Professional Documents

Culture Documents

Minimum-Time Trajectory of Robot Manipulator

Uploaded by

jagm2000Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum-Time Trajectory of Robot Manipulator

Uploaded by

jagm2000Copyright:

Available Formats

Minimum-Time Trajectory of Robot Manipulator

Using Harmony Search Algorithm

Panwadee Tangpattanakul and Pramin Artrit

Department of Electrical Engineering, Faculty of Engineering, Khon Kaen University,

Khon Kaen 40002 Thailand

E-mail : panwadee.t@gmail.com

Abstract-The optimal trajectory planning is an important

function in a robot control area. Generally, the operating function

of manipulators requires the highest performance such as

minimum time, minimum energy, and no damage to the system.

This paper proposes a minimum time trajectory planning that is

clamped with cubic splines and uses Harmony Search (HS)

algorithm for solving the optimization problem. Minimum time is

chosen to be the objective function as time is critical for

productivities in the industrial. However, kinematics constraints

such as velocities, accelerations and jerks limitation are still

considered. In this work, the simulation of the 6-DOFs robot

manipulator trajectory is employed to determine the minimum

time trajectory planning. The best solution from two techniques,

the HS and the Sequential Quadratic Programming (SQP), are

compared. The results show that the HS method obtains the

optimal interval time better than the SQP method and it does not

require finding the initial interval time value for the optimization

process. This reduces the complication and time consuming of the

optimization process.

Keywords-Robotics, Minimum Time, Trajectory Planning,

Cubic Splines, Harmony Search

I. INTRODUCTION

In the present, many researchers are developing algorithms

for obtaining the optimal trajectory planning of robot

manipulators. Their works are different in three commonly

problems: the objective function of optimization problems,

trajectory forms, and optimization techniques. The objective

functions of the optimization problem are focused in the

traveling time [1-4], jerk [4] or energy [5-7] minimization. The

trajectory forms are employed the polynomials [5], splines that

know some angular position nodes and clamps with the

piecewise cubic splines [2-4] or the B-splines [6,8]. The

optimization techniques are investigating, for example, the

Sequential Quadratic Programming (SQP) technique [2,4,8],

the Genetic Algorithm (GA) technique[5,7], the Simulated

Annealing (SA) technique[5], or the Hybrid of Sequential

Weight Increasing Factor Technique (SWIFT) and the GA [9].

This paper proposes a minimum-time trajectory of robot

manipulator which is clamped with cubic splines and uses

Harmony Search (HS) method for solving the optimization

problem. Minimum traveling time trajectory planning and

considering each joint velocity, acceleration and jerk

constraints are important in optimal trajectory planning

problems. This is because these constraints are typically

concerned in industrials productivity. Cubic splines are often

chosen to form the trajectory because it has continuity in

position, velocity and acceleration pattern. It requires less

complex polynomial (a 3

rd

order polynomial) where the high-

order polynomial can lead to oscillation from the Runges

phenomenon. The optimal trajectory planning which is

clamped with cubic splines was proposed in [4]. In the paper A.

Gasparetto and V. Zanotto used the Sequential Quadratic

Programming (SQP) technique for solving the optimization

problem. In [2], the reason for using SQP technique is SQP had

implemented and tested in term of efficiency, accuracy, and

frequency of successful convergence. However SQP can be

attracted by local minima and the objective function and

constraints must ensure to be continuity of second order.

In this paper, the Harmony Search (HS) algorithm is selected

to replace the SQP for solving this problem. An advantage of

the HS over the SQP is that it is an efficient heuristic

optimization algorithm and does not require finding the initial

interval time value for the optimization process. While, the

SQP technique needs the suitable initial values, which adding

the finding process, otherwise it can be trapped in a local

minimum. Therefore, the HS technique eliminates the initial

value finding process. It reduces the difficulty for the solving

procedure. Moreover, if any conditions are changed, in SQP

method, the new initial value must be found.

This paper is organized as follow. In Section II, the

trajectory which be clamped with cubic splines is formulated

for solving the constrained optimization problem. The

objective function and the kinematics constraints are shown.

Section III, describes the Harmony Search (HS) algorithm,

optimization process and the HS parameters. In Section IV, the

simulation model of 6-DOFs robot arm minimum time

trajectory is employed to be the testing system and the results

between the best solutions which are obtained by the HS and

the SQP method are compared. Finally, the work is concluded

in Section V.

II. MINIMUM-TIME TRAJECTORY CLAMPED WITH CUBIC

SPLINES

In order to determine the minimum-time trajectory clamped

with cubic splines, three problems: a) formulation of the

trajectory clamped with cubic splines, b) constrained

optimization problems, and c) constrains formulations, need to

be processed.

A. Formulation of the trajectory clamped with cubic splines

Robot trajectory defined from the end effector is calculated

via an inverse kinematics transformation of each robots joint.

This transformation gives a set of robot joint position values,

978-1-4244-3388-9/09/$25.00 2009 IEEE

q

j,i

, where j and i represent a joint number and a knot,

respectively. Knot is a set of position points that one joint

moves from the initial position(knot 1) to the terminal position

(knot n) and the joint arrives its series of knot at the time

t

1

,t

2

,, t

i

,,t

n

, respectively. An n is number of via-points from

the initial to the terminal. The joint position is also called a

joint vector. A path pattern between consecutive via-points of

each joint is connected through the cubic splines function.

Velocities and accelerations of the initial and the terminal

conditions are specified to be zero. These conditions cause two

equations of the cubic spline algorithm become zero and the

path pattern cannot be solved. Therefore, two extra knots

(position values at time t

2

and t

n-1

) are added and their position

values are not specified, see Table II. Let h

i

= t

i+1

- t

i

be the

interval time [t

i+1

, t

i

] and Q

j,i

(t

i

) be the cubic polynomial for the

j-th joint in the interval time [t

i+1

, t

i

]. The second derivative of

Q

j,i

(t) is a linear interpolation which can be written as [4]:

. 1 ,..., 1 ; ) ( ) ( ) (

1 , ,

1

,

=

=

+

+

n i t Q

h

t t

t Q

h

t t

t Q

i i j

i

i

i i j

i

i

i j

(1)

Integrating equation (1) for the given points Q

j,i

(t

i

) = q

j,i

and

Q

j,i

(t

i+1

) = q

j,i+1

, the following interpolation functions are

obtained:

2

1 ,

2

1

,

,

) (

2

) (

) (

2

) (

) (

i

i

i i j

i

i

i i j

i j

t t

h

t Q

t t

h

t Q

t Q + =

+

+

+

+ +

6

) (

6

) (

, , 1 , 1 , i i j i

i

i j i i j i

i

i j

t Q h

h

q t Q h

h

q

(2)

and

3 1 , 3

1

,

,

) (

6

) (

) (

6

) (

) (

i

i

i i j

i

i

i i j

i j

t t

h

t Q

t t

h

t Q

t Q + =

+

+

). (

6

) (

) (

6

) (

1

, , 1 , 1 ,

t t

t Q h

h

q

t t

t Q h

h

q

i

i i j i

i

i j

i

i i j i

i

i j

+

+

+ +

(3)

Using the continuity condition on velocities and

accelerations, a system of 2 n linear equations solving for

2 n unknowns

1 , , 3 , 2 ), (

,

= n i t Q

i i j

is obtained [3] as;

( ) ( ) ( ) [ ] .

1 1 , 3 3 , 2 2 ,

B t Q t Q t Q A

T

n n j j j

=

(4)

In (4), the matrix Ais non-singular, see in [3].

B. Constrained optimization problem

The modern industrial sector often uses the robots. The

important consideration to increase the productivity is traveling

time of robot manipulators. Therefore, the minimization of

traveling time is the objective function that is investigated. It

leads to trajectories with large value of the kinematics

quantities (velocities, accelerations and jerks). They cause to

oscillate and overshoot, so it is difficult to control the position

tracking and the actuator may be damaged. Thus the velocities,

accelerations, jerks constraints must also be considered in the

optimization process.

Hence, the objective function and constraints for finding the

optimal trajectory planning problem can be formulated as;

N j JC t q

N j AC t q

N j VC t q to subject

h

j j

j j

j j

n

i

i

, , 2 , 1 , ) (

, , 2 , 1 , ) (

, , 2 , 1 , ) (

min

1

1

=

=

=

=

(5)

where VC

j

is the velocity constraint for jth joint.

AC

j

is the acceleration constraint for jth joint.

JC

j

is the jerk constraint for jth joint.

N is number of robot joints.

The interval times h

i

between via-points are computed by the

constrained optimization problem (5).

C. Constraints formulation

The velocity constraints of the optimization problem are

formulated into the maximum absolute value of velocities at

the extreme points t

i

or t

i+1

or t

i

* where 0 ) (

*

,

*

,

= =

i i j i j

t Q Q

in

each interval [4]. The velocity constraints become:

{ }

. 1 , , 1 ; , , 1

; , ) ( , ) ( max

*

, 1 , ,

= =

+

n i and N j

VC Q t Q t Q

j i j i i j i i j

(6)

The acceleration constraints are formulated from the

acceleration linear function and the maximum absolute value

exists at t

i

or t

i+1

. The acceleration constraints become:

{ } . , , 1 ; , , max

, 1 ,

N j AC Q Q

j n j j

=

(7)

The jerk constraints are formulated from the rate of change

of acceleration.

. 1 , , 1 ; , , 1 ;

, 1 ,

= =

+

n i and N j JC

h

Q Q

j

i

i j i j

(8)

The equation (6)-(8) are the constraints of the optimization

problem in equation (5).

III. HARMONY SEARCH ALGORITHM

Harmony Search is a heuristic optimization algorithm[10]. It

has been shown that HS outperforms various optimization

methods in many optimization problems [11]. HS mimics the

improvisation of music players for searching the better

harmony. The comparison between optimization and music

performance process is shown in Table I.

The steps in the procedure of HS are as follows:

Step1: Initialize a Harmony Memory (HM) by randomness.

Step2: Improvise a new harmony from HM.

Step3: If the new harmony is better than minimum harmony

in HM, include the new harmony in HM, and exclude

the minimum harmony from HM.

Step4: If stopping criteria are not satisfied, go to step2.

There are 2 parameters for considering all the parts of the

feasible set that lead to obtain the global solution.

The first parameter is called Harmony Memory Considering

Rate (HMCR) which ranges from 0 to 1. It is the probability

for choosing a variable value from HM. For example, if

HMCR = 0.95, then 95% of variable values are chosen from

HM and 5% are not from HM. Hence HS can find notes

randomly within the possible playable range without

considering HM.

The second parameter is called Pitch Adjustment Rate (PAR)

that is the probability for shifting to neighboring values within

a range of possible values.

TABLE I

COMPARISON BETWEEN OPTIMIZATION AND MUSIC PERFORMANCE [10]

The Harmony Search(HS) has been developed by combining

features of others heuristic optimization methods. It employs

the preserving the history of past vectors similar to Tabu

Search (TS) and ability to vary the adaptation rate from

Simulated Annealing (SA). Furthermore, HS manages several

vectors simultaneously in the process similarly to the Genetic

Algorithm (GA). However, the major difference between GA

and HS is that HS makes a new vector from all existing vectors

and can independently consider each component variable in a

vector, while GA utilizes only two of the existing vectors and

keep the structure of a gene.

IV. SIMULATION RESULTS

The simulation compares two techniques, the Sequential

Quadratic Programming (SQP) and the Harmony Search (HS)

because the best result had so far given in the simulation of the

6 DOFs robot manipulator system proposed by Gasparetto and

Zanotto[4]. The knot position (via-point) and kinematics

constraints of the joints are shown in Table II, III, respectively.

Gasparettos algorithm[4] determined the initial interval time

value and used SQP techniques (from fmincon function of

MATLAB) for minimum time trajectory (k

T

= 1, k

J

= 0). The

SQP techniques result for minimum time trajectory is

8.5726sec. The comparison algorithm replaces the SQP with

the HS. The HS simulation results give the minimum time

trajectory 8.5718sec for 10,000 iterations and 8.5577sec for

200,000 iterations. Although the HS process uses the more

number of iteration, the whole SQP process takes computation

time nearby the 10,000 iterations of HS process. The process

time is not concerned as the optimal trajectory planning is

often run off-line. Therefore, the HS method gives a better time

of trajectory than SQP method where the kinematics constraint

is satisfied. Moreover, HS obtains the best solution without the

initial value finding time process.

The simulation results, which are reported in Fig.1- Fig.6,

use HS technique with the 6 DOFs robot manipulator, 6 via-

points and the total interval traveling time is 8.5577sec. The

figures show each joint minimum time trajectories and their

derivatives (velocities, accelerations and jerks). This shows

that HS method is efficient enough to solve an optimal robot

trajectory planning. It yields the best solution that gives the

minimum time trajectory and satisfies the kinematics limitation

constraints of the optimization problem.

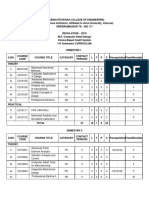

TABLE II

KNOT POSITIONS OF EACH ROBOT MANIPULATOR JOINT

Joint Point1

(deg)

Point2

(deg)

Point3

(deg)

Point4

(deg)

Point5

(deg)

Point6

(deg)

1 -10 Extra

knot

60 20 Extra

knot

55

2 20 50 120 35

3 15 100 -10 30

4 150 100 40 10

5 30 110 90 70

6 120 60 100 25

TABLE III

KINEMATIC CONSTRAINTS OF EACH ROBOT MANIPULATOR JOINT

Joint Velocity (deg/s) Acceleration (deg/s

2

) Jerk (deg/s

3

)

1 100 60 60

2 95 60 66

3 100 75 85

4 150 70 70

5 130 90 75

6 110 80 70

V. CONCLUSION AND FUTURE WORK

The algorithm, which is proposed in this paper, is the

minimum time trajectory planning that is clamped with cubic

splines using Harmony Search (HS) method as the

optimization technique. The objective function is minimum

interval traveling time of robot manipulator with the

kinematics constraints (velocity, acceleration and jerk).

Harmony Search (HS) algorithm successfully obtains the better

solution than Sequential Quadratic Programming (SQP)

algorithm while the consumed process time is nearby.

Moreover HS does not need to use the initial values in the

optimization solving process like SQP. If the SQP algorithm

randomizes the initial value, the solution may be the local

optima. For HS, the initial value finding step can be eliminated.

The study case indicates that, HS algorithm is efficient for

solving the optimal trajectory and the obtained trajectory keep

under the kinematics limitations.

The future work is the HS method application for optimal

trajectory planning of pneumatic muscle actuator robot arm.

ACKNOWLEDGMENT

This research was supported by Chang Puak Mordindang

Scholarship, Faculty of Engineering, Khon Kaen University.

Especially, the author would like to thank Dr. Zong Woo Geem

for the original Harmony Search code, Dr.Sujin Bureerat for

the MATLAB optimization toolbox and Dr.Anupap

Meesomboon for all suggestions.

REFERENCES

[1] B. Cao and G. I. Dodds, Time-Optimal and Smooth Joint Path

Generation for Robot Manipulators, Control, 1994. Control '94. Volume

2., International Conference on , vol.2, pp.1122-1127, 21-24 Mar 1994.

[2] T. Chettibi, H. E. Lehtihet, M. Haddad and S. Hanchi, Minimum Cost

Trajectory Planning for Industrial Robots, European Journal of

Mechanics - A/Solids, vol.23, no.4, pp.703-715, Jul-Aug 2004.

[3] S. F. P. Saramago and V. Steffen Jr., Optimization of the trajectory

planning of robot manipulator taking into account the dynamics of the

system, Mech. Mach. Theory, vol.33, no.7, pp. 883-894, 1998.

Comparison factor Optimization Music Performance

Best state Global Optimum Fantastic Harmony

Estimated by Objective Function Aesthetic Standard

Estimated with Values of Variables Pitches of Instruments

Process unit Each Iteration Each Practice

[4] A. Gasparetto and V. Zanotto, A technique for time-jerk optimal

planning of robot trajectories, Robotics and Computer-Integrated

Manufacturing, vol.24, pp.415-426, 2008.

[5] D. P. Garg and M. Kumar, Optimization Techniques Applied to

Multiple Manipulators for Path Planning and Torque Minimization,

Engineering Applications of Artificial Intelligence, vol.15, no.3-4,

pp.241-252, Jun-Aug 2002.

[6] A. R. Hirakawa and A. Kawamura, Proposal of Trajectory Generation

for Redundant Manipulators Using Variational Approach Applied to

Minimization of Consumed Electrical Energy, Advanced Motion

Control, 1996. AMC '96-MIE. Proceedings., 1996 4th International

Workshop on , vol.2, pp.687-692, 18-21 Mar 1996.

[7] G. Capi, S. Kaneko, K. Mitobe, L. Barolli and Y. Nasu, Optimal

Trajectory Generation for a Prismatic Joint Biped Robot Using Genetic

Algorithms, Robotics and Autonomous Systems, vol.38, no.2, pp. 119-

128, 28 Feb 2002.

[8] C. Xu, A. Ming and M. Shimojo, Optimal Trajectory Generation for

Manipulator with Strong Nonlinear Constraints and Multiple Boundary

Conditions, Robotics and Biomimetics (ROBIO) 2004. IEEE

International Conference on, pp. 192-197, 22-26 Aug. 2004.

[9] X. Zhu, H. Wang and M. Zhao, Using nonlinear constrained

optimization methods to solve manipulators path planning with hybrid

genetic algorithms, Robotics and Biomimetics (ROBIO). 2005 IEEE

International Conference on, pp.718-723, 2005.

[10] Z. W. Geem, J. H. Kim and G. V. Loganathan, A new heuristic

optimization algorithm: Harmony Search, SIMULATION, vol.76, no.2,

pp.60-68, 2001.

[11] K. S. Lee and Z. W. Geem, A new meta-heuristic algorithm for

continuous engineering optimization: harmony search theory and

practice, Computer methods in applied mechanics and engineering,

vol.194, pp.3902-3933, 2005.

Figure 1. Joint 1

Figure 2. Joint 2

Figure 3. Joint 3

Figure 4. Joint 4

Figure 5. Joint 5

Figure 6. Joint 6

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- European Journal of Operational Research: Zhipeng Lü, Jin-Kao HaoDocument10 pagesEuropean Journal of Operational Research: Zhipeng Lü, Jin-Kao HaoMr. NobodyNo ratings yet

- FTCS Nutshell PDFDocument2 pagesFTCS Nutshell PDFaseman1228No ratings yet

- Targate-Maths Booklet (Non Dowloadable)Document102 pagesTargate-Maths Booklet (Non Dowloadable)Sonal Kumar AgrawalNo ratings yet

- Computational Fluid DynamicsDocument2 pagesComputational Fluid DynamicsbandaruthrilokraoNo ratings yet

- Multi-Objective Goal Attainment Optimization - MATLAB & Simulink ExampleDocument6 pagesMulti-Objective Goal Attainment Optimization - MATLAB & Simulink ExampleYutaka TakaharaNo ratings yet

- CSE-CS&BS - CS& Syllabus - UG - R20Document43 pagesCSE-CS&BS - CS& Syllabus - UG - R20Sumanth 7899No ratings yet

- Tan, Emil Angelo O. Barcelona, John Rey Tortugo, Jonathan Olayvar, ClarkDocument3 pagesTan, Emil Angelo O. Barcelona, John Rey Tortugo, Jonathan Olayvar, ClarkAnonymous 1VhXp1No ratings yet

- Polynomials Division of Polynomials By: A. Long Division B. Synthetic DivisionDocument27 pagesPolynomials Division of Polynomials By: A. Long Division B. Synthetic DivisionyesNo ratings yet

- Cv7803 Numerical Methods FinalDocument3 pagesCv7803 Numerical Methods FinalJiye LiuNo ratings yet

- Tutorial Sheet 2Document2 pagesTutorial Sheet 2Srijanak DeNo ratings yet

- Traveling Salesman Problem: A Case Study: Dr. Leena Jain Mr. Amit BhanotDocument3 pagesTraveling Salesman Problem: A Case Study: Dr. Leena Jain Mr. Amit BhanotmaddymahekNo ratings yet

- A New Operational Matrix Based On Bernoulli PolynomialsDocument52 pagesA New Operational Matrix Based On Bernoulli PolynomialsSheraz KhanNo ratings yet

- I.S.F.D y T. #103: Profesorado de Técnicos Prof: Martín MellerDocument11 pagesI.S.F.D y T. #103: Profesorado de Técnicos Prof: Martín MellerAriel LeucipoNo ratings yet

- Optimal Control of Two - and Three-Dimensional Imcompressible Navier-Stokes FlowsDocument27 pagesOptimal Control of Two - and Three-Dimensional Imcompressible Navier-Stokes FlowsnewmetroNo ratings yet

- 15 Feb Putter PartnersDocument7 pages15 Feb Putter PartnersAtri RoyNo ratings yet

- A Note On A New Two Variable Analogue of Hermite PolynomialsDocument8 pagesA Note On A New Two Variable Analogue of Hermite PolynomialsTI Journals PublishingNo ratings yet

- Example 1Document22 pagesExample 1Rohan sharmaNo ratings yet

- High Order Finite Element Methods For Electromagnetic Field ComputationDocument177 pagesHigh Order Finite Element Methods For Electromagnetic Field ComputationEndless LoveNo ratings yet

- Product of MonomialDocument3 pagesProduct of MonomialMaria Nerissa Gomop-asNo ratings yet

- Sathyabama University: Register NumberDocument4 pagesSathyabama University: Register NumberAnonymous MFFOxujrRNo ratings yet

- The Resolvent Cubic of A Quartic PolynomialDocument2 pagesThe Resolvent Cubic of A Quartic PolynomialRachmat HidayatNo ratings yet

- CLL113 Term Paper PDFDocument8 pagesCLL113 Term Paper PDFpabloNo ratings yet

- Pre University h2 Further MathematicsDocument22 pagesPre University h2 Further MathematicsLeng RyanNo ratings yet

- CBSE Class 9 Mathemaics Important Questions Polynomials: The Coefficient of in The Polynomial Is 1Document19 pagesCBSE Class 9 Mathemaics Important Questions Polynomials: The Coefficient of in The Polynomial Is 1LakshNo ratings yet

- Numerical Methods Multibody DynamicsDocument287 pagesNumerical Methods Multibody DynamicsMax Vazquez-Cedeno0% (1)

- Linear Algebra With Applications 2nd Edition Holt Solutions Manual DownloadDocument56 pagesLinear Algebra With Applications 2nd Edition Holt Solutions Manual DownloadLaura Mckinnon100% (27)

- Numerical Solutions of Second Order Boundary Value Problems by Galerkin Residual Method On Using Legendre PolynomialsDocument11 pagesNumerical Solutions of Second Order Boundary Value Problems by Galerkin Residual Method On Using Legendre PolynomialsIOSRjournalNo ratings yet

- Anna UniversityDocument26 pagesAnna UniversityNagasubramaniyan SankaranarayananNo ratings yet

- Spring 2017 ME 523: Numerical Solutions Applied To Heat Transfer and Fluid MechanicsDocument5 pagesSpring 2017 ME 523: Numerical Solutions Applied To Heat Transfer and Fluid MechanicsAbcd EfghNo ratings yet

- PGCDR18Document68 pagesPGCDR18Santosh PapleNo ratings yet