Professional Documents

Culture Documents

Tehnologia Posi Strut1

Tehnologia Posi Strut1

Uploaded by

Sorin RavoianuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tehnologia Posi Strut1

Tehnologia Posi Strut1

Uploaded by

Sorin RavoianuCopyright:

Available Formats

CONTENTS

Posi-Joist Flooring

An Introducton to Posi-Joists

Ground Floor Applicatons

Intermediate Floor Applicatons

Separatng Floor Applicatons

Standard Details

Span Informaton

Site Handling and Storage

Roof Applicatons

Posi-Rafer Standard Details

The X-Rafer

Posi-Atc trusses

Wall Applicatons

The Posi-Stud

Sample constructon details

The World of Posi

Technology

THE POSI - STRUT TECHNI CAL HANDBOOK

Issue 2

Page 2

Introducing Posi-Joist

You simply cant aford to ignore the

advantages of the Posi-Joist system.

To start with, because Posi-Joist

combines the lightness of timber with

the strength of the Posi-Strut steel

web, you can span far greater

distances than would be possible with

alternative timber products.

This gives you unequalled design

freedom across a wide range of

applications for both foor and roof in

domestic, industrial and commercial

applications. The Posi-Joist allows

a variety of internal room layouts

within an external shell due to its clear

spanning capabilities.

THE ALTERNATIVE

JOIST SYSTEM

Available in Six Standard Depths

PS8 202mm

PS9N 225mm PS14N 373mm

PS10N 253mm PS16N 421mm

PS12N 304mm

Posi-Joist is a tested product with a European Technical Approval

ETA-07/0161. Fire tests of 30, 60 and 90 minutes have been success-

fully passed. Acoustc tests for impact and airborne sound transfer

have also been successfully passed. See Page 10 for more details.

Page 3

The Posi-Joist ability to span greater

distances than its timber competitors

and the fact that they are fully

competitive with steel and concrete

beams makes it immediately obvious

that they ofer considerable savings in

raw materials. The open web design

gives the contractor another important

advantage: it makes installation of

service and utilities far simpler and

quicker, reducing both labour costs

and build-up time on site.

Whats more, since they eliminate

the need for load-bearing intermediate

walls they dramatically cut overall

building costs.

Quite simply, theres no more efcient

or economical way to construct

foors and roofs.

ECONOMY

FLEXIBILITY IN USE

Design fexibility is inherent in the

concept of the Posi-Joist. The depth

length and specifcation can be adjusted

to produce an enormous number of

diferent specifcations, each with

clearly defned performance criteria.

In addition, end details of the beam can

be altered to give a variety of

support conditions.

You will never come up short with the

Posi-Joist Trimmable End. Each end can

incorporate a solid timber block which

can be engineered with up to 130mm

allowance for trimming on site .

EFFICIENCY

Exceptional foor performance

from a minimum 72mm wide

fxing surface makes fooring

easy, controls shrinkage and

with precision engineering it all

reduces those tiresome return

visits and remedial work.

More benefts such as the

unique open web design pro-

vide an area in which Plumbers

and Electricians will fnd it easy

and convenient to work. The

jobs done far more quickly and

the contractor makes worth-

while savings.

There when you need it

Posi-Joists Trimmable End

provides feld cutting

fexibility!

Even on long spans, no herring bone

strutting is necessary with the Posi-

Joist system. If the

span exceeds 4m a

strong-back is installed at

mid-span.

The Posi-Joist can adequately span

for fat and pitched roofs.

Its span capability and timber fang-

es make it the more desirable alter-

native to all steel systems.

Page 4

Tested by TRADA and accepted by the

NHBC , staggered Posi-Strut webbing

reduces the material content of the joist

providing economic and environmental

savings.

TRIM-IT VARIATION

MATERIAL SAVINGS

Posi-Joists can be designed to include single sid-

ed Posi-Strut webbing where appropriate to

provide considerable material savings.

The use of staggered webs can give as much as a

12% reduction in the amount of steel used in a

Posi-Joist compared to its competitors.

This webbing technique is subject to a patent and

is typical of the ongoing development

of Posi-Joist.

The Trim-It end detail provides a fexible

end detail perfect for applications with

varying and uncertain spans. Trimmed

on site prior to installationup to

600mm can be removed per Posi-Joist.

Maximum 600mm can be trimmed from a stock length

Ground Floor Applications

The World of Posi Technology

Ground Floor Applications

Page 6

Ground Floor Applications

1Since there is no ceiling attached to the underside of the Posi-Joists, the bottom fange will not

have any lateral restraint. Therefore, multiple spans should either be avoided, or restraint noggins

should be inserted at bottom fange level on each side of internal supports where the lower fange is

likely to be in compression.

2The absence of a ceiling will result in a ground foor feeling less stif when compared with other

foors of the same joist depth and span. Additionally the kitchen/utility areas containing large kitch-

en appliances that produce dynamic movement are likely to be located on the ground foor. It may

be appropriate to consider specifying more stringent defection limits than those normally applied.

This should be discussed with the building designer early in the project cycle to control vibration per-

formance.

3When planning the arrangement of Posi-Joists for suspended ground foors consideration

should be given where practical to making the joists discontinuous between kitchen/utility areas

supporting large kitchen appliances and living/dining areas, so as to minimise the occurrence of ap-

pliance induced vibration in living areas.

4The environment within a suspended ground foor is classifed as Service Class 2 and hence the

defection characteristics of the Posi-Joists may be diferent than for intermediate foors. Provided

the void beneath the foor is well ventilated and drained and the ground cover layer inert the foor

will perform as expected.

5Joists in suspended ground foor applications need particular attention to construction detailing

with regard to ground preparation, ventilation, insulation and disabled access.

DPC

DPC

150mm min

150mm min

When designing Posi-Joists for use in suspended ground foors the following ground foor specifc

points should be considered:

Notes to Diagram

The ground cover layer should be inert and resist the passage of moisture. One of the following con-

structions may be used, although other options may also be suitable:

i) 50mm of inert sand, gravel or concrete on 300 micron (1200g) polythene (1000g if PIFA branded) lapped and

turned at the edges, on 25mm sand blinding;

ii) 100mm concrete on well consolidated hardcore;

iii) 50mm concrete on polythene membrane on 50mm sand blinding.

Page 7

Ground Floor Applications

Notes to Diagram (Continued)

On sites where external ground levels are higher than internal, the internal ground cover should fall

to a suitable drainage outlet.

Under foor ventilation should be in accordance with The Building Regulations and ventilator manu-

facturer specifcations. Special care should be taken to ensure that adequate cross-ventilation is

achieved. A minimum clear height of 150mm should be provided between the underside of the joists

and the internal ground cover.

Where protection is required against Radon gas or other ground gases, specialist advice should be

sought.

Insulation requirements will vary depending on the foor size and should be calculated by the Building

Designer for each foor construction. Insulation can be installed in ground foor constructions by sup-

porting the insulation between the Posi-Joists on either a rigid mesh, a breather membrane or fbre-

board fxed between the joists.

The World of Posi Technology

Intermediate Floor Applications

Page 9

Intermediate Floor Applications

Typical Construction Details

Posi-Joists can be built into the inner leaf of an external cavi-

ty wall as illustrated. This method of construction meets the

thermal and air leakage requirements of Building Regulations

Approved Document L1 &L2 (2006) provided that the perime-

ter of the Posi-Joist is sealed with silicone sealant as shown

and the wall is insulated to the Building Designers specifca-

tion. Alternative proprietary built-in constructions may be

used, such as joist end caps, provided that they have been

shown by third party tests to meet or exceed the air leakage

performance of the construction illustrated. The construction

illustrated provides lateral restraint to the wall. Note: Certain

end caps may not provide lateral restraint to the wall, and re-

straint straps may therefore be required.

Posi-Joists can be supported in masonry hangers at an

external masonry wall. This method of construction meets

the thermal and air leakage requirements of Building Reg-

ulations Approved Document L1 & L2(2006). This detail

does not provide lateral restraint to the wall unless a re-

straint type hanger is used, if standard masonry hangers

are used restraint straps will be required.

This detail illustrates a popular construction detail for support-

ing Posi-Joists at an external timber frame wall. This con-

struction meets the thermal and air leakage requirements of

Building Regulations Approved Document L1 & L2 (2006) pro-

vided that the foor edge is insulated by a material with a mini-

mum R-value of 0.75m K/W and that a bead of sealant is

placed between the skirting board and the foor deck and that

an efective air barrier is maintained within the foor zone by

means of solid noggins or header joists. The construction pro-

vides lateral restraint to the wall provided that the connection

is designed and detailed by the Building Designer.

Silicone Sealant

Block work to contnue between Posi-Joists to provide

restraint. Note: This is not allowed on solid external walls

Top Chord restraint fxed between Posi-Joists. (Choose correct

hanger for load, bearing width and coursework level of hanger

bearing fange.)

Page 10

Intermediate Floor Applications

Fire and Sound Resistance

Plasterboard Ceiling

Fire resistance

from below

Sound resistance

from above

The requirement for fre resistance is normally 30 minutes for

1st and 2nd foors and this is provided almost entirely by the

ceiling plasterboard. The responsibility for the plasterboard

specifcation and fxing rests with the Building Designer.

Posi-Joist foors with a variety of foor build ups have been

independently tested and certifed for 30, 60 and 90 minutes

fre resistance.

The following table provides details of Posi-Joist

fre certifcation.

Time Period Floor Build-up

30 Minutes

12.5mm Britsh Gypsum Gyproc Wallboard with 5mm Plaster Skim and a 22mm Chipboard

walking surface

30 Minutes 15mm Britsh Gypsum Gyproc Wallboard with a 22mm Chipboard walking surface

30 Minutes with Down lighters 15mm Britsh Gypsum Wallboard with a 22mm Chipboard walking surface

60 Minutes Robust Detail E-FT-3See Page 12 for details

90 Minutes

2 No. layers of 15mm Lafarge Firecheck plasterboard suspended on galvanised resilient bars

fxed to the underside of the Posi-Joists. 18mm Oriented Strand Board (OSB) subdeck.

The requirement for sound resistance of foors in England and Wales is that they should achieve a sound

reduction of 40dB for airborne sound based on laboratory tests. The following table provides details of

Posi-Joist acoustic laboratory test results.

Floor Build-up

Weighted Airborne

Sound Reduction

253mm Posi-Joist, 22mm Chipboard walking surface, 100mm Insulaton 44

253mm Posi-Joist, 22mm Chipboard walking surface. No insulaton. 43

253mm Posi-Joist, 18mm Ply walking surface, 100mm Insulaton 41

223mm Posi-Joist, 22mm Chipboard walking surface, 100mm Insulaton 44

223mm Posi-Joist, 22mm Chipboard walking surface. No insulaton. 42

Note: 15mm Gypsum Wallboard ceiling used throughout, fxes to the Posi-Joists at 300mm centres using 38mm Gyproc drywall

timber screws.

Separating Floor Applications

The World of Posi Technology

Separating Floor Applications

Page 12

Separating Floor Applications

Separating foors need to meet enhanced requirements for fre resistance and sound resistance when com-

pared to intermediate foors. Consequently the additional materials used to meet these requirements mean

that the dead weight of a separating foor will be signifcantly greater than the notional dead weight of an in-

termediate or ground foor.

The period of fre resistance required is at least 60 minutes and this is provided almost entirely by the ceiling

plasterboard. The responsibility for the plasterboard specifcation and fxing rests with the Building Designer.

Posi-Joist foors with a ceiling construction comprising of 2 No. layers of 12.5mm Gyproc Fireline plasterboard

have successfully passed 60 minute fre testing.

Sound Resistance in Separating Floors

RSD E-FT3

Separating foors need to achieve sound reductions of greater

than 45dB for airborne sound and less than 62dB for impact

sound and this should be demonstrated by pre-completion

testing on site, or by adherence to Robust Details.

Robust Detail E-FT-3 is the tested, proven detail for the use of

Posi-Joists in separating foors in timber frame construction.

The detail comprises of ceiling treatment CT2 made up of two

layers of 15mm (nominal 12.5 kg/m) freline plasterboard

fxed with 25mm and 42mm screws to resilient bars at 400mm

centres. On top of an 18mm T&G Subdeck, a resilient compo-

site deep batten system with a minimum depth of 70mm is

placed with 25mm (10-33kg/m) insulation placed between the

battens. On these battens a 19mm Gypsum based board

(nominal 13.5kg/m) is placed with a fnal deck of 18mm (min)

T&G fooring board on top.

Working in conjunction with our partners Prestoplan, MiTek ensured that Posi-Joist

was the frst metal web joist system in the UK to obtain a Robust Detail for the

resistance to the passage of sound.

Page 13

When an acceptable Posi-Joist design has been achieved with respect to structural, fre and sound requirements

it should be noted that the performance of any separating foor can be compromised by poor detailing and work-

manship. In particular care should be taken to isolate foor fnishes from wall fnishes since friction between ceiling

lining, coving and dry-lining can result in impact sound transfer from the upper dwelling to the lower dwelling.

Separating Floor Applications

An alternative separating foor detail for Posi-Joist is the

Screedfo dB system.

With a build up of only 74mm from sub-deck to fnished surface, a Screed-

fo dB foor can be considerably shallower than some common construc-

tion details. This often allows the removal of a course of brickwork at each

level.

Ideal for under foor heating systems, services may be run in ducting

through the screed, or through the open web zone of the Posi-Joist. Un-

like other joist systems there is no requirement to add a service void below

the standard ceilingonce more conserving the height of the building.

The Screedfo dB system should only be installed once the roof and win-

dows are in place and the building is weather tight. Ideally, any services

which penetrate the foor zone should also be installed to allow them to be

isolated acoustically. The screed takes 24 hours to cure sufciently to be

walked on. During this period, windows should be kept shut to prevent too

rapid drying. After 24 hours, some windows should be opened to provide

ventilation. The screed will then dry at a rate of nearly 2mm per day, a typi-

cal foor will fully dry over a 3 week period. Floor fnishes, including tiles,

can then be applied.

Posi-Joists have undergone long term testing with

Screedfo and have obtained a TRADA Q Mark. The

process of obtaining a Robust Detail for this method of

construction is under way.

High quality compression

resistant foam

FSC certfed moisture

resistant fbre board

500 gauge polythene slip

membrane

40mm Screedfo anhydrite

screed

Page 14

Posi-Joist Standard Details

Masonry Bearing Details

Contnuous 47x72mm

top chord restraint fxed

over ribbon block

Figure 3: Masonry Hanger Detail. With contnuous ledger. Minimum

bearing determined by design (choose correct hanger for load, bearing

width and coursework level of hanger bearing fange).

Figure 4: Top Chord Built into Masonry

Note: This is not allowed on single skin external walls

Contnuous 38x38mm

Ledger fxed to wall to

support ceiling

Gap

Silicone Sealant

Figure 1: Botom Chord Built Into Masonry

Block work to contnue between Posi-Joists to provide

restraint. Note: This is not allowed on single skin external walls

Figure 2: Masonry Hanger Detail. Top Chord restraint fxed between

Posi-Joists. (Choose correct hanger for load, bearing width and

coursework level of hanger bearing fange.)

Soil Pipe Corner Details

Figure 5: Fixing Around Soil Vent Pipe Using Bearers

38x38 bearers fxed directly to the wall to pick up both foor

and ceiling.

Masonry Hanger

Masonry Hanger

Solid tmber or

LVL trimmer

(depth to suit)

Simpson IUB

hangers

Figure 6: Fixing Around Soil Vent Pipe Using Trimmer

See Robust Detail E-FT-3 (11) for treatment of service void

penetratng the separatng foor.

Page 15

Posi-Joist Standard Details

Figure 7: Non-load bearing parttons parallel to Posi-Joists

Timber Frame Details

47x89mm

packing piece

Gap

38x38mm contnuous

plasterboard

47x89mm

contnuous pack

Ringbeams in solid

tmber or LVL

Service

void

Posi-Joists

bearing on wall

First Posi-Joist set

back approx 200mm

from wall Plasterboard noggin

47x89mm packs

between Posi-Joists

Figure 8: Timber Frame Party Wall (with service void)

Floor comprising: 22mm T&G chipboard on 19mm plasterboard and plank on

47x75mm resilient foor batten at 400mm centres on 18mm T&G chipboard. All

T&G edges glued.

Ceiling (not shown) comprising: 2 layers 15mm Gyproc Fireline board on 25mm

resilient bars at 400mm centres. First layer fxed with 25mm Gyproc screws at

230mm centres. Second layer fxed with 42mm gyproc screws at 230mm cen-

tres. Staggered with frst layer. Lay Fireline board in echelon pattern with stag-

gered joints. Ceiling boards and fxings must not penetrate or touch joists

Bead of sealant applied to foor deck

prior to fxing 19mm plasterboard plank.

Service Void

Posi-Strut web

Mineral wool cavity barrier

100mm mineral wool insulaton quilt

weight 1036 kg/m

Figure 10: Botom Chord Fixing to Timber Frame

(with contnuous restraint)

Contnuous 47x72mm top

chord restraint fxed over

ribbon block

Head binder

Figure 11: Botom Chord Fixing to Timber Frame

(with restraint noggins)

Head binder

47x72mm top chord

restraint noggins

Figure 9: Top Chord Fixing to Timber Frame

Page 16

Posi-Joist Standard Details

Figure 13: Edge Closure Detail

Posi-Joist requires a minimum 50mm bearing

35mm Prefabricated edge closure

Pre-faced with sheathing and

insulated as required

Internal Bearing Details

Figure 14: Top Chord Fixing to Steel Downstand Beam

47x97mm between

chords

Timber pack fxed to

beam (size to suit)

Gap

Timber plate fxed to

top of beam

Figure 15: Steel Beam Within Floor Zone

Posi-Joist botom chord to be notched over steel bearer plate

without interfering with connector plate

Steel Bearer Plate

Fully welded to under

side of steel

45mm Rim Board

(Depth to Suit)

Packing to

top of steel

sizes to

suit

Solid tmber block

(grain parallel to span)

Note: This is not allowed on external walls or fre walls.

Timber Frame Details (Continued)

Figure 12: Edge Closure Detail Using MiTek F-Frame

Where there are larger openings in the upper storey wall which cause

a concentrated load a suitable tmber vertcal should be inserted un-

der the point load to transfer it down to the wall below.

Posi-Strut

braces at

maximum

2400mm centres

Plasterboard noggins

Insulaton Bats

Figure 16: Contnuous Posi-Joist Through

Masonry

Figure 17: Shared Internal Bearing Figure 18: Internal Bearing

Page 17

Strongback Bracing DetailsFix at Maximum 4.0 Metre Centres

Strongback

Positon strongback

tght to the under

side of the top

chord. As close as

possible to centre of

joist for maximum

efect.

Insert strongback

through

Posi-Joists before

fxing joists. It may

not be possible

afer the joists have

been fxed.

Figure 19: Strongback DetailPosi-Joists with Strongback blocks

38x75mm (min) blocks twice nailed to top and botom members and

twice nailed to brace using 3.1x75mm long galvanised wire nails.

Twice nailed to

brace using

3.1x75mm long

galvanised wire

nails.

Figure 21: Horizontal Restraint Straps Fixed Directly to Strongback

Strap fxed with a minimum of four fxings of which at least one is to

be over the third joist.

Figure 20: Strongback DetailPosi-Joists with built in vertcals

Posi-Joists can be designed with built in tmber vertcals for

strongback fxing. The strongback is twice nailed as above.

Figure 22: Strongback Splice

1200mm long splice fxed with 10 no 3.1x100mm long galva-

nised wire nails each side of splice, nailed through and

clenched over on far side.

Posi-Joist Standard Details

Web Size Min. Strongback Secton

PS8 & PS9 35 x 97 mm

PS10(N) 35 x 120 mm

PS12(N) 35 x 145 mm

PS14(N) & PS16(N) Min 35 x 145 mm *

Strongback Size Chart

* The deeper the strongback, the stifer the foor

Figure 23: Strongback Detail for Change of Span

38x75mm (min) blocks twice nailed to top and botom

members and twice nailed to brace using 3.1x75mm long

galvanised wire nails.

Page 18

Posi-Joist Standard Details

Stairwell Details

Simpson IUB

hangers

Simpson SDS

Screws

Figure 24: Staircase Opening

Trimmer to be notched over the botom fange of the hanger

Solid tmber or

LVL trimmer

(depth to suit)

Simpson LBV

hanger

Single or double

ply Posi-Joist

Beam

Figure 25: Posi-Joist to Posi-Joist Connecton

Plywood nailed to both faces of trimmer beam. Ply/nailing as

specifed by design

Figure 26: Posi-Joist to Posi-Joist Connecton

Botom member of Posi-Joist to be notched over the fange

of the hanger

Simpson IUB

hanger

Figure 28: Narrow Opening Detail

Beam (depth to

suit sloted

through trimmers)

Packing piece to

pick up ceiling

Figure 27: Narrow Opening Detail

Trimmer to be

notched over

the botom

fange of the

hanger

Simpson IUB

hangers

W

Circle

Dia

Square

Rectangle Depth

Posi-

Strut

Size

50 75 100 125 150 175 200

Rectangle Width

PS8 108 105 95 270 180 90 - - - -

PS9N 134 130 115 310 240 180 100 - - -

PS10N 159 150 135 320 270 210 160 80 - -

PS12N 210 190 155 350 310 260 210 160 110 70

Maximum Duct Sizes

W

Page 19

Posi-Joist Standard Details

Internal Load Bearing Walls

Figure 29: Posi-Joists Parallel to Internal Load Bearing Wall

Using MiTek F-Frame

Where there are larger openings in the upper storey wall which

cause a concentrated load a suitable tmber vertcal should be

inserted under the point load to transfer it down to the wall

below. Plasterboard noggins atached as shown.

Beam width

to suit wall. Depth to Suit

Posi-Joist. Plasterboard

noggins either side

Blocking width

to suit wall. Depth

to Suit Posi-Joist.

Plasterboard nog-

gins either side

Contnuous

Posi-Joists

Posi-Strut braces at maximum 2400mm centres

Figure 30: Posi-Joists Parallel to Internal Load Bearing Wall

Figure 31: Contnuous Posi-Joists Perpendicular to Internal

Load Bearing Wall

Blocking

width to suit

wall. Depth to

Suit

Posi-Joist.

Plasterboard

noggins either

side

Figure 32: Butng Posi-Joists Perpendicular to Internal Load

Bearing Wall

Where this detail is used in a Posi-Joist cassete constructon

an additonal blocking brace should be included to secure the

blocks.

Page 20

Posi-Joist Span Information

Indicative Span Information

If you are a member of the iStructE or RIBA you can download a free version of the 20/20 Posi-Joist design

software from the MiTek website to allow you to accurately specify Posi-Joist designs.

The following indicative table as to be used as a typical guide to the clear span-

ning capabilities of Posi-Joists. Please consult a licensed Posi-Joist manufactur-

er prior to specifying Posi-Joist sizes to discuss the loading conditions for the

entire foor.

Click here to download the latest list of licensed Posi-Joist manufacturers.

600mm Centres

Overall Depth of Posi-Joist 72mm Joist Width 97mm Joist Width

202mm (PS8 Posi-Joist) 4300mm 4800mm

225mm (PS9(N) Posi-Joist) 4750mm 5100mm

253mm (PS10(N) Posi-Joist) 5100mm 5600mm

304mm (PS12(N) Posi-Joist) 5800mm 6200mm

These are indicative Posi-Joist clear spanning capabilities based upon domestic foor loads including a partition load. Posi-Joists

can span greater clear spans by reducing the joist centres, increasing the joist width ; and by increasing the size of the strongback

brace. Consult a licensed Posi-Joist manufacturer to establish the correct Posi-Joist depth to specify for your foor.

Free Posi-Joist

design Sofware

Page 21

Storage on site should be for a limited period of

time prior to erection of the Posi-Joists.

Posi-Joists should either be stored vertically or

on the fat. If stored vertically there should be inter-

mediate bearers at node points not within the bay

of a joist, as shown below. If stored in a fat posi-

tion, sufcient bearings should be provided to pre-

vent excessive lateral bending.

It is recommend that completed Posi-Joists be

strapped together and wrapped in a waterproof

protective covering to protect them from short

term exposure to inclement weather.

Special precautions should be taken when stacking

top chord supported foor cassettes to prevent the

stack lozenging in storage. Additional bracing to

the ends of the stack should be fxed to stop lateral

movement. Care should be taken when handling

the Posi-Joists to avoid bending, twisting or drop-

ping.

When loading/ofoading with a crane, slings should

always be attached to the timber chords or the cas-

sette lifting points, and not to the metal webs to

avoid buckling. Slings should be attached at panel

points closest to the quarter points of the Posi-

Joists as shown below.

Site Handling & Storage

Set Out & Placement

Posi-Joists are generally placed perpendicular to

the load bearing supporting walls and should be lo-

cated so that the distance between them does not

exceed the design spacing always consult the Posi-

Joist layout drawing and proceed with erection of

the foors as follows:-

1- Plan the erection sequence and place the Posi-

Joists close to where they are required, only dis-

tribute a sufcient number of joists around the build-

ing which an be erected in a reasonable period of

time. Posi-Joists should be protected from inclem-

ent weather and stored as noted above.

2- Before lifting the Posi-Joists to scafold level do

make sure the correct end of the joist is at the ap-

propriate support as the end details may be difer-

ent. Also be aware of any internal supports which

are being used and that the special internal bearing

detail for the joist is in the correct position.

3- If the Posi-Joists are supported over more than 2

supports make sure all the supports are the same

level and when the joists are lifted into place they

rest on all of the supports.

4- If the Posi-Joists are supported on masonry

hangers, make sure they are the ones specifed and

are frmly anchored in place and that the masonry is

cured in line with hanger requirements. Joists

should have a full bearing with no more than a 5mm

gap between the end of the joist and the face of the

hanger. Masonry hangers with a cavity return and

integral strap provide lateral restraint to wall heads.

5- Make sure the Posi-Joists are erected the correct

way around, the joists will normally be marked

"TOP" and the frst metal web will normally start at

the top of the Posi-Joists.

Bearers as close as

possible to web points

Bearers directly under web points

Use fabric sling.

Do not use chains or

wire rope which may

damage webs

60 or less

Page 22

6- The Posi-Joists are positioned to coincide with

the deck joints, the frst of which is normally

1210mm away from the wall face in masonry con-

struction or 1200mm from the cavity face in Timber

Frame construction when the deck extends to the

cavity face; when the joists are spaced at 400 or

600mm centres. There is normally a 10mm perime-

ter gap between the face of the deck and the face

of the wall in masonry construction to allow for po-

tential expansion of the deck. The board material is

normally 1200 x 2400mm, the long dimension span-

ning at 90 to the joist span. The remaining joists

are normally spaced on a grid of 400, or 600mm

centres, on occasion at 480mm centres.

7- When the deck is set out from the face of the

wall it is normal to have the frst joist edge 50mm

from the face of the wall where in Timber Frame

construction with the deck set out from the cavity

face it is normal to not have a joist close to a wall,

the deck and plasterboard being supported on a

timber ledger nailed to the frame. Carefully follow

the layout drawing and the wall/joist interface de-

tails provided by the Building Designer, in particular

in Timber Frame where the joist centres and the

stud centres may have to line through.

8- The penultimate Posi-Joist in the run is set out

on the standard module and the last joist is posi-

tioned similar to the frst in the run.

9- Posi-Joist stair trimmer joists and trimmers will

be required around stair openings which may be on

the main joist grid or usually of the grid. Set these

joists out strictly in accordance with the architectur-

al and Posi-Joist layout drawing and fx the trim-

mer joist to the stair trimmer and the trimmed joists

to the trimmer joist with the metal hangers speci-

fed making sure that any 2 ply joists are adequately

connected together as detailed.

10- To temporary brace and space the Posi-Joists

which have been laid in position fx a piece of 22 x

97 bracing to the top of the joists at their ends and

mid span or around 2.4m centres on spans longer

than 4.8m.

Site Handling & Storage

11- Install the strongback bracing as detailed, the

strongback is always installed on edge not on fat and

must be fxed to the integral strongback blocks or

noggin pieces nailed to the face of the joist. The

strongback must be fxed tight to the underside of

the top chord. Due to the width of the Posi-Joist

chords and the additional stifness installed in the

foor due to the strongback bracing, it will not nor-

mally be necessary to employ any temporary diagonal

bracing.

12- When all the Posi-Joists have been positioned

and fxed in place, the partition noggins, perimeter

noggins, rim boards, when required can be installed,

and in the case of masonry construction the steel lat-

eral restraint straps should be fxed in place at no

greater than 2m centres and should extend over 3

joists.

13- The foor carcass is now ready to receive the deck-

ing material and acoustic material where required.

14- The maximum load of sheet materials temporary

stored on the Posi-Joists is 250kg/m2 and should not

be greater than 300mm deep. This equates to 16

sheets of 18mm chipboard, 13 sheets of 22mm chip-

board or 20 sheets of 15mm plasterboard. Where the

sheets are stacked by hand they should span length-

ways across the joists, (Fig 1), when lifted mechanical-

ly they should be seated on 5 bearers the width of

which are 600mm longer than the width of the

board. (Figs 2 & 3).

Page 23

DOs and DONTs

DONT

Drill holes in the

timber chords

DONT

Cut notches in

the timber

DONT

Cut through the

timber chords

DONT

Cut or remove

the metal webs

DO

Store as shown in handling

and storage section

DO

Lift the Posi-Joists in a

vertical position

DO

Use the open web feature

for services

DO

Protect Posi-Joists from

inclement weather

The World of Posi Technology

Roof Applications

Page 25

Posi-Rafter Standard Details

Recommended eaves and apex details for use with

Posi-Rafters. All of these details are available for

use by trained Posi-Rafter designers in the MiTek

20/20 design software.

Page 26

The X-Rafter

This exciting new roofng system provides a fexible room in the

roof solution capable of providing the thermal performance that

will increasingly be required by the planned revisions to Part L of

the Building Regulations. The MiTek Posi-Strut technology en-

sures that the roof panels are lightweight and easy to install. The

system arrives on site, felted and counter battened ensuring that

the roof is watertight in a short period of time.

The environmental benefts include the low U-Values that the sys-

tem can achieve of 0.17 W/mK; timbers impeccable sustainability

credentials; and the design of the loft as a cold area thus further

reducing the energy consumption of the dwelling.

Based on a MiTek Posi-Joist floor, the working

platform for the Posi X-Rafter roof is assured with the

use of laser levels.

Flat top spandrels are positioned incorporating

location slots for the ceiling cassettes. The spandrel

panels are stubbed as required by the roof dimensions.

The structural ceiling cassette incorporating the roof

support purlins are located. Timber frame dwarf walls

are positioned to provide a second Posi X-Rafter support.

Apex spandrel panels are positioned using the struc-

tural ceiling as a safe working platform.

Posi X-Rafter cassettes are positioned and fastened to

the supports. Posi X-Rafters are insulated at the point

of manufacture and are pre-felted and battened.

The underside of the Posi X-Rafter cassette is clad with

OSB in the room area only.

Dormer windows are easily catered for by the system. Insulation material costs are lower than competitive

systems as the loft area is a cold area, reducing the

energy consumption of the dwelling.

Call us for information on how to become a licensed

MiTek Posi X-Rafter manufacturer.

Page 27

Ideal for use in narrow fronted gable to gable housing, the X-Rafter system starts with fat top structural

gable panels, fxed to ofsite manufactured Posi-Joist foor cassettes.

Spanning between the two structural gable panels, the next element of the X-Rafter system to be posi-

tioned is a pre-fabricated structural ceiling cassette with up-stand beams to provide the support for the

X-Rafter roof cassettes.

Page 28

Pre-Insulated, felted and counter battened ofsite, the X-Rafter cassettes are craned into position.

The Posi-Joist cassette foor and the structural ceiling cassettes form two safe working platforms provid-

ing that the appropriate harnessing is worn by the installation team.

Page 29

The apex spandrels are lowered into position to complete the cold roof space above the pre-insulated

ceiling panels.

Wind and water tight in hours not days, the X-Rafter combines health and safety benefts with all the

benefts of ofsite timber engineering manufacture. Contact MiTek for further information.

Page 30

By rotating the timber fanges through 90 so that the

timber is on edge rather than on fat, the Posi-Joist

becomes much stifer and the span capabilities are

increased. The subsequent resulting instability of the

on-edge joist can be removed by specifying that the

Posi-Joists are pre-fabricated into cassettes for ease

of installation.

Posi-Attic Trusses

Maximise Your Living Space with the MiTek Posi-Attic

Combining the solid feel of a MiTek Posi-Joist with

the benefts of a conventional attic truss, the

MiTek Posi-Attic enables you to span much larger

spans than conventional systems. The strength of

the Posi-Joist foor provides increased living space

within the attic, delivering maximum value to the

home owner.

The Posi-Joist foor is ideal for easy installation of Heat Recovery Ventilation Systems, soil pipes and the in-

creasingly diverse range of services installed in modern homes

Picture reproduced with thanks to Pasquills

Posi-Joist Roof Cassettes

Picture reproduced with thanks to Donaldson McConnell (Midlands) Ltd

The World of Posi Technology

Wall Applications

Page 32

The Posi-Stud

outer leaf of masonry

drained and vented 50mm cavity

High Performance Breather Membrane

OSB Sheathing

2 No. 150mm layers of 35 lambda Mineral Wool

OSB Sheathing

Posi-Stud flled with Mineral Wool

inner lining of plasterboard

vapour control layer

300mm Posi-Stud

Batened service zone

Calculated U-Value: 0.12 W/mK

Calculated U-Value: 0.17 W/mK

200mm Posi-Stud

outer leaf of masonry

drained and vented 50mm cavity

High Performance Breather Membrane

OSB Sheathing

2 No. 100mm layers of 35 lambda Mineral Wool

OSB Sheathing

Posi-Stud flled with Mineral wool

inner lining of plasterboard

vapour control layer

Batened service zone

Page 33

Sample Posi-Stud Details

Sample floor to wall

connection detail

Sample exterior

connection detail

Sample wall to roof connection detail

Sample sole plate connection detail

Page 34

Posi-Stud Photographs

Picture reproduced with thanks to OReilly Timber Frame

Page 35

MiTek Industries Ltd

Grazebrook Industrial Park

Peartree Lane

Dudley

DY2 0XW

t: 01384 451400 f: 01384 451411

www.mitek.co.uk

Posi-Stud Photographs

You might also like

- Incubadora Serie 800Document8 pagesIncubadora Serie 800VENTAS 01 QUIMICA UNIVERSONo ratings yet

- Drafting Men's Pants PatternDocument4 pagesDrafting Men's Pants Patterndanut_doc64% (11)

- Drafting Men's Pants PatternDocument4 pagesDrafting Men's Pants Patterndanut_doc64% (11)

- CopycatsDocument20 pagesCopycatsRosie Guerra-Hunt100% (5)

- Typical Deck Details Master HAO B70-1120P - ADA - 201803071309540634Document27 pagesTypical Deck Details Master HAO B70-1120P - ADA - 201803071309540634Diego Jaramillo BeckerNo ratings yet

- Greb Straw Bale TechniqueDocument1 pageGreb Straw Bale Techniquedanut_docNo ratings yet

- Direct2D SuccinctlyDocument187 pagesDirect2D SuccinctlyLayon Ribeiro100% (1)

- Forms 6-12 MCQ DbskoolDocument3 pagesForms 6-12 MCQ DbskoolMehedi Hasan AkNo ratings yet

- (Abu-Farsakh, Murad Yusuf Alshibli, Khalid Puppa PDFDocument314 pages(Abu-Farsakh, Murad Yusuf Alshibli, Khalid Puppa PDFbeck.26No ratings yet

- 5E Lesson Plan Template: HandoutDocument5 pages5E Lesson Plan Template: Handoutapi-509847491No ratings yet

- Shaping CNC-cut Plywood Structures ReportDocument84 pagesShaping CNC-cut Plywood Structures Reportlebob12No ratings yet

- UK TechnBroschDocument52 pagesUK TechnBroschMarcos AmorimNo ratings yet

- LVL Handbook - Europe PDFDocument228 pagesLVL Handbook - Europe PDFbenNo ratings yet

- Wood Joint Work Part 4Document2 pagesWood Joint Work Part 4Lo M'hNo ratings yet

- Screws Design Guide VU 1.1 PDFDocument52 pagesScrews Design Guide VU 1.1 PDFLoma100% (1)

- Roofing Manual PDFDocument12 pagesRoofing Manual PDFOwen0% (1)

- APLIKASI Cee Dan Zee Purlin: Pt. Bluescope Lysaght Indonesia June 2014Document34 pagesAPLIKASI Cee Dan Zee Purlin: Pt. Bluescope Lysaght Indonesia June 2014gama adisetiantoNo ratings yet

- JJI-Joists Technical Manual Fourth EditionDocument44 pagesJJI-Joists Technical Manual Fourth Editionneel123210% (1)

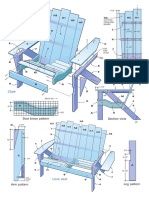

- Chair Wood WorkingDocument3 pagesChair Wood WorkingharriszoomNo ratings yet

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDocument13 pagesFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MX0% (1)

- ArchiCAD 12 BrochureDocument8 pagesArchiCAD 12 BrochurePratheesh JaisonNo ratings yet

- Cut Saw SP720 - EN - Webb2011Document16 pagesCut Saw SP720 - EN - Webb2011MAKRONNo ratings yet

- EnerSIP Construction ManualDocument53 pagesEnerSIP Construction ManualIvan Klyuchka100% (2)

- TBA 09 Detailing of Clay MasonryDocument42 pagesTBA 09 Detailing of Clay MasonryHenderson CheungNo ratings yet

- Wide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFDocument92 pagesWide Module Pan Skip Joist Spandrel Torsion Concrete Floor Design Detailing PDFGonzalo Gomez CastilloNo ratings yet

- Metsec Wall Construction PDFDocument40 pagesMetsec Wall Construction PDFCal MoranNo ratings yet

- Mega Anchor PDFDocument16 pagesMega Anchor PDFalexmuchmure2158No ratings yet

- Timber FloorsDocument30 pagesTimber FloorsGlistering DharNo ratings yet

- Diaphragm Action and Design - SpringerDocument3 pagesDiaphragm Action and Design - SpringerGuillermo Agustín Yáñez QuezadaNo ratings yet

- A Com Ecu PateDocument5 pagesA Com Ecu Pateheels1310No ratings yet

- CSSBI 59 05 IntroductionDocument8 pagesCSSBI 59 05 IntroductionrigaschNo ratings yet

- Nepal Wood 2017Document4 pagesNepal Wood 2017ShouruvhRajouriaNo ratings yet

- LP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedDocument10 pagesLP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedMinuteman ModelworksNo ratings yet

- WikiHouseUK Proposal v2 SSMDocument25 pagesWikiHouseUK Proposal v2 SSMOlivier HennysonNo ratings yet

- Wood ScrewsDocument178 pagesWood ScrewsOmar AL-jazairiNo ratings yet

- SIGA CLT Cross Laminated Timber GuideDocument20 pagesSIGA CLT Cross Laminated Timber GuideAlberto CumerlatoNo ratings yet

- Woodworking Machines Planer - Is Designed To SurfaceDocument5 pagesWoodworking Machines Planer - Is Designed To SurfaceatikahzulkipeliNo ratings yet

- Basement InsulationDocument12 pagesBasement InsulationAdam RossmillerNo ratings yet

- Systemline Guide 3Document62 pagesSystemline Guide 3Zamfira OctavianNo ratings yet

- Light Gauge Steel Profiles Case StudyDocument2 pagesLight Gauge Steel Profiles Case StudyDeepum HalloomanNo ratings yet

- Ent. Porch: Part of Walkway All AroundDocument1 pageEnt. Porch: Part of Walkway All AroundbiencvalencerinaNo ratings yet

- TE Plywood BrochureDocument6 pagesTE Plywood BrochureomahasessionsNo ratings yet

- All CladdingDocument44 pagesAll CladdingalloytarungNo ratings yet

- Smart CabinetsDocument52 pagesSmart Cabinetsarijit.samalNo ratings yet

- Prefab Building Elements For Affordable Housing.Document41 pagesPrefab Building Elements For Affordable Housing.shrikant100% (7)

- Bor11999 NSW Manual Bk1 Structural Fire AccusticDocument72 pagesBor11999 NSW Manual Bk1 Structural Fire AccusticEmanuel Ifrim100% (1)

- Deck Span Tables Treated PineDocument3 pagesDeck Span Tables Treated Pineciviliglen0% (1)

- Rheinzink Roof Covering SystemsDocument16 pagesRheinzink Roof Covering Systemspablo_658No ratings yet

- Bs-Id Technical Drawing GuideDocument16 pagesBs-Id Technical Drawing GuideJudea CaballeroNo ratings yet

- East Vancouver Single-Family Passive House Case Study: July, 2019Document8 pagesEast Vancouver Single-Family Passive House Case Study: July, 2019Carlos D100% (1)

- Analysis of Shear Walls For Multi-Storey Timber BuildingsDocument54 pagesAnalysis of Shear Walls For Multi-Storey Timber BuildingsrahimmullaNo ratings yet

- Modular Connection DesignDocument21 pagesModular Connection DesignChristianJohandaCostaNo ratings yet

- Joining Wood: Joint FamiliesDocument8 pagesJoining Wood: Joint FamiliesAaron RalstonNo ratings yet

- Duck Pull Toy: Project 19247EZDocument3 pagesDuck Pull Toy: Project 19247EZBSulliNo ratings yet

- YTONG - Perfect SolutionDocument16 pagesYTONG - Perfect SolutionJoseph ChenNo ratings yet

- C & Zed Purlins Design Manual and Catalogue BC783d01Document31 pagesC & Zed Purlins Design Manual and Catalogue BC783d01GnabBangNo ratings yet

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- Modular CatalogueDocument88 pagesModular CatalogueMartin CabreraNo ratings yet

- Cavityrock Detail-06 Window Head Detail TechguideDocument3 pagesCavityrock Detail-06 Window Head Detail TechguideD MNo ratings yet

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- W0 Odshop N3 Ws November 2016Document76 pagesW0 Odshop N3 Ws November 2016starpulseNo ratings yet

- Bailey Platinum Plus Steel Stud Track For Drywall FramingDocument4 pagesBailey Platinum Plus Steel Stud Track For Drywall FramingHenryNo ratings yet

- SIP-Structural Insulated PanelsDocument4 pagesSIP-Structural Insulated PanelsHan JoeNo ratings yet

- Presentation - Slides MALONE Mass Timber Connections Webinar 210609Document91 pagesPresentation - Slides MALONE Mass Timber Connections Webinar 210609AntonNo ratings yet

- 4,500-7,000 LB Electric Forklift Trucks PDFDocument14 pages4,500-7,000 LB Electric Forklift Trucks PDFForklift Systems IncorporatedNo ratings yet

- Building TechnologyDocument4 pagesBuilding TechnologyDanica LuarezNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Hollowcore Floor Systems: The Benefits of Hollowcore FloorsDocument5 pagesHollowcore Floor Systems: The Benefits of Hollowcore Floorskundanika prasadNo ratings yet

- Alg A MicDocument2 pagesAlg A Micdanut_docNo ratings yet

- Sail Bags Snorkels Rudder Dagger Board CoversDocument1 pageSail Bags Snorkels Rudder Dagger Board Coversdanut_docNo ratings yet

- Top MaxDocument2 pagesTop Maxdanut_docNo ratings yet

- Straw Bale Green HomeDocument13 pagesStraw Bale Green Homedanut_docNo ratings yet

- Isca Class Rules Effective: October 5, 2006 (Cancels Previous Rules and Interpretations)Document12 pagesIsca Class Rules Effective: October 5, 2006 (Cancels Previous Rules and Interpretations)danut_docNo ratings yet

- Qubo 2: Della Valentina Office SpaDocument1 pageQubo 2: Della Valentina Office Spadanut_docNo ratings yet

- Sailing Inflatable KayakDocument10 pagesSailing Inflatable Kayakdanut_docNo ratings yet

- Perfect Roast PotatoesDocument4 pagesPerfect Roast Potatoesdanut_docNo ratings yet

- SunfishDocument5 pagesSunfishdanut_docNo ratings yet

- Pattern Layout: ' - Hem FacingDocument4 pagesPattern Layout: ' - Hem Facingdanut_docNo ratings yet

- Pattern Layout: Women S Suitstyle JacketDocument5 pagesPattern Layout: Women S Suitstyle Jacketdanut_docNo ratings yet

- Tailored TrousersDocument1 pageTailored Trousersdanut_doc100% (2)

- Pattern Layout: Front AND Neck FacingDocument4 pagesPattern Layout: Front AND Neck Facingdanut_docNo ratings yet

- Pattern Layout: ' - Curved SleeveDocument12 pagesPattern Layout: ' - Curved Sleevedanut_docNo ratings yet

- Hobie Parts Accessories PricelistDocument9 pagesHobie Parts Accessories Pricelistdanut_docNo ratings yet

- PPWP 1Document9 pagesPPWP 1danut_doc100% (1)

- Pattern FOR Women S Pants Waistband Extra PiecesDocument6 pagesPattern FOR Women S Pants Waistband Extra Piecesdanut_doc100% (1)

- Pattern FOR Women S Pants BackDocument15 pagesPattern FOR Women S Pants Backdanut_docNo ratings yet

- Skiathos - Captain BarefootDocument4 pagesSkiathos - Captain Barefootdanut_docNo ratings yet

- Corfu Beaches - Corfu Nudist BeachesDocument6 pagesCorfu Beaches - Corfu Nudist Beachesdanut_doc0% (1)

- Sail TrimmingDocument2 pagesSail Trimmingdanut_docNo ratings yet

- Sailing Summer 2013Document72 pagesSailing Summer 2013danut_docNo ratings yet

- Making The Tyvek SailDocument5 pagesMaking The Tyvek Saildanut_docNo ratings yet

- Mango ProcessingDocument8 pagesMango ProcessingelgibinNo ratings yet

- Introduction To Parlay Call Control and Related Topics: Ravi Jain and John-Luc BakkerDocument34 pagesIntroduction To Parlay Call Control and Related Topics: Ravi Jain and John-Luc BakkergaborkNo ratings yet

- Unit-2 ANS KEYDocument13 pagesUnit-2 ANS KEYRajaNo ratings yet

- MW 1Document6 pagesMW 1abhi_engg06No ratings yet

- Wind Tunnel Experiments Procedure in UPMDocument5 pagesWind Tunnel Experiments Procedure in UPMMohd AnuarNo ratings yet

- Louver WeightDocument2 pagesLouver WeightAbhay Sisodia50% (2)

- Maica Joules S. Montehermoso BSA-21ADocument4 pagesMaica Joules S. Montehermoso BSA-21AMaica Joules MontehermosoNo ratings yet

- PSSSB Kanungo PaperDocument24 pagesPSSSB Kanungo PaperRahul BangaNo ratings yet

- PAN & Aadhaar Updation FormDocument1 pagePAN & Aadhaar Updation FormNiraj KumarNo ratings yet

- SpecoDocument24 pagesSpecoElumalai SrinivasanNo ratings yet

- Defense Works Int ST Inspect Maint and Test at Petrol Sites MechandElec PDFDocument53 pagesDefense Works Int ST Inspect Maint and Test at Petrol Sites MechandElec PDFbiglee82No ratings yet

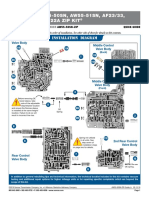

- AW55-50SN, AW55-51SN, AF23/33, Re5F22A Zip Kit: Installation DiagramDocument10 pagesAW55-50SN, AW55-51SN, AF23/33, Re5F22A Zip Kit: Installation DiagramRomeo Taranu100% (2)

- Stream Control Transmission ProtocolDocument3 pagesStream Control Transmission ProtocoldiporufaiNo ratings yet

- PCT 353607Document46 pagesPCT 353607eddy1588No ratings yet

- Part I - Research Proposal: St. Paul University Surigao College of EngineeringDocument2 pagesPart I - Research Proposal: St. Paul University Surigao College of EngineeringJoenetha Ann ApariciNo ratings yet

- ABB MES AstraZenecaDocument51 pagesABB MES AstraZenecaMarcio Issao WatanabeNo ratings yet

- GP CatalogueDocument69 pagesGP Cataloguekrsna ANo ratings yet

- Wp50 DraftDocument40 pagesWp50 DraftMutazYM1No ratings yet

- Mega RecoverykeyDocument28 pagesMega RecoverykeyNikesh PandeyNo ratings yet

- CMF MonitorDocument136 pagesCMF MonitorJoyce ShiNo ratings yet

- 95 DDocument563 pages95 DGutium AlexeyNo ratings yet

- Checking The Piston Diameter Checking The Piston Pin Boss BoreDocument1 pageChecking The Piston Diameter Checking The Piston Pin Boss BorePHUONG NGUYENNo ratings yet

- Dalton Reamy: University of North Texas, Eagle Commons LibraryDocument1 pageDalton Reamy: University of North Texas, Eagle Commons Libraryapi-559098220No ratings yet

- Selection Guide For Transformer-Primary Fuses inDocument78 pagesSelection Guide For Transformer-Primary Fuses inJose Alberto Rodriguez100% (1)