Professional Documents

Culture Documents

Lincoln E110

Uploaded by

David Carlos Uscamayta BorondaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lincoln E110

Uploaded by

David Carlos Uscamayta BorondaCopyright:

Available Formats

T H E L I N C O L N E L E C T R I C C O M P A N Y

2

A Worldwide Tradition

of Excellence and

Innovation Since 1895

Li ncol n El ectri cs commi tment to provi di ng the most

i nnovati ve, cost- effecti ve, qual i ty wel di ng and cutti ng

sol uti ons i s one that has gui ded our company for more

than 100 years. Thi s, coupl ed wi th our technol ogi cal

l eadershi p and worl dwi de manufacturi ng and di stri buti on

resources, enabl es us to provi de competent and rel i abl e

sol uti ons for each of our customers. Because of our broad

range of products and servi ces, Li ncol n El ectri c i s the One

Source for al l of your wel di ng and cutti ng needs. We pro-

vi de the most advanced equi pment and consumabl es, the

most responsi ve trai ni ng and support, and above al l , the

most i nnovati ve appl i cati ons to refi ne your enti re wel di ng

process. And, when i t comes to servi ce, Li ncol n El ectri c

stands out i n the i ndustry wi th an unprecedented network

of more than 3,000 di stri butors, techni cal representati ves

and research engi neers, ready to provi de uni quel y tai l ored

sol uti ons to your toughest wel di ng probl ems. No matter

what your i ndustry, our wel di ng experti se wi l l transl ate i nto

sol uti ons that work speci fi cal l y for you.

Proven Expertise

Li ncol n offers:

a worl dwi de presence wi th manufacturi ng pl ants,

di stri buti on centers, and sal es offi ces strategi cal l y

l ocated around the gl obe.

i ndustri al experti se from our work wi th al l l evel s of

i ndustry rangi ng from hi gh- tech automati on, to heavy

equi pment, to l i ght metal repai r.

appl i cati on- speci fi c support provi ded by our extensi ve

sal es and di stri butor organi zati on, recogni zed as the

wel di ng i ndustrys l argest, most thoroughl y trai ned

customer support network.

INTRODUCTION

3

Innovative Technology

Li ncol n l eads the i ndustry wi th product offeri ngs, i ncl udi ng:

equi pment that refl ects the l atest i ndustry devel opments

i ncl udi ng sti ck wel ders, TIG wel ders, CV MIG wel ders,

CC/ CV mul ti - process wel ders, pl asma cutti ng, engi ne

dri ven wel ders, wi re feeders, roboti c/ automati on

systems, and envi ronmental systems.

a ful l l i ne of sti ck, TIG, MIG, fl ux- cored and submerged

arc consumabl es for carbon and l ow al l oy steel , stai nl ess

steel , hardfaci ng, cast i ron and non- ferrous appl i cati ons.

gas apparatus such as gas regul ators, fl ow meters and

gas torches suppl i ed through our Harri s Cal ori fi c l i ne.

Total Solutions

Li ncol n El ectri c i s your One Source for al l wel di ng and

cutti ng needs, because of our:

i ntegrated systems offeri ng a total sol uti ons approach

to your wel di ng needs.

Guaranteed Cost Reducti on programs offeri ng uni que

management approaches to guaranteed process and

materi al savi ngs.

trai ni ng and consul ti ng rangi ng from i ni ti al system

confi gurati ons, to cl assroom trai ni ng for new techni ques

and materi al s to ongoi ng si te vi si ts.

Lincoln Quality

Qual i ty i s an establ i shed tradi ti on at Li ncol n El ectri c that i s

veri fi ed on a conti nui ng basi s by organi zati ons such as UL,

CSA, AWS, ASME, NEMA, Ll oyds, Det Norske Veri tas,

Mi l i tary, ISO, Nucl ear and others.

Li ncol n El ectri c i s commi tted to wel di ng your worl d

together, i mprovi ng your processes and l oweri ng

your costs.

The Lincoln Electric Company World headquarters is located in Cleveland, Ohio, U. S. A.

www.lincolnelectric.com

www.lincolnelectric.com

M o n s t e r Tr u c k s

Benefits

Racing drives our technologies.

When you try our new welders,

you will discover what the race

teams have learned . . . Lincolns

new TIGs start better and the

MIGs weld better. That is why

every CART team, over half

the Winston Cup teams,

every full-time IRL team and

nearly every NHRA team has

switched to Lincoln welders.

Dont settle for second

best. Try a Lincoln.

Education

Lincoln Electric is com-

mitted to sharing our

welding technologies

with the racing

industry placing

a heavy empha-

sis on safety.

Thats

why

R A C I N G S # 1

U S AC

N AS C AR

N H R A

C AR T

I R L

AR C A Tr u c k s

I H R A

I n f i n i t i P r o S e r i e s

C H O I C E I N W E L D I N G

we offer motorsports welding programs at our

corporate headquarters. Register early because

we will sell out.

Support

Lincoln Electric offers technical

support to any race team. We

also provide no charge track-

side welding services at over

100 race tracks. In addition,

we sponsor trackside welding

icons such as Paul Le Sage/

Team Torch and Kelly Campbell/

KoolKraft.

Sponsorships

Lincoln Electric is a contingency sponsor for

NHRA, USAC, NASCAR Busch Grand National

Series, NASCAR Busch North Series, NASCAR

Winston West Series, NASCAR Weekly Racing

Series and Contingency Connection. Lincoln is

the official Welder of ARCA, IRL, USAC and the

Indianapolis Motor Speedway. Lincoln is also

officially licensed by NASCAR. We are

committed!

N H R A

Te a m To r c h

I H R A

K o o l K r a f t

6

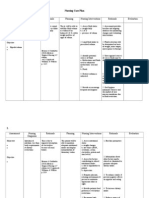

Opening Paragraph

Thi s i s a general descri pti on of

the product. It may i ncl ude fea-

tures and appl i cati ons of the

product.

Input & Output Icons

See bel ow for descri pti ons.

Processes

Recommended arc wel di ng

processes for the product.

Advantage Lincoln

Thi s secti on hi ghl i ghts the key

features and benefi ts of the

product.

Catalog Section

Identi fi es catal og secti on

for easy- to- fi nd products.

Product Picture

Detai l ed photo of Li ncol n

products.

Product Name

Offi ci al Li ncol n

product name.

Recommended Options

These secti ons l i sts the

most popul ar opti ons

requested for each product.

Ordering

To order, sel ect the

product number that best

fi ts your wel di ng needs.

Technical

Specifications

Common speci fi cati ons,

rati ngs, di mensi ons and

wei ght for the product.

www.lincolnelectric.com

USING THIS CATALOG

Output Icons

For constant current sti ck

and TIG processes

For constant vol tage MIG,

fl ux- cored and subarc

processes

For mul ti process constant

current or constant vol tage

appl i cati ons

CC

CV

CV

CC

Peak auxi l i ary power ouput

Conti nuous auxi l i ary

power output

Wi re feeder

.5

kW

11 P

10

kW

Al ternati ng current

wel di ng output

Di rect current

wel di ng output

Al ternati ng or di rect

current wel di ng output

AC

DC

AC

DC

Input Icons

Si ngl e phase i nput power

Three phase i nput power

Si ngl e or three phase

i nput power

1

PHASE

3

PHASE

1

3

PHASE

50 Hertz i nput power

60 Hertz i nput power

50/ 60 Hertz i nput power

Engi ne Dri ven

Gas, Di esel or LPG

50

Hz

60

Hz

60

50

Hz

115 vol t AC

Wi re feeder i nput power

42 vol t AC

Wi re feeder i nput power

40 vol t DC

Wi re feeder i nput power

115

VAC

42

VAC

40

VDC

7

TABLE OF CONTENTS

www.lincolnelectric.com

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Using this Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Source Selection Guide . . . . . . . . . . 8-10

Stick Welders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

TIG Welders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-25

MIG Welders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-30

Multi-Process Welders . . . . . . . . . . . . . . . . . . 31-41

Multi-Operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42-43

Engine Driven Welders . . . . . . . . . . . . . . . . 44-63

Wire Feeder/Welders . . . . . . . . . . . . . . . . . . . . 64-72

Semiautomatic Wire Feeders . . . . . . . . 73-89

Automatic Wire Feeders . . . . . . . . . . . . . . 90-91

Plasma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92-95

Environmental Systems . . . . . . . . . . . . . . . . 96-97

Automated Solutions . . . . . . . . . . . . . . . . . . 98-104

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Harris

Products . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Consumables . . . . . . . . . . . . . . . . . . . . . . . . 107-142

Educational Materials. . . . . . . . . . . . . . . . 143-144

Web Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8

www.lincolnelectric.com

POWER SOURCE SELECTION GUIDE

Stick Welders

AC- 225C CC AC 40- 225 A I 1 60 11 E2.40

AC- 225 CC AC 40- 225 A I 1 50,60 12 E2.30

AC/ DC 225/ 125 CC AC 40- 225 A I 1 50,60 13 E2.60

DC 30- 125 A I L

Ideal arc 250 CC AC 35- 300 A I G 1 50,60 14 E2.70

DC 40- 250 A I L G L

V100- S CC DC 8- 100 A I L 1 50,60 15 E2.140

V160- S CC DC 5- 160 A I I 1 50,60 16 E2.145

V275- S CC DC 5- 275 A I L I L 1/ 3 50,60 17 E2.161

R3R- 400 CC DC 60- 500 A I L G L 3 60 18 E2.100

R3R- 500 CC DC 75- 625 A I L G L 3 60 19 E2.100

TIG Welders

Square Wave TIG CC AC 8- 175 A I I G 1 50,60 20 E3.35

175 PRO DC

Preci si on TIG CC AC 2- 340 A I I G 1 50,60 22 E3.42

275 DC

Preci si on TIG CC AC 2- 420 A I I I 1 50,60 23 E3.51

375 DC

V160- T CC DC 5- 160 A L I I I 1 50,60 24 E3.105

V205- T AC/ DC CC

AC

6- 200 A L I I I 1 50,60 25 E3.110

DC

MIG/Flux-Cored

SP- 135T CV DC 25- 135 A I I 1 60 62 E7.21

SP- 135 Pl us CV DC 25- 135 A I I 1 60 63 E7.22

SP- 175T CV DC 30- 175 A I I 1 60 64 E7.34

SP- 175 Pl us CV DC 25- 175 A I I 1 60 66 E7.35

Power MIG 215 CV DC 30- 250 A I I 1 50,60 67 E7.51

Power MIG 255 CV DC 30- 300 A I I 1 60 69 E7.53

Power MIG 300 CV DC 5- 350 A I I I I I L 1 50,60 70 E7.56

CV- 250 CV DC 30- 300 A I I 3 60 26 E4.10

7- 32 V

CV- 300 CV DC 50- 400 A I I 3 60 27 E4.20

7- 37 V

CV- 400 CV DC 60- 500 A I I I 3 60 28 E4.30

12- 42 V

CV- 655 CV DC 70- 815 A I I L I 3 50,60 29 E4.40

13- 44 V

STT II STT DC PK. 0- 450 STT 3 50,60 30 E4.52

Bkgrd. 0- 125 I

M

o

d

e

P

o

w

e

r

S

o

u

r

c

e

P

o

l

a

r

i

t

y

R

a

n

g

e

:

A

=

a

m

p

s

V

=

v

o

l

t

s

S

t

i

c

k

T

I

G

H

i

-

F

r

e

q

F

l

u

x

-

C

o

r

e

d

S

u

b

m

e

r

g

e

d

A

r

c

A

r

c

G

o

u

g

i

n

g

P

h

a

s

e

P

a

g

e

L

i

t

e

r

a

t

u

r

e

T

I

G

S

c

r

a

t

c

h

OUTPUT PROCESS INPUT

KEY: Excel l ent I Good/ Fai r L Opti onal G

H

e

r

t

z

P

u

l

s

e

d

M

I

G

T

I

G

P

u

l

s

e

T

I

G

T

o

u

c

h

-

S

t

a

r

t

T

M

9

www.lincolnelectric.com

POWER SOURCE SELECTION GUIDE

Multi-Process Welders

V350- PRO CC DC 5- 425 A I L I G I G I L 1/ 3 50,60 32 E5.91

CV 15- 37 V

DC- 400 CC DC 60- 500 A I L G I I I I 3 60 33 E5.20

CV 12- 42 V

DC- 600 CC DC 70- 850 A I L G I I I I 3 50,60 34 E5.40

CV 13- 44 V

DC- 655 CC DC 50- 815 A I L G I I I I 3 50,60 35 E5.46

CV 13- 44 V

DC- 1000 CC DC 150- 1300 A L I I I 3 50,60 36 E5.50

CV 16- 46 V

DC- 1500 CC DC 200- 1500 A I I L 3 50,60 37 E5.60

CV 20- 60 V

AC- 1200 CC AC 200- 1500 A I 1 50,60 38 E5.70

Power Wave CC DC 5- 425 A L L I I I L 1/ 3 50,60 39 E5.145

355 CV 15- 34 V

Power Wave CC DC 5- 570 A L L I I I I 3 50,60 40 E5.160

455 CV 10- 43 V

Power Wave CC DC 5- 570 A L L I I I I 3 50,60 41 E5.170

455/ STT CV 10- 43 V

STT 5- 325 A

I

Mul ti - Wel d CC DC+ 30- 350 A I I I L 3 50,60 43 E5.300

System CV onl y 15- 40 V

M

o

d

e

P

o

w

e

r

S

o

u

r

c

e

P

o

l

a

r

i

t

y

R

a

n

g

e

:

A

=

a

m

p

s

V

=

v

o

l

t

s

S

t

i

c

k

T

I

G

H

i

-

F

r

e

q

F

l

u

x

-

C

o

r

e

d

S

u

b

m

e

r

g

e

d

A

r

c

A

r

c

G

o

u

g

i

n

g

P

h

a

s

e

P

a

g

e

L

i

t

e

r

a

t

u

r

e

T

I

G

S

c

r

a

t

c

h

OUTPUT PROCESS INPUT

KEY: Excel l ent I Good/ Fai r L Opti onal G

H

e

r

t

z

P

u

l

s

e

d

M

I

G

T

I

G

P

u

l

s

e

T

I

G

T

o

u

c

h

-

S

t

a

r

t

T

M

Plasma

Pro- Cut 25 CC DC 12- 25 A 3/ 8" maxi mum I L L 1 50,60 91 E11.51

Pro- Cut 55 CC DC 25- 60 A 3/ 4" maxi mum I I I 1/ 3 50,60 92 E11.60

Pro- Cut 80 CC DC 35- 85 A 1- 1/ 4" maxi mum I I I 1/ 3 50,60 93 E11.70

M

o

d

e

P

o

w

e

r

S

o

u

r

c

e

P

o

l

a

r

i

t

y

R

a

n

g

e

:

A

=

a

m

p

s

V

=

v

o

l

t

s

C

u

t

G

o

u

g

e

P

i

e

r

c

e

P

h

a

s

e

P

a

g

e

L

i

t

e

r

a

t

u

r

e

C

u

t

t

i

n

g

OUTPUT PROCESS INPUT

H

e

r

t

z

T

h

i

c

k

n

e

s

s

STT

Engine Driven Welders

Power Arc CC AC 70- 125 A I G 44 E6.20

4000 4 KW E6.20.1

Wel danpower CC DC 50- 125 A I L G 45 E6.51

125 4.5 KW

Ranger 10,000 CC/ CV AC 50- 225 A I L G L I I G 46 E6.92

DC 50- 210 A

10p KW

Ranger 3 Phase CC/ CV AC 50- 225 A I L G L I I G 47 E6.94

DC 50- 210 A

11.5p KW

Ranger 250 CC/ CV DC 20- 250 A I I I G I I I G 49 E6.103

9p KW

Ranger 250 LPG CC/ CV DC 20- 250 A I I I G I I I LPG 50 E6.104

9p KW

Ranger 305G CC/ CV DC 20- 305 A I I I G I I I G 51 E6.117

10p KW

Ranger 305D CC/ CV DC 20- 305 A I I I G I I I D 52 E6.118

10p KW

SAE- 400 CC DC 80- 575 A I L G G I D 53 E6.180

3 KW

SAE- 400 CC DC 80- 575 A I L G G I D 54 E6.185

Wel d N Ai r 3 KW

SAE- 400 CC DC 80- 575 A I L I D 55 E6.180.1

Severe Duty 3 KW

Pi pel i ner 200G CC DC 40- 300 A I G G I G 56 E6.131

1.75 KW

Pi pel i ner 200D CC DC 40- 300 A I G G I D 57 E6.132

1.75 KW

Cl assi c II CC DC 40- 325 A I L G G G I D 58 E6.140

3 KW

Cl assi c 300G CC DC 40- 350 A I L G G G I G 59 E6.156

3 KW

Cl assi c 300D CC DC 40- 350 A I L G G G I D 60 E6.155

3 KW

Commander 300 CC/ CV DC 30- 375 A I I I G I I I D 61 E6.205

10 KW

Vantage 500 CC/ CV DC 30- 575 A I I I G I I I D 62 E6.216

12 KW

Ai r Vantage 500 CC/ CV DC 30- 575 A I I I G I I I D 63 E6.217

12 KW- 1

20 KW- 3

10

www.lincolnelectric.com

POWER SOURCE SELECTION GUIDE

M

o

d

e

P

o

w

e

r

S

o

u

r

c

e

P

o

l

a

r

i

t

y

R

a

n

g

e

:

A

=

a

m

p

s

V

=

v

o

l

t

s

T

I

G

T

o

u

c

h

-

S

t

a

r

t

T

M

F

l

u

x

-

C

o

r

e

d

S

u

b

m

e

r

g

e

d

A

r

c

A

r

c

G

o

u

g

i

n

g

E

n

g

i

n

e

L

i

t

e

r

a

t

u

r

e

S

t

i

c

k

OUTPUT PROCESS

KEY: Excel l ent I Good/ Fai r L Opti onal G

P

a

g

e

P

u

l

s

e

d

M

I

G

T

I

G

H

i

-

F

r

e

q

T

I

G

S

c

r

a

t

c

h

AC-225C

AC-225C

www.lincolnelectric.com

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs. (kg)

AC- 225C K1357 230/ 1/ 60 170A/ 25V/ 20% 45A 40- 225 Amps 15.25 x 14 x 13.5 84

Max. Output: Max: 50A Max. OCV: 58V (387 x 356 x 343) (38)

225A/ 25V/ 10%

STICK WELDERS

11

The AC- 225C i s a sti ck wel di ng power source wi th conti nu-

ous output control from 40- 225 amps. The AC- 225C

produces an extremel y smooth wel di ng arc, at any amper-

age setti ng, for most wel di ng appl i cati ons. The AC- 225C

can be used for a vari ety of materi al s i ncl udi ng carbon, l ow

al l oy and stai nl ess steel s, from 16 gauge sheet metal to

heavy pl ate.

Processes

Sti ck

Advantage Lincoln

Conti nuous output control for fi ne heat adj ustment.

Easy to set- up. Comes wi th attached i nput cabl e and

pl ug.

Easy to operate wi th ful l range conti nuous amperage

output control .

Low cost operati on, onl y a few cents per wel di ng hour.

Smooth arc makes i t easy to wel d wi th di fferent el ec-

trodes, i ncl udi ng mi l d steel , l ow hydrogen, stai nl ess

steel and hardfaci ng el ectrodes.

225 amp AC output i s enough for 3/ 16" di ameter general

purpose mi l d steel el ectrodes and most 5/ 32" si zes.

Opti onal carbon arc torch for brazi ng and sol deri ng

appl i cati ons, for heati ng rusty nuts for easi er removal ,

and for bendi ng or strai ghteni ng metal .

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Base Unit Includes

Insul ated el ectrode hol der and cabl e.

Heavy duty work cl amp and cabl e.

Sampl e pack of el ectrodes.

Hel pful Wel ders Gui de.

Input cabl e wi th attached pl ug.

Order

K1357 AC- 225C 230/ 1/ 60

Literature

E2.40

Output Input

CC

AC

1

PHASE

60

Hz

AC-225

AC-225

www.lincolnelectric.com

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle(1) Rated Output Range in. (mm) lbs. (kg)

AC- 225 K1170 230/ 1/ 60 225A/ 25V/ 20%(1) 50A 40- 225 Amps 109

K1170- 4 Max. OCV: 79V 24 x 17.25 x 12 (49.5)

AC- 225 K1290 220/ 1/ 50 225A/ 25V/ 15% 63A 50- 250 Amps (610 x 438 x 305) 108

Max. OCV: 76V (49.0)

STICK WELDERS

12

The AC- 225 i s Li ncol ns best sel l i ng arc wel der of al l ti me.

It has a broad wel di ng amperage range of 40- 225 amps.

The AC- 225 produces an extremel y smooth AC arc for

wel di ng a wi de vari ety of materi al s i ncl udi ng carbon, l ow

al l oy, and stai nl ess steel s as wel l as cast i ron. Metal s 16

gauge and heavi er can be easi l y arc wel ded wi th the

AC- 225.

Processes

Sti ck

Advantage Lincoln

Easy to i nstal l . Comes wi th attached i nput cabl e and

pl ug.

Easy to operate. Ful l range 40- 225 amp sel ector swi tch

qui ckl y sets the wel di ng current and ensures a uni form

arc each and every ti me you wel d.

Smooth arc makes i t easy to wel d wi th di fferent el ec-

trodes, i ncl udi ng mi l d steel , l ow hydrogen, stai nl ess

steel and hardfaci ng el ectrodes.

225 amp AC output i s enough for 3/ 16" di ameter general

purpose mi l d steel el ectrodes and 5/ 32" si zes of other

el ectrodes.

Opti onal carbon arc torch for brazi ng and sol deri ng

appl i cati ons, for heati ng rusty nuts for easi er removal ,

and for bendi ng or strai ghteni ng metal .

Fan- cool ed for extra thermal protecti on.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Base Unit Includes

Insul ated el ectrode hol der and cabl e.

Li ghtwei ght heashi el d wi th l enses.

Heavy duty work cl amp and cabl e.

Sampl e pack of el ectrodes.

Hel pful Wel ders Gui de.

Input cabl e wi th attached pl ug.

Recommended General Options

Wheel Ki t

Order

K1170 AC- 225 230/ 1/ 60

K1170- 4 AC- 225 230/ 1/ 60 (i ncl udes Wheel Ki t and

Gl oves)

K1290 AC- 225 220/ 1/ 50

Literature

E2.30

(1) Except 75 amp setti ng whi ch can be used conti nuousl y for 1 hour.

Output Input

CC

AC

1

PHASE

60

Hz

50

Hz

Dimensions Net

Product Product Input Rated Output Input Current @ Output H x W x D Weight

Name Number Power Current/Voltage/Duty Cycle Rated Output Range in. (mm) lbs. (kg)

AC/ DC K1297 230/ 1/ 60 AC: 225A/ 25V/ 20% AC: 50 40- 225 Amps AC 24 x 17.25 x 12 124

225/ 125 DC: 125A/ 25V/ 20% DC: 36 Max. OCV: 79V (610 x 438 x 305) (56.3)

30- 125 Amps DC

Max. OCV: 73V

AC/ DC K1299 220/ 1/ 50 AC: 225A/ 25V/ 15% AC: 55 50- 250 Amps AC 123

225/ 125 DC: 125A/ 25V/ 15% DC: 41 Max. OCV: 76V (55.8)

35- 135 Amps DC

Max. OCV: 69V

AC/DC 225/125

AC/DC 225/125

www.lincolnelectric.com

STICK WELDERS

13

The AC/ DC 225/ 125 i s the del uxe versi on of the worl d

renowned AC- 225 arc wel der. The AC/ DC 225/ 125 i s an arc

wel di ng power source wi th an AC wel di ng output range of

40- 225 amps and a DC wel di ng output range of 30- 125

amps. It i s an extremel y useful sti ck wel di ng power source

for mai ntenance repai r, fabri cati on, constructi on, erecti ng

and hardfaci ng appl i cati ons. Can al so be used for cutti ng

and pi erci ng hol es i n steel .

Processes

Sti ck, TIG

Advantage Lincoln

Easy to i nstal l . Comes wi th attached i nput power cabl e

and pl ug.

Easy to operate wi th front mounted AC/ DC pol ari ty

swi tch and ful l range amperage sel ector swi tch for

accurate and dependabl e procedure setti ng.

Tradi ti onal desi gn provi des l ong- l i fe and l ow cost

operati on.

Compact si ze al l ows for easy storage and handl i ng.

AC or DC wel di ng output for compl ete sti ck wel di ng

versati l i ty.

Smooth arc makes i t easy to wel d wi th di fferent el ec-

trodes, i ncl udi ng mi l d steel , l ow hydrogen, stai nl ess

steel and hardfaci ng el ectrodes.

Use the el ectrode pol ari ty swi tch on the front of the

machi ne to sel ect a DC wel di ng arc where a stabl e arc i s

essenti al .

Sel ect an AC wel di ng arc for l arge di ameter general pur-

pose el ectrodes for wel di ng heavi er pl ate where hi gher

deposi ti on rates and travel speeds are desi red.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Base Unit Includes

Insul ated el ectrode hol der and cabl e.

Heavy duty work cl amp and cabl e.

Hel pful Wel ders Gui de.

Input cabl e wi th attached pl ug.

Recommended General Options

Wheel Ki t

Order

K1297 AC/ DC 225/ 125 230/ 1/ 60

K1299 AC/ DC 225/ 125 220/ 1/ 50

Literature

E2.60

Output Input

CC

AC

DC

1

PHASE

60

Hz

50

Hz

Dimensions

Product Product Input Rated Output Input Current @ H x W x D Net Weight

Name Number Power Current/Voltage/Duty Cycle Rated Output Output Range in. (mm) lbs. (kg)

Ideal arc 250 K1053- 7 208/ 230/ 460/ 1/ 60 AC: 250A/ 30V/ 30% 95/ 86/ 43A 35- 300 Amps AC 27 x 19 x 21.5 350

K1053- 9 (w/ PFC) DC: 250A/ 30V/ 30% 75/ 68/ 34A Max. OCV: 72V (686 x 483 x 546) (159)

K1053- 8 230/ 460/ 575/ 1/ 60 86/ 43/ 34A 40- 250 Amps DC

K1053- 10 (w/ PFC) 68/ 34/ 27A Max. OCV: 70V

K1054- 3 380/ 415/ 500/ 1/ 50 50/ 46/ 38A

K1054- 4 220/ 380/ 440/ 1/ 50 86/ 50/ 43A

Idealarc

250

Idealarc

250

www.lincolnelectric.com

STICK WELDERS

14

The Ideal arc 250 i s the cl assi c workhorse of the Li ncol n

El ectri c sti ck wel di ng power source l i ne. It produces up to

300 amps of brute AC wel di ng strength or down to 40

amps of smooth DC wel di ng performance. Add the opti on-

al TIG Modul e to create a versati l e AC/ DC TIG wel der for

wel di ng al umi num or other al l oy metal s. The Ideal arc 250

i s wel l sui ted for i ndustri al producti on wel di ng appl i ca-

ti ons, for mai ntenance and repai r shops where wel di ng

versati l i ty i s needed, and for the shop or farm where

ruggedness and durabi l i ty i s requi red.

Processes

Sti ck, TIG, Gougi ng

Advantage Lincoln

Outstandi ng arc stabi l i ty, transformer desi gn and bui l t- i n

stabi l i zer provi des popout- resi stant wel di ng wi th al l AC

el ectrodes.

AC output i s 300 amps maxi mum. 250 amps DC output

for maxi mum qual i ty wi th every type of el ectrode i ncl ud-

i ng l ow hydrogen, stai nl ess steel , hardfaci ng,

al umi num and bronze.

Easy set- up and operati on. Ful l range conti nuous

current control di al wi th current i ndi cator for exact heat

requi red for each j ob.

Change pol ari ty wi th a twi st of the wri st AC, DC+

or DC- .

Stackabl e case desi gn al l ows machi nes to be stacked

3 hi gh to save val uabl e fl oor space.

Fan- cool ed for extra thermal protecti on.

60Hz model s CSA NRTL/ C certi fi ed.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Power Factor Capaci tor Ki t, Undercarri age

Recommended Stick Options

Accessory Ki t

Recommended TIG Options

TIG Modul e, Contactor Ki t, TIG Modul e Control Cabl e

Order

K1053- 7 Ideal arc 250 208/ 230/ 460/ 1/ 60

K1053- 8 Ideal arc 250 230/ 460/ 575/ 1/ 60

K1054- 3 Ideal arc 250 380/ 415/ 500/ 1/ 50

K1054- 4 Ideal arc 250 220/ 380/ 440/ 1/ 50

Wi th Power Factor Capaci tors:

K1053- 9 Ideal arc 250 208/ 230/ 460/ 1/ 60

K1053- 10 Ideal arc 250 230/ 460/ 575/ 1/ 60

Literature

E2.70

Output Input

CC

AC

DC

1

PHASE

60

Hz

50

Hz

Invertec

V100-S

Invertec

V100-S

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power(1) Duty Cycle(2) Rated Output Range in. (mm) lbs. (kg)

Invertec K1577- 1 115/ 1/ 50/ 60 100A/ 24V/ 15% 32A(3) 8- 100A 6 x 10 x 14 9.9

V100- S 85A/ 23.5V/ 20% 25A(4) 20- 24V (152 x 254 x 356) (4.5)

70A/ 23V/ 20% 20A Max. OCV: 67V

STICK WELDERS

The Invertec V100- S i s an ul tra hi gh speed i nverter power

source that del i vers premi um arc performance i n one of the

smal l est packages avai l abl e today. The V100- S provi des

thi s l evel of performance i n both sti ck wel di ng and scratch

start TIG wel di ng modes.

Processes

Sti ck, TIG

Advantage Lincoln

Great for sti ck wel di ng wi th popul ar Li ncol n el ectrodes

such as Fl eetwel d 35, Fl eetwel d 37, Fl eetwel d 180 and

Excal i bur 7018.

Scratch start DC TIG operati on wi th premi um arc wel di ng

performance down to as l ow as 8 amps.

Bui l t- i n Hot Start for easy el ectrode starti ng.

Compact, l i ghtwei ght desi gn wei ghs l ess than 10 l bs. for

the ul ti mate i n portabi l i ty.

115V i nput for use i n a wi de vari ety of l ocati ons.

Rugged pl asti c case for worry- free portabi l i ty and shock

resi stance.

Thermostati c protecti on for l ong l i fe of el ectroni c

components.

Bui l t- i n over vol tage protecti on.

Il l umi nated On/ Off swi tch for easy user feedback.

Meets IEC 60974- 1 standards for safety.

One- year warranty on parts and l abor.

Base Unit Includes

Twi st- Mate pl ug

Sti ck el ectrode hol der and cabl e

Work cl amp and cabl e

Recommended TIG Options

PTA- 17V 2 cabl e TIG Torch, PTA- 17V Parts Ki t

Order

K1577- 1 Invertec V100- S 115/ 1/ 50/ 60

Literature

E2.140

(1) Input power above 20% of nomi nal wi l l cause i nternal damage.

(2) Hi gher duty cycl es can be achi eved when TIG wel di ng because the wel di ng vol tage i s l ower.

(3) Requi res a 30 amp branch ci rcui t.

(4) Requi res a 20 amp branch ci rcui t.

www.lincolnelectric.com

15

Output Input

CC

DC

1

PHASE

60

50

Hz

Invertec

V160-S

Invertec

V160-S

www.lincolnelectric.com

Dimensions

Product Product Rated Output Input Current @ H x W x D Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output(1) Output Range inches (mm) lbs. (kg)

115V/ 1/ 50/ 60 60A/ 22.4V/ 100% Sti ck 20A

(20A Branch Ci rcui t) 90A/ 13.6V/ 100% TIG

Invertec K1844- 1 115V/ 1/ 50/ 60 80A/ 23.2V/ 100% Sti ck 25A 5- 160 Amps DC 13 x 8 x 17 24

V160- S (30A Branch Ci rcui t) 110A/ 14.4V/ 100% TIG Max OCV: 48V (330 x 203 x 432) (11)

230V/ 1/ 50/ 60 130A/ 25.2V/ 100% Sti ck 25A

(30A Branch Ci rcui t) 130A/ 15.2V/ 100% TIG

STICK WELDERS

16

The Invertec V160- S DC i nverter sti ck wel der exhi bi ts

excel l ent arc control , for popul ar el ectrodes such as

Fl eetwel d 35, Fl eetwel d 37, Fl eetwel d 180 and

Excal i bur 7018. Add an opti onal gas val ve styl e TIG torch

and you al so have a very affordabl e DC Touch- Start TIG

wel di ng machi ne. Its auto- reconnect 115/ 230V 50/ 60Hz

i nput combi ned wi th i ts rugged, portabl e package make i t

i deal for remote wel di ng appl i cati ons.

Processes

Sti ck, TIG

Advantage Lincoln

Sui tabl e for a wi de range of operati ons wi th an output

range from 5 160 DC amps.

Two modes of operati on: Sti ck and DC Touch- Start

TIG.

Ideal for sti ck wel di ng wi th popul ar Li ncol n el ectrodes,

i ncl udi ng Fl eetwel d 35, Fl eetwel d 37, and

Excal i bur 7018.

Features adj ustabl e arc control to adj ust the arc force

and start characteri sti cs.

Advanced i nverter technol ogy for superi or arc

performance.

Li ghtwei ght, rugged package for ul ti mate portabi l i ty and

durabi l i ty.

Auto- reconnect between 115/ 230V 50/ 60Hz i nput power

el i mi nates operator error.

Li ne vol tage compensati on enabl es use on remote power

from an engi ne dri ven generator.

Thermal and vol tage overl oad protecti on for l ong l i fe of

i nternal components.

Three- year warranty on parts and l abor.

Base Unit Includes

115V Input cord (10 ft.) and pl ug (NEMA 5- 15P)

20 Amp Pl ug (NEMA 5- 20P)

Ful l y adj ustabl e shoul der strap

Sti ck el ectrode hol der and cabl e

Work cl amp and cabl e

Recommended General Options

Wel di ng Cart

Recommended Stick Options

Remote Output Control

Recommended TIG Options

TIG- Mate 17V Ai r- Cool ed TIG Torch Starter Pack,

Twi st- Mate Torch Adapter, Foot Amptrol , Start Pedal Foot

Amptrol , Hand Amptrol

Order

K1844- 1 Invertec V160- S 115/ 230/ 1/ 50/ 60

Literature

E2.145

(1) Input amps on 60 Hz i nput.

Output Input

CC

DC

1

PHASE

60

50

Hz

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs (kg)

Invertec K2269- 1 208/ 230/ 460/ 275A/ 31V/ 35% 38/ 37/ 19/ 16 13.6 x 9.0 x 20.25 54.5

V275- S 575/ 3/ 60 250A/ 30V/ 60% 34/ 33/ 17/ 14 (345 x 229 x 514) (24.7)

200A/ 28V/ 100% 27/ 25/ 13/ 11 5- 275A

208/ 230/ 460/ 275A/ 29- 31V/ 35% 68/ 67/ 38/ 31

575/ 1/ 60 250A/ 30V/ 60% 63/ 62/ 33/ 27

200A/ 28V/ 100% 49/ 48/ 26/ 21

220/ 380/ 400/ 250A/ 30V/ 35% 32/ 20/ 19/ 18/ 17

415/ 440/ 3/ 50 200A/ 28V/ 100% 25/ 15/ 15/ 14/ 13 5- 250A

220/ 380/ 400/ 250A/ 30V/ 35% 63/ 42/ 40/ 38/ 36

415/ 440/ 1/ 50 200A/ 28V/ 100% 48/ 32/ 30/ 29/ 27

Invertec

V275-S

Invertec

V275-S

STICK WELDERS

The V275- S power source i s i deal for the ri gors of the

constructi on si te. IP23S rated and equi pped wi th weather-

resi stant features, thi s Sti ck and TIG power source i s

desi gned for outdoor use. Up to 275 amps of output gi ves

you access to a greater number of sti ck el ectrodes, and out-

standi ng E6010 performance (Fl eetwel d 5P). The V275- S i s

avai l abl e as a si ngl e uni t or mounted i n 8- pack racks for

conveni ence on the constructi on si te. Standard features

such as sel ectabl e Hot Start and adj ustabl e Arc Force

provi de a l evel of arc control you wont fi nd anywhere el se

i n thi s cl ass of machi ne.

Processes

Sti ck, TIG, Gougi ng

Advantage Lincoln

Trul y outstandi ng E6010 and E7018 performance usi ng

up to 7/ 32 (5.6mm) di ameter el ectrodes that enabl es

both whi p and drag techni ques for a vari ety of construc-

ti on and fabri cati on appl i cati ons.

Touch- Start TIG desi gn permi ts the DC TIG wel di ng arc

to be establ i shed wi thout hi gh- frequency starti ng.

Ai r Carbon Arc cutti ng and gougi ng wi th up to 3/ 16

(4.8mm) di ameter carbon el ectrode.

Adj ustabl e Arc Force and a two- posi ti on Hot Start swi tch

provi de a l evel of arc control you wont fi nd i n compara-

bl e machi nes.

25 more amps than competi tor model s provi des access

to a greater number of sti ck el ectrode types, di ameters,

and appl i cati ons.

No de- rati ng on si ngl e phase as wi th competi ti ve model s

get the same performance usi ng si ngl e or three phase

i nput.

Onl y power source i n i ts cl ass that meets IP23S

envi ronmental rati ng.

Al umi num chassi s, protecti ve boots on swi tches and

potted and trayed PC boards for extreme envi ronmental

protecti on.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Twi st- Mate Cabl e Receptacl e, Twi st- Mate Cabl e Pl ug

Recommended Stick Options

Accessory Ki t, Remote Output Control

Recommended TIG Options

17V Ai r- Cool ed TIG- Mate Starter Pack, Twi st- Mate Torch

Adapter, Foot Amptrol , Hand Amptrol ,

Order

K2269- 1 Invertec V275- S

K2269- 2 Invertec V275- S (Rack Model )

K2199- 2 Invertec V275- S 8- pack Inverter Rack

Literature

E2.161

www.lincolnelectric.com

17

Output Input

CC

DC

1

3

PHASE

60

Hz

50

Hz

R3R-400

R3R-400

www.lincolnelectric.com

Input

Rated Output Current @ Dimensions Net

Product Product Input Current/Voltage/ Rated Output H x W x D Weight

Name Number Power Duty Cycle Output Range in. (mm) lbs (kg)

R3R- 400 K1285- 16 230/ 460/ 3/ 60 400A/ 36V/ 60% 74/ 37A 60- 500A 27.5 x 22.3 x 32 402

Max. OCV: 67V (699 x 566 x 813) (183)

STICK WELDERS

18

Look to the R3R- 400 power source from Li ncol n El ectri c for

your heavy- duty sti ck wel di ng needs. Whether youre usi ng

mi l d steel , l ow hydrogen, stai nl ess steel or hardfaci ng el ec-

trodes, the Ideal arc R3R- 400 produces a smooth, qual i ty

arc for consi stent resul ts day- i n and day- out. The R3R- 400

provi des pi ece of mi nd wi th i ts tradi ti onal , fan- cool ed

desi gn for l ong l i fe expectancy and l ow cost operati on, cal i -

brated current control knob for si mpl e and easy procedure

setti ng, and al l weather protecti on i ncl udi ng a powder pai nt

fi ni sh for durabi l i ty i n even the roughest envi ronments. The

R3R- 400 i s al so a proven DC TIG wel der si mpl y add TIG

accessori es and a cyl i nder of shi el di ng gas. Want to show

off your arc gougi ng ski l l s? The R3R- 400 can hel p you do

that too!

Processes

Sti ck, TIG, Gougi ng

Advantage Lincoln

Great operator appeal . The R3R- 400 produces a qual i ty,

l ow spatter, smooth arc wi thout pop- outs. Li ne vol tage

fl uctuati ons of up to 10% are handl ed by the R3Rs

i nput compensati on functi on, whi ch keeps the output

constant.

Easy to operate. Cal i brated current control knob makes

procedure setti ng si mpl e and easy. Pol ari ty swi tch,

vol tmeter and ammeter are standard.

Smooth arc makes i t easy to wel d wi th mi l d steel , l ow

hydrogen, stai nl ess steel and hardfaci ng el ectrodes.

Stackabl e case desi gn wi th bui l t- i n l i ft hook al l ows for

easy storage and handl i ng. Machi nes can safel y be

stacked three hi gh to conserve fl oor space.

Submersi on di pped transformer assembl y for added

corrosi on and moi sture protecti on.

Total l y encl osed fan motor i s permanentl y l ubri cated.

Desi gned to NEMA speci fi cati ons.

The R3R- 400 i s capabl e of arc gougi ng usi ng a carbon

el ectrode wi th a maxi mum di ameter of 5/ 16" (7.9mm).

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Undercarri age

Recommended Stick Options

Accessory Ki t, Remote Output Control

Recommended TIG Options

Pro- Torch TIG Torches, TIG Modul e, Docki ng Ki t, Hand

Amptrol , Foot Amptrol , Contactor Ki t, Water Val ve Ki t,

TIG Control Cabl e, TIG Control Cabl e Extensi on, Del uxe

Adj ustabl e Gas Regul ator and Hose Ki t

Order

K1285- 16 230/ 460/ 3/ 60

Literature

E2.100

Output Input

CC

DC

3

PHASE

60

Hz

Input

Rated Output Current @ Dimensions Net

Product Product Input Current/Voltage/ Rated Output H x W x D Weight

Name Number Power Duty Cycle Output Range in. (mm) lbs (kg)

R3R- 500 K1286- 16 230/ 460/ 3/ 60 500A/ 40V/ 60% 88/ 44A 75- 625A 27.5 x 22.3 x 32 446

Max OCV: 67V (699 x 566 x 813) (203)

R3R-500

R3R-500

STICK WELDERS

Look to the R3R- 500 power source from Li ncol n El ectri c for

your heavy- duty sti ck wel di ng needs. Whether youre usi ng

mi l d steel , l ow hydrogen, stai nl ess steel or hardfaci ng el ec-

trodes, the Ideal arc R3R- 500 produces a smooth, qual i ty

arc for consi stent resul ts day- i n and day- out. The R3R- 500

provi des pi ece of mi nd wi th i ts tradi ti onal , fan- cool ed

desi gn for l ong l i fe expectancy and l ow cost operati on, cal i -

brated current control knob for si mpl e and easy procedure

setti ng, and al l weather protecti on i ncl udi ng a powder pai nt

fi ni sh for durabi l i ty i n even the roughest envi ronments. The

R3R- 500 i s al so a proven DC TIG wel der si mpl y add TIG

accessori es and a cyl i nder of shi el di ng gas. Want to show

off your arc gougi ng ski l l s? The R3R- 500 can hel p you do

that too!

Processes

Sti ck, TIG, Gougi ng

Advantage Lincoln

Great operator appeal . The R3R- 500 produces a qual i ty,

l ow spatter, smooth arc wi thout pop- outs. Li ne vol tage

fl uctuati ons of up to 10% are handl ed by the R3Rs

i nput compensati on functi on, whi ch keeps the output

constant.

Easy to operate. Cal i brated current control knob makes

procedure setti ng si mpl e and easy. Pol ari ty swi tch,

vol tmeter and ammeter are standard.

Smooth arc makes i t easy to wel d wi th mi l d steel , l ow

hydrogen, stai nl ess steel and hardfaci ng el ectrodes.

Stackabl e case desi gn wi th bui l t- i n l i ft hook al l ows for

easy storage and handl i ng. Machi nes can safel y be

stacked three hi gh to conserve fl oor space.

Submersi on di pped transformer assembl y for added

corrosi on and moi sture protecti on.

Total l y encl osed fan motor i s permanentl y l ubri cated.

Desi gned to NEMA speci fi cati ons.

The R3R- 500 i s capabl e of arc gougi ng usi ng a carbon

el ectrode wi th a maxi mum di ameter of 3/ 8" (9.5mm).

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Undercarri age

Recommended Stick Options

Accessory Ki t, Remote Output Control

Recommended TIG Options

Pro- Torch TIG Torches, TIG Modul e, Docki ng Ki t, Hand

Amptrol , Foot Amptrol , Contactor Ki t, Water Val ve Ki t,

TIG Control Cabl e, TIG Control Cabl e Extensi on, Del uxe

Adj ustabl e Gas Regul ator and Hose Ki t

Order

K1286- 16 230/ 460/ 3/ 60

Literature

E2.100

www.lincolnelectric.com

19

Output Input

CC

DC

3

PHASE

60

Hz

Square Wave TIG

Square Wave

TIG 175 PRO

www.lincolnelectric.com

Input Current @

Rated Output Rated Output Dimensions Net

Product Product Input Current/Voltage/ DC TIG & Output H x W x D Weight

Name Number Power Duty Cycle(1) AC/DC Stick AC TIG Range(2) in. (mm) lbs (kg)

Square K1478- 3 208/ 230/ 1/ 60 59/ 53A 72/ 65(3)A DC: 8- 175A

Wave AC: 9- 175A 19.5 x 13.7 x 25.0 185

TIG 175 K1478- 4 460/ 575/ 1/ 60 150A/ 26V/ 25% 27/ 22A 33/ 27A Max. OCV: 59V DC (495 x 348 x 635) (84)

PRO Max. OCV: 74V AC

K1582- 2 240/ 380/ 415/ 54/ 33/ 30A 71/ 41/ 37A

1/ 50/ 60

TIG WELDERS

20

The Square Wave TIG 175 PRO features the i ndustry-

proven arc performance and rel i abi l i ty preferred by race

teams, avi ati on enthusi asts and l i ght i ndustri al TIG fabri ca-

tors, especi al l y for l ow amperage appl i cati ons. Thi s great

AC/ DC TIG and sti ck wel der del i vers a wi de and useful

amperage range go as l ow as 8 amps! Professi onal l evel

features i ncl ude Square Wave Technol ogy for smooth arc

stabi l i ty and Auto Bal ance AC TIG control .

Processes

Sti ck, TIG

Advantage Lincoln

Excel l ent l ow amperage TIG starti ng performance down

to 8 amps DC, 9 amps AC.

Square Wave Technol ogy reduces tungsten spi tti ng

and resul ti ng el ectrode erosi on and del i vers a smooth,

stabl e AC wel di ng arc.

Great general purpose sti ck wel der on both AC and DC

for steel , stai nl ess steel , cast i ron and hardfaci ng appl i -

cati ons.

Standard Auto Bal ance control automati cal l y provi des

opti mal mi x of cl eani ng acti on vs. penetrati on for each

amperage setti ng wi thout compl ex, or di ffi cul t to under-

stand, user control s.

Pul se TIG wel di ng capabl e When youre ready, expand

your TIG wel di ng potenti al wi th the opti onal TIG pul ser

uni t.

Shi el di ng Gas Prefl ow and Postfl ow Bui l t- i n 1/ 2 sec-

ond prefl ow and 15 second afterfl ow ti mers purge and

protect the wel d and tungsten.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on power source. One year on Foot

Amptrol , Regul ator & Fl ow Gauge and TIG Torch &

Cabl e. 90 days warranty on El ectrode Hol der & Cabl e

and Work Cl amp & Cabl e.

Base Unit Includes

PTA- 9 TIG Torch, Twi st- Mate Torch Adapter, Foot Amptrol ,

Gas Regul ator & Fl ow Gauge, Sti ck El ectrode Hol der, Work

Cl amp & Cabl e, Input Cabl e (K1478- 3 onl y), Sampl e Pack

Sti ck El ectrode, Instructi onal Vi deo

Recommended General Options

Undercarri age

Recommended TIG Options

Hand Amptrol , Start Pedal Foot Amptrol , Arc Start Swi tch,

Parts Ki t, TIG Pul ser, Cut Length Consumabl es, Pro-

Torch TIG Torches, Twi st- Mate Torch Adapter, Cool - Arc

40 Water Cool er, Water Cool er Hoses (CGA to CGA), Water

Hose Coupl er

Order

K1478- 3 Square Wave TIG 175 PRO 208/ 230/ 1/ 60

K1478- 4 Square Wave TIG 175 PRO 460/ 575/ 1/ 60

K1582- 2 Square Wave TIG 175 PRO

240/ 380/ 415/ 1/ 50/ 60

Literature

E3.35

(1) Based on a 10 mi nute peri od. Addi ti onal rati ngs i ncl ude: 125A/ 25V/ 40%, 110A/ 24V/ 60% and 90A/ 24V/ 100%. Al l rati ngs at 104F (40C).

(2) Wi th Amptrol . Wi thout Amptrol , 10- 175A DC and AC.

(3) The Nati onal El ectri cal Code permi ts operati on at rated output and duty cycl e from a 50 amp receptacl e when suppl y l i nes and fuses are properl y si zed.

See Power Source operators manual .

Output Input

CC

AC

DC

1

PHASE

60

Hz

50

Hz

www.lincolnelectric.com www.lincolnelectric.com www.lincolnelectric.com

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs. (kg)

275A/ 31V/ 40% 80/ 72/ 36A wi th PFC

K1826- 1 208/ 230/ 460/ 1/ 60 104/ 94/ 47A w/ o PFC

225A/ 29V/ 60% 64/ 58/ 29A wi th PFC DC: 2- 340A

Preci si on 86/ 78/ 39A w/ o PFC AC: 5- 340A 31 x 22 x 26 397

TIG 275 275A/ 31V/ 40% 35/ 28A wi th PFC Max. OCV: (787 x 559 x 660) (180)

K1826- 2 460/ 575/ 1/ 60 47/ 38A w/ o PFC 75V

225A/ 29V/ 60% 29/ 23A wi th PFC

39/ 31A w/ o PFC

275A/ 31V/ 40% 82/ 47/ 43A wi th PFC

K1827- 1 220/ 380/ 415/ 1/ 50/ 60 103/ 60/ 53A w/ o PFC

225A/ 29V/ 60% 66/ 38/ 35 w/ PFC

87/ 50/ 46 w/ o PFC

Precision TIG 275

Precision TIG

275

TIG WELDERS

The Power To Perform!

Patented Mi cro- Start Technol ogy provi des unri val ed and

revol uti onary arc performance i deal for cri ti cal AC or DC

wel di ng i n fabri cati on, aerospace, producti on, motorsports,

and vocati onal appl i cati ons. Avai l abl e i n both machi ne- onl y

model s or i n a conveni ent Ready- Pak Package, the

Preci si on TIG 275 combi nes both outstandi ng val ue-

added features, wi th preci si on arc performance to meet al l

of your wel di ng needs.

Processes

Sti ck, TIG

Advantage Lincoln

Patented Mi cro- Start technol ogy for state- of- the- art

l ow amperage starti ng: as l ow as 2 amps DC, or 5 amps

AC.

Smooth, control l abl e focused arc for preci si on TIG

wel di ng performance.

Neat/ organi zed cabl e management wi th i ntegrated torch

hol ster.

Water- cool ed torch connecti ons wi th no adapters si de

mounted to keep out of the way and protected.

Take the hassl e out of orderi ng - Order a Ready- Pak

pre- assembl ed wel di ng package.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Advanced Control Panel , Undercarri age, Power Factor Ki t,

Work Cl amp and Cabl e Assembl y

Recommended Stick Options

Sti ck Accessory Ki t, Remote Output Control

Recommended TIG Options

Pro- Torch TIG Torches, Cabl e Adapters, Under- Cool er

Cart Water Cool er, Water Sol enoi d Ki t, Harri s Argon

Fl owmeter Regul ator, Foot Amptrol , Start Pedal Foot

Amptrol , Hand Amptrol , Arc Start Swi tch, Cut Length

Consumabl es

Order

K1826- 1 Preci si on TIG 275 208/ 230/ 460/ 1/ 60

K1826- 2 Preci si on TIG 275 460/ 575/ 1/ 60

K1827- 1 Preci si on TIG 275 220- 230/ 380- 400/

415/ 1/ 50/ 60

K1825- 1 Preci si on TIG 275 208/ 230/ 460/ 1/ 60

(Ready- Pak Pkg.)

Literature

E3.42

www.lincolnelectric.com

22

Output Input

CC

AC

DC

1

PHASE

60

Hz

50

Hz

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs. (kg)

375A/ 35V/ 40% 112/ 102/ 51A

K1833- 1 208/ 230/

460/ 1/ 60 350A/ 34V/ 60% 102/ 92/ 46A DC: 2- 420A

Preci si on AC: 5- 420A 31 x 22 x 26 507

TIG 375 375A/ 35V/ 40% 102/ 51/ 41A Max. OCV: (787 x 559 x 660) (230)

K1833- 2 230/ 460/ 80V

575/ 1/ 60 350A/ 34V/ 60% 92/ 46/ 37A

375A/ 35V/ 40% 119/ 69/ 63A

K1834- 1 230/ 380/ 415/

1/ 50/ 60 350A/ 34V/ 60% 110/ 64/ 59A

Precision TIG375

Precision TIG

375

TIG WELDERS

The Power To Perform!

The Preci si on TIG 375 del i vers the Power to Perform

setti ng a new standard i n Square Wave Technol ogy.

Combi ni ng outstandi ng val ue- added features and patented

Mi cro- Start Technol ogy, the Preci si on TIG has the wi dest

range of wel di ng current i n i ts cl ass featuri ng up to 25

more amps of power at 40% duty cycl e and a superi or

l ow- end. Thi s machi ne comes standard wi th ful l featured

sequenci ng and pul si ng control s and power factor

correcti on.

Processes

Sti ck, TIG

Advantage Lincoln

Patented Mi cro- Start technol ogy for state- of- the- art

l ow amperage starti ng: as l ow as 2 amps DC, or 5 amps

AC.

Smooth, control l abl e focused arc for preci si on TIG

wel di ng performance.

Neat/ organi zed cabl e management wi th i ntegrated torch

hol ster.

Water- cool ed torch connecti ons wi th no adapters si de

mounted to keep out of the way and protected.

Standard power factor correcti on for reduced i nput

current draw.

Take the hassl e out of orderi ng - Order a Ready- Pak

pre- assembl ed wel di ng package.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Undercarri age, Work Cl amp and Cabl e Assembl y

Recommended Stick Options

Sti ck Accessory Ki t, Remote Output Control

Recommended TIG Options

Pro- Torch TIG Torches, Cabl e Adapters, Under- Cool er

Cart Water Cool er, Water Sol enoi d Ki t, Harri s Argon

Fl owmeter Regul ator, Foot Amptrol , Start Pedal Foot

Amptrol , Hand Amptrol , Arc Start Swi tch, Cut Length

Consumabl es

Order

K1833- 1 Preci si on TIG 375 208/ 230/ 460/ 1/ 60

K1833- 2 Preci si on TIG 375 230/ 460/ 575/ 1/ 60

K1834- 1 Preci si on TIG 375 220- 230/ 380- 400/

415/ 1/ 50/ 60

K1903- 1 Preci si on TIG 375 208/ 230/ 460/ 1/ 60

(Ready- Pak Pkg.)

Literature

E3.51

Output Input

CC

AC

DC

1

PHASE

60

Hz

50

Hz

www.lincolnelectric.com

23

Invertec

V160-T

Invertec

V160-T

Dimensions

Product Product Rated Output Input Current @ H x W x D Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output(1) Output Range inches (mm) lbs. (kg)

115V/ 1/ 50/ 60 90A/ 13.6V/ 100% TIG 20A

20A Branch Ci rcui t 60A/ 22.4V/ 100% Sti ck

Invertec K1845- 1 115V/ 1/ 50/ 60 110A/ 14.4V/ 100% TIG 25A 5- 160 Amps DC 13 x 8 x 17 24

V160- T 30A Branch Ci rcui t 80A/ 23.2V/ 100% Sti ck Max OCV: 48V (330 x 203 x 432) (10.8)

230V/ 1/ 50/ 60 130A/ 15.2V/ 100% TIG 25A

30A Branch Ci rcui t 130A/ 25.2V/ 100% Sti ck

TIG WELDERS

The Invertec V160- T i s a ful l functi on DC TIG i nverter

i ntended for al l oy fabri cati on or cri ti cal mai ntenance work.

Its bui l t- i n gas handl i ng capabi l i ty and choi ce of Hi gh

Frequency or Touch- Start TIG starti ng make i t i deal for a

wi de vari ety of tough TIG appl i cati ons. The V160- T can al so

wel d sti ck wi th a vari ety of popul ar Li ncol n sti ck el ectrodes.

Its portabl e, rugged desi gn and auto- sensi ng 115/ 230V

50/ 60Hz operati on make i t i deal for both shop or fi el d use.

Processes

Sti ck, TIG

Advantage Lincoln

Advanced i nverter technol ogy del i vers superi or TIG

performance.

Sel ectabl e Touch- Start TIG starti ng or hi gh frequency

starti ng makes i t easy to establ i sh an arc under a vari ety

of condi ti ons.

Bui l t- i n pul si ng functi ons gi ve you greater control over

thi n materi al s.

Add TIG capabi l i ty to your arsenal by usi ng remote

power from an engi ne dri ven generator.

Auto- reconnect between 115/ 230V 50/ 60Hz i nput power

el i mi nates operator error.

Integral gas and power connector for si mpl e torch

connecti ons and qui ck changes between TIG and sti ck

wel di ng.

Li ghtwei ght, rugged package make i t easy to take TIG

wel di ng capabi l i ty where i ts needed.

Thermal and vol tage overl oad protecti on for l ong l i fe of

i nternal components.

Three- year warranty on parts and l abor.

Base Unit Includes

115V Input cord (10 ft.) and pl ug (NEMA 5- 15P)

20 Amp Pl ug (NEMA 5- 20P)

Twi st- Mate Torch Adapter for PTA- 9 or - 17 one- pi ece

torch

Ful l y adj ustabl e shoul der strap

Work cl amp and cabl e

Recommended General Options

Wel di ng Cart

Recommended Stick Options

Sti ck El ectrode Hol der Cabl e Assembl y

Recommended TIG Options

TIG- Mate 17 Ai r- Cool ed TIG Torch Starter Pack,

TIG- Mate 20 Water- Cool ed TIG Torch Starter Pack,

Harri s Argon Fl owmeter Regul ator, Foot Amptrol , Hand

Amptrol , Arc Start Swi tch, Cool Arc 40 Water Cool er, Cut

Length Consumabl es

Order

K1845- 1 Invertec V160- T 115/ 230/ 1/ 50/ 60

Literature

E3.105

(1) Input amps on 60 Hz i nput.

www.lincolnelectric.com

24

Output Input

CC

DC

1

PHASE

60

50

Hz

Invertec

V205-T

Invertec

V205-T AC/DC

www.lincolnelectric.com

Input

Rated Output Current @ Dimensions Net

Product Product Input Current/Voltage/ Rated Output H x W x D Weight

Name Number Power Duty Cycle Output(1) Range in. (mm) lbs. (kg)

150A/ 16.0V/ 40% TIG 34.0A

115V/ 1/ 50/ 60 120A/ 14.8V/ 60% TIG 24.5A

100A/ 14.0V/ 100% TIG 18.9A

200A/ 18.0V/ 40% TIG 28.8A

Invertec 230V/ 1/ 50/ 60 170A/ 16.0V/ 60% TIG 17.8A 6- 200A

V205- T K1855- 1 140A/ 15.6V/ 100% TIG 14.2A Max. OCV: 15 x 8.5 x 19 33

AC/ DC 110A/ 24.4V/ 35% Sti ck 34.0A 53.7V (381 X 216 X 483) (15)

115V/ 1/ 50/ 60 90A/ 23.6V/ 60% Sti ck 26.0A

70A/ 22.8V/ 100% Sti ck 18.9A

180A/ 27.2V/ 35% Sti ck 28.8A

230V/ 1/ 50/ 60 150A/ 26.0V/ 60% Sti ck 22.6A

130A/ 25.2V/ 100% Sti ck 18.7A

TIG WELDERS

25

The Invertec V205- T AC/ DC i s i deal for cri ti cal AC or DC

TIG wel di ng appl i cati ons. Thi s ful l featured TIG wel der i s

al so capabl e of sti ck wel di ng. Vari abl e AC frequency al l ows

you to focus the arc when preci se arc control i s requi red.

The 115/ 230V auto- reconnect makes the V205- T AC/ DC

trul y fl exi bl e and the rugged, portabl e, l i ghtwei ght desi gn i s

i deal for shop or fi el d envi ronments.

Processes

Sti ck, TIG

Advantage Lincoln

Advanced i nverter technol ogy opti mi zes arc performance

i n a l i ghtwei ght package. Wei ghs onl y 33 l bs. (15 kg).

AC or DC output for a wi de vari ety of materi al types and

thi cknesses.

Three modes of operati on DC TIG, AC TIG or Sti ck.

Ful l - featured TIG control s.

Auto- reconnects for 115/ 230V 50/ 60Hz i nput power.

Li ne vol tage compensati on al l ows remote power from an

engi ne dri ven generator.

Adj ustabl e AC frequency al l ows you to focus the arc for

preci se arc control .

Take the hassl e out of orderi ng - Order a One- Pak

wel di ng package (some assembl y requi red).

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Base Unit Includes

230V Input cord and pl ug (10 ft.)

Twi st- Mate Torch Adapter for PTA- 9 or - 17 one- pi ece

torch

Twi st- Mate adapter for work cabl e

Ful l y adj ustabl e shoul der strap

Recommended General Options

Wel di ng Cart

Recommended TIG Options

TIG- Mate 17 Ai r- Cool ed TIG Torch Starter Pack,

TIG- Mate 20 Water- Cool ed TIG Torch Starter Pack,

Harri s Argon Fl owmeter Regul ator, Foot Amptrol , Hand

Amptrol , Arc Start Swi tch, Cut Length Consumabl es

Order

K1855- 1 Invertec V205- T AC/ DC 115/ 230/ 1/ 50/ 60

K2350- 1 Invertec V205- T AC/ DC 115/ 230/ 1/ 50/ 60

(One- Pak Pkg.)

Literature

E3.110

(1) Input amps on 60Hz i nput.

Output Input

CC

AC

DC

1

PHASE

60

50

Hz

CV-250

CV-250

Rated Output Input Current Dimensions Net

Product Product Input Current/Voltage/ @ Rated H x W x D Weight

Name Number Power Duty Cycle Output Output Range in. (mm) lbs (kg)

230/ 460/ 300A/ 32V/ 60% 56/ 28/ 22A 7- 32V 24.6 x 19.5 x 27 300

CV- 250 K1355- 4 575/ 3/ 60 250A/ 30V/ 100% 51/ 26/ 20A 30- 300A (625 x 495 x 686) (136)

Max. OCV: 50V

MIG WELDERS

The CV- 250 i s an effi ci ent, val ue- packed, constant vol tage

DC power source that del i vers superi or arc stabi l i ty and

wel di ng performance. The CV- 250s smart engi neeri ng and

sturdy constructi on make i t an excel l ent choi ce for a wi de

range of wel di ng appl i cati ons especi al l y i nvol vi ng mi l d

steel , stai nl ess steel , al umi num and al l oy wel di ng

materi al s.

Processes

MIG, Fl ux- Cored

Advantage Lincoln

Di gi tal vol tmeter/ ammeter faci l i tates operator confi dence

and preci se setti ngs.

Magnum Twi st- Mate output connectors make hook-

up as wel l as changes i n i nductance or pol ari ty fast

and easy. (Two Twi st- Mate pl ugs i ncl uded.)

Qui ck, si mpl e 14 pi n MS- type (Amphenol ) wi re feeder

connecti on.

Mi croprocessor- based control PC board has bui l t- i n

di agnosti cs for qui ck troubl eshooti ng.

Internal components i ncl udi ng wi ndi ngs, recti fi ers and

ci rcui t boards are coated to protect agai nst the effects of

moi sture and corrosi ves!

Choose l ow i nductance for appl i cati ons i nvol vi ng CO

2

shi el di ng gas, or when wel di ng mi l d steel or very thi n

materi al s.

Use hi gh i nductance for wel di ng heavi er materi al s or

when usi ng 75% Argon/ 25% CO

2

gas.

El ectroni c and thermostati c protecti on from current

overl oad and excessi ve temperatures.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Remote Output Control , Remote Control Cabl e Adapter,

Twi st- Mate Cabl e Connectors, Undercarri age, Uni versal

Adapter Pl ug

Recommended Wire Feeder Options

LN- 7, LN- 7 GMA, LN- 742, LN- 10, DH- 10, LN- 15, LN- 25,

Cobramati c

Order

K1355- 4 CV- 250 230/ 460/ 575/ 3/ 60

Literature

E4.10

www.lincolnelectric.com

26

Output Input

CV

DC

3

PHASE

60

Hz

NOTE: Cobramati c i s a regi stered trademark of MK Products, Inc.

CV-300

CV-300

www.lincolnelectric.com

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs. (kg)

K1352- 1 208/ 230/ 460/ 3/ 60 300A/ 32V/ 100% 66/ 60/ 30A

CV- 300 400A/ 36V/ 60% 67/ 61/ 31A 50- 400A 24.6 x 19.5 x 27 300

K1352- 2 230/ 460/ 575/ 3/ 60 300A/ 32V/ 100% 60/ 30/ 24A 7- 37V (625 x 495 x 686) (136)

400A/ 36V/ 60% 61/ 31/ 24A

MIG WELDERS

27

When i t comes to wel di ng mi l d steel , stai nl ess steel , al u-

mi num and al l oy materi al s, you wont fi nd a more rel i abl e

power source than Li ncol n El ectri cs CV- 300. Equi pped wi th

el ectroni c and thermostati c protecti on, PC boards wi th

bui l t- i n di agnosti cs and sol i d state ci rcui try, the CV- 300 i s

bui l t to l ast. Thi s wel l - engi neered constant vol tage DC arc

wel di ng uni t i s al so a versati l e, steady performer. The dual

i nductance posi ti ons make i t fast and easy to sel ect desi red

output characteri sti cs. Di gi tal vol tmeter and ammeter set-

ti ngs can be preset. The CV- 300 generates an excepti onal

MIG and fl ux- cored arc.

Processes

MIG, Fl ux- Cored

Advantage Lincoln

Sol i d state ci rcui try provi des extra l ong l i fe duri ng

repeti ti ve appl i cati ons.

Di gi tal vol tmeter/ ammeter provi des excepti onal accuracy

and preci se presettabl e val ues.

Mi croprocessor based control PC board has bui l t- i n

di agnosti c routi nes for qui ck, easy troubl eshooti ng.

Al l ci rcui t boards are protected wi th a speci al i nsul ated

coati ng to extend l i fe and ensure rel i abl e performance.

El ectroni c and thermostati c protecti on from current

overl oad or excessi ve temperatures.

Provi des col d el ectrode wi th a sol i d state contactor

when the tri gger i s rel eased for added safety and conven-

i ence.

Magnum Twi st- Mate output connectors make hook-

up tool - l ess as wel l as changes i n i nductance or pol ari ty

fast and easy. Two Twi st- Mate Cabl e Pl ugs (K852- 95)

i ncl uded.

Provi des l i ne vol tage compensati on for mai ntai ni ng wel d

consi stency, even wi th changes of 10%.

Choose l ow i nductance connecti on when usi ng CO

2

shi el di ng gas, or when short arc wel di ng mi l d steel or

other thi n materi al s.

Choose hi gh i nductance connecti on when usi ng 75%

Argon/ 25% CO

2

gas, or when deal i ng wi th stai nl ess

steel or short arc wel ds on heavy materi al s.

Take the hassl e out of orderi ng - Order a Ready- Pak

pre- assembl ed wel di ng package.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Remote Output Control , Remote Control Cabl e Adapter,

Twi st- Mate Cabl e Connectors, Undercarri age, Uni versal

Adapter Pl ug

Recommended Wire Feeder Options

LN- 7, LN- 7 GMA, LN- 742, LN- 10, DH- 10, LN- 15, LN- 25,

Cobramati c

Order

K1352- 1 CV- 300 208/ 230/ 460/ 3/ 60

K1352- 2 CV- 300 230/ 460/ 575/ 3/ 60

K1791- 2 CV- 300 208/ 230/ 460/ 3/ 60

(Ready- Pak Package)

Literature

E4.20

Output Input

CV

DC

3

PHASE

60

Hz

NOTE: Cobramati c i s a regi stered trademark of MK Products, Inc.

CV-400

CV-400

Dimensions

Product Product Rated Output Input Current @ H x W x D Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs. (kg)

CV- 400 K1346- 13 230/ 460/ 3/ 60 400A/ 36V/ 100% 77/ 39A 60- 500A 27.5 x 22.2 x 32 383

450A/ 38V/ 60% 80/ 40A 12- 42V (699 x 564 x 813) (174)

K1346- 14

(w/ di ode)

MIG WELDERS

Why i s the CV- 400 one of our most popul ar power

sources? Because i ts a great combi nati on of power,

performance, and versati l i ty. Desi gned pri mari l y for i ndus-

tri al MIG and fl ux- cored appl i cati ons, the CV- 400 del i vers

excel l ent arc stabi l i ty and wel d consi stency. Thi s wel di ng

workhorse i s an outstandi ng choi ce for heavy- duty j obs

wi th materi al s such as mi l d steel , stai nl ess steel , al umi num

and al l oy materi al s.

Processes

MIG, Fl ux- Cored, Gougi ng

Advantage Lincoln

Ful l output control potenti ometer and anal og meters l et

operator accuratel y regul ate power l evel s.

Sol i d state ci rcui try provi des extra l ong l i fe duri ng

repeti ti ve appl i cati ons.

Li ncol ns uni que fi xed i nductance desi gn del i vers

excepti onal arc characteri sti cs.

Opti onal factory i nstal l ed di ode al l ows uti l i zati on of

col d- i nch and sensi ng features of NA- 3, NA- 5, or NA- 5R

automati c feeders.

Connect wi re feeders vi a ei ther 14- pi n MS- type or

termi nal stri p.

Output studs for wel d cabl es.

115V and 42V wi re feeder auxi l i ary power wi th ci rcui t

breaker protecti on.

Internal components, i ncl udi ng wi ndi ngs, recti fi ers and

ci rcui t boards, are coated to protect agai nst the effects of

moi sture and corrosi on!

El ectroni c and thermostati c protecti on from current over-

l oad and excessi ve temperatures. Indi cator l i ght l ets you

know when machi ne i s reset.

Take the hassl e out of orderi ng - Order a Ready- Pak

pre- assembl ed wel di ng package.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Remote Output Control , Remote Control Adapter,

Undercarri age, Jumper Pl ug Ki t

Recommended Wire Feeder Options

LN- 7, LN- 7 GMA, LN- 742, LN- 8, LN- 9, LN- 9 GMA, LN- 10,

DH- 10, LN- 15, LN- 25, LN- 35, NA- 3, NA- 5, NA- 5R,

Cobramati c

Order

K1346- 13 CV- 400 230/ 460/ 3/ 60

K1346- 14 CV- 400 (wi th di ode) 230/ 460/ 3/ 60

K2285- 1 CV- 400 230/ 460/ 3/ 60

(Ready- Pak Package)

Literature

E4.30

www.lincolnelectric.com

28

Output Input

CV

DC

3

PHASE

60

Hz

NOTE: Cobramati c i s a regi stered trademark of MK Products, Inc.

CV-655

CV-655

www.lincolnelectric.com

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs (kg)

K1480- 1 230/ 460/ 3/ 60 94/ 47A

K1480- 5 575/ 3/ 60 38A 70- 815A

K1481- 1 230/ 400/ 3/ 50/ 60 650A/ 44V/ 100% 94/ 54A 13- 44V 27.5 x 22.2 x 38.0 670

CV- 655 K1481- 2 380/ 500/ 3/ 50/ 60 815A/ 44V/ 60% 56/ 43A Max. OCV: (699 x 565 x 965) (304)

K1481- 4 200/ 400/ 3/ 50/ 60 107/ 54A 48V

K1481- 5 415/ 3/ 50/ 60 52A

MIG WELDERS

29

Energy effi ci ency, rel i abi l i ty and excepti onal performance

are what set the CV- 655 apart from the rest. Desi gned

pri mari l y for heavy- duty appl i cati ons, the CV- 655 i s an out-

standi ng choi ce for MIG and fl ux- cored wel di ng on mi l d

steel , stai nl ess steel , al umi num and al l oys.Thi s sturdy,

powerful DC power source handl es CV semi automati c

submerged arc wel di ng and arc gougi ng wi th ease.

Equi pped wi th el ectroni c and thermostati c protecti on, PC

boards wi th bui l t- i n di agnosti cs and sol i d state contactors,

the CV- 655 i s bui l t to l ast.

Processes

MIG, Fl ux- Cored, Submerged Arc, Gougi ng

Advantage Lincoln

Cal i brated output control l ets operator accuratel y regu-

l ate power l evel s.

Li ne vol tage compensati on mai ntai ns wel d consi stency,

even wi th l i ne vol tage changes of 10%.

115- vol t dupl ex receptacl e provi des 20 amps of auxi l i ary

power.

Separate output studs al l ow the operator to sel ect hi gh or

l ow i nductance.

Panel swi tches al l ow operator to change setti ngs at the

power source or wi re feeder.

Sol i d state ci rcui try provi des extra l ong l i fe duri ng

repeti ti ve appl i cati ons.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Di gi tal Meter Ki t, Ai r Fi l ter Ki t, Dual Process Swi tch,

Remote Output Control , Remote Control Adapter,

Undercarri age

Recommended Wire Feeder Options

LN- 7, LN- 7 GMA, LN- 742, LN- 8, LN- 9, LN- 9 GMA, LN- 10,

DH- 10, LN- 15, LN- 23P, LN- 25, LN- 35, NA- 3, NA- 4, NA- 5,

NA- 5R, Cobramati c

Order

K1480- 1 CV- 655 230/ 460/ 3/ 60

K1480- 5 CV- 655 575/ 3/ 60

K1481- 1 CV- 655 230/ 400/ 3/ 50/ 60

K1481- 2 CV- 655 380/ 500/ 3/ 50/ 60

K1481- 4 CV- 655 200/ 400/ 3/ 50/ 60

K1481- 5 CV- 655 415/ 3/ 50/ 60

Literature

E4.40

Output Input

CV

DC

3

PHASE

60

Hz

50

Hz

NOTE: Cobramati c i s a regi stered trademark of MK Products, Inc.

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs (kg)

Peak Current:

K1525- 1 208/ 230/ 460/ 3/ 60 32/ 30/ 16A 0- 450A

Invertec 225A/ 29V/ 60% Background 23.2 x 13.2 x 24.4 117

STT II K1526- 1 200/ 220/ 380/ 415/ 200A/ 28V/ 100% 33/ 30/ 18/ Current: (589 x 336 x 620) (53)

440/ 3/ 50/ 60 17/ 16A 0- 125A

Max. OCV: 85V

K1526- 2 200/ 208/ 380/ 400/ 415

Invertec

STT II

Invertec

STT II

MIG WELDERS

STT Surface Tension Transfer

Ti red of spatter, fumes, burnthrough, or poor fi t- up sl owi ng

down producti vi ty? The revol uti onary STT II power source

can sol ve your wel di ng probl ems by combi ni ng hi gh

frequency i nverter technol ogy wi th advanced Waveform

Control Technol ogy i n pl ace of tradi ti onal short arc MIG

wel di ng. The STT IIs preci se control of the el ectrode cur-

rent duri ng the enti re wel di ng cycl e si gni fi cantl y reduces

fumes, spatter, and gri ndi ng ti me. In addi ti on, the uni t

offers i ndependent control of wi re feed speed and current.

Processes

MIG- STT

Advantage Lincoln

Current i s provi ded i ndependent of wi re feed speed

unl i ke conventi onal machi nes.

Operates wi th l arger di ameter wi res to potenti al l y l ower

el ectrode costs.

Requi res l ess operator ski l l and mi ni mal trai ni ng.

Produces l ess fumes to hel p protect workers and the

envi ronment.

Hot Start control to provi de arc starti ng preci si on.

El i mi nates col d l appi ng on open root j oi nts for pi pe and

pressure vessel s.

Desi gned for opti mum arc performance wi th 100% CO

2

on steel .

Accurate control of heat i nput reduces di storti on and

burnthrough.

Mi ni mal spatter reduces cl eani ng ti me of parts and fi x-

turi ng.

Background tai l out current control s beadshape, penetra-

ti on and the overal l heat i nput.

Peak and Background current LED meters for accurate

procedure setti ng.

Manufactured under a qual i ty system certi fi ed to ISO

9001 requi rements.

Three- year warranty on parts and l abor.

Recommended General Options

Power Source Remote Output Control , Twi st- Mate Cabl e

Connectors, STT Sense Lead Ki t, Inverter and Wi re Feeder

Cart

Recommended Wire Feeder Options

STT- 10, LN- 742, LN- 15

Order

K1525- 1 208/ 230/ 460/ 3/ 60

K1526- 1 200/ 220/ 380/ 415/ 440/ 3/ 50/ 60

K1526- 2 200/ 208/ 380/ 400/ 415/ 3/ 50/ 60

Literature

E4.52

www.lincolnelectric.com

30

Output Input

STT DC

3

PHASE

60

Hz

50

Hz

www.lincolnelectric.com

Rated Output Input Dimensions Net

Product Product Input Current/Voltage/ Current @ Output H x W x D Weight

Name Number Power Duty Cycle Rated Output Range in. (mm) lbs (kg)

K1728- 5 200- 208/ 230/ 380- 350A/ 34V/ 60% 3- ph: 50/ 42/ 28- 26/ 23/ 18 5- 425A

Invertec K1728- 6 415/ 460/ 575/ 3/ 50/ 60 1- ph: 94/ 85/ 54/ 42/ 37 Max 14.8 x 13.3 x 27.9 81

V350- PRO K1728- 7 208/ 230/ 415/ 3- ph: 41- 39/ 36/ 23- OCV: (376 x 338 x 709) (36.7)

K1728- 11 460/ 575/ 1/ 50/ 60 300A/ 32V/ 100% 22/ 19/ 16 80V DC

1- ph: 76/ 69/ 41/ 36/ 31

Invertec V350-PRO

Invertec

V350-PRO

MULTI-PROCESS WELDERS

The Invertec V350- PRO i s a versati l e, mul ti - purpose, mul ti -

process power source thats l i ghtwei ght and portabl e.

Avai l abl e i n constructi on, factory, advanced process and

factory rack model s, the V350- PRO i s capabl e of doi ng

vi rtual l y any j ob, whether i n the shop or on the constructi on

si te. The V350- PRO i s capabl e of sti ck, DC TIG, MIG, Pul sed

MIG

(1)

, fl ux- cored and arc gougi ng, maki ng i t the most

versati l e i nverter power source i n i ts cl ass. And i ts bui l t

tough to handl e the ri gors of harsh envi ronments.

Processes

Sti ck, TIG, MIG, Pul sed

(1)

, Fl ux- Cored, Gougi ng

Advantage Lincoln

Choose the Constructi on Model for economy and l i ght-

wei ght portabi l i ty, the Factory Model for ful l remote

capabi l i ti es, and the Advanced Process Model for pul sed

MIG appl i cati ons.

Al l i nput vol tages and frequenci es are both si ngl e and

three phase rated no output derati ng necessary on