Professional Documents

Culture Documents

What Is Ram - tcm4 520227

What Is Ram - tcm4 520227

Uploaded by

unknownsaylorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Ram - tcm4 520227

What Is Ram - tcm4 520227

Uploaded by

unknownsaylorCopyright:

Available Formats

DNV SOFTWARE A LEADING PROVIDER OF SOFTWARE FOR RISK

What is RAM?

RAM stands for Reliability, Availability and Maintainability. It is a methodology used to predict asset performance

for a given configuration in terms of reliability, maintainability and availability. Our products go beyond traditional

RAM analysis by adding capabilities related to operations tailored to the Oil and Gas industry which provides as

result utilisation and production efficiency. D! "oftware Advanced RAM tools can also be used as #rocess

Reliability Modelling, #lant $ide #erformance Modelling or simply RAM Modelling.

D! "oftware Advanced RAM tools can be separated into two groups%

- Maros, the choice for &pstream and Midstream analysis

- 'aro, the choice for Downstream and (ogistics analysis

'he analysis is performed by modelling the asset while considering all of the factors that can potentially impact on

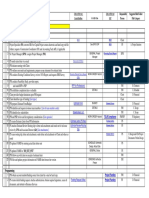

production. An overview of the typical aspects covered in an advanced RAM analysis for oil and gas assets is shown

in )igure *.

)igure * + Advanced RAM analysis overview

WWW.DNVSOFTWARE.COM What is RAM? | WHITE PAPER | 2

SIMULATION

'he most powerful approach to this type of analysis is to use simulation techni,ues. 'his means applying a

structured process to mathematically evaluate the behaviour of a system. A common simulation approach for

reliability modelling is to use an -.vent+Driven/ algorithm based on Monte 0arlo simulation to create life+cycle

scenarios of the system under investigation accounting for its reliability, maintainability, operating policies and

cost1revenue data. 2y simulating a large number of life+cycles, conclusions can be drawn about the characteristics

of the configuration and forecasts made about what the e3pected efficiency will be.

'he main benefit of using simulation is that it is well suited for highly comple3 scenarios, which most oil and gas

assets typically are. )or real life scenarios of this type, analytical solutions become close to impossible. "imulation

also captures the dynamics of a system by allowing highly specialised events to be modelled or system

reconfigurations to ta4e place over time. 'he results allow the wea4 lin4s to be e3posed ,uic4ly and thus aid in

identification of ways to improve the reliability.

WHAT ARE THE BENEFITS OF MAROS AND TARO?

Maros and 'aro allow you to predict production efficiency of a process, and provide a foundation for the

optimisation of the process. 2y optimising production efficiency and minimising the costs associated with

production 5maintenance, manning, material etc.6, the most profitable process configuration can be identified and

selected.

INCREASING THE PRODUCTION EFFICIENCY

'hese are several ways in which Maros and 'aro analyses can help to increase production efficiency%

2y identifying areas where changes to e,uipment1unit configuration, procedures, training, operation etc.

can reduce the li4elihood of production downtime.

2y allowing you to ma4e ad7ustments to the process e.g. by introducing redundancy in the process where

it ma4es a larger impact. (oo4ing at e,uipment criticality allows the bottlenec4s of the process to be

identified. 'his also avoids inefficient e3penditure on redundancy where it is not effective.

2y ma4ing it easy to perform sensitivity studies to compare the impact of modifications to the process

with a base case.

2y assessing how and when to boost production and what impact it has on production efficiency.

2y allowing you to optimise production by using the right flaring philosophies.

2y determining the production impact of feed storage and utility systems.

2y allowing you to perform spare e,uipment analysis to minimise downtime due to not having spares

when needed.

2y assessing alternative maintenance strategies to minimise downtime due to mobili8ation constraints.

WWW.DNVSOFTWARE.COM What is RAM? | WHITE PAPER | 3

)igure 9 + #roduction .fficiency forecasted by a Maros simulation

MINIMISING COSTS

'hese are several ways in which Maros and 'aro analyses can help to minimise costs

2y minimising the contract losses due to production failures. Allowing for production compensation

means that contracts can be satisfied even though there are production losses, which in turn will prevent

associated costs.

2y avoiding e3cessive attention to areas that are non+critical, and instead focus on areas where

improvements and modifications will ma4e a larger impact.

2y performing the analysis at an early stage, the study will allow for enhancement suggestions that would

have been much more e3pensive if carried out at a later stage.

2y allowing you to optimise the spare stoc4 level.

2y allowing you to optimise maintenance resources.

OTHER BENEFITS FROM RUNNING MAROS AND TARO INCLUDE

2y drawing up the full process in Reliability 2loc4 Diagrams and replaying lifecycle simulations, an

increased understanding of the process and the potential failures will be gained.

It can be used to demonstrate compliance with performance targets where applicable.

It allows assessment of economic viability of pro7ects1products.

It allows for evaluation and comparison of different approaches for replacement, rehabilitation1life

e3tension or disposal of aging facilities.

WWW.DNVSOFTWARE.COM What is RAM? | WHITE PAPER | 4

ASSET LIFECYCLE

It is feasible to perform an advanced RAM study at all stages in the life of an asset. )or e3ample: performed early in

design process, Maros and 'aro allow the assessment of competing development options such as )#"O vs. subsea

development vs. platform, etc. "uch an assessment can rapidly feed into a net present value assessment of each

option. Once the development option has been selected, further cost benefit analysis can be performed e.g.

e3amining the benefit of additional installed capacity, or the penalties of reduced redundancy.

During the operational phase the impact of alternative operational philosophies or maintenance strategies may be

e3amined. )or gas gathering and producing networ4s, the level of ris4 associated with alternative gas sales

agreements and nomination levels can be ,uantified.

)igure ; + #hases of Asset (ifecycle

QUESTIONS ANSWERED

'ypical ,uestions as4ed that Maros and 'aro can help you answer are%

<ow does e,uipment1unit reliability impact production=

$hat happens if I improve e,uipment reliability=

$hat happens if e,uipment performance is worse than e3pected=

"hould I spare e,uipment to increase reliability=

$hat is the impact of preventive, corrective and opportune maintenance strategies=

$hat si8e storage tan4s should I have=

$hat is the impact of unit over+design 5catch+up6 margins=

$hat is the optimum unit configuration in order to ma3imise production1availability=

$ill it be possible to meet the customers demand for products= $hat is the supply efficiency to each

customer=

$hat is the impact of adding new production facilities and decommissioning e3isting facilities=

$hat will the impact of ageing facilities1wells be on achieved performance=

WWW.DNVSOFTWARE.COM What is RAM? | WHITE PAPER | 5

SUCCESSFUL APPLICATIONS

'hese are some e3amples of asset types where Maros and 'aro have successfully been used in the past%

ew upstream production assets 5offshore and onshore6

Mature upstream production assets 5offshore and onshore6

ormally &nattended Installations

)#"Os

Oil refineries

#etrochemical plants

"ubsea operations

Onshore Oil > Gas #rocessing 'erminals

Gas and (G supply chains

#ower stations

)igure ? + #hotos of typical ob7ects of interest in Advanced RAM analyses

You might also like

- Availability Workbench Tutorial PDFDocument246 pagesAvailability Workbench Tutorial PDForangeproximity0% (2)

- Tips To Perform A Ram Study Webinar Presentation - tcm4-539661Document38 pagesTips To Perform A Ram Study Webinar Presentation - tcm4-539661Brenda Davis100% (3)

- Reliability, Availability and Maintainability: ©2020, Monaco Engineering Solutions - ALL RIGHTS RESERVEDDocument7 pagesReliability, Availability and Maintainability: ©2020, Monaco Engineering Solutions - ALL RIGHTS RESERVEDFabio Kazuo OshiroNo ratings yet

- 217 PlusDocument3 pages217 PlusArunkumar SundararajanNo ratings yet

- Mil STD 1629aDocument54 pagesMil STD 1629aBaba JohnehNo ratings yet

- Abb Rec670 Acse Relay TestDocument10 pagesAbb Rec670 Acse Relay Testm khNo ratings yet

- A Project Report ON Crime Reporting: (HCL Info System LTD)Document89 pagesA Project Report ON Crime Reporting: (HCL Info System LTD)Amit Gupta82% (17)

- RAM Analysis Software For Upstream Oil and Gas - MarosDocument4 pagesRAM Analysis Software For Upstream Oil and Gas - MarosJohn KingsleyNo ratings yet

- Introduction To RAM ModellingDocument5 pagesIntroduction To RAM ModellingJohn KingsleyNo ratings yet

- Ram ModelingDocument18 pagesRam Modelingapi-249066222No ratings yet

- RAM (Reliability, Availability and Maintainability) Analysis Version2Document4 pagesRAM (Reliability, Availability and Maintainability) Analysis Version2John KingsleyNo ratings yet

- RAM (Reliability, Availability and Maintainability) Analysis Version1Document5 pagesRAM (Reliability, Availability and Maintainability) Analysis Version1John KingsleyNo ratings yet

- RCM Alan PrideDocument16 pagesRCM Alan PrideambuenaflorNo ratings yet

- Asset Management Practises at Qatargas PDFDocument11 pagesAsset Management Practises at Qatargas PDFJuandeDios Huayllani DelgadoNo ratings yet

- Rcm3 May 2017 Course Brochure v01Document3 pagesRcm3 May 2017 Course Brochure v01Syed Nadeem AhmedNo ratings yet

- Kuliah Reliability, Availability, Maintain AbilityDocument50 pagesKuliah Reliability, Availability, Maintain AbilitySumarlin Hari Wibowo100% (2)

- Managing A Condition Monitoring Program: Get The Monitoring Right!Document9 pagesManaging A Condition Monitoring Program: Get The Monitoring Right!Michaelben Michaelben100% (1)

- RAM Methodology Review PresentationDocument24 pagesRAM Methodology Review PresentationAli Akram100% (1)

- Reliability Ab PDFDocument4 pagesReliability Ab PDFLuis Alberto SanchezNo ratings yet

- Reliability Centered Maintenance - Wikipedia PDFDocument37 pagesReliability Centered Maintenance - Wikipedia PDFEndhy Wisnu NovindraNo ratings yet

- What Is Reliability - Centered MaintenanceDocument6 pagesWhat Is Reliability - Centered Maintenancearchie zambranoNo ratings yet

- AV ME SOP 02 Criticality AnalysisDocument4 pagesAV ME SOP 02 Criticality AnalysisjfejfeNo ratings yet

- Reliability EngineeringDocument17 pagesReliability EngineeringPratik PanchalNo ratings yet

- Introduction To RCM by L.cherifDocument37 pagesIntroduction To RCM by L.cherifKhalid Mahmood100% (1)

- Services - RAM StudyDocument3 pagesServices - RAM StudyMubarik AliNo ratings yet

- Questions of Reliability Centered MaintenanceDocument15 pagesQuestions of Reliability Centered Maintenancemariana100% (1)

- Condition Based Reliability, Availability, Maintainability, and Safety (CB-RAMS) ModelDocument15 pagesCondition Based Reliability, Availability, Maintainability, and Safety (CB-RAMS) ModelganeshdhageNo ratings yet

- Technical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Document14 pagesTechnical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Elisony EdwardNo ratings yet

- Application of Reliability Centred Maintenance To Dynamic PlantDocument13 pagesApplication of Reliability Centred Maintenance To Dynamic Plantgvc1No ratings yet

- RCM Benchmarking SoftwareDocument8 pagesRCM Benchmarking SoftwareAndres Felipe Torres100% (1)

- Reliability, Availability, MaintainabilityDocument76 pagesReliability, Availability, MaintainabilityWilly K. Ng'etich100% (2)

- Guide To Finding and Using Reliability Data For QRADocument26 pagesGuide To Finding and Using Reliability Data For QRAkwatta46No ratings yet

- AssetManagementStandards ConsolidadoDocument203 pagesAssetManagementStandards ConsolidadoOsvaldo Augusto Velásquez BahamondezNo ratings yet

- Reliability Centred Mai NotDocument2 pagesReliability Centred Mai NotAhmed El-FayoomiNo ratings yet

- Applications of Maintenance OptimizationDocument12 pagesApplications of Maintenance OptimizationmelatorNo ratings yet

- CBM & RCM Applied On Nuclear Power PlantsDocument11 pagesCBM & RCM Applied On Nuclear Power PlantsGeert Henk WijnantsNo ratings yet

- Reliability Centered Maintenance Optimization For Power Distribution Systems 2014 International Journal of Electrical Power Energy SystemsDocument8 pagesReliability Centered Maintenance Optimization For Power Distribution Systems 2014 International Journal of Electrical Power Energy SystemsJAVIERNo ratings yet

- Hazard Analysis and Risk Assessments For Industrial Processes Using FMEA and Bow-Tie MethodologiesDocument13 pagesHazard Analysis and Risk Assessments For Industrial Processes Using FMEA and Bow-Tie MethodologiesratrihaningdsNo ratings yet

- RAM AnalysisDocument5 pagesRAM AnalysisDia Putranto HarmayNo ratings yet

- Reliability Centered MaintenanceDocument15 pagesReliability Centered MaintenanceEdmund YoongNo ratings yet

- Global Maintenance and Reliability Indicators - Flyer - GMARI - V3 PDFDocument2 pagesGlobal Maintenance and Reliability Indicators - Flyer - GMARI - V3 PDFgecko232243100% (1)

- 7 RBM Rbi RCMDocument71 pages7 RBM Rbi RCMNur Azizah NasutionNo ratings yet

- MIMS - Manual InstructionsDocument16 pagesMIMS - Manual InstructionsRebby2412No ratings yet

- Failure Mode Effects and Criticality Analysis PDFDocument2 pagesFailure Mode Effects and Criticality Analysis PDFMacNo ratings yet

- Maintenance EngineeringDocument34 pagesMaintenance EngineeringpsenthilpkumarNo ratings yet

- PERD Where For Art Thou Failure Rate Data PDFDocument10 pagesPERD Where For Art Thou Failure Rate Data PDFganeshdhageNo ratings yet

- FMEA BasicsDocument23 pagesFMEA Basicsashwin jacksonNo ratings yet

- Reliability-Centered Maintenance Planning Based On Computer-Aided FMEADocument7 pagesReliability-Centered Maintenance Planning Based On Computer-Aided FMEAAhmed El-FayoomiNo ratings yet

- Implementing RCM To SAP R3Document9 pagesImplementing RCM To SAP R3Dia Putranto Harmay100% (1)

- RCMDocument2 pagesRCMMohd Idris MohiuddinNo ratings yet

- Reliability Centred MaintenanceDocument19 pagesReliability Centred Maintenancefaraherh amberNo ratings yet

- Process and Equipment Reliability PaperDocument12 pagesProcess and Equipment Reliability PaperganeshdhageNo ratings yet

- Reliability L D Arya PDFDocument169 pagesReliability L D Arya PDFHusnain nawaz siddiquiNo ratings yet

- The Asset Management Landscape: Second EditionDocument57 pagesThe Asset Management Landscape: Second EditionEduardo Estrada100% (1)

- S Reliability Centered Maintenance (RCM) : Tudy of ExistingDocument97 pagesS Reliability Centered Maintenance (RCM) : Tudy of Existingamrina23No ratings yet

- Rbi RBMDocument12 pagesRbi RBMn73686861No ratings yet

- IBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionFrom EverandIBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionNo ratings yet

- Reliability Program ManagementDocument14 pagesReliability Program Managementloveselvan43No ratings yet

- DNV RAM FPSO White PaperDocument7 pagesDNV RAM FPSO White PaperOkonji C Stephen100% (1)

- 1999 05语法笔记Document11 pages1999 05语法笔记zhangj5No ratings yet

- 1998.10 国内考试真题 Section 1: Listening ComprehensionDocument19 pages1998.10 国内考试真题 Section 1: Listening Comprehensionzhangj5No ratings yet

- Project Handover GuidelinesDocument17 pagesProject Handover Guidelineszhangj5No ratings yet

- Project Handover GuidelinesDocument17 pagesProject Handover Guidelineszhangj5No ratings yet

- FIDIC Presentation PDFDocument6 pagesFIDIC Presentation PDFzhangj5No ratings yet

- TIME Schedule CPF3 Internal Chain Link FenceDocument1 pageTIME Schedule CPF3 Internal Chain Link Fencezhangj5No ratings yet

- Road Const Inspection ProcedureDocument15 pagesRoad Const Inspection Procedurezhangj5No ratings yet

- Road Const Inspection ProcedureDocument15 pagesRoad Const Inspection Procedurezhangj5No ratings yet

- Standard Operating ProcedureDocument23 pagesStandard Operating Procedurezhangj5No ratings yet

- Project Delivery Checklist PDFDocument8 pagesProject Delivery Checklist PDFzhangj5No ratings yet

- F3 WS3-3DPipeJunction OgridV12Document12 pagesF3 WS3-3DPipeJunction OgridV12Love SemsemNo ratings yet

- WD Caviar SE: Desktop Hard DrivesDocument2 pagesWD Caviar SE: Desktop Hard DrivesZoran ŠušakNo ratings yet

- Alone TogetherDocument2 pagesAlone TogetherIan Bennydick CajayonNo ratings yet

- 5-6193034 Hydraulik SL GBDocument35 pages5-6193034 Hydraulik SL GB----No ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- Soviet Tank Corps, 1942 - 1945Document2 pagesSoviet Tank Corps, 1942 - 1945Greg ChalikNo ratings yet

- Drone and Uav'sDocument22 pagesDrone and Uav'sBHARGAVA REDDYNo ratings yet

- Alco EP 73Document2 pagesAlco EP 73fery anggriawanNo ratings yet

- Sap Bods 4.2 Sap Bods 4.2 Sap Bods 4.2: Course Content 2015 Course Content Course ContentDocument5 pagesSap Bods 4.2 Sap Bods 4.2 Sap Bods 4.2: Course Content 2015 Course Content Course ContentShiva KumarNo ratings yet

- Rate AnalysisDocument15 pagesRate AnalysisBhagirath Bishnoi100% (1)

- DC 442Document8 pagesDC 442Tony DeligiorgisNo ratings yet

- Interbase With PHP On Windows. A Step-By-step TutorialDocument3 pagesInterbase With PHP On Windows. A Step-By-step Tutorialmasirul2009No ratings yet

- Design ThinkingDocument3 pagesDesign ThinkingAndrea MendonçaNo ratings yet

- Cellular Automata in Generative Electronic Music and Sonic ArtDocument30 pagesCellular Automata in Generative Electronic Music and Sonic ArtAgence AudiosphericNo ratings yet

- High Resistance Grounding SystemDocument7 pagesHigh Resistance Grounding Systemmohammed shreatehNo ratings yet

- Signalling Points CodesDocument3 pagesSignalling Points CodesSamSameleviNo ratings yet

- Asimov Vs MichealDocument3 pagesAsimov Vs Michealsam iam / Salvatore Gerard MichealNo ratings yet

- DX DiagDocument37 pagesDX DiagKoushik SenNo ratings yet

- Hausman & Page Discuss RUDDocument8 pagesHausman & Page Discuss RUDRENTAVOTERNo ratings yet

- Mobile Printer SPP-R210 BixolonDocument2 pagesMobile Printer SPP-R210 BixolonBixolonGlobalNo ratings yet

- Cambridge Audio A1 A2 Parts List SchematicsDocument10 pagesCambridge Audio A1 A2 Parts List SchematicsEu ToteuNo ratings yet

- 7890 GC Heated Zones Quick Reference GuideDocument4 pages7890 GC Heated Zones Quick Reference GuideDannFlorezNo ratings yet

- Programme ISC 105th Imphal PDFDocument74 pagesProgramme ISC 105th Imphal PDFDebasish DewanNo ratings yet

- Brochure TR 7750.PDF - JotronDocument4 pagesBrochure TR 7750.PDF - JotronMinh HuỳnhNo ratings yet

- SEED AgreementsDocument10 pagesSEED AgreementsNithin VarghzzNo ratings yet

- Strategic Audit of A Commercial WebsiteDocument18 pagesStrategic Audit of A Commercial WebsiteMaelia BianchiNo ratings yet

- RWS Page17Document1 pageRWS Page17thoufiqNo ratings yet