Professional Documents

Culture Documents

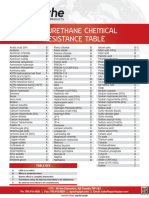

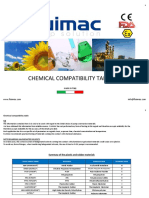

Chemical Properties A-F

Uploaded by

GreggC66Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Properties A-F

Uploaded by

GreggC66Copyright:

Available Formats

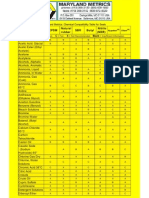

Reagent LDPE HDPE PP PMP PVC PC PS SAN ABS ACRYLIC PTFE PFA E-CTFE

Tem perature C 20 50 20 50 20 50 20 50 20 50 20 50 20 50 20 50 20 50 20 50 20 50 20 50 20 50

Tem perature F 68 122 68 122 68 122 68 122 68 122 68 122 68 122 68 122 68 122 68 122 68 122 68 122 68 122

A cetaldehyde

A cetic A cid

A cetic A nhydride

A cetone

A cetyl C hloride

A m m onium C hloride (10% )

A m m onium H ydroxide (28% )

A m yl A cetate

A niline

A qua Regia

Benzaldehyde

Benzene

Benzoic A cid

Boric A cid (10% )

Brom ine G as (D ry)

Brom ine W ater

Butyl A cetate

Butyl A lcohol

Butyric A cid

C alium H ydroxide (Saturated)

C arbon D isulphide

C arbon Tetrachloride

C hlorine G as (D ry)

C hlorine W ater

C hloroform

C itric A cid

m -C resol

C yclohexane

D ibutylphthalate

p-D ichlorobenzene

D iethyl Ether

D iethylene G lycol

D im ethyl Form am ide

D ioxane

Ethyl A cetate

Ethyl A lcohol

Ethyl C hloride

Ethylene C hloride

Ethyl O xide

Fluorine G as (D ry)

Form aldehyde (Form alin)

Form ic A cid

Fuel O il

This chart gives general guidelines only on the chem ical resistance of plastics. There are m any factors w hich influence

chem ical resistance - alw ays test for your ow n application before selecting the appropriate product. If you have any

doubts, please contact our Technical D epartm ent for advice.

Excellent resistance

no attack

G ood resistance

m inor attack

Lim ited resistance

m oderate attack

Poor resistance, attacked or

dissolved, not recom m ended

N o inform ation

available

You might also like

- Garbon Rigid PocketDocument3 pagesGarbon Rigid Pocketmikael8118No ratings yet

- Chelating Extractants: Equilibrium Constant of Liquid–Liquid Distribution ReactionsFrom EverandChelating Extractants: Equilibrium Constant of Liquid–Liquid Distribution ReactionsNo ratings yet

- Chemical Resistance TableDocument1 pageChemical Resistance TableSteve FransiscusNo ratings yet

- Polyurea Resistance ChartDocument1 pagePolyurea Resistance ChartTanmay GorNo ratings yet

- Compound Selection Guide for Chemical ResistanceDocument6 pagesCompound Selection Guide for Chemical ResistanceRolando DoderoNo ratings yet

- O-Ring Compatibility Chart: All Pressure Filtration Resources All Bench Scale Equipment ResourcesDocument10 pagesO-Ring Compatibility Chart: All Pressure Filtration Resources All Bench Scale Equipment ResourcesAli Raza KaisraniNo ratings yet

- Tekncoat - Technical - Data (1) - 017Document1 pageTekncoat - Technical - Data (1) - 017aboali8686No ratings yet

- Code of Federal RegulationsDocument36 pagesCode of Federal RegulationsSicat Mark BantiyanNo ratings yet

- Storage GroupsDocument1 pageStorage GroupsEva Pa'e ONo ratings yet

- VITLAB Genius2 Simplex2 Recommended Application RangeDocument1 pageVITLAB Genius2 Simplex2 Recommended Application RangeNur RosyidahNo ratings yet

- PEEK Chemical ResistanceDocument4 pagesPEEK Chemical ResistancemarcalpiNo ratings yet

- Chemical Resistance ChartDocument2 pagesChemical Resistance ChartPinyaporn VeerapraditNo ratings yet

- Polymers and BiomoleculesDocument93 pagesPolymers and BiomoleculesSajaNo ratings yet

- 316L Stainless Steel Chemical Compatibility PDFDocument5 pages316L Stainless Steel Chemical Compatibility PDFsujingthetNo ratings yet

- Chemical Resistance of PlasticsDocument2 pagesChemical Resistance of PlasticsAFLAC ............100% (2)

- Acrylic Pmma Chemical Compatibility Chart From IsmDocument11 pagesAcrylic Pmma Chemical Compatibility Chart From IsmDeidra CadeNo ratings yet

- Transducer Disinfectants and Cleaning SolutionsDocument10 pagesTransducer Disinfectants and Cleaning SolutionsMario RamosNo ratings yet

- Chemical Corrosion Chart 2Document40 pagesChemical Corrosion Chart 2teddydeNo ratings yet

- Chemical Resistance ChartDocument20 pagesChemical Resistance Chartharsh shah100% (1)

- Chemical Compatibility TableDocument28 pagesChemical Compatibility TableBea LubaoNo ratings yet

- IBC-code Chapter 17Document15 pagesIBC-code Chapter 17karibasappa1No ratings yet

- Versa MaticDocument40 pagesVersa MaticRelu123No ratings yet

- Lint Interceptors: General InformationDocument6 pagesLint Interceptors: General InformationKrishna PATELNo ratings yet

- 870 43 18 Technical Documentation Sika AnchorFix 3030 (06 2018) 1Document15 pages870 43 18 Technical Documentation Sika AnchorFix 3030 (06 2018) 1Lucian BogorodeaNo ratings yet

- Nomenclature SheetDocument24 pagesNomenclature SheetEkta MishraNo ratings yet

- Chemical Resistance ChartDocument4 pagesChemical Resistance Charterminb1525No ratings yet

- Organic Chemistry: Alcohols, Phenols, Ethers, and Thiols (ANSWER KEYSDocument28 pagesOrganic Chemistry: Alcohols, Phenols, Ethers, and Thiols (ANSWER KEYSHazel Anne NagaNo ratings yet

- Chemical Compatibility Table For SealsDocument3 pagesChemical Compatibility Table For Sealspi31415926535No ratings yet

- Activated Carbon Adsorption ListDocument4 pagesActivated Carbon Adsorption ListmaryamNo ratings yet

- Chem - Res Chart BoyserDocument24 pagesChem - Res Chart Boyseragrocel_bhv5591No ratings yet

- Recommended Storage Groups for Common ChemicalsDocument2 pagesRecommended Storage Groups for Common ChemicalsRodrigoNo ratings yet

- HDPE Chemical Compatibility & Resistance Chart: Explanation of FootnotesDocument8 pagesHDPE Chemical Compatibility & Resistance Chart: Explanation of FootnotesRozaq Alfan WNo ratings yet

- Exam: Carbonyl CompoundsDocument28 pagesExam: Carbonyl Compoundsffffffff dfdfdfNo ratings yet

- Acrylic Polycarbonate CompatibilityDocument2 pagesAcrylic Polycarbonate CompatibilityfcordNo ratings yet

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet

- Chemset 101 M16Document12 pagesChemset 101 M16Zilong ZhangNo ratings yet

- RUBBER Chemical Resistance ChartDocument13 pagesRUBBER Chemical Resistance ChartBradNo ratings yet

- Lijst Oplosbaarheden NLDocument2 pagesLijst Oplosbaarheden NLAfshin FattahiNo ratings yet

- PolymersDocument11 pagesPolymersEzhil MukilNo ratings yet

- Eco-GPE™: General Purpose EpoxyDocument5 pagesEco-GPE™: General Purpose EpoxyServandoNo ratings yet

- Citral: Properties, Synthesis, and UsesDocument29 pagesCitral: Properties, Synthesis, and Usespavi yuvaraniNo ratings yet

- Compressed Non-Asbestos Sheet Chemical Compatibility Chart: Teadit North AmericaDocument8 pagesCompressed Non-Asbestos Sheet Chemical Compatibility Chart: Teadit North AmericaNikeNo ratings yet

- 304 Stainless Steel Chemical Compatibility ChartDocument1 page304 Stainless Steel Chemical Compatibility ChartchenNo ratings yet

- ETHER (Exercise) Module-4Document14 pagesETHER (Exercise) Module-4Raju SinghNo ratings yet

- 61051feaf8b15a0065e2cbe9 - ## - Polymers - Practice SheetDocument4 pages61051feaf8b15a0065e2cbe9 - ## - Polymers - Practice SheetEbanNo ratings yet

- Chemical Listing For O-RingsDocument80 pagesChemical Listing For O-Ringssham_riteshNo ratings yet

- Tick The Correct Option.: Chemistry Entry Test MCAT By: Sagheer Ahmad Gudara M.Phill ChemistryDocument4 pagesTick The Correct Option.: Chemistry Entry Test MCAT By: Sagheer Ahmad Gudara M.Phill ChemistrykamranNo ratings yet

- Technical Documentation AnchorFix 2Document17 pagesTechnical Documentation AnchorFix 2TimoNo ratings yet

- Specificaties ECEMDocument1 pageSpecificaties ECEMFlorence de SlegteNo ratings yet

- 4 Gate 2008Document16 pages4 Gate 2008lovehopeNo ratings yet

- CLS AN 107 ChemCompPlasticDocument1 pageCLS AN 107 ChemCompPlasticPim ChaNo ratings yet

- PCT MCQ With AnswerDocument22 pagesPCT MCQ With AnswerswapnilNo ratings yet

- Chem Compat Chart - HaywardDocument12 pagesChem Compat Chart - HaywardpdlhNo ratings yet

- Chemical Resistance GuideDocument16 pagesChemical Resistance GuidePette MingNo ratings yet

- General Organic Chemistry (IUPAC) - DPP 06 (Of Lecture 07)Document2 pagesGeneral Organic Chemistry (IUPAC) - DPP 06 (Of Lecture 07)shishiranand25No ratings yet

- CH 13Document30 pagesCH 13ffffffff dfdfdfNo ratings yet

- Tealon Chemical Compatibility Chart: Product TF1570 TF1580 TF1590 Quimflex SH Quimflex 24B TF 1510Document11 pagesTealon Chemical Compatibility Chart: Product TF1570 TF1580 TF1590 Quimflex SH Quimflex 24B TF 1510NikeNo ratings yet

- V TypeDocument3 pagesV Typemikael8118No ratings yet

- ST1630 Green Data SheetDocument4 pagesST1630 Green Data SheetAdolf NguyễnNo ratings yet

- Bam GGR 003 Procedural Rules On The Suitability Proof For Alternative Plastics ResinsDocument4 pagesBam GGR 003 Procedural Rules On The Suitability Proof For Alternative Plastics ResinsGreggC66No ratings yet

- 3DCoach Help FileDocument16 pages3DCoach Help FileGreggC66No ratings yet

- Handbook ArcheryDocument68 pagesHandbook Archeryjaybudd50100% (22)

- Use and Care of PlasticsDocument1 pageUse and Care of PlasticspsnmyNo ratings yet

- m41 ch06Document49 pagesm41 ch06RahulNo ratings yet

- Mondo Bulletin PlasticsDocument8 pagesMondo Bulletin PlasticsGreggC66No ratings yet

- Plyometric Training Football DrillsDocument4 pagesPlyometric Training Football DrillsGreggC66No ratings yet

- Stacking Business in Your FavourDocument2 pagesStacking Business in Your FavourGreggC66No ratings yet

- J FC Brochure Sept 09Document8 pagesJ FC Brochure Sept 09GreggC66No ratings yet

- Chemical Compatibility ChartDocument29 pagesChemical Compatibility ChartGreggC66No ratings yet

- nps4C TMPDocument6 pagesnps4C TMPLewis SimonNo ratings yet

- SPX Air StandardsDocument9 pagesSPX Air StandardsGreggC66No ratings yet

- Coaching and Games Development in - The Club PDFDocument12 pagesCoaching and Games Development in - The Club PDFGreggC66No ratings yet

- Core Stability Training Programme for Back Pain ReliefDocument5 pagesCore Stability Training Programme for Back Pain ReliefLewis SimonNo ratings yet

- Fluid Needs and Hydration Needs For Children PDFDocument2 pagesFluid Needs and Hydration Needs For Children PDFGreggC66No ratings yet

- Parentsv and Guardians PDFDocument3 pagesParentsv and Guardians PDFGreggC66No ratings yet