Professional Documents

Culture Documents

HVAC - Duct Construction PDF

HVAC - Duct Construction PDF

Uploaded by

Luis DomdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HVAC - Duct Construction PDF

HVAC - Duct Construction PDF

Uploaded by

Luis DomdCopyright:

Available Formats

HVAC Duct Construction

Bob Wasilewski

Project Manager, Technical Resources

SMACNA

HVAC Duct Construction

Standards

WHAT?

WHY?

HOW?

Today's Program

1

st

2

nd

Edition HVAC-DCS

Review Joints and Limitations

Transverse Joints & Reinforcements

Use of the Pressure Class Tables

Tie Rod Addendum

Documents Preceding 2nd Edition

HVAC-DCS

Low Velocity Systems Duct Manual

First Edition 1959

Second Edition 1963

Third Edition 1967

Low Velocity Duct Construction Standard

1969

Documents Preceding 2nd Edition

HVAC-DCS

Low Pressure Duct Construction Standard

Fifth Edition 1976

High Velocity Duct Systems Manual

First Edition 1965

High Velocity Duct Construction Standards

Second Edition 1969

Documents Preceding 2nd Edition

HVAC-DCS

High Pressure Duct Construction Standards

Third Edition 1975

Duct Liner Application Standard

First Edition 1971

Second Edition 1975

Documents Preceding 2nd Edition

HVAC-DCS

Flexible Duct Installation Standards

First Edition 1979

Second Edition 1980

HVAC Duct Construction Standards --

Metal and Flexible

First Edition 1985

Major Changes from First Edition

GENERAL

Text edited to be more reader-friendly

Reading aids added

Static pressure only as the basis for duct

construction classification -- velocity

levels deleted (Table 1-1)

Major Changes from First Edition

Chapter 7 revised to facilitate use for

equivalent and comparable tests and ratings

Model project specification added

Reminders to designers to show all required

fire, smoke, radiation and volume control

dampers on contract drawings are accented

Major Changes from First Edition

Boiler breeching omitted

Volume damper construction is more

specific

Lead radiation shielding added

Metrics are included

Air terminal runouts and supports are

revised

Major Changes from First Edition

RECTANGULAR DUCT REVISIONS

Negative pressure construction given for

4", 6", and 10" w.g.

Six feet reinforcement schedules added

Reinforcement schedules extended to 120"

width

Major Changes from First Edition

Tie rod alternatives expanded for both

positive and negative pressures

TDC and TDF joint systems included and

rated as T-25a and T-25b joints

T-24a joint added as a modification of T-24

Major Changes from First Edition

Use of 26 gage added for 4", 6" and 10"

pressures

Trapeze hanger tables expanded to cover

the 120" width range

Duct liner pin schedule adjusted

Infrequently used joints (T-4, 8, 17, 18,

19, 20 and 23) omitted

Major Changes from First Edition

Round, Flexible and Oval Duct Revisions

Duct pressure classes revised to be positive

and negative at 2", 4" and 10" w.g.

Crimped joint connection length changed

from 1" to 2"

Rectangular branch taps into round added

for straight or 45 degree lead-in-entry

Major Changes from First Edition

Type 1 reinforcement of oval duct now has

an internal tie rod (based on ASHRAE test

program)

Maximum support spacing for round

flexible duct and connector changed from

10 feet to 5 feet

Additional riser support details are

provided

DUCT SYSTEMS

SIZINGS

FITTINGS, ETC.

FIRE/SMOKE

PROTECTION

CODE

COMPLIANCE

DUCT

CONSTRUCTION

CODE

COMPLIANCE

SMACNA

HVAC-DCS

2

ND

ED. 1995

INSPECTION

CODE

COMPLIANCE

DUCT SYSTEMS

ENGINEER

Design Considerations:

CFM

Static Pressure

Duct Size

Fitting Type

Construction Pressure

Class

CONTRACTOR

Construction Considerations:

Panel Thickness (Gage)

Pressure Class (as specified)

Panel Width/Height

Joint Type/Spacing

Intermediate Reinforcement

Type/Spacing

DEPENDENT VARIABLES

REGULAR DUCTS

+10% +7.5%

Tolerance: Tolerance:

1" on 85"-120"

Class Rating + 25% 3/4" on 25"-84"

Field: 5/8"on 19"-24" 49"-120"

1/2" on 13"-18" W/200 on

Class Rating + 50% 3/8" on 12" Dn. 1/4" on 48" w.

Lab: Sheet: Joint and Reinf.

Maximum Test

Pressure

Maximum Deflection

Duct Systems

Used for the movement of air in

HVAC/Exhaust systems

Ducts are classified based on maximum

operating pressure

0.5" w.g. positive or negative

1.0" w.g. positive or negative

2.0" w.g. positive or negative

Duct Systems (Continued)

Ducts are classified based on maximum

operating pressure

3.0" w.g. positive or negative

4.0" w.g. positive or negative

6.0" w.g. positive or negative

10.0" w.g. positive or negative

TABLE 1-2

STANDARD DUCT SEALING REQUIREMENTS

EXAMPLE 1

Duct Size 24" x 24"

Pressure Class 2" w.g.

Sheet Stock

Joints/Reinforcements 8 ft / 4 ft

Standing S

EXAMPLE 2

Duct Size 42" x 24"

Pressure Class 3" w.g.

5 ft Coil Line

Joints/Reinforcements 5 ft / 2 ft

TDC or TDF

MIDPANEL TIE ROD (MPT)

" w.g. - 6" w.g.

37" - 96"

Duct Dimension

Rectangular Duct

Mid Panel Tie Rod Addendum

Joints All

Tie Rods Threaded Rod or

Tubing/Conduit with Threaded Insert

Additional Application Tables,

Qualifications and Reader Aids Included

FIGURE 1-3 TIE ROD ATTACHMENTS

FIGURE 1-4 TRANSVERSE (GIRTH) JOINTS

FIGURE 1-4 TRANSVERSE (GIRTH) JOINTS

FIGURE 1-4A SPECIAL JOINT PROFILES

FIGURE 1-5 LONGITUDINAL SEAMS

RECTANGULAR DUCT

TABLE 1-24 UNREINFORCED DUCT (WALL THICKNESS)

TABLE 1-25

T-1 FLAT DRIVE ACCEPTED AS REINFORCEMENT

FIGURE 1-7 UNREINFORCED DUCT

FIGURE 1-8 CROSSBROKEN DUCT & BEADED DUCT

FIGURE 1-9 DUCT REINFORCED ON TWO SIDES

FIGURE 1-10 DUCT REINFORCED ON ALL SIDES

FIGURE 1-12 DUCT OVER 120" (3048 MM) WIDE

FIGURE 1-15 CORNER CLOSURES - FLANGES

FIGURE 2-22 DUCT LINER INTERRUPTION

TABLE 3-2A ROUND DUCT GAGE UNREINFORCED POSITIVE

PRESSURE

TABLE 3-2B ROUND DUCT GAGE NEGATIVE PRESSURE

FIGURE 3-1 SEAMS ROUND DUCT AND FITTINGS

FIG. 3-2 TRANSVERSE JOINTS ROUND DUCT

FIGURE 3-6 FLAT OVAL DUCTS

FIGURE 3-9 FLEXIBLE DUCT SUPPORTS

FIGURE 3-10 FLEXIBLE DUCT SUPPORTS

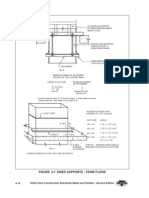

TABLE 4-1 RECTANGULAR DUCT HANGERS MIN. SIZE

TABLE 4-2 MINIMUM HANGER SIZES FOR ROUND DUCT

FIGURE 4-4 LOWER HANGER ATTACHMENTS

Questions

&

Answers

You might also like

- Smacna Cad Standard-Second EditionDocument149 pagesSmacna Cad Standard-Second Editionmimeow100% (2)

- ASHRAE Duct DesignDocument13 pagesASHRAE Duct DesignJose Darwin Margate100% (2)

- Duct ConstructionDocument163 pagesDuct ConstructionWarren Bryer100% (11)

- Smacna Duct Designfundamentals PDFDocument151 pagesSmacna Duct Designfundamentals PDFandi nainggolan100% (1)

- Smacna Fire DamperDocument89 pagesSmacna Fire Dampersmartayaz1987100% (1)

- Rectangular Duct & FittingsDocument26 pagesRectangular Duct & Fittingsmakmak90% (1)

- SMACNA Successful Building Project CoordinationDocument27 pagesSMACNA Successful Building Project CoordinationMohammed Hassan Mohiuddin Khan50% (2)

- Hvac Duct Constrction Examples: Ashrae January 26, 2009 Mark Terzigni Project Manager SmacnaDocument54 pagesHvac Duct Constrction Examples: Ashrae January 26, 2009 Mark Terzigni Project Manager SmacnaAdhanom G.No ratings yet

- Chilled Water PipingDocument34 pagesChilled Water Pipingapi-2599951798% (50)

- DuctDocument60 pagesDuctdenizkund100% (5)

- Inspection of Double Tube Sheet Exch - Presentation1Document37 pagesInspection of Double Tube Sheet Exch - Presentation1Jignesh Pandya100% (1)

- HVAC Duct Construction StandardsDocument308 pagesHVAC Duct Construction StandardsGuilherme Valadares100% (1)

- High Velocity Duct Design Tips by TraneDocument50 pagesHigh Velocity Duct Design Tips by TraneInventor SolidworksNo ratings yet

- Piping Code ComparisonDocument5 pagesPiping Code ComparisonAndy Hakim83% (6)

- SmacnaDocument32 pagesSmacnaamo3330100% (14)

- Good Better Best Duct DesignDocument67 pagesGood Better Best Duct DesignNiong David100% (1)

- SMACNA Round Industrial Duct Construction Standards - Chapter 2 Industrial Duct ApplicationsDocument2 pagesSMACNA Round Industrial Duct Construction Standards - Chapter 2 Industrial Duct ApplicationsMinh Tran50% (2)

- استاندارد SMACNADocument310 pagesاستاندارد SMACNASeyed100% (1)

- City Gas Distribution Basics 1584287870 PDFDocument60 pagesCity Gas Distribution Basics 1584287870 PDFDeepak SharmaNo ratings yet

- Smacna Duct ConstructionDocument23 pagesSmacna Duct ConstructionKaustubh Bidkar100% (2)

- Duct Systems Design GuideDocument186 pagesDuct Systems Design GuideIbrahem Salameh100% (6)

- Smacna Cad StandardDocument149 pagesSmacna Cad Standardilm11280088% (8)

- Eh Price Flow FactorsDocument46 pagesEh Price Flow FactorsKyle W. Nelson100% (2)

- SMACNA Duct Construction Standards - 3rd Edition - 2005Document396 pagesSMACNA Duct Construction Standards - 3rd Edition - 2005Eric E' Sandoval A100% (7)

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70No ratings yet

- Duct Design and InstallationDocument61 pagesDuct Design and InstallationOlanrewaju Abyss100% (5)

- Vent&BlowdownCatalog PDFDocument19 pagesVent&BlowdownCatalog PDFktsnl100% (1)

- Piping Layout UDLDocument24 pagesPiping Layout UDLLegend Anbu100% (1)

- Fire Damper Installation 2Document9 pagesFire Damper Installation 2Mirza Mohammed Yousuf BaigNo ratings yet

- SMACNA Duct ConstructionDocument2 pagesSMACNA Duct ConstructionSaqib_Manzoor__9876100% (8)

- Manual For Duct Work SpecificationsDocument18 pagesManual For Duct Work SpecificationsAmos OchienoNo ratings yet

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsDocument4 pagesA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- Rectangular Duct & Fittings: Specifications ForDocument12 pagesRectangular Duct & Fittings: Specifications ForEric MagnayeNo ratings yet

- Duct Construction ChartDocument23 pagesDuct Construction ChartMattNo ratings yet

- Heat ExchangersDocument49 pagesHeat Exchangersbluelion_19100% (1)

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- #2 Pipes Class & Thickness (Handout)Document19 pages#2 Pipes Class & Thickness (Handout)farhanNo ratings yet

- Reasonable VelocityDocument4 pagesReasonable VelocityRaithab IlsurNo ratings yet

- Acca Manual J and D Mechanical RequirementsDocument1 pageAcca Manual J and D Mechanical Requirementsmsmith6477No ratings yet

- ANSI/ASHRAE/IESNA Standard 90.1-2004: U.S. Department of Energy Building Energy Codes ProgramDocument222 pagesANSI/ASHRAE/IESNA Standard 90.1-2004: U.S. Department of Energy Building Energy Codes Programcuccu107100% (2)

- Duct & Vent EngineeringDocument70 pagesDuct & Vent Engineeringtop20202080% (5)

- TWI CSWIP 3.2 WIS 10 Senior Welding Inspection Calibration: World Centre For Materials Joining TechnologyDocument36 pagesTWI CSWIP 3.2 WIS 10 Senior Welding Inspection Calibration: World Centre For Materials Joining TechnologyGaapchuNo ratings yet

- Hydro Testing ProcedureDocument12 pagesHydro Testing ProcedureGaapchuNo ratings yet

- Submarine Pipeline Hydraulic Design, Internal Pressure Design & Material SelectionDocument23 pagesSubmarine Pipeline Hydraulic Design, Internal Pressure Design & Material Selectionjiangqi75100% (1)

- Smacna Duct LeakageDocument3 pagesSmacna Duct Leakageanton7786No ratings yet

- ANSI-SMACNA 2006 HvacDuctStandardsDocument64 pagesANSI-SMACNA 2006 HvacDuctStandardsErica Morrison100% (1)

- Gen 253 Dep 31.38.01.11-Gen., Section 3.5Document5 pagesGen 253 Dep 31.38.01.11-Gen., Section 3.5vermaakash220% (1)

- AccaDocument38 pagesAccawwe_himanshuNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Smacna StandardsDocument2 pagesSmacna StandardsJoão Cavalcanti50% (6)

- Ul555 555S 702 PDFDocument2 pagesUl555 555S 702 PDFRiaz ahmed100% (2)

- Spec Pe Pipe Tubing Fittings WaterDocument12 pagesSpec Pe Pipe Tubing Fittings WatersabahiraqNo ratings yet

- Heat ExchangersDocument14 pagesHeat ExchangersPrateek JainNo ratings yet

- SSPC CS 29 PDFDocument5 pagesSSPC CS 29 PDFGaapchu100% (1)

- 1 Are Series SCD RCD Cat v08Document20 pages1 Are Series SCD RCD Cat v08adils1No ratings yet

- Federal Skilled Worker Program Immigration-Assessment-Form 1Document9 pagesFederal Skilled Worker Program Immigration-Assessment-Form 1ThomasNo ratings yet

- Duct ConstructionDocument75 pagesDuct ConstructionJavier VespaNo ratings yet

- A Review of The Revisions To API 14.3 - AGA 3 - Part 2, DifferentDocument6 pagesA Review of The Revisions To API 14.3 - AGA 3 - Part 2, DifferentmaserrasNo ratings yet

- RE TEC 008 Mechanical Compliance Sheet HVACDocument3 pagesRE TEC 008 Mechanical Compliance Sheet HVACramis0007No ratings yet

- 1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutDocument17 pages1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutSupriadi TansiNo ratings yet

- Technical Info (1) - Hose and FittingDocument24 pagesTechnical Info (1) - Hose and FittingJohn MaNo ratings yet

- Ruskin FlowbarDocument28 pagesRuskin Flowbarcoach joeNo ratings yet

- 6 Annexure 6 Technical Specification of Piping-2021-07!07!04!12!52Document23 pages6 Annexure 6 Technical Specification of Piping-2021-07!07!04!12!52mech1kingNo ratings yet

- Jet Nozzles DUKDocument14 pagesJet Nozzles DUKKerx EndranoNo ratings yet

- SSPC CS 36Document5 pagesSSPC CS 36Gaapchu0% (1)

- Notification: Petroleum and Natural Gas Regulatory BoardDocument9 pagesNotification: Petroleum and Natural Gas Regulatory BoardGaapchuNo ratings yet

- STD 184 PDFDocument27 pagesSTD 184 PDFGaapchuNo ratings yet

- Jaso C103 1995 (En)Document11 pagesJaso C103 1995 (En)GaapchuNo ratings yet

- Crane Code of PracticeDocument67 pagesCrane Code of PracticeGaapchuNo ratings yet

- Guidelines For Implementation of The Inspection, Measuring and Test Equipment Requirements in Reference To The Iso 9000:2000 Series StandardsDocument11 pagesGuidelines For Implementation of The Inspection, Measuring and Test Equipment Requirements in Reference To The Iso 9000:2000 Series StandardsGaapchuNo ratings yet

- Project We Like: Bhanu Pratap Singh ADMISSION NO.-HPGD/AP19/0788. Batch - April 2019Document57 pagesProject We Like: Bhanu Pratap Singh ADMISSION NO.-HPGD/AP19/0788. Batch - April 2019Gaapchu100% (1)

- RT InterpretationDocument10 pagesRT InterpretationoomoomNo ratings yet

- Property Metric Unit Standard Unit: Properties of Saturated Steam - SI UnitsDocument18 pagesProperty Metric Unit Standard Unit: Properties of Saturated Steam - SI UnitsGaapchuNo ratings yet

- Boiler & Pressure Vessel Safety: To Provide Guidance For The Safe Operation and Maintenance of Pressure VesselsDocument11 pagesBoiler & Pressure Vessel Safety: To Provide Guidance For The Safe Operation and Maintenance of Pressure VesselsGaapchu100% (2)