil bath method the bearing should be elevated so that the bearing is heated by the oil and not directly by the heat source.

- Air can be blown across a hot bearing to help it cool. Do not cool the bearing by water.

- Do not Spin the bearings with compressed Air.

IMPORTANT NOTE:

The accuracy of this data on thermal expansion is solely for Bearing Cones made of Timken specified grade of steel. The

correctness of this data also depends upon various other factors like mode of heating, duration of heating, environmental factors

etc which are beyond the control of the Timken Company and/or its affiliates. For the above reasons, this data is submitted solely

to provide you, a customer of the Timken Company and/or its affiliates, with data to assist you in mounting the bearings suitably.

No Warranty, expressed or implied, of the fitness for particular purpose is made by the submission of this data.

THE TIMKEN COMPANY

You might also like

- MaK 8M25C MaintenancePlanDocument36 pagesMaK 8M25C MaintenancePlanЮрий Семёнов100% (1)

- Asme Flange RatingsDocument4 pagesAsme Flange RatingsvaliullahNo ratings yet

- Pressure Temperature Charts ASTMDocument4 pagesPressure Temperature Charts ASTMAnonymous rdv9nb1No ratings yet

- Combined Resin Silicon Bushing Comem CRS-ABB OS EN-12-12-2019Document12 pagesCombined Resin Silicon Bushing Comem CRS-ABB OS EN-12-12-2019dlawless6249No ratings yet

- SOI EOI Simple CalcDocument4 pagesSOI EOI Simple CalcParus BogdanNo ratings yet

- Areas DiseñoDocument15 pagesAreas DiseñoJONAIKER EDGAR MARTINEZ MALDONADONo ratings yet

- HPAEC Acid - Standard Graph - ALG HUM-LaptopvanG-2Document741 pagesHPAEC Acid - Standard Graph - ALG HUM-LaptopvanG-2geert.schalkNo ratings yet

- Second Engine Timing Vs Load HotDocument2 pagesSecond Engine Timing Vs Load HotSmoking WheelsNo ratings yet

- Electrolitico 2017 Alcatel RevisarDocument19 pagesElectrolitico 2017 Alcatel RevisarJUAN CHAMPACNo ratings yet

- Electrolitico 2017 Alcatel RevisarDocument19 pagesElectrolitico 2017 Alcatel RevisarJUAN CHAMPACNo ratings yet

- Electrolitico 2017 Tienda RevisarDocument23 pagesElectrolitico 2017 Tienda RevisarJUAN CHAMPACNo ratings yet

- Cases Will Remain Available For Use Until Annulled by The Applicable Standards CommitteeDocument5 pagesCases Will Remain Available For Use Until Annulled by The Applicable Standards CommitteeMMD Siddhiranj 335MWNo ratings yet

- Timing Vs Load HotDocument2 pagesTiming Vs Load HotSmoking WheelsNo ratings yet

- Conversion Mm2 To CmilDocument1 pageConversion Mm2 To CmilMakarand KhareNo ratings yet

- Micro Precision Calibration, Inc. Local Calibration ProcedureDocument3 pagesMicro Precision Calibration, Inc. Local Calibration ProcedureWuzekNo ratings yet

- BABFAR Vaporization TablesDocument1 pageBABFAR Vaporization TablesKareemNo ratings yet

- ESTIMATES-CSG For Slab and WallsDocument2 pagesESTIMATES-CSG For Slab and WallsRoland CepedaNo ratings yet

- Taller 2 SimulacionDocument332 pagesTaller 2 SimulacionYajaira DomínguezNo ratings yet

- Electrolíticos - Lucero 2017 1Document15 pagesElectrolíticos - Lucero 2017 1JUAN CHAMPACNo ratings yet

- Book 1Document2 pagesBook 1Tulit TresiaNo ratings yet

- 7.900 8.650 C3 11.500 100% 0.120 8.650 9.400 C3 11.500 100% 0.120 9.400 10.150 C3 11.500 100% 0.120 10.150 10.900 C3 11.500 100% 0.120 10.900 11.500 C3 11.500 100% 0.120Document6 pages7.900 8.650 C3 11.500 100% 0.120 8.650 9.400 C3 11.500 100% 0.120 9.400 10.150 C3 11.500 100% 0.120 10.150 10.900 C3 11.500 100% 0.120 10.900 11.500 C3 11.500 100% 0.120José R. Arenas FloresNo ratings yet

- Fungsi Bangunan: KantorDocument25 pagesFungsi Bangunan: KantorZanDayat AKNo ratings yet

- 3300-15R-142 A 240K-C2-1:100: Ball MillDocument1 page3300-15R-142 A 240K-C2-1:100: Ball MillLeo Unocc YauriNo ratings yet

- Timing Low Load Cold and HotDocument2 pagesTiming Low Load Cold and HotSmoking WheelsNo ratings yet

- SSS PhilHealth TableDocument3 pagesSSS PhilHealth Tablegwen calluengNo ratings yet

- NACA64 A17 CoordsDocument7 pagesNACA64 A17 Coordsmohsen mansourNo ratings yet

- Catalouge GTRDocument2 pagesCatalouge GTRMr Nilesh ShahNo ratings yet

- Data With Imbalance of 50 Gram On Left Plane Dummy ApparatusDocument31 pagesData With Imbalance of 50 Gram On Left Plane Dummy ApparatusjjjNo ratings yet

- Graphic CBRDocument10 pagesGraphic CBRARMANDO ESTRSADANo ratings yet

- Molded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, ADocument16 pagesMolded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, AGlenn GregorioNo ratings yet

- Ampacidad de Cables de Baja TensiónDocument1 pageAmpacidad de Cables de Baja TensiónGualaNo ratings yet

- InventoryDocument5 pagesInventoryAhmed El TayebiNo ratings yet

- Ready Tax Chart 2022-23Document8 pagesReady Tax Chart 2022-23jav3d762No ratings yet

- Welding CablesDocument1 pageWelding CablesanuradhaNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetluaiNo ratings yet

- Clutch Release BearingDocument32 pagesClutch Release Bearingvaibhav ahujaNo ratings yet

- EMPRENDIMIENTO COSTO TOTALnathalyRDocument2 pagesEMPRENDIMIENTO COSTO TOTALnathalyRNathaly RoseroNo ratings yet

- Inch Mill Smallnumbers 2017 PDFDocument1 pageInch Mill Smallnumbers 2017 PDFMuhammad FayyazNo ratings yet

- R1Document1 pageR1lordoffireNo ratings yet

- Inch Mill Smallnumbers 2017Document1 pageInch Mill Smallnumbers 2017Muhammad FayyazNo ratings yet

- Comprission Ratio 8 Coprission Ratio 10Document5 pagesComprission Ratio 8 Coprission Ratio 10zjpixrejNo ratings yet

- Reporte de Ventas Detallado: Facturas Electrónicas: Serie Número Cliente Doc Cliente Nombre Fecha de EmisionDocument15 pagesReporte de Ventas Detallado: Facturas Electrónicas: Serie Número Cliente Doc Cliente Nombre Fecha de EmisionGisela VillanuevaNo ratings yet

- Reporte de Ventas Detallado: Facturas Electrónicas: Serie Número Cliente Doc Cliente Nombre Fecha de EmisionDocument15 pagesReporte de Ventas Detallado: Facturas Electrónicas: Serie Número Cliente Doc Cliente Nombre Fecha de EmisionGisela VillanuevaNo ratings yet

- Pages From Vacuum - Condensers-5Document1 pagePages From Vacuum - Condensers-5boeiniNo ratings yet

- Air Flow PerformanceDocument1 pageAir Flow PerformanceAli MustafaNo ratings yet

- Scale Factor Drawing Limits / Plot ScaleDocument2 pagesScale Factor Drawing Limits / Plot ScaleReymond IgayaNo ratings yet

- Book 1Document14 pagesBook 1Prima AdhiyasaNo ratings yet

- PIc F 8159estimateDUCTDocument26 pagesPIc F 8159estimateDUCTArt JamesNo ratings yet

- Tables de VolumeDocument17 pagesTables de VolumezahirNo ratings yet

- Ak Biaya No 2Document5 pagesAk Biaya No 2Yunitiar RestiNo ratings yet

- EartDocument4 pagesEart2mhabibuNo ratings yet

- Direct Buried Filled Cables Type CefeDocument5 pagesDirect Buried Filled Cables Type CefeKhaled BellegdyNo ratings yet

- Weight Chart of Ci SpecialsDocument5 pagesWeight Chart of Ci Specialsrangareddy gridNo ratings yet

- Pressure Temperature Rating For Astm a216-A217-A351 - Asme b16.34-2004Document3 pagesPressure Temperature Rating For Astm a216-A217-A351 - Asme b16.34-2004alikajbafNo ratings yet

- Quality 100crmo7: Lucefin GroupDocument1 pageQuality 100crmo7: Lucefin GroupPaulo ZechinNo ratings yet

- G GGGGG GGGGG GGGGGDocument8 pagesG GGGGG GGGGG GGGGGWiliams PongoNo ratings yet