Professional Documents

Culture Documents

Adirondack Plans

Adirondack Plans

Uploaded by

James VanceCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adirondack Plans

Adirondack Plans

Uploaded by

James VanceCopyright:

Available Formats

BY VERN GRASSEL I PHOTOS BY DAN CARY WORKSHOP

L

A

R

R

Y

O

K

R

E

N

D

Because I grew up in upstate New

York, Ive always been a big fan of

the Adirondack chair. I appreciated

the wide armrests, contoured seat and

curved back, but I didnt like the bulky

appearance and the low seat that made

getting up difficult. So when I was

asked to build a modern version of this

A SLEEK,

COMFORTABLE

UPDATE OF A

CLASSIC DESIGN

CONTEMPORARY

ADIRONDACK CHAIR

American classic, I was thrilled to be

able to make some changes.

My goal was to come up with a

sleek, stylized outdoor chair that still

had the look, feel and comfort of a tra-

ditional Adirondack. After you build

the version shown in the plans on p. 7,

grab a cold lemonade and have a seat

I think youll agree that the mission

was a success.

Instead of using one of the common

types of exterior-rated boards, such as

cedar or pressure treated pine, I built

these chairs using a new product

called Perennial Wood. These boards

are Southern pine that has gone

through an interesting new treatment

process (see First Impressions, p. 8).

The boards measured 7/8 in. thick

x 5-3/8 in. if you prefer, you can

substitute other types of wood deck

boards and the cutting dimensions

will remain the same.

BUILD THE LEG ASSEMBLIES

Whenever I build a piece of furni-

ture that has a lot of curved profles,

I make full-size templates of all of

the curved parts. This approach is es-

pecially useful for building multiple

pieces. (It will come in handy in the

future, when your neighbor sits in

your chair and asks you to build one

for him.) I draw the shape on 1/4-in.

plywood or hardboard, cut it out and

then trace the template on the actual

parts (photo 1, below).

Once youve made the templates, cut

the four legs to the rough sizes stated

in the cutting list (above) before cutting

them to their fnal shapes. Use a miter

saw to cut the ends of the back legs (B)

at 35 degrees; then use a jigsaw or a

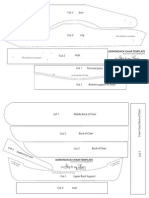

KEY NO. DESCRIPTION SIZE

A 2 Front legs 7/8 x 3 x 25-1/4 in.

B 2 Back legs 7/8 x 5-3/8 x 34 in.

C 2 Front leg brackets 7/8 x 2-3/8 x 25-1/4 in.

D 2 Armrest supports 7/8 x 2 x 21-3/8 in.

E 2 Seat supports 7/8 x 5-3/8 x 23-1/2 in.

F 1 Seat front 7/8 x 2-3/4 x 22 in.

G 7 Seat slats 7/8 x 2-1/4 x 22 in.

H 1 Back seat slat 7/8 x 3-7/8 x 22 in.

I 2 Armrests 7/8 x 5-3/8 x 25-3/4 in.

J 1 Lower back rail 7/8 x 4 x 22 in.

K 1 Middle back rail 7/8 x 5-3/8 x 25-3/4 in.

L 1 Upper back rail 7/8 x 3-3/4 x 22 in.

M 1 Middle back slat 7/8 x 5-3/8 x 33-3/4 in.

N 2 Inside back slats 7/8 x 5-3/8 x 32-1/4 in.

O 2 Outside back slats 7/8 x 5-3/8 x 30-3/4 in

7/8 x 5-3/8 x 96-in. deck boards (7)

1/4 x 2-1/2-in. stainless steel carriage bolts, washers and nuts (6)

1-5/8-in. deck screws (1 box)

2-1/2-in. deck screws (6)

Semitransparent stain or paint (1 quart)

band saw to cut the curves (photo 2,

p. 9), and clean them up with a sander.

Cut the armrest supports (D) to size

and then drill four pilot holes for the

screws that will attach the supports to

the armrest. These holes should be slight-

ly oversize (roughly 3/16 in. dia.) to allow

the shank of the 2-1/2-in. screws to slide

freely in the countersunk holes. This will

allow you to easily draw the armrest tight

and avoid splitting the supports.

Next, use a router equipped with a

1/8-in.-radius roundover bit to ease the

edges. If you dont have a 1/8-in.-dia.

bit, you can use a slightly larger roun-

dover bit, such as a 1/4-in.-radius bit,

and set the router height so that the bit

is not cutting at its full cutting depth.

To build each leg assembly, fasten

the front leg (A) and back leg (B) to the

armrest support (D). Do not attach the

front leg brackets (C) at this time. Fol-

low the spacing in the drawing, and

clamp the pieces in place to keep the

assembly square. Drill pilot holes and

countersinks; then fasten the legs with

1-5/8-in. deck screws (photo 3).

MAKE THE SEAT

Rip a 35-degree bevel along the top

edge of the seat front (F); then mark

and cut an arched profle (with a rise of

about 1 in.) in the bottom edge. Next,

make a template for the seat supports

(E). Trace the template on each seat

Make full-size templates for the curved pieces so you can trace the contours

on the actual parts.

1

1/4-in. plywood

pattern

35-degree angles

CUTTING LIST

SHOPPING LIST

J

D

I

B

H

E

L

C

K

O N M

ARMREST

DETAIL

M N

O

K

K

L

J

B

B

D

D

D

I

I

I

A

H

G

E

E

F

G

G

G

A

A

C

C

B

C

35 BEVEL

1 SQUARE = 1"

20 BEVEL

1/4 x 2-1/2"

STAINLESS-STEEL

CARRIAGE BOLT

24 BEVEL

3/8"

PILOT

HOLES

4"

1-1/2"

1-1/8"

2-3/4"

1-3/4"

13-3/4"

11-3/8"

29"

4"

5-1/2"

7"

WORKSHOP

I

L

L

U

S

T

R

A

T

I

O

N

B

Y

M

I

C

H

A

E

L

A

N

D

E

R

S

O

N

CONTEMPORARY ADIRONDACK CHAIR

support and cut the shape. Then cut

the seat slats (G) to size and ease the

top edges with a router and a 1/8-in.-

radius roundover bit.

Attach the seat front to the seat

supports, lining up the top edge of

the seat fronts bevel with the top

edge of the seat supports (E). Posi-

tion the front seat slat (G) so that it

overhangs about 1/2 in., and attach

it to the seat supports with a single

1-5/8-in. screw centered in each end.

Attach the rest of the slats, working

your way to the back of the seat and

leaving a 1/4-in. gap between slats.

Do not attach the back seat slat (H)

yet; youll do that after youve as-

sembled the back.

ASSEMBLE THE CHAIR BOTTOM

Lay one of the leg assemblies on its

side and position the seat assembly

on the legs. The bottom edge of the

front of the seat support should be

11-3/4 in. above the bottom of the front

leg, and the bottom edge of the back

of the seat support should measure

10 in. from the floor. Attach the seat

assembly with a single 1-5/8-in. screw

driven into each leg (photo 4, p. 9). Offset

these screws to allow for the bolt hole

that you will later drill into the center of

each leg connection. Flip the chair over

and attach the other leg assembly.

2

With the leg as-

sembly on its side,

use a t emporary

spacer to raise the

bottoms of the legs

so they are level and

use a square to keep

the l eg assembly

square while screw-

ing the legs into the

armrest support.

3

Attach the seat assembly to the

two leg assemblies with 1-5/8-in.

screws.

4

Framing

square

Holes in armrest

support for attaching

armrest

Angle the jigsaw base and cut the

beveled curves in one pass. Move

slowly around the faceted corners.

5

20-degree

bevel

Cut close to the line

and then sand up to

the line to create a

smooth, refned curve.

FIRST IMPRESSIONS

This is the rst time Ive used Peren-

nial Lumber, Southern yellow pine

treated with heat, pressure and an

organic compound to make it much

more resistant to water absorption.

When the lumber was delivered, the

rst thing I noticed was its strong vine-

gar odor (which eventually fades away).

The next thing I observed was that the

straight-grain boards were free of knots

and completely at and straight. The

wood machined well and was a pleasure

to work with. The downside is that the

treatment process left the boards harder

and heavier, and they had a tendency

to split if I overtightened the screws or

didnt drill pilot holes. For more infor-

mation on this relatively new lumber

option, visit PerennialWood.com. VG

Temporary

spacer

7

With the chair bottom upright

and the four legs firmly on level

ground, the middle back rail is

ready to be fastened to the arm-

rests with bolts.

6

1/8-in. spacers

Center the back

assembl y on t he

middle back rail and

screw it in place be-

fore attaching the

back seat slat (H).

8

WORKSHOP

Set the chair-bottom assembly up-

right on a level surface and attach

the front leg brackets (C) with three

1-5/8-in. screws. Next, cut the middle

back rail (K) that will be attached to

the back of the armrest supports and

armrests. Tilt the jigsaw base to cut a

20-degree bevel; then cut the inside

curve profile of the middle back rail

(photo 5, p. 9). Note that the back rails

curve profle and the back seat slat are

faceted to ft the back slats. Set the jig-

saw base at 90 degrees to cut the back

edge of the middle back rail.

Place the middle back rail on the

notched ends of the armrest supports

and attach it with 1-5/8-in. screws.

Next, place the armrests (I) on the

armrest supports, clamp the parts in

place and drive 2-1/2-in. screws up

through the holes in the bottom of

the armrest supports. Drill a 1/4-in.

bolt hole through each armrest and

the middle back rail (photo 6, top, left).

Fasten the parts with 1/4- x 2-1/2-in.

stainless steel carriage bolts, washers

and nuts.

Next, drill the bolt holes through the

legs and seat supports. Make sure that

all four legs are sitting flat and level

when you drill the holes and tighten

the bolts.

ADD THE BACK

Lay out and cut the back

slats (M, N, O) to shape.

I used a jigsaw to cut

close to the line on the

long tapers and then

sanded up to the line

with a belt sander. You

could also cut the long

tapers on the three in-

side slats using a band

saw or a table saw with

a tapering jig. Ease the edges with a

router and roundover bit.

Attach the back slats to the upper

and lower back rails, starting with

the middle back slat (M). Center the

upper back rail (L) on the back of the

middle slat and 7 in. below the top.

Attach the slat with a 1-5/8-in. screw.

Use a 1/8-in. spacer to align the two

inside back slats (N) on either side of

the middle slat. Position the upper

back rail 5-1/2 in. below the top edge

of each inside slat.

I found it easier to attach the three

inside slats (M and N) to the lower

back rail (J) before adding the two out-

side back slats (O). Center the lower

back rail 3/8 in. above (and parallel

to) the bottom of the middle back slat

and screw it in place. Use the 1/8-in.

spacers and screw the inside back

slats in place.

Next, attach the outside back slats

(O) to the upper and lower back rails

(photo 7, p. 10). Position the top of the

upper back rail 4 in. below the top of

the outside slats. Note: The bottom of

the back slats will extend past the lower

back rail at different lengths because of

the curve. I left them long because they

are hidden by the back seat slat, and

the extra length helps to strengthen

the screw joint.

Set the lower back rail (J) in the

seat-support notches and screw it in

place. Center the back assembly on

the middle back rail and fasten with

a 1-5/8-in. screw in the center of each

slat (photo 8).

Tilt the jigsaw base to cut roughly a

24-degree bevel, and cut the back seat

slat (H). Adjust the fit as necessary;

then attach the slat to the seat sup-

ports with 1-5/8-in. screws.

I fnished the chairs with gray semi-

transparent deck stain for a natural

weathered look. Of course, you can ap-

ply the stain or paint of your choice to

achieve the look you desire. Once the

fnish cures, pour yourself some lem-

onade and sit awhile.

Handyman Cl ub l ife member Vern

Grassel is a custom furniture build-

er, cabinetmaker and woodworking

designer in Elk River, Minnesota.

When assembling the back,

work from the center out and from

the top down.

You might also like

- Central Park MapDocument1 pageCentral Park MapAndrés Dinamarca GallardoNo ratings yet

- How to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerFrom EverandHow to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerRating: 5 out of 5 stars5/5 (2)

- Woodworking Plans - Box-Joint JigDocument8 pagesWoodworking Plans - Box-Joint Jig_Godfather100% (3)

- Woodsmith Shaker Style WorkbenchDocument22 pagesWoodsmith Shaker Style Workbenchricheklund92% (12)

- Make Your Own Cutting Boards: Smart Projects & Stylish Designs for a Hands-On KitchenFrom EverandMake Your Own Cutting Boards: Smart Projects & Stylish Designs for a Hands-On KitchenRating: 5 out of 5 stars5/5 (1)

- Complete Table Saw Book, Revised Edition: Step-by-Step Illustrated Guide to Essential Table Saw Skills, Techniques, Tools and TipsFrom EverandComplete Table Saw Book, Revised Edition: Step-by-Step Illustrated Guide to Essential Table Saw Skills, Techniques, Tools and TipsRating: 3.5 out of 5 stars3.5/5 (2)

- Make A Rocking Muskoka Chair Out of Composite Wood 2 PDFDocument8 pagesMake A Rocking Muskoka Chair Out of Composite Wood 2 PDFCocis CosminNo ratings yet

- WS23218 Smartphone-Amplifier PDFDocument6 pagesWS23218 Smartphone-Amplifier PDFMariano100% (2)

- The Essential "All Purpose" Workbench: Challenging ProjectDocument34 pagesThe Essential "All Purpose" Workbench: Challenging ProjectB. IonutNo ratings yet

- Portable Dovetail Jig WorkcenterDocument8 pagesPortable Dovetail Jig Workcentergmand6850% (2)

- Adirondack Chair Plans 10pagesDocument10 pagesAdirondack Chair Plans 10pagesNilton100% (2)

- Bench - Classic Cedar GardenDocument11 pagesBench - Classic Cedar Gardenvdbroger100% (1)

- Carrinho FerramentaDocument10 pagesCarrinho Ferramentapaulo75% (4)

- WJ088 Garden BenchDocument13 pagesWJ088 Garden BenchOsvaldo Moraes100% (1)

- Adirondack ChairDocument11 pagesAdirondack ChairMoises Martins Rocha100% (1)

- DPROJ02Document13 pagesDPROJ02VhomBoris75% (4)

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- How to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseFrom EverandHow to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- How to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)From EverandHow to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)Rating: 5 out of 5 stars5/5 (1)

- WOOD Store: Thank You!Document12 pagesWOOD Store: Thank You!lacroitoruNo ratings yet

- Folding Portable WorkbenchDocument19 pagesFolding Portable WorkbenchVideoSurv SynologyNo ratings yet

- Folding Workbench PlansDocument11 pagesFolding Workbench Plansbwatkins6No ratings yet

- Adriondack Chair Template 2012Document2 pagesAdriondack Chair Template 2012pocetnikNo ratings yet

- Silla MaderaDocument12 pagesSilla Maderagmo2189No ratings yet

- WS23342 - Welcoming Hall Bench PDFDocument12 pagesWS23342 - Welcoming Hall Bench PDFMarianoNo ratings yet

- Woodworking Plans - Router JigsDocument6 pagesWoodworking Plans - Router Jigsjumapamo75% (4)

- Chair 8Document18 pagesChair 8Naga Raj100% (2)

- Mission Style Open Shelf Bathroom Vanity: AdvancedDocument22 pagesMission Style Open Shelf Bathroom Vanity: AdvancedMaricruz Valdivieso de PalaciosNo ratings yet

- Garage Storage SystemsDocument20 pagesGarage Storage SystemsIwan Setiawan100% (2)

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableNebojša Jovanov100% (1)

- American Woodworker: OCTOBER 2002Document9 pagesAmerican Woodworker: OCTOBER 2002JvlValenzuelaNo ratings yet

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- From MagazineDocument5 pagesFrom Magazine- yAy3e -No ratings yet

- Creating A Ring HolderDocument3 pagesCreating A Ring Holderapi-522254901No ratings yet

- WB31238 Diy-WorkbenchDocument8 pagesWB31238 Diy-WorkbenchFrancois VaaltynNo ratings yet

- Woodworking Plans - Kitchen WorkstationDocument14 pagesWoodworking Plans - Kitchen WorkstationBob Kowalski100% (4)

- TV Lift Cabinet PDFDocument16 pagesTV Lift Cabinet PDFAlbuquerque100% (1)

- Miter Spline Tenon Jig PDFDocument6 pagesMiter Spline Tenon Jig PDFFranciscoCotoNo ratings yet

- 8A Thickness SanderDocument15 pages8A Thickness SanderAulia Haq Aqoby100% (1)

- Making Toggle ClampsDocument7 pagesMaking Toggle ClampsGermanHund100% (2)

- Ladder ShelvesDocument1 pageLadder ShelvesGigi Franco100% (1)

- Router Table FenceDocument11 pagesRouter Table Fenceleo100% (2)

- Ultimate WorkbenchDocument8 pagesUltimate WorkbenchEric Gruff0% (1)

- How To Build Modern Barstools Like A ProDocument17 pagesHow To Build Modern Barstools Like A Progerman100% (1)

- Woodworking For The BackyardDocument164 pagesWoodworking For The BackyardAli Bazlamit100% (14)

- Miter Saw BenchDocument1 pageMiter Saw BenchJon DavisNo ratings yet

- Broken Arch Mantel Clock Plans: © 2005 by Robert E. Reedy All Rights ReservedDocument25 pagesBroken Arch Mantel Clock Plans: © 2005 by Robert E. Reedy All Rights ReservedLinNo ratings yet

- Perfect Mortise and Tenon JointsDocument8 pagesPerfect Mortise and Tenon Jointspiedrahec100% (1)

- Cutting Perfect TapersDocument2 pagesCutting Perfect TapersGsmHelp100% (1)

- Drawer Book-Runners Guides KickersDocument12 pagesDrawer Book-Runners Guides KickersDillon HartsykerNo ratings yet

- WoodSmith Leg Bench Vise PlansDocument12 pagesWoodSmith Leg Bench Vise PlansKaren Rathbun88% (8)

- Patio Chair - FH01SEPDocument6 pagesPatio Chair - FH01SEPTikarko Nakama100% (1)

- Woodworking Plans - Entertainment CenterDocument12 pagesWoodworking Plans - Entertainment Centerapi-3822020100% (6)

- Moxon's Ingenious Bench Vise: Jig JournalDocument2 pagesMoxon's Ingenious Bench Vise: Jig Journaloqab18100% (1)

- Pocket Hole JoineryDocument5 pagesPocket Hole JoineryJessica Sanders100% (3)

- Woodsmith-W1001 (Bookcases, Cabinets - Shelves, Volume 2)Document100 pagesWoodsmith-W1001 (Bookcases, Cabinets - Shelves, Volume 2)maggy_24100% (5)

- Woodsmith Precision Crosscut SledDocument10 pagesWoodsmith Precision Crosscut Sledssnvet86% (7)

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopFrom EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopNo ratings yet

- Anorexia Research Paper - Essay 1Document5 pagesAnorexia Research Paper - Essay 1api-329151535No ratings yet

- Geometry Worksheet 3 - Proofs: AB AC AD Bac D BD CD D Abcd M AB K AD KMC KDCDocument4 pagesGeometry Worksheet 3 - Proofs: AB AC AD Bac D BD CD D Abcd M AB K AD KMC KDCJane ChangNo ratings yet

- Aquarian Theospophist Vol-3-1-SupplementDocument25 pagesAquarian Theospophist Vol-3-1-SupplementJohnVNo ratings yet

- Display PDF - PHPDocument9 pagesDisplay PDF - PHPRinky KapoorNo ratings yet

- Cyber Bullying Is The Use of Digital Technologies With An Intent To OffendDocument2 pagesCyber Bullying Is The Use of Digital Technologies With An Intent To Offendcassandra7montezNo ratings yet

- Head and Neck Assessment NursingDocument8 pagesHead and Neck Assessment NursingNicks NacarioNo ratings yet

- CUI Texto Examen Multimedia Nivel 6 Curso BasicoDocument2 pagesCUI Texto Examen Multimedia Nivel 6 Curso BasicobertoniramiroNo ratings yet

- (MANTO) Module ExamDocument5 pages(MANTO) Module ExamBManto, Aerith RomaineNo ratings yet

- Zombie: Bad WolvesDocument4 pagesZombie: Bad WolvesYulia Tri AnggraeniNo ratings yet

- Kelas 11 Intensif UAS BAHASA INGGRIS SEMESTER 1Document5 pagesKelas 11 Intensif UAS BAHASA INGGRIS SEMESTER 1Nur InayahNo ratings yet

- I Am BigfootDocument2 pagesI Am Bigfootapi-549013212No ratings yet

- Sister Style The Politics of Appearance For Black Women Political Elites Nadia E Brown All ChapterDocument67 pagesSister Style The Politics of Appearance For Black Women Political Elites Nadia E Brown All Chapterkelly.carter342100% (5)

- Asking QuestionsDocument9 pagesAsking QuestionsChandradeep Reddy Teegala100% (1)

- Oxford University PressDocument58 pagesOxford University PressHaseena V K K MNo ratings yet

- Establishment of All India Muslim LeagueDocument3 pagesEstablishment of All India Muslim LeagueMuhammad Ateeq100% (1)

- Safety and Health Practices in The Kitchen: STVEP-7 TVE ExploratoryDocument19 pagesSafety and Health Practices in The Kitchen: STVEP-7 TVE ExploratoryPoseidon NipNo ratings yet

- The Mountain As Stabilizers For The Earth From The Quranic PerspectiveDocument7 pagesThe Mountain As Stabilizers For The Earth From The Quranic PerspectiveBilal KhlaifatNo ratings yet

- Intimatething Karel CapekDocument184 pagesIntimatething Karel Capekrajan thuvaraNo ratings yet

- Hemodinamic Description of Volleyball Atlet Before and After Competing in Banyumas DistrictDocument11 pagesHemodinamic Description of Volleyball Atlet Before and After Competing in Banyumas DistrictariNo ratings yet

- Bambang National High School Remedial Exam in Poetry AnalysisDocument1 pageBambang National High School Remedial Exam in Poetry AnalysisShai ReenNo ratings yet

- MAT 271 Probability and Statistics Lecture 1: Introduction: Asst. Prof. N. Kemal UreDocument28 pagesMAT 271 Probability and Statistics Lecture 1: Introduction: Asst. Prof. N. Kemal UreSerkan Burak ÖRSNo ratings yet

- Value of Production Income StatementsDocument12 pagesValue of Production Income StatementsnootsheiNo ratings yet

- Revolutionizing Loan Origination With GenAI - A Closer LookDocument3 pagesRevolutionizing Loan Origination With GenAI - A Closer LookAbhishek KumarNo ratings yet

- Primary Source Lesson PlanDocument3 pagesPrimary Source Lesson Planapi-311017794No ratings yet

- Facility Documentation ChecklistDocument3 pagesFacility Documentation ChecklistIT westNo ratings yet

- GENDERDocument9 pagesGENDERKeneth NagumNo ratings yet

- Job Skills ChecklistDocument4 pagesJob Skills Checklistapi-320402088No ratings yet

- RCU510 DescriptionDocument15 pagesRCU510 DescriptionValentin JonovNo ratings yet

- Estado de Cuenta 08-06-2020Document274 pagesEstado de Cuenta 08-06-2020Coordinador ColantaNo ratings yet