Professional Documents

Culture Documents

Development of Textile Reinforced Composites For Aircraft Structures

Development of Textile Reinforced Composites For Aircraft Structures

Uploaded by

solnegro70 ratings0% found this document useful (0 votes)

18 views9 pagesOriginal Title

10.1.1.30.296.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views9 pagesDevelopment of Textile Reinforced Composites For Aircraft Structures

Development of Textile Reinforced Composites For Aircraft Structures

Uploaded by

solnegro7Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Development of Textile Reinforced Composites

for Aircraft Structures

H. Benson Dexter

NASA Langley Research Center

Hampton, VA 23681 USA

To be presented at the

4th International Symposium for Textile Composites

Kyoto Institute of Technology

Kyoto, Japan

October 12-14, 1998

1

Development of Textile Reinforced Composites

for Aircraft Structures

H. Benson Dexter

NASA Langley Research Center

Hampton, Virginia 23681, USA

ABSTRACT

NASA has been a leader in development of

composite materials for aircraft applications during

the past 25 years. In the early 1980s NASA and

others conducted research to improve damage

tolerance of composite structures through the use of

toughened resins but these resins were not cost-

effective. The aircraft industry wanted affordable,

robust structures that could withstand the rigors of

flight service with minimal damage. The cost and

damage tolerance barriers of conventional laminated

composites led NASA to focus on new concepts in

composites which would incorporate the automated

manufacturing methods of the textiles industry and

which would incorporate through-the-thickness

reinforcements. The NASA Advanced Composites

Technology (ACT) Program provided the resources

to extensively investigate the application of textile

processes to next generation aircraft wing and

fuselage structures. This paper discusses advanced

textile material forms that have been developed,

innovative machine concepts and key technology

advancements required for future application of

textile reinforced composites in commercial transport

aircraft. Multiaxial warp knitting, triaxial braiding

and through-the-thickness stitching are the three

textile processes that have surfaced as the most

promising for further development.

Textile reinforced composite structural elements that

have been developed in the NASA ACT Program are

discussed. Included are braided fuselage frames and

window-belt reinforcements, woven/stitched lower

fuselage side panels, stitched multiaxial warp knit

wing skins, and braided wing stiffeners. In addition,

low-cost processing concepts such as resin transfer

molding (RTM), resin film infusion (RFI), and

vacuum-assisted resin transfer molding (VARTM)

are discussed. Process modeling concepts to predict

resin flow and cure in textile preforms are also

discussed.

KEYWORDS: Textile Reinforced Composites,

Braiding, Knitting, Stitching, Resin Transfer

Molding, Process Modeling

1.0 INTRODUCTION

NASA initiated a research program in the early

1980s to exploit the potential of textile reinforced

composites as a cost-effective method of producing

damage-tolerant primary aircraft structures [1].

Several textile material forms, including 2-D and 3-D

weaving and braiding, multiaxial warp knitting, and

through-the-thickness stitching were evaluated.

Structural performance, fabricability, scale-up

potential, and manufacturing cost were the primary

focus of this research. Some of the potential benefits

of textile reinforced composites are as follows:

reduced material and assembly labor costs through

automated fabrication of multilayer multidirectional

preforms; reduced machining and material scrap

through use of near net shape preforms; elimination

of cold storage requirements and limits on shelf life

for prepreg; reduced tooling costs for vacuum-

assisted resin transfer molding compared to

conventional autoclave processes; and improved

damage tolerance and out-of-plane strength as a

result of through-the-thickness stitching.

In the late 1980s NASA researchers were looking to

develop breakthrough technologies that would

significantly change the way composite structures

were being built. The NASA Advanced Composites

Technology (ACT) program [2], provided the impetus

and resources to pursue these goals. Working with

aircraft manufacturers, universities, and specialty

textile fabricators, NASA began to develop a

preliminary design database on available material

forms and to focus research on key technology issues.

At that point in time, textile reinforced composites

moved from being a laboratory curiosity to large

scale aircraft hardware development. Initial

emphasis was on mechanical properties and

structural performance, but the need for cost-

effective fabrication concepts kept surfacing as the

key technology need. With the new focus on

affordability, NASA awarded several contracts to

industry to begin development of new tooling

concepts that could produce aircraft-quality textile

reinforced composite structures[3]. Resin injection

methods such as resin transfer molding(RTM), resin

2

film infusion (RFI), and vacuum-assisted resin

transfer molding (VARTM) would be the keys to

successful fabrication of composite structures from

dry textile preforms.

This paper summarizes the development of advanced

material forms, textile machine advancements,

analytical process models, fabrication of aircraft

structural components, and lessons learned working

with various textile material forms, machines and

processes.

2.0 TEXTILE MATERIAL FORMS AND

STRUCTURAL ELEMENTS

As preliminary design databases were generated,

NASA and the U.S. aircraft manufacturers began to

focus on the textile processes that offered the most

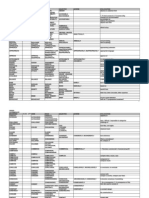

promise. The textile processes listed in figure 1 were

evaluated. The advantages and limitations of each

process were established and decisions on further

development were made. The textile material forms

shown in figure 2 have shown the most promise for

application to aircraft structures. Multiaxial warp

knitting is a highly tailorable automated process that

produces multidirectional broadgoods for large area

coverage. Two-dimensional and three-dimensional

braids are used to create stiffeners, frames and

beams with complex cross-sections. Through-the-

thickness stitching is an effective way to debulk

preforms and to achieve improved out-of-plane

strength and damage tolerance of composite

structures.

The structural elements shown in figure 3 were

selected by NASA and the aircraft manufacturers to

demonstrate the applicability of textiles to fuselage

structures. The combination of weaving and stitching

was used to fabricate lower fuselage side panel

preforms[4]. The fuselage panel shown in figure 4

has four circumferential frames and four longitudinal

stiffeners. The intersections of the woven stiffeners

and frames have continuous fibers through the

intersection to provide structural continuity. The

flanges of the woven frames are stitched to the

woven skin material. Braided frames were used to

fabricate curved fuselage keel panels [5], a typical

panel is shown in figure 5. The fuselage parts were

fabricated with either matched metal heated RTM

tooling or RFI autoclave processes.

Because of the high load intensity and the propensity

for foreign object damage, NASA focused most of its

textiles research on damage tolerant wing structures,

figure 6. Since most of the wing weight is in the

upper and lower cover panels of the wing, they are a

logical choice for pursuit of cost and weight savings.

Some of the global design considerations for wing

panels include strength, stiffness, and damage

tolerance. Based on tests conducted previously by

NASA and Boeing (formerly McDonnell Douglas),

through-the-thickness stitching was chosen for the

wing cover panels because a 100-percent

improvement in compression-after-impact strength

compared to laminated tape composites could be

achieved [6].

Blade stiffeners and integral spar caps were chosen

by Boeing as stiffening elements for the upper and

lower wing cover panels. The upper cover skin

stiffeners and spar caps are fabricated with Saertex

multiaxial warp knit fabric. However, due to the

curvature of the lower wing cover panel, contoured

triaxially braided stiffeners were selected. The

stiffeners and spar caps were stitched onto the wing

skins to form integral wing cover panels with no

mechanical fasteners.

Before proceeding to design and fabrication of a full-

scale wing box, Boeing fabricated a 2.4 m by 3.7 m

stub box with the stitched/RFI process as shown in

figure 7. An interior view of a stub box cover panel

is shown in figure 8. This box was stitched with a

computer controlled heavy duty single needle

machine similar to those used in the quilting

industry. The stub box was successfully tested at

NASA Langley and met the design requirements set

forth by Boeing for commercial transport wing

structures.

3.0 ADVANCED TEXTILE MACHINE

DEVELOPMENT

The development of a high speed multi-needle

stitching machine and improvements in the

multiaxial warp knitting process were required to

achieve affordable full-scale wing structures. The

stitching machine had to be capable of stitching

cover panel preforms that were 3.0 m wide by 15.2 m

long by 38.1 mm thick at speeds up to 800 stitches

per minute. The multiaxial warp knitting machine

had to be capable of producing 2.5 m wide carbon

fabric with an areal weight of 1425 g/m

2

. The

advanced stitching machine shown in figure 9 was

developed by Ingersoll Milling Machine Company to

meet the requirements of a full-scale wing box [7].

The high speed stitching heads were developed by

Pathe Industries, Inc. The lower cover preform for

the full-scale wing box is shown on the stitching

machine bed in figure 9.

Multiaxial warp knitting is a highly automated

process for producing multilayer broadgoods.

Compared to woven broadgoods, the knitted fabrics

have less crimp since the individual tows are not

interlaced. Early machine concepts lacked proper

3

tension control to maintain fiber alignment. Saertex

and Liba teamed up to upgrade tension control

mechanisms and to improve overall quality of carbon

fabrics. A schematic of the Saertex/Liba machine is

shown in figure 10. This machine can produce 5-ply

carbon fabrics in one pass through the machine. A

two-step process is required to produce a 7-ply fabric

for the Boeing full-scale wing cover panels. Splicing

concepts have been developed to produce fabrics up

to 2.5 m wide.

4.0 FABRICATION OF TEXTILE

REINFORCED COMPOSITES

Three resin transfer processes are commonly used to

produce composites from dry textile preforms: (1)

resin transfer molding (RTM), (2) resin film infusion

(RFI), and (3) vacuum assisted resin transfer

molding (VARTM). RTM is a good process to

achieve high fiber volume fraction for complex

shapes such as the curved fuselage frames shown in

figure 5. RTM requires the use of expensive

matched metal heated tools, such as Invar, and high

pressure to pump liquid resin into net shape tools.

High quality parts can be achieved but the cost is

prohibitive for large parts such as wing skins.

RFI is a process being pursed by NASA and The

Boeing Company to develop cost-effective wing

structures for commercial transport aircraft [8]. The

RFI process developed by Boeing consists of an

outer mold line tool, an epoxy resin film, a near net

shape textile preform, an inner mold line tool and a

reusable vacuum bag. Resin slabs are placed on the

outer mold line tool and the preform and inner mold

line tools are placed on top of the resin. The entire

assembly is covered with a reusable vacuum bag and

the part is placed inside an autoclave. After the

resin is melted, vacuum pressure is used to infuse

resin into the preform. Once infiltrated, the part is

cured under pressure and temperature in an

autoclave. The keys to producing aircraft quality

parts with the RFI process are understanding the

compaction and permeability characteristics of the

preform and understanding kinetics and viscosity

profiles for the resin as a function of temperature.

Figure 11 shows a full-scale 13m long stitched/RFI

wing cover panel fabricated by Boeing under

contract to NASA. The one-piece reusable vacuum

bag used to cure the cover panel is shown in

figure12.

VARTM processes have been used for many years to

fabricate fiberglass reinforced composite structures.

The U.S. Naval Surface Warfare Center in Bethesda,

MD has been the major promoter of this technology

for composite marine applications [9]. The major

advantages of VARTM processes compared to

conventional autoclave processes are the lower cost

of tooling, reduced cost of energy to cure composite

parts, and almost unlimited part size(i.e., no size

constraints based on the size of the autoclave). Until

recently, VARTM was primarily used to fabricate

glass reinforced polyester and vinyl ester composites.

However, due to recent developments in resin and

preform technologies, aircraft manufacturers are

beginning to show significant interest in VARTM

processes for graphite-epoxy and graphite-

bismaleimide composite systems. One drawback to

VARTM processes has been low fiber volume

fraction compared to the higher fractions achievable

with autoclave pressure. However, stitching and

debulking methods have been developed to achieve

preforms that are near net shape with little or no

further compaction required during processing.

NASA has conducted contractual research with

Seemann Composites, Inc. to establish the feasibility

of their VARTM process to produce aircraft quality

composite structures. Their proprietary process,

called SCRIMP ( S eemann C omposites R esin

I njection M olding P rocess) utilizes a resin

distribution media to achieve full wet-out of the

preform, figure 13. In addition, Seemann has

developed a reusable bagging concept that

eliminates most of the costs associated with

conventional bagging procedures. Seemann

Composites has also demonstrated SCRIMP for

lightly-loaded general aviation aircraft structures.

Figure 14 shows the one-sided tooling concept and

the graphite preform for a small aircraft fuselage

section and figure 15 shows the completed

graphite/epoxy part after resin injection and cure.

Current and future tooling developments for integral

heating will eliminate the need for oven cure and

postcure of composite parts fabricated with VARTM

processes.

NASA is also investigating the feasibility of

SCRIMP to produce aircraft quality heavily-loaded

primary structures. Additional technology

development is required to achieve dimensional

control and acceptable fiber volume fractions for

thick structural elements. Innovative tooling

concepts will be required to meet typical assembly

tolerances for aircraft structures. Stitching will be

required to achieve near net shape prior to resin

injection. The reusable bagging concept for a three

stringer panel representative of wing structure is

shown in figure 16. The ease of removing this bag

from the stiffened panel is illustrated in figure 17,

and the finished panel (after resin injection and cure)

is shown in figure 18.

To eliminate trial and error processes, analytical

models are required to predict resin flow into textile

4

preforms. The models must be verified through

precise experiments to demonstrate the modeling

accuracy. Three-dimensional models are required to

capture response adequately for complex preforms

such as wing cover panels that contain

stitched/knitted fabric skins and stitched/braided

stiffeners. The objectives of the analytical model are

to predict flow front position, resin viscosity and

degree of cure as a function of temperature and time.

A 3-D RFI process simulation model is under

development by Virginia Polytechnic Institute and

State University [10]. The RFI simulation includes

resin flow, heat transfer, and thermochemical

elements. A schematic of the 3-D finite element

model for infusion of a stitched blade stiffener is

shown in Figure 19. Experiments are currently being

conducted to verify accuracy of the 3-D finite

element model. For a two-stringer stitched panel, the

predicted temperature distribution was within 6-

percent of measured temperature and the predicted

resin wet-out times were within 4 to 12-percent of

measured times.

5.0 LESSONS LEARNED FROM TEXTILE

DEVELOPMENT

Early attempts to develop complex equipment to

fabricate near net shape multidirectional multilayer

fabrics were unsuccessful. This result was primarily

caused by the fact that various textile technologies

were being stretched beyond their technical

boundaries. Two- and three-dimensional braiding

showed a lot of potential but available machine

capacity limited the architecture and the size of the

preforms that could be achieved. Folding or

postforming of triaxial braided preforms offered the

most flexibility in achieving small cross-section

complex shapes. Multiaxial warp knitting proved to

be the best process for large area multiaxial

multilayer broadgoods but structural shapes had to be

achieved through postforming and stitching.

Through-the-thickness stitching proved to be the best

textile process to achieve improved damage

tolerance. Compared to processing with glass fibers,

all textile machines investigated had to be slowed

considerably when carbon fibers were used. Lessons

learned to-date indicate that no one machine can

produce the desired fiber architectures for all

complex shape aircraft structural preforms. In

addition, more stringent in-process controls and

inspection techniques are needed to minimize scrap

and to reduce costs. Invariably, processing defects

and handling damage will occur. Since scrap of

large expensive parts is not an option, repair

concepts must be developed. Methods to reinfuse

resin starved areas must be developed and repair

concepts to restore damaged structure to original

strength must also be developed.

Analytical models are required to eliminate costly

trial and error processes that are frequently used in

tool design and development of processing cycles.

Resin viscosity and cure kinetics must be

characterized to consistently achieve high quality

composite parts. Since compaction and permeability

behavior are different for each fiber architecture and

preform configuration, empirical relationships must

be developed for input to analytical models.

Tooling concepts that can accommodate variability

in dry preform bulk and permeability must be

developed to achieve uniform resin flow and fiber

wet-out. Dimensional tolerances on tooling is

critical to avoid racetracking or short circuiting of

resin during the infusion process. Further

development of compaction methods and soft

tooling concepts such as VARTM will lead to

reduced scrap and lower manufacturing costs.

6.0 CONCLUDING REMARKS

Major advancements in the development of textile

preforms in concert with resin transfer tooling

concepts makes it feasible to fabricate high quality

damage tolerant aircraft structures with these

material forms and processes. Recent developments

in improved tension control of tows in the multiaxial

warp knitting process have made this the material of

choice for large area multidirectional broadgoods.

Innovative tooling concepts have been developed to

produce curved braided preforms for application to

fuselage frames and wing stiffeners for commercial

transport aircraft. NASA and Boeing have

demonstrated that through-the-thickness stitching of

dry textile preforms can provide a 100-percent

increase in damage tolerance of composite wing

structures compared to laminated tape construction

techniques.

Recent investments in a second generation stitching

machine with multiple heads are expected to pay-off

in terms of improved quality, higher speed, and lower

cost. Low cost resin transfer molding processes are

now being applied to fabrication of aircraft quality,

heavily-loaded primary structures. Modeling studies

of resin transfer molding will focus on prediction of

resin flow into complex textile preforms to insure

high quality, high speed fabrication at lower costs.

Additional development of out-of-autoclave vacuum-

assisted resin transfer molding (VARTM) processes

could lead to significantly lower tooling and

fabrication costs for large area composite structures.

5

7.0 REFERENCES

1. Dexter, H. B.; Camponeschi, E. T. and Peebles,

L., ed., Proceedings of Working Group Meeting

on 3-D Composite Materials, NASA CP 2420,

1986.

2. Dexter, H. B. and Stein, B. A.: Advanced

Composite Materials for Airframe Structures,

Fiber-TEX 1987- First Conference on Advanced

Engineering Fibers and Textile Structures for

Composites, NASA CP 3001, Part 1, 1988, pp. 1-

29.

3. Davis, J. G., Jr. and Bohon, H. L., ed.: First

NASA Advanced Composites Technology

Conference, NASA CP 3104 , Part 1, 1991.

4. Suarez, J. A. and Buttitta, C., et al.: Novel

Composites for Wing and Fuselage Applications-

Textile Reinforced Composites and Design

Guidelines, NASA Contractor Report 201612,

September 1996.

5. Jackson, A. C.; Barrie, R. C. and Chu, R.L.:

Textile Composite Fuselage Development,

Proceedings of the Third NASA ACT

Conference, NASA CP 3178, Vol 1, Part 1,

1992, pp. 79-96.

6. Hawley, A. V.: Detail Design Development of a

Transport Aircraft Composite Wing,

Proceedings of the Sixth NASA/DoD ACT

Conference, NASA CP 3326, Vol 1, Part 1,

1996, pp. 131-154.

7. Thrash, P. J., and Miller, J. I.: Design of a

Stitching Machine for Transport Aircraft

Composite Wings, Proceedings of the Sixth

NASA/DoD ACT Conference, NASA CP 3326,

Vol 1, Part 1, 1996, pp. 191-208.

8. Markus, A. M.: Resin Transfer Molding for

Composite Primary Wing and Fuselage

Structures, Proceedings of the Ninth

DoD/NASA/FAA Conference on Fibrous

Composites in Structural Design, NASA CP

3154, 1992, pp. 141-167.

9. Critchfield. M.O., et al, Low-Cost Fabrication

of Composite Ship Structures Using Vacuum-

Assisted Resin Transfer Molding, Proceedings

of the Composites in Marine Applications

Symposium, November, 1992, Seattle, WA.

10. Loos, A. C., et al, Resin Film Infusion(RFI)

Process Simulation of Complex Wing

Structures, Proceedings of the Fifth NASA/DoD

Advanced Composites Technology Conference,

NASA CP 3294, Vol 1, Part 2, 1995, pp. 811-

833.

Multiaxial

Warp Knit

Stitching

Good in-plane properties

Highly automated process

provides excellent damage

tolerance and out-of-plane strength

Excellent assembly aid

Low

out-of-plane

properties

Small reduction in

in-plane properties

Poor accessibility

to complex

curved shapes

Good tailorability for balanced

in-plane properties

Highly automated preform

fabrication process

Multi-layer high throughput

material suited for large area coverage

3-D Woven Fabric

2-D Braided Preform

3-D Braided Preform

Limited tailorability

for off-axis

properties

Poor drapability

Size limitation due to

machine availability

Low out-of-plane

properties

Slow preform

fabrication process

Size limitation due to

machine availability

Moderate in-plane and out-of-plane

properties

Automated preform fabrication process

Limited woven shapes possible

Good balance in off-axis properties

Automated preform fabrication process

Well suited for complex curved shapes

Good drapability

Good balance in in-plane and

out-of-plane properties

Well suited for complex shapes

Textile Process Advantages Limitations

Low Crimp

Uniweave

2-D Woven

Fabric

Good in-plane properties

Good drapability

Highly automated preform

Fabrication process

Integrally woven shapes possible

Suited for large area coverage

Extensive data base

Low transverse and

out-of-plane properties

Poor fabric stability

Labor intensive

ply lay-up

Limited tailorability

for off-axis

properties

Low out-of-plane

properties

High in-plane properties

Good tailorability

Highly automated preform

fabrication process

Figure 1. Application potential of textile reinforced

composite materials for aircraft structures.

Multiaxial warp knit

(stitched & unstitched)

3-D braid Knitted/stitched

2-D triaxial braid

(stitched & unstitched)

Figure 2. Textile material forms.

6

Skin/Stiffened Panels

Circumferential Frames

Window Belt

Keel Beam Frames

Figure 3. Application of textile reinforced

composites in fuselage structures.

Figure 4. Woven/stitched lower fuselage side panel

preform.

Figure 5. Curved braided frames for fuselage keel

structure.

Upper And Lower

Cover Panels

Intercostal Clips Main Landing

Gear Attachment

Stiffeners And

Spar Caps

Figure 6. Application of textile reinforced

composites in wing structures.

Figure 7. Stitched/resin film infused wing stub

box.

Figure 8. Interior view of stub box cover panel.

7

Figure 9. Advanced stitching machine for wing

cover panels.

Figure 10. Schematic of Saertex/Liba multiaxial

warp knitting machine.

Figure 11. Stitched/Resin film infused composite

wing cover panel.

Figure 12. Reusable vacuum bag for wing cover

panel.

Advantages of low-cost RTM process:

Resin and fiber used in lowest cost form

Prepreg process eliminated

Freezer storage & shelf life problems

eliminated

Low cost, one-sided tooling

Low energy, low pressure out-of-autoclave

processing

Utilizes net-shape, damage tolerant textile

preforms

Large integral structure minimizes secondary

bonding and fastening

Challenges for aircraft applications:

Out-of-autoclave cure resins with adequate

properties

Dimensional tolerances with low-cost tooling

Figure 13. Low-cost vacuum-assisted resin transfer

molding process.

Figure 14. Vacuum-assisted resin transfer molding

tooling for fuselage section.

8

Figure 15. Vacuum-assisted resin transfer molded

fuselage section.

Figure 16. Reusable vacuum bag for VARTM of

3-stringer panel.

Figure 17. Removal of reusable vacuum bag from

VARTM stiffened panel.

Figure 18. Stiffened panel fabricated by VARTM.

Ply Drop Off Single Blade Stiffener

Preform/Tooling Assembly

Program Structure

Flow

Heat Transfer

Resin Kinetics

Resin Viscosity

Preform Compaction

Residual Stress and Warpage

Aluminum caul sheet

Aluminum blocks

Aluminum baseplate

Stitched

graphite

preform

Figure 19. Three-dimensional resin film fusion

model.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Appendix D Scope of Work PipelineDocument43 pagesAppendix D Scope of Work PipelineAnonymous xh8IDaKzT100% (7)

- ScienceDocument227 pagesScienceDean Kesten100% (3)

- Resimli Phrasal VerbsDocument61 pagesResimli Phrasal Verbscemnuy88% (25)

- Geotech Design ChecklistDocument25 pagesGeotech Design ChecklistpkNo ratings yet

- 1700 Toefl WordsDocument262 pages1700 Toefl WordsHanh PhamNo ratings yet

- Grammar Scan Answer KeyDocument49 pagesGrammar Scan Answer Keycemnuy94% (18)

- Powerwave RepeatersDocument17 pagesPowerwave RepeatersRiznanz0% (1)

- How To Improve Your Academic Writing PDFDocument24 pagesHow To Improve Your Academic Writing PDFipqtrNo ratings yet

- Short Fiber Composite TheoryDocument8 pagesShort Fiber Composite TheorycemnuyNo ratings yet

- Solutions To Problems For 2D & 3D Heat and Wave EquationsDocument15 pagesSolutions To Problems For 2D & 3D Heat and Wave EquationscemnuyNo ratings yet

- Set8 PDFDocument16 pagesSet8 PDFcemnuy100% (1)

- Page Numbering: Home Getting StartedDocument10 pagesPage Numbering: Home Getting StartedcemnuyNo ratings yet

- Upper Intermediate Level Word ListDocument10 pagesUpper Intermediate Level Word ListcemnuyNo ratings yet

- Photo StudioDocument146 pagesPhoto StudioXavier Douet100% (2)

- c7 Linear Programming, GraphicDocument38 pagesc7 Linear Programming, GraphichidaNo ratings yet

- Pu Cet PG Prospectus 2019Document124 pagesPu Cet PG Prospectus 2019Sidhant GuptaNo ratings yet

- Gartner MQ 2013 Strategic SourcingSuites PDFDocument53 pagesGartner MQ 2013 Strategic SourcingSuites PDFBabalawoOggundaObaraNo ratings yet

- Unit Ii 0.1 Intro To Design and Selection of Materials PDFDocument44 pagesUnit Ii 0.1 Intro To Design and Selection of Materials PDFsshridhar2008No ratings yet

- BPR Case StudyDocument5 pagesBPR Case StudyAmol PhadaleNo ratings yet

- Report DharanDocument11 pagesReport DharanMishal LimbuNo ratings yet

- Hassan Kamel Al SabbahDocument5 pagesHassan Kamel Al SabbahbildsaffNo ratings yet

- ATMDocument12 pagesATMKiran BasiNo ratings yet

- Fibromat MTS series-PET - 240227 - 113902Document1 pageFibromat MTS series-PET - 240227 - 113902fendi brsbNo ratings yet

- About GenpactDocument2 pagesAbout GenpactPatrick AdamsNo ratings yet

- French Air ForceDocument7 pagesFrench Air Forcesamirsamira928No ratings yet

- KLELINE CatalogueDocument24 pagesKLELINE CatalogueJorge GonzalezNo ratings yet

- Norma Astm 674-80Document13 pagesNorma Astm 674-80Rosario Gaytan100% (1)

- Akshay Ferrocement WardrobeDocument1 pageAkshay Ferrocement Wardrobe1DC20AT025 Ganesh AkshayNo ratings yet

- Tuesday Training - WorkshopsDocument20 pagesTuesday Training - Workshops560107No ratings yet

- DP World Internship ReportDocument40 pagesDP World Internship ReportSaurabh100% (1)

- Design Pizza CutterDocument11 pagesDesign Pizza CutterChristian CarestiaNo ratings yet

- Still - MX PDFDocument8 pagesStill - MX PDFtomy112No ratings yet

- Simple Magazine #9Document4 pagesSimple Magazine #9Ngôn ngữ AnhNo ratings yet

- SkodaDocument12 pagesSkodaGirish AgarwalNo ratings yet

- IRC-xxxxx - XXXX - 001: GratingDocument2 pagesIRC-xxxxx - XXXX - 001: GratingTarek YehiaNo ratings yet

- ProcessForce enDocument24 pagesProcessForce enRitesh H RawalNo ratings yet

- Pak Suzuki Supply ChainDocument21 pagesPak Suzuki Supply Chainshanesmith12No ratings yet

- 'Air Astana ' Airline Industry OrganisationDocument5 pages'Air Astana ' Airline Industry OrganisationФариза ЛекероваNo ratings yet

- Product Design ReportDocument22 pagesProduct Design Reportsheldoncooper691017No ratings yet

- Techno Commercial Bid QuestionnaireDocument10 pagesTechno Commercial Bid QuestionnairehariNo ratings yet

- Pressure and Leakage Management in A Water System Using Integrated Mathematical Models and Specialist SoftwareDocument13 pagesPressure and Leakage Management in A Water System Using Integrated Mathematical Models and Specialist SoftwareGiancarlo ItaNo ratings yet