Professional Documents

Culture Documents

Adv 1 2

Uploaded by

Quan Nguyen HaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adv 1 2

Uploaded by

Quan Nguyen HaiCopyright:

Available Formats

Compressor and Pump Curves 1

1

Compressor and Pump Curves

1999 - AEA Technology plc - All Rights Reserved.

ADV 1_2.pdf

2 Compressor and Pump Curves

2

Workshop

In this module, compressor and pump curves will be used to model the

behaviour of simulated compressors and pumps. Using curves to

model these unit operations allows HYSYS to accurately simulate actual

plant equipment.

Learning Objectives

Once you have completed this module, you will be able to:

Specify and attach head and efficiency curves to compressors

Use single and multiple curves to model compressors

Attach head curves to pumps

Accurately model existing plant equipment with HYSYS

Prerequisites

Before beginning this module, you need to know how to:

Define and import a fluid package

Add streams and unit operations to the PFD

Compressor and Pump Curves 3

3

Compressor Curves

Using compressor curves in your HYSYS simulation allows you to

accurately model existing plant equipment. You can determine if an

existing compressor is able to meet the specifications of your process.

Using compressor curves allows HYSYS to calculate heads and

efficiencies that are dependant on the flow rate. If the flow rate through

the compressor is known to be constant, a single flow rate and

efficiency can be supplied. If, however, the flow rate is expected to

change, using a compressor curve will allow HYSYS to calculate new

heads and efficiencies based on the current flow rate.

This results in greater accuracy in the simulation, and allows HYSYS to

more closely model actual plant equipment.

Defining the Fluid Package

Before we begin any simulation in HYSYS, we must first define the

appropriate fluid package.

1. Start a New Case and add a Fluid Package.

2. Select the Sour PR EOS package

3. Add the following components: H

2

O, H

2

S, CO

2

, C1, C2, C3, i-C4,

and n-C4.

4 Compressor and Pump Curves

4

Installing a Stream

1. Add a Material Steam to the PFD with the following data:

In This Cell... Enter...

Name Feed

Temperature 70

o

C (160

o

F)

Pressure 130 kPa (19 psia)

Molar Flow 500 kgmole/hr (1100 lbmole/hr)

Mole Fraction [H

2

O] 0.24

Mole Fraction [H

2

S] 0.07

Mole Fraction [CO

2

] 0.06

Mole Fraction [C1] 0.04

Mole Fraction [C2] 0.11

Mole Fraction [C3] 0.25

Mole Fraction [i-C4] 0.08

Mole Fraction [n-C4] 0.15

Compressor and Pump Curves 5

5

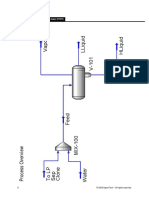

Adding the Compressor

1. Add a Compressor to the PFD.

2. Enter the following information on the Connections page:

3. On the Parameters page, ensure that the Polytropic and Adiabatic

efficiency boxes both read <empty>.

These values must read <empty> because the efficiencies will be

calculated from the compressor curves, and defining the same value in

two places will always result in a consistency error.

In This Cell... Enter...

Inlet Stream Feed

Outlet Stream Outlet

Energy Stream Comp Duty

Compressor button

6 Compressor and Pump Curves

6

4. On the Curve page, select the Adiabatic radio button in the

Efficiency group. Press the Add Curve button, and enter the data

as shown here:

5. Close the above view and activate Curve-1 on the Curves page.

Ensure that the Enable Curves box on the Curves page is

checked.

Be sure to use the correct units

for the curve.

We do not need to enter a

compressor speed because we

are only entering one curve.

However, multiple curves with

different speeds can be used.

Compressor and Pump Curves 7

7

6. The pressure of the outlet stream can be seen on the Work Sheet

page, or you can choose Show Table when object-inspecting the

outlet stream on the PFD. The compressors efficiencies can be

found on the Results page.

Optional Exercise

It is desired to have an outlet pressure of 300 kPa (44 psia).

Use an Adjust operation with the following information:

What is the Outlet Pressure of the compressor? __________

What is the Adiabatic Efficiency? __________

The Polytropic Efficiency?___________

In This Cell... Enter...

Adjusted Variable Feed - Molar Flow

Target Variable Outlet - Pressure

Specified Target Value 300 kPa (44 psia)

Step Size 5 kgmole/hr (10 lbmole/hr)

Iterations 50

What is the Molar Flow rate if the Outlet Pressure is set at

300 kPa (44 psia)? __________

Can you think of an easier way of doing this? __________

How? __________

Save your case!

8 Compressor and Pump Curves

8

Multiple Curves

Typically, industrial compressors are able to run at multiple speeds

depending on the current demand. HYSYS allows users to enter

multiple compressor curves that each represent a specified speed.

Once the curves are entered, any compressor speed can be specified

and the head and efficiency are calculated automatically.

In this exercise, a Natural Gas compressor will be examined to

determine the outlet pressure of a multi-speed compressor.

1. Begin a new case and import the fluid package Nat-Gas.fpk from

the diskette provide with this course.

2. Add a new stream to the PFD with the following data:

3. Add a Compressor to the PFD with this data:

4. Delete the default Adiabatic Efficiency value on the Parameters

page. Again, the efficiency will be calculated from the compressor

curves.

In This Cell... Enter...

Name LP Gas

Temperature 10

o

C (50

o

F)

Pressure 1700 kPa (245 psia)

Molar Flow Rate 1500 kgmole/hr (3300 lbmole/hr)

Comp. Mole Fraction - C1 0.99

Comp. Mole Fraction - C2 0.002

Comp. Mole Fraction - C3 0.0005

Comp. Mole Fraction - N2 0.005

Comp. Mole Fraction - CO2 0.0025

In This Cell... Enter...

Inlet LP Gas

Outlet HP Gas

Energy Comp Duty

Compressor and Pump Curves 9

9

5. Add the four curves shown below to the compressor. Note that

the curves have been supplied in Field units. (If you are using SI

units, you must change the Flow and Head units to those shown

here before you enter the curve data).

Note that compressor speeds

must be entered here as

multiple curves are being

used.

10 Compressor and Pump Curves

10

The plots for efficiency and

head versus flow can be seen

by pressing the Plot Curves

button on the Curves page.

Compressor and Pump Curves 11

11

6. Ensure that all of the curves are activated, and the Enable Curves

box is checked. These curves are polytropic curves, therefore the

Polytropic radio button must be checked in the Efficiency group

on the Curves page.

7. On the Curves page, enter a speed of 11 000 per min.

Optional Exercise

1. Delete the specified compressor speed of 11 000 per minute.

2. Enter a pressure of 5000 kPa (725 psia) for the HP Gas stream.

3. HYSYS will automatically calculate the compressor speed needed

to meet this outlet pressure.

What is the pressure of the HP Gas stream? __________

What is the compressor speed needed to achieve the

specified outlet pressure? __________

What are the Adiabatic and Polytropic efficiencies of the

compressor under these conditions? __________

What is the temperature of the HP Gas? __________

Instead of entering all of the

curve data, open the HYSYS

case Comp_Shortcut.hsc on

the disk supplied with this

module, and begin on step 6.

Save your case!

12 Compressor and Pump Curves

12

Pump Curves

As with compressor curves, pump curves are used to allow HYSYS to

accurately model existing pumps. Pump curves allow the pressure rise

across the pump to be dependent on the flow rate of liquid.

The pump curves are entered into HYSYS using a form different than

the form used for compressor curves. With pump curves the

coefficients of an expression, up to the fifth order, are entered into

HYSYS rather than the actual data points.

Defining the Fluid Package

1. Begin a new case and select the Peng Robinson EOS package.

2. Add the components n-Hexane, n-Heptane, and n-Octane.

Installing a Stream

Add a new stream to the PFD and enter the following information:

The coefficients can be

obtained from a spreadsheet

program capable of nonlinear

regression, such as EXCEL, or

may be supplied by the pumps

manufacturer.

In This Cell... Enter...

Name LP Mixture

Temperature 25

o

C (77

o

F)

Pressure 120 kPa (18 psia)

Liquid Volume Flow 500 m

3

/hr (76,000 BPD)

Comp. Mass Fraction [Hexane] 0.60

Comp. Mass Fraction [Heptane] 0.30

Comp. Mass Fraction [Octane] 0.10

Compressor and Pump Curves 13

13

Adding the Pump

1. Add a Pump to the PFD and enter the following information:

2. On the Curves page, enter the following data:

In This Cell... Enter...

Inlet LP Mixture

Outlet HP Mixture

Energy Pump Duty

Efficiency (Parameters Page) 75 %

Pump button

In This Cell... Enter...

Coefficient A 3000

Coefficient B -2.0

Coefficient C -0.005

All Other Coefficients 0

Units for Head m

Flow Basis Act. Vol. Flow

Units for Flow m

3

/hr

14 Compressor and Pump Curves

14

3. Ensure that the Activate Curves box is checked.

4. The pressure of the product stream can be seen on the Worksheet

tab.

What is the outlet pressure of the pump? __________

The pump sales representative, who supplied the curve

data, guaranteed an outlet pressure of 5000 kPa (725 psia)

at the specified flow rate. Should you fill out the purchase

order? __________

Save your case!

You might also like

- 2 Stage CompressionDocument18 pages2 Stage CompressionSyed Muzamil Ahmed100% (3)

- Expanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943Document14 pagesExpanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943TayebASherifNo ratings yet

- Column For New OnesDocument8 pagesColumn For New OnesSpicyNo ratings yet

- Compressor CurvesDocument10 pagesCompressor CurvesSyed Muzamil AhmedNo ratings yet

- 08 - Column Pressure ReliefDocument10 pages08 - Column Pressure ReliefjeedanNo ratings yet

- 1.3.5 PreHeat TrainDocument20 pages1.3.5 PreHeat TrainflowealthNo ratings yet

- Introduction To HYSYS Steady StateDocument22 pagesIntroduction To HYSYS Steady StatebehnamhfNo ratings yet

- Simulation of Unit Operations With HYSYSDocument5 pagesSimulation of Unit Operations With HYSYSĐậu Bắp50% (2)

- Chemical Engineering 422 Simulation With Hysys: NotesDocument9 pagesChemical Engineering 422 Simulation With Hysys: NotesNoor Ul HaqNo ratings yet

- 01 GettingStartedDocument34 pages01 GettingStartedRyan GonzalesNo ratings yet

- Crude Tower Simulation-HYSYS v8.6Document42 pagesCrude Tower Simulation-HYSYS v8.6EstrellaNo ratings yet

- Using Calc LevelsDocument16 pagesUsing Calc LevelsSyed Muzamil Ahmed100% (1)

- D. Reactions in HYSYS - NewDocument12 pagesD. Reactions in HYSYS - NewRafael FaioliNo ratings yet

- 1.3.10 Optimization Crude ColumnDocument12 pages1.3.10 Optimization Crude ColumnflowealthNo ratings yet

- Aspen HYSYS Task Sheet PDFDocument8 pagesAspen HYSYS Task Sheet PDFIbrahim Ben AmeurNo ratings yet

- Appliation Example Hydrate InhibitionDocument21 pagesAppliation Example Hydrate Inhibitionreclatis14100% (1)

- 1.3.9 Rating Heat ExchangerDocument18 pages1.3.9 Rating Heat ExchangerMelva NainggolanNo ratings yet

- Self Guided Demo - Aspen Shell and Tube Exchanger V8.8Document45 pagesSelf Guided Demo - Aspen Shell and Tube Exchanger V8.8HarySetiyawanNo ratings yet

- 02 PropaneRefrigerationLoopDocument26 pages02 PropaneRefrigerationLoopChristian ChineduNo ratings yet

- 8 PDFDocument8 pages8 PDFNicandroGonzalesNo ratings yet

- A-Extensions in HYSYSDocument4 pagesA-Extensions in HYSYSSyed Muzamil AhmedNo ratings yet

- Jump Start - Multiple Valve Analysis in Aspen HYSYS and Aspen Plus - TempDocument16 pagesJump Start - Multiple Valve Analysis in Aspen HYSYS and Aspen Plus - TempphantanthanhNo ratings yet

- Dynamic SimulationDocument22 pagesDynamic SimulationUsama IqbalNo ratings yet

- Simulation Reciprocating Compressor in HYSYSDocument4 pagesSimulation Reciprocating Compressor in HYSYSLenaldy Nuari GarnokoNo ratings yet

- Hysyssimulation 150728103911 Lva1 App6891Document161 pagesHysyssimulation 150728103911 Lva1 App6891Mohamed RjebNo ratings yet

- Advanced Recycle Operations 1Document44 pagesAdvanced Recycle Operations 1Kajer quemarNo ratings yet

- 11-4005 HYSYS Acid Gas Cleaning JSG RefreshDocument16 pages11-4005 HYSYS Acid Gas Cleaning JSG Refresh1youb tvNo ratings yet

- AspenHYSYSRefiningV7 2 OpsDocument478 pagesAspenHYSYSRefiningV7 2 Opsnguyennha1211100% (1)

- The HYSYS SpreadsheetDocument10 pagesThe HYSYS SpreadsheetSyed Muzamil AhmedNo ratings yet

- TASC Evaluation of A Heat ExchangerDocument6 pagesTASC Evaluation of A Heat ExchangerJesus Andres SuarezNo ratings yet

- Aspen HysysDocument314 pagesAspen HysysAntonio VargasNo ratings yet

- 01 GettingStartedInSteadyStateDocument20 pages01 GettingStartedInSteadyStatetaeebNo ratings yet

- Model A Refrigerated Gas Plant Workshop: ObjectiveDocument25 pagesModel A Refrigerated Gas Plant Workshop: Objectivemiri-256No ratings yet

- Advanced Simulation Case Using HysysDocument232 pagesAdvanced Simulation Case Using HysysridhajamelNo ratings yet

- Atmospheric Crude ColumnDocument19 pagesAtmospheric Crude ColumnYonathan ArevaloNo ratings yet

- AT-05197 - HYSYS - Study Guide - 2 PDFDocument8 pagesAT-05197 - HYSYS - Study Guide - 2 PDFahmedNo ratings yet

- Gravity Separator Fundamentals and DesignDocument29 pagesGravity Separator Fundamentals and Designmatrix69No ratings yet

- Transitioning From Steady State To Dynamics 1Document24 pagesTransitioning From Steady State To Dynamics 1Roger Jhosmar Soliz ArispeNo ratings yet

- Aspen HYSYS Compressor Surge Analysis Feature TutorialDocument23 pagesAspen HYSYS Compressor Surge Analysis Feature TutorialVu Tran100% (1)

- Compressor and Pump Curves 1Document14 pagesCompressor and Pump Curves 1Francis Londoño CarrizoNo ratings yet

- Hysys Class 5Document5 pagesHysys Class 5Salim ChohanNo ratings yet

- 01 Getting StartedDocument32 pages01 Getting StartedSufyan KhanNo ratings yet

- Column SizingDocument16 pagesColumn SizingSyed Muzamil Ahmed100% (9)

- Petroleum Refinery Engineering (CHL 794) Department of Chemical Engineering, Iitd Tutorial Sheet - 4Document15 pagesPetroleum Refinery Engineering (CHL 794) Department of Chemical Engineering, Iitd Tutorial Sheet - 4'Tuan Syafiq'No ratings yet

- Advanced Process Modeling Using HYSYSDocument282 pagesAdvanced Process Modeling Using HYSYSnguyennha121175% (4)

- HYSYS Tutorial PDFDocument282 pagesHYSYS Tutorial PDFpanduNo ratings yet

- Chlorobenzene Plant TutorialDocument21 pagesChlorobenzene Plant Tutorialdjona lokimaNo ratings yet

- Tutorial 5Document6 pagesTutorial 5Hafiz Mudaser AhmadNo ratings yet

- Manual (Simulation)Document17 pagesManual (Simulation)Asad RazaNo ratings yet

- TUTORIAL DE COMPRESI Ôn - HYSYS PDFDocument18 pagesTUTORIAL DE COMPRESI Ôn - HYSYS PDFShirley Hernandez JimenezNo ratings yet

- Construct A Pre-Heat Train Model Workshop: ObjectiveDocument26 pagesConstruct A Pre-Heat Train Model Workshop: Objectivemiri-256No ratings yet

- Reboiled AbsorberDocument22 pagesReboiled AbsorberAsmaa Harraz0% (2)

- H00413783LAB3Document8 pagesH00413783LAB3Huda AlkhouriNo ratings yet

- Hysys Liquid PumpingDocument8 pagesHysys Liquid PumpingEkundayo JohnNo ratings yet

- Final Project ReportDocument15 pagesFinal Project Reportwhãts brøNo ratings yet

- HYSYS Training 2013Document27 pagesHYSYS Training 2013Kokil JainNo ratings yet

- Pms Lab 2Document2 pagesPms Lab 2Uzair AftabNo ratings yet

- 04 NGLFractionationTrainDocument20 pages04 NGLFractionationTraingerbasio100% (1)

- Asad 3Document6 pagesAsad 3Asad RazaNo ratings yet

- 04 ColumnDynamicsDocument18 pages04 ColumnDynamicsabhmarsNo ratings yet

- Bio EthanolDocument303 pagesBio EthanolSyed Muzamil Ahmed100% (2)

- A-Extensions in HYSYSDocument4 pagesA-Extensions in HYSYSSyed Muzamil AhmedNo ratings yet

- The HYSYS SpreadsheetDocument10 pagesThe HYSYS SpreadsheetSyed Muzamil AhmedNo ratings yet

- Using Calc LevelsDocument16 pagesUsing Calc LevelsSyed Muzamil Ahmed100% (1)

- Adv 8 1Document10 pagesAdv 8 1Micu Ionut BogdanNo ratings yet

- Reactions With HYSYSDocument16 pagesReactions With HYSYSSyed Muzamil AhmedNo ratings yet

- Column SizingDocument16 pagesColumn SizingSyed Muzamil Ahmed100% (9)

- The HYSYS SpreadsheetDocument16 pagesThe HYSYS SpreadsheetSyed Muzamil Ahmed67% (6)

- Rating Heat ExchangersDocument16 pagesRating Heat ExchangersSyed Muzamil Ahmed100% (1)

- 07 Drawer RunnersDocument20 pages07 Drawer RunnersngotiensiNo ratings yet

- Structural Evaluation TechniquesDocument6 pagesStructural Evaluation TechniquesMohan NaikNo ratings yet

- Boiler Efficiency PresentationDocument13 pagesBoiler Efficiency PresentationAhmad Sabree Abdul BasitNo ratings yet

- Opc Da Client ManualDocument29 pagesOpc Da Client ManualantoNo ratings yet

- Tafl KCS 402 Cia-I 2019-20Document2 pagesTafl KCS 402 Cia-I 2019-20vikNo ratings yet

- Nice Neotech - Opera Plus Warmer 5000 - 6Document1 pageNice Neotech - Opera Plus Warmer 5000 - 6David Gnana DuraiNo ratings yet

- KKC Model Number System2Document3 pagesKKC Model Number System2zayerirezaNo ratings yet

- PDS Example Collection 24-01-11 - Open PDFDocument52 pagesPDS Example Collection 24-01-11 - Open PDFMichael GarrisonNo ratings yet

- 2008 MuchiriDocument20 pages2008 MuchiriBushra AzharNo ratings yet

- Flight Inspection of GAST D Approach and Taxi Guidance Systems - v1Document10 pagesFlight Inspection of GAST D Approach and Taxi Guidance Systems - v1Olivier LaylyNo ratings yet

- Norma Astm d5731 PLTDocument6 pagesNorma Astm d5731 PLTrodriahumNo ratings yet

- Unit 9: Areas and PerimetersDocument22 pagesUnit 9: Areas and PerimetersSanchit GargNo ratings yet

- 10 Detection of Signals in NoiseDocument20 pages10 Detection of Signals in NoisekirankumarrathNo ratings yet

- Chapter OverviewDocument57 pagesChapter OverviewWajiha SharifNo ratings yet

- Breaker King Obsolete Book PDFDocument30 pagesBreaker King Obsolete Book PDFPatrick OlmosNo ratings yet

- User AgentDocument2 pagesUser AgenthuongNo ratings yet

- C Programming Board Solve PDFDocument12 pagesC Programming Board Solve PDFEstiak Hossain ShaikatNo ratings yet

- Chapter 1Document10 pagesChapter 1Moon LytNo ratings yet

- 10th Class-Maths Text Book-NewDocument400 pages10th Class-Maths Text Book-NewVishnu Muddasani100% (1)

- 05 - A Statistical Analysis of Body Measurements of Filipino WomenDocument15 pages05 - A Statistical Analysis of Body Measurements of Filipino WomenJenberrose G TrelinskiNo ratings yet

- Pre Calculus ExamDocument37 pagesPre Calculus Exammoncarla lagon100% (1)

- Fork LiftDocument4 pagesFork Lifttamer goudaNo ratings yet

- Certification Authorities Software Team (CAST) Position Paper CAST-30Document12 pagesCertification Authorities Software Team (CAST) Position Paper CAST-30Adeen KhanNo ratings yet

- FSX Cessna 172SP OldDocument4 pagesFSX Cessna 172SP Oldaccgh5No ratings yet

- Pedestrian Volume Studies: A Case Study in The City of GothenburgDocument80 pagesPedestrian Volume Studies: A Case Study in The City of GothenburgPaula A. FigueroaNo ratings yet

- CONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Document4 pagesCONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Ronny HasanNo ratings yet

- Inertia FormulasDocument4 pagesInertia FormulasLoysa Agtarap MataNo ratings yet

- Weather ForecastsDocument5 pagesWeather ForecastsGianina MihăicăNo ratings yet

- 2009 06 02 Library-Cache-LockDocument9 pages2009 06 02 Library-Cache-LockAbdul WahabNo ratings yet

- Exploit Writing Tutorial Part 1 - Stack Based Overflows - Corelan TeamDocument54 pagesExploit Writing Tutorial Part 1 - Stack Based Overflows - Corelan Teamdamir_krstanovicNo ratings yet