Professional Documents

Culture Documents

Duct Electric Heater

Duct Electric Heater

Uploaded by

Arun MaliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duct Electric Heater

Duct Electric Heater

Uploaded by

Arun MaliCopyright:

Available Formats

/wEPDwUKLTU4NDA3NTcxOWQYAQUeX19Db250cm9sc1JlcXVpcmVQb3N0QmFja0tleV9fFgEFFWRubjpJTkdFTklNRU5VMTpfY3RsMKlmdIv3WVDyPX4CFemBotxudOeq

Home

About

o Company

Company Profile

Qualified Design Engineer

Consistant Quality

On Time Delivery

Rush Service Rate Schedule

Standard Features

Optional Features

Pricing

Packaging

o

o Mission Statement

o

o News

o

o See where BTU duct heaters are being used.

o

o Testimonials

o

o Privacy Policy

o

o Terms of Use

Products

o Electric Duct Heaters

Single Phase Electric Duct Heaters

Three Phase Electric Duct Heaters

Duct Heater Options

Warranty

Submittal Data Form

Model Numbering

o

o Unitary Heaters

Air Pro Unitary Heaters

Air Therm Unitary Heaters

American Best Unitary Heaters

Bard Unitary Heaters

Coldpoint Unitary Heaters

Coleman Unitary Heaters

Dayton / Grainger Unitary Heaters

Evcon Unitary Heaters

First Company Unitary Heaters

Goettl Unitary Heaters

Kenmore Unitary Heaters

Luxaire Unitary Heaters

Magic Aire Unitary Heaters

Moncrief Unitary Heaters

Rheem Unitary Heaters

Ruud Unitary Heaters

Unitairy Products Group

United Refrigeration

USA Coil

Weatherking Unitary Heaters

York Unitary Heaters

o

o Load Banks

o

o Parts & Accessories

Air Pressure Switches

Contactors (magnetic)

Contactors (quiet)

Fan Switches (automatic)

Fuses (power) one time for resistive loads

Fuses -time delay)-for motor loads

Fusible Links (micro devices 4 series) w

Fusible Link Assemblies (micro devices) with cross

Heater Elements & Replacement Kits

Limit Switches (automatic)

Manual Resets & Firestats

Outdoor Thermostats

Relays (fan & switching)

Sequencers (time delay relays)

Time Delay Relays (fan control)

Transformers (class 2 and others)

o

o Process Heaters

Quote/Submittal Forms

o Quote Form

o

o Duct Heater Submittal Form

o

o Element Replacement Form

Technical Data

o Heater Selection & Sizing Formulas

o

o Element Replacement Guide

o

o Basic Wiring

o

o Service Tips

o

o Technical Data PDF Printable

o

o Thermostat and SCR Instructions

o

o Model Numbering

FAQ

o Service Tips

Contact Us

Electric Duct Heating Blog: Toast

Heater Selection & Sizing

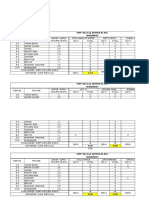

Determining the Size of your Duct Heater

A one KW heater will produce 3,413 BTU's per hour. If you know the CFM of your air handler and the temperature rise needed, you can use the

chart below to approximate the KiloWatt rating of the duct heater needed for your application.

For example: If you need a 40 degree temperature rise, and your air handler puts out 2000 CFM, identify the point at which the 40 degree

temperture rise line intersects with the 2000 CFM line and you will see that a 25 KW heater is needed to do the job.

Rated Voltage

Most heaters are designed for a rated voltage. If your site has a voltage above or below rating, (it will usually be below the rated voltage), your

heater will generate a different output.

A 240 V rated Heater with a supply of 230 V will yield only 92% of its rated output.

A 240 V rated Heater with a supply of 220 V will yield only 84% of its rated output.

A 240 V rated Heater with a supply of 208 V will yield only 75% of its rated output.

Electric heaters are purely resistive loads, amperage will decline with applied voltage.

MINIMUM AIRFLOW REQUIREMENTS

To operate properly, duct heaters need minimum quantities of air flow. An inlet air temperature of 77F will require approximately 65 CFM of air

flow per KW, that is typical for straight cooling. When operating a heat pump with inlet air temperature of 110F, approximately 120 CFM of air

flow per KW will be needed. Check our Installation Manual for final Airflow determination. (The above is a conservative "Rule of Thumb" if

the heater fills the duct).

HEATER PERFORMANCE FORMULAS

MULTIPLIERS FOR DETERMINING THE AMPERAGE DRAW OF DUCT HEATERS

1 Phase @120 Volts KW times 8.333 1 Phase @208 Volts KW times 4.808

1 Phase @220 Volts KW times 4.545 1 Phase @230 Volts KW times 4.348

1 Phase @240 Volts KW times 4.167 1 Phase @277 Volts KW times 3.610

1 Phase @480 Volts KW times 2.083 1 Phase @600 Volts KW times 1.667

3 Phase @208 Volts KW times 2.776 3 Phase @220 Volts KW times 2.624

3 Phase @230 Volts KW times 2.510 3 Phase @240 Volts KW times 2.406

3 Phase @480 Volts KW times 1.203 3 Phase @600 Volts KW times 0.962

MAXIMUM KW PER CIRCUIT AND BEGINNING OF OVERCURRENT REOUIREMENTS

Voltage 120V 208V 220V 230V 240V

1 Phase 5.76 9.98 10.56 11.04 11.52

3 Phase ------ 17.29 18.29 19.12 19.95

Voltage 277V 460V 480V 550V 600V

1 Phase 13.29 22.08 23.04 26.40 28.80

3 Phase ------ 38.24 39.90 45.72 49.88

Note: ln each group throughout the Price Lists, the highest KW for a particular voltage and phase without circuit fusing is listed, just before a

Heater with an asterisk after the price.

SELECT CAREFULLY AND SAVE !!!

Substantial cost increases result when additional elements, controls and/or circuits are required. We are not suggesting that you purchase less

capacity than you need but sometimes a lower KW will be quite adequate and will save you a bundle!!!

Example: If an 11.5KW Heater @ 240V 1 @ will do the job, why use the 12KW Heater @ 240V costing at least 40% more because it is over

the allowable 48 Amps per Circuit and requires costly Overcurrent Protection.

Example: If the situation is right and a good safe job can be done, it might be well to consider the installation of separate Heaters, each rated less

than 48 Amps and not requiring Overcurrent Protection from the factory. Possibly a Heater in each duct branch or more than one Heater in the

main duct could be used. Our Heaters are Listed so that this may be done in a ganged fashion to fill the cross- sectional area or one after the

other if the inlet to any Heater is 110'F or less.

FIELD WIRING OF DUCT HEATERS

Field Wires to Heater Controls Compartments or Fuse Panels must be Copper suitable for 75'C (1 67'F). In the following table we show actual

maximum load permitted which is 80% of the total ampacity of the wire when there are 6 or less conductors in a conduft and 70% when the

conductors exceed 6. U.L. requires that a neutral be counted as a conductor in units rated 120 or 277 Volts. However, they do not require that

you count grounding wires.

Note:

Heaters with built-in fusing are designed to accept field

electrical supplies as follows:

1 Ph. 20 to 48A @ 208 to 600V-1 Supply

1 Ph. 49 to 144A @ 208 to 240V-1 Supply

3 Ph. 24 to 48A @ 208 to 600V-1 Supply

3 Ph. 49 to 96A @ 208 to 240V-1 Supply

3 Ph. 97 to 144A @ 208 to 240V-1 or 3 Supplies

3 Ph. 49 to 96A @ 300 to 600V-1 or 2 Supplies

Option: Item just above - 1 Supply most other heaters have provision for 48A, or 96A supply circuits in multiple. Heaters requiring circuit

fusing are also available with smaller control boxes and a seperate U.L. Listed Remote Fuse Panel. Consult Factory for additional information.

TEMPERATURE EQUIVALENT TABLE

For other equivalents not listed

in table use following formulas:

F=C X 1.8 + 32

C=F - 32 / 1.8

Electric Resistance Heat Values can be

found by direct application of Ohm's

Law and other known electrical values

or equations. Formulas and applications

considered are limited to those of

benefit to people involved in sales or

service of Electric Duct Heaters.

In Formulas and Applications

considered below: The square root of 3

(3) = 1.732

P = Watts

E = Volts

KW = 1,000

Watts

I = Amps

R = Ohms

1 KW = 3,413

BTUH

FORMULAS AND APPLICATION:

I = P/E

or

Amps = Watts + Volts

EXAMPLE: To determine the Amperage draw of a 9.8 KW

Heater at 208V Single Phase, divide Watts by Volts as per

formula. (9800 + 208 = 47.1 A) For a balanced load Three

Phase Heater the Single Phase answer is divided by 43.

(47.1 + 1.732 = 27.2A)

P =EI

or

Watts = Volts X Amps

EXAMPLE: To determine the KW of a 240V Single Phase

Heater drawing 40 Amps, multiply Volts X Amps as per

formula (240 X 40 - 9600 Watts or 9.6KW). For a balanced

load Three Phase Heater the Single Phase answer is

multiplied by @ (9.6 X 1.732 - 16.63KW).

USEFUL IN HEATER SELECTION: To determine how

much KW you can connect to a limited available Amperage

and/or wire size. You may not want to exceed a 48 Amp

Circuit which would add considerable expense for Circuit

Fusirig required by U.L. and National Electric Code.

EXAMPLE: You need a Heater not more than 48 Amps at

240V Single Phase. Multiply Volts X Amps as per formula

(240 X 48 - 11,500 Watts or 11.5KW). For a balanced load

Three Phase Heater, the Single Phase answer is multiplied

by iq (1 1.5 X 1.732 - 19.9KW).

P =

E/R or

Watts = Volts Squared @ Ohms

This formula is used to derate the Heater output (Watts)

when a lower voltage is applied. Element Resistance

(Ohms) remains the same so the reduced output is directly

related to the square of the Voltage change.

EXAMPLE: You have a Heater rated 19.6KW, Three Phase

at 24OV, 47.2A. and want to connect R to a 208V supply

and determine the new KW output. Proposed Volts squared

divided by the rated Volts squared = the multiplier. 208 x

208 _ 43.264 _ .75 This .75 x 19.6KW at 240V - 14.7KW at

208V. 240 x @40 57,600

Note that the Amps go down at the reduced voltage. Using

the first formula above for Three Phase, 14,700 divided by

208V - 70.7 Amps and that figure divided by il (1.732) -

40.8 Amps.

For further examples of connecting Heaters to lower

voltages please see the chart that has been worked out on

the back of this page. You will note also that the Wattage

and related BTUH drop at a faster rate than the Amperage.

CONNECTING TO LOWER VOLTAGES

When a heater with fixed resistance in ohms is connected to a lower than rated voltage, the Wattage and BTUH output as well as Amps will be

reduced as shown in the Chart below.

CONNECTING TO HIGHER VOLTAGES

NEVER connect a Heater to a higher voltage than the Data Plate ratingl Just as the output drops with lower applied voltage, it increases even

more rapidly with a higher voltage.

Heater

Rated

Voltage

Lower

Applied

Voltage

% of Heater

Wattage and

BTUH

% of Heater

Data Plate

Amps.

600 575

550

92%

84%

96%

92%

480 460

440

92%

84%

96%

92%

277 265

254

92%

84%

96%

92%

240 230

220

208

201

92%

84%

75%

70%

96%

92%

87%

84%

208 200

190

92%

84%

96%

92%

120 115

110

92%

84%

96%

92%

EXAMPLE: Connect 240 V to a 208 V Heater, 17.25 KW, 3 Ph., 47.9 Amps.

RESULT: Heater output increases to 23 KW drawing 55.3 Amps at 240V.

1. Amp Draw is now over the 48 per circuit allowed bu UL and NEC

2. The Element output is now at 1/3 more than factory design limit.

3. Contactor and other component capacities may be exceeded.

4. Safe Wattage Density may now be exceeded and Heater short cycles.

5. UL Label and Warranty are VOID!!

6. Product Liability passes from us! YOU WILL HAVE PROBLEMS!!!

RESISTANCE IN OHMS CALCULATED FOR VARIOUS HEATERS

You are not generally required to know the Ohms of Elements in a Heater unless you need replacement(s) and, even then, you would specify the

KW, Voltage, Phase etc. from the Heater Data Plate with the KW per Element determined by dividing total KW by the number of Elements.

Sometimes it is necessary to know the Ohms for replacements, particularly for Three Phase Heaters. You may measure the total Ohms of two or

more pieces and, when possible, supply nameplate data, Element coil O.D. etc. A review of some sample formulas below will show that it is

important to be able to distinguish between Delta or Star (Wye) Three-Phase construction.

R = E/I

or

Resistance in Ohms = Volts divided by Amps. You may

apply this formula when you have a single element Heater

or when you have an Amp reading of just one Element of a

Single or Three-Phase, Delta-wired Heater. Each Element is

calculated as Single Phase. See note below to get Cold

Ohms.

R -

E2/P or

Resistance in Ohms - Volts squared divided by Wafts. This

formula can be used except for Three-Phase, Star

Connected Elements. See "Basic Electric Heat Wiring

Diagrams" to help identify Star (Wye) Elements. In a Star-

wired set of Elements, you divide the Voltage by V7

(1.732) and then proceed to calculate Resistance by the

Formula. EXAMPLE: Take a 20 KW Heater, Three-Phase

at 240V. with 6 Elements, 3,333 Wafts each that are

designed as two 10 KW, star-wired sets. 240 V divided by

1.732 = 138.6 V to be used when applying the Formula.

138.6 squared = 19,210. This divided by 3,333 = 5.76 Hot

Ohms each. NOTE: Ohms calculated by formula must be

reduced by 5 to 10 percent to allow for the extra Resistance

an Element will have when R is heated. This answer is now

Cold Ohms that we use in Element design. The proper wire

gauge must be chosen to result in enough surface area to

dissipate the heat and avoid premature failure.

Heater Selection & Sizing

Home | About | Products | Quote/Submittal Forms | Technical Data | FAQ | Contact Us | Electric Duct Heating Blog: Toast

2012 Bel Thermal Units, Inc.

Bel Thermal Units, Inc. "BTU" 4810 NW 35th Avenue Miami, Florida 33142 | Phone: (954) 566-0043 | Fax: (954) 563-7941 Email:

btu@belthermal.com

The information in this website is proprietary and may not be copied or reprinted with out the express permission of Bel Thermal Units, Inc.

Installation instructions and other documentation is made available to purchasers of Bel Thermal products and may not be used, copied or

distributed by any other party.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Chiller Vs VRFDocument26 pagesChiller Vs VRFalmig20080% (15)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fully Extended: (CD11-2) Straight Duct, Flexible (Abushakra 2004 and Culp 2011Document1 pageFully Extended: (CD11-2) Straight Duct, Flexible (Abushakra 2004 and Culp 2011almig200No ratings yet

- ASHRAE Duct DesignDocument13 pagesASHRAE Duct DesignJose Darwin Margate100% (2)

- Expansion Tank Sizing Calculation Hydronic SystemDocument16 pagesExpansion Tank Sizing Calculation Hydronic SystemNay Myo OoNo ratings yet

- Sump Submersible Pumps DesignDocument4 pagesSump Submersible Pumps DesignAnonymous wIPMQ5rhNo ratings yet

- (CR11-1) Straight Duct, Rectangular (Huebscher 1948) : Tel: FaxDocument1 page(CR11-1) Straight Duct, Rectangular (Huebscher 1948) : Tel: Faxalmig200No ratings yet

- Vvip Villa at Almina Place BasementDocument8 pagesVvip Villa at Almina Place Basementalmig200No ratings yet

- Expansion Tanks I Zings 2012Document7 pagesExpansion Tanks I Zings 2012henhuangNo ratings yet

- 11Document1 page11almig200No ratings yet

- Ligends: West Yas - Residential 1017 VILLASDocument1 pageLigends: West Yas - Residential 1017 VILLASalmig200No ratings yet

- 5 7 Sidewall Standard Spray SprinklersDocument7 pages5 7 Sidewall Standard Spray Sprinklersalmig200No ratings yet

- (CR3-1) Elbow, Smooth Radius Without Vanes (Idelchik 1986, Diagram 6-1)Document1 page(CR3-1) Elbow, Smooth Radius Without Vanes (Idelchik 1986, Diagram 6-1)almig200No ratings yet

- The Hazren Williams FormulaDocument3 pagesThe Hazren Williams Formulaalmig200No ratings yet

- Design Options For HVAC Distribution SystemsDocument68 pagesDesign Options For HVAC Distribution Systemscathybravo100% (3)

- Integration of HVAC System Design With Simplified Duct DistributionDocument2 pagesIntegration of HVAC System Design With Simplified Duct Distributionalmig200No ratings yet

- Table E103Document3 pagesTable E103almig200No ratings yet

- 5 7 Sidewall Standard Spray SprinklersDocument7 pages5 7 Sidewall Standard Spray Sprinklersalmig200No ratings yet

- Leed Hvac Design Leed Commissioning Jorge Mbo SmriDocument39 pagesLeed Hvac Design Leed Commissioning Jorge Mbo Smrialmig200100% (1)

- Specifications and FormulasDocument1 pageSpecifications and Formulasalmig200No ratings yet

- Chilled Water Pipe Insulation Method StatementDocument2 pagesChilled Water Pipe Insulation Method StatementGündoğdu Akın75% (4)

- Input Required Data in Yellow Field OnlyDocument7 pagesInput Required Data in Yellow Field Onlyalmig200No ratings yet