Professional Documents

Culture Documents

Design of 6 Sigma in Matlab - 1 Carte

Design of 6 Sigma in Matlab - 1 Carte

Uploaded by

realpaladinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of 6 Sigma in Matlab - 1 Carte

Design of 6 Sigma in Matlab - 1 Carte

Uploaded by

realpaladinCopyright:

Available Formats

2

0

0

7

T

h

e

M

a

t

h

W

o

r

k

s

,

I

n

c

.

Design for Six Sigma with MATLAB

Kevin Cohan

The MathWorks, Inc.

2

Design for Six Sigma

http://www.dtic.mil/ndia/2003test/kiemele.pdf

1

10

100

1000

R

e

l

a

t

i

v

e

C

o

s

t

t

o

M

a

k

e

a

D

e

s

i

g

n

C

h

a

n

g

e

Product Stage

Research Design Development Production

Classic Six Sigma

focuses here

DFSS focuses here

3

DMAIC Methodology

Define the problem / defects

Measure the current performance level

Analyze to determine the root causes of the problem / defects

Improve by identifying and implementing solutions

that eliminate the root causes

Control by monitoring the performance of the improved process

M

D

A

I

C

http://www.dtic.mil/ndia/2003test/kiemele.pdf

D M A I C

2

0

0

7

T

h

e

M

a

t

h

W

o

r

k

s

,

I

n

c

.

Example

Optimization of an

Engine Cooling Fan Design

Image courtesy of Novak Conversions

5

Define:

Define the Problem

Existing engine isnt cooled sufficiently

under difficult driving conditions

New design requirement

Airflow > 875 cubic feet per minute

Approach

Optimize design factors

for maximum airflow

Use the MATLAB product family to

implement the DMAIC methodology

D M A I C

Image courtesy of Novak Conversions

6

Measure:

Measure Cooling Fan Performance

Import historical data

from Excel

Establish baseline

for comparison

Mean = 842 ft

3

/ min

Std Dev = +2 ft

3

/ min

D M A I C

7

Analyze:

Analyze Factors that Affect Performance

Three design factors

we can modify

Clearance

Distance

Pitch

Min Max

Distance from radiator (d) 1.0 1.5 inches

Blade pitch angle (p) 15 35 degrees

Blade tip clearance (c) 1.0 2.0 inches

Factors

Range

Units

D M A I C

8

Analyze:

Analyze Factors that Affect Performance

Gather additional data from existing system

Modify our design factors and measure performance

Fit a model to the performance data

Evaluate the model to understand the

effect of each design factor

What tests do we run?

and how many?

D M A I C

(

d

)

(

p

)

(

c

)

Test Run

D

i

s

t

a

n

c

e

f

r

o

m

r

a

d

i

a

t

o

r

B

l

a

d

e

p

i

t

c

h

a

n

g

l

e

B

l

a

d

e

t

i

p

c

l

e

a

r

a

n

c

e

P

e

r

f

o

r

m

a

n

c

e

1 ? ? ?

2

3

n

9

Analyze:

Analyze Factors that Affect Performance

Use a designed experiment to gather performance data

Choose the Box-Behnken function to determine

points in the design space

D M A I C

10

Analyze:

Analyze Factors that Affect Performance

Fit a quadratic model to the data (regstats function)

D M A I C

AF = B

0

+ B

1

X

1

+ B

2

X

2

+ B

3

X

3

+

B

4

X

1

X

2

+ B

5

X

1

X

3

+ B

6

X

2

X

3

+

B

7

X

1

2

+ B

8

X

2

2

+ B

9

X

3

2

AF = Airflow (ft

3

/min)

X

1

= Distance from radiator (inches)

X

2

= Fan pitch angle (degrees)

X

3

= Tip clearance between fan blades

and shroud (inches)

11

Analyze:

Analyze Factors that Affect Performance

Use rstool to visually inspect interaction between all three design

factors (distance, pitch, clearance) simultaneously

D M A I C

12

Improve:

Improve the Cooling Fan Performance

Use optimization to automate the task of

finding the maximum airflow

fmincon function

D M A I C

13

Improve:

Improve the Cooling Fan Performance

Use uncertainty analysis to ensure a robust design

Two main contributors

Model uncertainty

Manufacturing variability

D M A I C

Model noise

0.00 +/- 0.96 ft

3

/min

Distance from radiator (d) 1.00 +/- 0.005 inch

Blade pitch angle (p) 27.3 +/- 0.5 degrees

Blade tip clearance (c) 1.00 +/- 0.005 inch

Factors Nominal Value and Tolerance

14

Improve:

Improve the Cooling Fan Performance

Use Monte Carlo simulation to determine

impact of these variations

Mean = 882 ft

3

/ min

Std Dev = +2 ft

3

/ min

D M A I C

15

Control:

Control the Manufacturing and Installation

Use Statistical Process Control (SPC)

techniques to monitor and

control manufacturing and

installation of the fan

D M A I C

16

Summary

Continued emphasis on quality initiatives

Data analysis increasingly becoming an

integral part of the engineering design process

MATLAB product family can

support these initiatives

2

0

0

7

T

h

e

M

a

t

h

W

o

r

k

s

,

I

n

c

.

Questions?

2

0

0

7

T

h

e

M

a

t

h

W

o

r

k

s

,

I

n

c

.

You might also like

- Connecting Rod Bearings - Install: Table 1Document3 pagesConnecting Rod Bearings - Install: Table 1David Apaza HurtadoNo ratings yet

- Cad Cam Third Edition Solution ManualDocument155 pagesCad Cam Third Edition Solution ManualGabriel Dias100% (2)

- Measuring Internal Combustion Engine In-Cylinder Pressure With LabviewDocument2 pagesMeasuring Internal Combustion Engine In-Cylinder Pressure With LabviewJose Luis RattiaNo ratings yet

- Kpi For Design TeamDocument23 pagesKpi For Design TeamGiap le Dinh100% (1)

- W7 Robust Design TaguchiDocument21 pagesW7 Robust Design TaguchiFaisal SevenfoldNo ratings yet

- MMIC Design Flow Using ADSDocument64 pagesMMIC Design Flow Using ADSphithuc0% (1)

- 1 IntroductionDocument76 pages1 IntroductionsililloNo ratings yet

- Urexam: $GVVGT 5gtxkeg Kijgt 3Wcnkv (Document10 pagesUrexam: $GVVGT 5gtxkeg Kijgt 3Wcnkv (Abhishek Satyam JhaNo ratings yet

- DOE and Robust Parameter DesignDocument40 pagesDOE and Robust Parameter DesignIonut DumistrascuNo ratings yet

- 08m13e11 - Update Training FARO CAM2 Measure X Workbook For The Student - June 2005Document146 pages08m13e11 - Update Training FARO CAM2 Measure X Workbook For The Student - June 2005Bita MohajerniaNo ratings yet

- Reliability Analysis and Robust Design - MatlabDocument18 pagesReliability Analysis and Robust Design - MatlabJean Callata Chura100% (1)

- 2011 SRM Summer2011 11webDocument40 pages2011 SRM Summer2011 11webozzy22No ratings yet

- Term Project ReportDocument32 pagesTerm Project Reportankit1312No ratings yet

- Robust Design Taguchi Module 808Document17 pagesRobust Design Taguchi Module 808moragorNo ratings yet

- DMAIC TemplateDocument39 pagesDMAIC Templateunknown139No ratings yet

- 10 - Proof of Concept Project CloseOut Presentation - CRMDocument12 pages10 - Proof of Concept Project CloseOut Presentation - CRMBalavignesh VenugopalNo ratings yet

- Brake Dynamometer Development For Drexel University Fsae Race TeamDocument22 pagesBrake Dynamometer Development For Drexel University Fsae Race TeamgustavoNo ratings yet

- AFES One Stop Solution For Foundation DesignDocument43 pagesAFES One Stop Solution For Foundation Designhoga_dreamlandNo ratings yet

- Dump 2 MB-300Document7 pagesDump 2 MB-300Matthew VijayNo ratings yet

- Xam Pass: Exam: Microsoft 70-452Document6 pagesXam Pass: Exam: Microsoft 70-452Draven MorgensternNo ratings yet

- Design XplorerDocument36 pagesDesign XplorerAndrey ZagorulkoNo ratings yet

- COCOMO EstimatingDocument40 pagesCOCOMO EstimatingMohamedMoideenNagoorMeeranNo ratings yet

- Vijeo BasicDocument321 pagesVijeo BasicAmaraa GanzorigNo ratings yet

- IE 458-Design For AssemblyDocument33 pagesIE 458-Design For AssemblymustufahaiderNo ratings yet

- CF DesignDocument4 pagesCF DesignrdsrajNo ratings yet

- Sae Technical Paper Series: Meisen Li and Linjie HuangDocument8 pagesSae Technical Paper Series: Meisen Li and Linjie HuangGopinath GopiNo ratings yet

- Data Center DesignDocument36 pagesData Center DesignKunjan Kashyap0% (1)

- Bpms Project TemplateDocument25 pagesBpms Project TemplateFederico VargasNo ratings yet

- Experiment No. 1: AIM: To Study About CAD, CAM and CAE Software and Its AdvantagesDocument8 pagesExperiment No. 1: AIM: To Study About CAD, CAM and CAE Software and Its AdvantagessuryavigneNo ratings yet

- EyecadDocument16 pagesEyecadahmadhatakeNo ratings yet

- Simulation Import PDFDocument18 pagesSimulation Import PDFSouar YoucefNo ratings yet

- Improving Air Flow Uniformity at Burner ExitDocument3 pagesImproving Air Flow Uniformity at Burner ExitMehul PatelNo ratings yet

- Introduction To Design For Assembly and Manufacturing: (Cost Effective)Document81 pagesIntroduction To Design For Assembly and Manufacturing: (Cost Effective)maladcondomNo ratings yet

- Vijeo BasicDocument321 pagesVijeo BasicirfanWPKNo ratings yet

- 000 421Document46 pages000 421Sheena VargheseNo ratings yet

- Introduction To Robust Design (Taguchi Method)Document8 pagesIntroduction To Robust Design (Taguchi Method)design_rajeevNo ratings yet

- Stamping Die Solution Overview Updated 01142011Document36 pagesStamping Die Solution Overview Updated 01142011HerberPerazaNo ratings yet

- WINSEM2022-23 MEE3502 ETH VL2022230500781 2022-12-21 Reference-Material-IDocument24 pagesWINSEM2022-23 MEE3502 ETH VL2022230500781 2022-12-21 Reference-Material-IwewewewNo ratings yet

- Improve An Engine Cooling Fan Using Design For Six Sigma Techniques PDFDocument7 pagesImprove An Engine Cooling Fan Using Design For Six Sigma Techniques PDFGUESSOUMANo ratings yet

- CAESES STARCCM OptimizationDocument46 pagesCAESES STARCCM Optimizationalex mobile100% (1)

- DMAIC Project TemplateDocument17 pagesDMAIC Project TemplateArockia Sagayaraj100% (1)

- Cae PPT - 02-Mar-2921Document24 pagesCae PPT - 02-Mar-2921Ramesh Kavitha Sanjit 18BME0677No ratings yet

- Simulation of A Windtunnel2020-21Document9 pagesSimulation of A Windtunnel2020-21abdul5721No ratings yet

- TOSCA Structure 81 Short SeminarDocument37 pagesTOSCA Structure 81 Short SeminarmhsafeNo ratings yet

- Simcenter STAR CCM Version 2019.3 New Features Fact SheetDocument43 pagesSimcenter STAR CCM Version 2019.3 New Features Fact SheetEsaNo ratings yet

- Digitized Shape Editor V5R19Document95 pagesDigitized Shape Editor V5R19zaid_msd786No ratings yet

- Tech 149: Unit 3: Computer Integrated Manufacturing Technology: (CAD & CAM)Document26 pagesTech 149: Unit 3: Computer Integrated Manufacturing Technology: (CAD & CAM)Prabha KaranNo ratings yet

- Professional Cloud Architect - 6Document10 pagesProfessional Cloud Architect - 6nm.nielitNo ratings yet

- 18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022Document13 pages18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022srinivas kanakalaNo ratings yet

- CourseworkDocument4 pagesCourseworkSami ullahNo ratings yet

- Datastage 7.5 CertificationDocument5 pagesDatastage 7.5 Certificationcms_gcolesNo ratings yet

- Chapter3 - Concurrent Engineering PDFDocument15 pagesChapter3 - Concurrent Engineering PDFSandeep GogadiNo ratings yet

- Product Design & CADDocument15 pagesProduct Design & CADHamizan MohdNo ratings yet

- Session22-A-SPICE Compliance Made Easy Case Studies and Lessons LearnedDocument49 pagesSession22-A-SPICE Compliance Made Easy Case Studies and Lessons LearnedHaissamNo ratings yet

- What'S New in Solidworks 2014 Solutions: Advanced Shape ControlDocument2 pagesWhat'S New in Solidworks 2014 Solutions: Advanced Shape ControlSunabouzuSenseiNo ratings yet

- DX8 01 GetStartedDocument32 pagesDX8 01 GetStartedPradeep Kumar Reddy BNo ratings yet

- Statistical Thinking: Improving Business PerformanceFrom EverandStatistical Thinking: Improving Business PerformanceRating: 4 out of 5 stars4/5 (1)

- AutoCAD 2019: A Problem - Solving Approach, Basic and Intermediate, 25th EditionFrom EverandAutoCAD 2019: A Problem - Solving Approach, Basic and Intermediate, 25th EditionNo ratings yet

- A Study On Insulation Coordination of A Wind Turbine Generator System and A Distribution LineDocument6 pagesA Study On Insulation Coordination of A Wind Turbine Generator System and A Distribution Linejomoran100% (1)

- A Web Based Management Information System For A Take Away in RestaurantsDocument4 pagesA Web Based Management Information System For A Take Away in RestaurantsThembo JimmyNo ratings yet

- Geog 1 Updated SyllabusDocument3 pagesGeog 1 Updated SyllabusSander Louie LeeNo ratings yet

- How To Print Layouts in Sap Business OneDocument65 pagesHow To Print Layouts in Sap Business OneshellydreNo ratings yet

- Blast Furnace Tap Hole and Tapping of The FurnaceDocument11 pagesBlast Furnace Tap Hole and Tapping of The Furnaceprashant mishraNo ratings yet

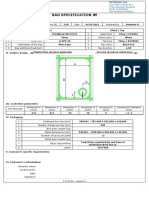

- Bag Specification 3LDocument1 pageBag Specification 3LBookWayNo ratings yet

- Coil Viscous Fan Drive TestDocument12 pagesCoil Viscous Fan Drive TestWilson BuenoNo ratings yet

- Cerberus 20 PRO ModularDocument6 pagesCerberus 20 PRO ModularFrancisco RamirezNo ratings yet

- Classic Honda: Marketing Strategies For Corporate Sales inDocument51 pagesClassic Honda: Marketing Strategies For Corporate Sales inAzm FaisalNo ratings yet

- Case Studies in Engineering Economics For Electrical Engineering StudentsDocument6 pagesCase Studies in Engineering Economics For Electrical Engineering Studentsryan macutoNo ratings yet

- Fouka Bay: Amin WahbaDocument1 pageFouka Bay: Amin WahbaGamal AhmedNo ratings yet

- Malika Burieva - ResumeDocument1 pageMalika Burieva - Resumeapi-704665033No ratings yet

- Parallel Pump OperationDocument5 pagesParallel Pump Operationarunima04100% (1)

- Certificación IEC - 1Document40 pagesCertificación IEC - 1Rosa TaylorNo ratings yet

- HP Man SM9.30 Programming Guide PDFDocument396 pagesHP Man SM9.30 Programming Guide PDFSrinidhi MaiyaNo ratings yet

- DragosDocument8 pagesDragosDragos CazaceanuNo ratings yet

- OSS Managed Services - A New Business Model For Service ProvidersDocument12 pagesOSS Managed Services - A New Business Model For Service ProviderstranceforgeNo ratings yet

- Final Payroll Project Report1Document86 pagesFinal Payroll Project Report1Amit Kumar64% (14)

- Electrical For Detached GaragesDocument15 pagesElectrical For Detached GaragesRaman AuarNo ratings yet

- IP 565 Water Effect On Particle CountingDocument5 pagesIP 565 Water Effect On Particle CountingJorge Muñiz100% (1)

- Comparison - Choke Equation Schlumberger vs. Texas A & I ModelsDocument16 pagesComparison - Choke Equation Schlumberger vs. Texas A & I ModelsJunaid MateenNo ratings yet

- Offer Process FormDocument1 pageOffer Process FormkumarNo ratings yet

- Boiler Dantrubin Control Rembang Dan PacitanDocument39 pagesBoiler Dantrubin Control Rembang Dan Pacitanbintang arcano lugasNo ratings yet

- Internship Report of PELDocument53 pagesInternship Report of PELRehan Aqeel100% (3)

- Apple PESTLE ReportDocument4 pagesApple PESTLE ReportAngeline SahagunNo ratings yet

- Micro Innovation Analysers PDFDocument82 pagesMicro Innovation Analysers PDFtonylorNo ratings yet

- Discrete Structures 1.1Document117 pagesDiscrete Structures 1.1Carl FernandesNo ratings yet

- Transformer Inspection Monthly ReportDocument11 pagesTransformer Inspection Monthly ReportIbnu RozaqNo ratings yet

- Active DirectoryDocument38 pagesActive DirectoryDeepak RajalingamNo ratings yet