Professional Documents

Culture Documents

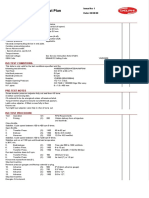

01EJ2000

Uploaded by

ForteLubCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01EJ2000

Uploaded by

ForteLubCopyright:

Available Formats

kg/cm

2

mm

INJECTION PUMP TEST SPECIFICATIONS

INJECTION PUMP

ENGINE TYPE

MANUFACTURER

VEHICLE MODEL

Rated Voltage

Pump Select Switch No. (ECD Controller)

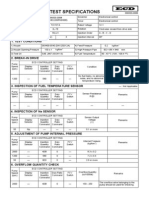

1. TEST CONDITIONS

1) Nozzle

2) Nozzle Opening Pressure

3) Test Oil

4) Feed Pressure

5) High Pressure Pipe

6) Fuel Temperature

2. BREAK-IN DRIVE

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Injection

Quantity

Command

Duty Ratio

Command

FCV Switch

Condition Remarks

No fuel leaks, no

abnormal noise,

and no abnormal

temperature rising.

3. INSPECTION OF FUEL TEMPERATURE SENSOR

Sensor Output

Voltage

(V)

4. INSPECTION OF Ne SENSOR

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Injection

Quantity

Command

Duty Ratio

Command

FCV Switch

Remarks

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Injection

Quantity

Command

Duty Ratio

Command

FCV Switch

Remarks

5. ADJUSTMENT OF PUMP INTERNAL PRESSURE

Internal Pressure

(kg/cm

2

)

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Injection

Quantity

Command

Duty Ratio

Command

FCV Switch

Remarks

Dimension KF (mm) Dimension K (mm)

Injection Order Injection Interval

kg/cm

2

Governor Type

Rotation

Timer

096500-2000

096500-2000 (VE4/10E2400RND200) TOYOTA

2C-TE CORONA

Electronic control Electronic control

A - B - C - D 90

Clockwise viewed from drive side 14 V

5.40 0.10 3.30 0.10

7

093400-2370 (DN12SD12A)

150 2

SAE J967 (ISO4113)

0.2

2 6 840

40 - 43 C (104 - 109.4 F)

1200 SPEED Less than 50B Drive more than 5 minutes.

Fuel

Temperature

1.85 1.5

50 Np 0.1 or more

2000

100

SPEED

SPEED

430

595

0

0

8.75 0.15

2.00 or more

By the regulating valve

For Hartridge AVM Test Benches

2003.03.20

Sensor Resistance

(k )

Target Quantity

AVM

(cc/200stcyl.)

6. OVERFLOW QUANTITY CHECK

Overflow Quantity

(cc/1000st)

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Injection

Quantity

Command

Duty Ratio

Command

FCV Switch

Remarks

The overflow valve belonging

to the pump should be used for

checking.

7. ADJUSTMENT OF TIMER

Timer Stroke

(mm)

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Injection

Quantity

Command

Duty Ratio

Command

FCV Switch

Remarks

9. PRESETTING FOR CAM ANGLE ADJUSTMENT

Adjust 2nd. and 3rd. digits

to get"Target Quantity"

8. SPV SCREW SETTING

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Duty Ratio

Command Remarks

Adjust 2nd. and 3rd. digits

to get"Target Quantity"

Injection Quantity

Command

Adjust SPV screw to get

"Target Quantity"

NOTE1 : Select "Record" position every time when recording the final correction value.

NOTE2 : When the correction value is raised by 1 level, the injection quantity is increased

approx. 0.04 - 0.06 cc/200st.

NOTE : Select "Record" position every time when recording the final correction value.

When the correction value is raised by 1 level, the injection quantity is increased approx. 0.04 - 0.06 cc/200st.

NOTE3 :

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

Display

Selector

Duty Ratio

Command Remarks

Injection Quantity

Command

Target Quantity

[ND-CPS]

(cc/200st)

First

digit

Second

digit

Third

digit

Target Quantity

[ND-CPS]

(cc/200st)

First

digit

Second

digit

Third

digit

2000 SPEED 430 0 167 - 267

2000

700

200

100

SPEED

SPEED

SPEED

SPEED

430

4C8

595

595

0

50

0

100

0

0

10.30 0.24

4.70 3.50

10.30 0.24

0

3.60 or more

0.40 or more

350

350

2000

Adjust

Adjust

Adjust

0

0

1

0 0 0

0

0

1.80 0.20

1.80 0.20

11.60 0.20

Keep the height of the SPV screw (shown in the figure) at 3.0 - 5.2 mm

H

350

350

Adjust

Adjust

2

2

0 0 100

100

3.40 0.14

3.40 0.14

096500-2000

Target Quantity

AVM

(cc/200stcyl.)

1.90 0.20

1.90 0.20

11.52 0.20

3.49 0.14

3.49 0.14

Record the final correction

value " "

Record the final correction

value " "

For Hartridge AVM Test Benches

10. ADJUSTMENT OF CAM ANGLE

Target Angle

(CA)

Pump

Speed

(rpm)

Remarks Standard

11. ADJUSTMENT OF FUEL DELIVERY

Fuel Delivery

[ND-CPS]

(cc/200stcyl.)

Pump

Speed

(rpm)

ECD CONTROLLER SETTING

First

Digit

Duty Ratio

Command

Remarks Reference

Max. Spread

In Delivery

(cc)

NOTE : Never forget removing pressure sensor from piping.

When the

correction

value is raised

by 1 level, the

injection

quantity is

increased

approx.

0.04 - 0.06

cc/200st.

First Digit : First digit (The leftest of 3 digits) of "Injection Quantity Command Value" input switch.

Recorded

injection

command

Adjust 2nd. and

3rd. digits to get

"Target Angle"

ECD CONTROLLER SETTING

Display

Selector

Duty Ratio

Command

FCV

Switch

Injection Quantity

Command

Display

Selector

NOTE : In cace of out of standard value at check points, adjust again from "SPV screw setting" procedure.

12. TIMING MARK RE-MARKING POSITION

Cam lift distance (plunger) should be Based on cylinder :

First

digit

Second

digit

Third

digit

350

350

Adjust

Adjust

3

3

0 0 100

100

2.2 0.5

100

100

350

350

700

700

1300

1300

2000

2000

1200

2600

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Adjust

Confirm

Confirm

4

5

6

7

8

9

A

B

C

D

E

F

0

0

0

0

0

0

0

0

0

0

0

0

3.54 0.24

12.54 0.40

1.80 0.14

8.14 0.24

4.72 0.16

9.62 0.24

3.44 0.16

13.08 0.22

4.60 0.18

11.60 0.24

5.56 0.26

5.98 0.50

1.20

0.34

0.50

0.50

0.40

48C - 4D6

590 - 5E2

43F - 47F

4E7 - 51D

447 - 479

4CD - 50B

37A - 3B8

4CB - 50D

2F3 - 343

43B - 46D

Check

Check

A 1.30 mm

096500-2000

Fuel Delivery

AVM

(cc/200stcyl.)

3.20 0.24

12.43 0.40

1.90 0.14

8.74 0.24

5.44 0.16

10.47 0.24

4.21 0.16

13.68 0.22

5.01 0.18

11.52 0.24

6.35 0.26

6.26 0.50

Record the final

correction value

" "

For Hartridge AVM Test Benches

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- ECD V3 V5 Ve Pump Denso Repair ManualDocument118 pagesECD V3 V5 Ve Pump Denso Repair Manualsimplu64997% (35)

- 781307Document23 pages781307ForteLubNo ratings yet

- Sistemas de inyección dieselDocument14 pagesSistemas de inyección dieselErick SantiagoNo ratings yet

- 101061-8530 - Bba ExplodidaDocument1 page101061-8530 - Bba ExplodidaForteLubNo ratings yet

- COVEC F Service ManualDocument55 pagesCOVEC F Service Manualorsm100% (12)

- 1068714150Document6 pages1068714150ForteLubNo ratings yet

- 2170Document9 pages2170ForteLubNo ratings yet

- 8134Document5 pages8134ForteLubNo ratings yet

- 1564Document3 pages1564ForteLubNo ratings yet

- Injection Pump Calibration Data: Engine ModelDocument1 pageInjection Pump Calibration Data: Engine ModelForteLubNo ratings yet

- 1047012043Document10 pages1047012043ForteLubNo ratings yet

- 01EJ3051Document3 pages01EJ3051ForteLubNo ratings yet

- 01EJ2010Document3 pages01EJ2010ForteLubNo ratings yet

- INJECTION PUMP TEST SPECIFICATIONS 096500-0080Document3 pagesINJECTION PUMP TEST SPECIFICATIONS 096500-0080ForteLub100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)