Professional Documents

Culture Documents

Use of Limit State Design in Foundation Engineering

Use of Limit State Design in Foundation Engineering

Uploaded by

Andreea LucaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use of Limit State Design in Foundation Engineering

Use of Limit State Design in Foundation Engineering

Uploaded by

Andreea LucaCopyright:

Available Formats

Engineers Australia

The Civil and Structural Engineering Panel

Use of Limit State Design in Foundation

Engineering

(Patrick Wong 17 April 2012)

Presentation Outline

1. Working Stress Design Method

2. Limit State Design Method

3. Comparison between the two methods

4. Case Study (Barangaroo South) 4. Case Study (Barangaroo South)

5. Conclusions

Working Stress Design Method

allowable bearing pressure for footings

allowable shaft friction and allowable end

Structural Engineers often ask the Geotechnical

Engineers to provide:

allowable shaft friction and allowable end

bearing pressure for piles

But what does Allowable mean? Is it:

Ultimate Capacity / Factor of Safety (FOS) ?

or FOS can be rewritten as: or FOS can be rewritten as:

FOS = Ultimate Capacity / Working Load

But what is the appropriate FOS (2, 2.5, 3)?

R

ug

Pile

Foundation

Load

R

Shallow

Footing

Load

P

w

Deflection

R

ug

P

w

Deflection

Choice of FOS is also affected by uncertainty in

material properties

F

r

e

q

u

e

n

c

y

Concrete

Legend

F

r

e

q

u

e

n

c

y

Material Strength

Soil

Mean strength

Working Stress Design Summary:

Allowable load = Ultimate Capacity / FOS

FOS should be dependent on:

tolerable deformation tolerable deformation

foundation stiffness (linear or non-linear?)

uncertainties in material properties/behaviour

But these factors are rarely considered adequately in

Working Stress Design

Rock

Class

Rock Strength

Allowable End

Bearing

Pressure

Allowable

Shaft

Adhesion

Example of Allowable Design Parameters given in a Recent Site

Investigation Report (settlement <1% footing width)

Class

Pressure

(kPa)

Adhesion

(kPa)

IV Shale

Extremely low to very

low

800 80

III Shale Medium strength 3000 300

II Shale High strength 8000 800

Why Limit State Design?

1960s identified two specific classes of problem not

adequately addressed by working stress designs:

Failures under extreme low probability events

Over-design in redundant structures Over-design in redundant structures

Failures under low probability events

Failures under low probability events

DESIGN WIND LOAD

Self weight less overtuning

= net compression

frictional resistance

Failures under low probability events

DESIGN WIND LOAD EXTREME WIND LOAD BUCKLE AND COLLAPSE

Self weight less overtuning Self weight less overtuning

= net compression = net uplift SLIDING

frictional resistance

Redundancy and indeterminate structures

Foundation Engineering

Definition of the Ultimate Limit State (ULS)

Definition in Austroads 1992 for foundations:

a. a limit state at which a mechanism is formed in the

ground

b. a limit state which involves a loss of static equilibrium or b. a limit state which involves a loss of static equilibrium or

rupture of a critical section of the structure due to

movements in the ground

Definition of the Serviceability Limit State (SLS)

Similar to working stress loads BUT strength of the

structure is not directly considered.

Acceptance criteria relate to the structure being able to

perform its intended function in terms of deflections, perform its intended function in terms of deflections,

crack widths, appearance etc.

The Ultimate Limit State Inequality Formula

ULS Loads Design Geotech Resistance

S* =S

g

R

ug

= R

ug

*

The Ultimate Limit State Inequality Formula

S* =S

g

R

ug

= R

ug

*

Load factor

typically >1

The Ultimate Limit State Inequality Formula

S* =S

g

R

ug

= R

ug

*

(Resistance)

Strength factor

typically <1

The Ultimate Limit State Inequality Formula

S* =S

g

R

ug

= R

ug

*

Assumes probability approximates to a constant factor

Assumes loads and resistance are independent

Idealised Probability Distribution

Idalised Probability Distribution using MEAN Values

0.6

0.8

1.0

1.2

1.4

P

r

o

b

a

b

i

l

i

t

y

D

e

n

s

i

t

y

load resistance Factor of Safety ~ 3.0

Strength Factor ~ 0.6

Load

Factor ~ 1.8

0.0

0.2

0.4

0 1 2 3 4 5

Action/Resistance

P

r

o

b

a

b

i

l

i

t

y

D

e

n

s

i

t

y

Strength Factor ~ 0.6 Factor ~ 1.8

probability

of failure

More Realistic Probability Distribution

"Realistic" Probability distributions of a simple loading including 5% characteristic values

0.8

1.0

1.2

1.4

1.6

1.8

P

r

o

b

a

b

i

l

i

t

y

D

e

n

s

i

t

y

load positive resistance negative resistance

load

factor

(LF)

~ 1.8

LF SF

5%

strength factor

(SF) ~ 0.6

5%

5% 5%

0.0

0.2

0.4

0.6

-3 -2 -1 0 1 2 3 4

Action/Resistance

P

r

o

b

a

b

i

l

i

t

y

D

e

n

s

i

t

y

~ 1.8 ~ 0.6

Higher probability for

smaller loads

Confusions In Terminology

Structural Engineer:

ULTIMATE LOAD

(= ULS Load = S*)

Confusions In Terminology

Structural Engineer:

ULTIMATE LOAD

(= ULS Load = S*)

Geotechnical Engineer:

ULTIMATE CAPACITY

(= R

ug

)

Confusions In Terminology

Structural Engineer:

ULTIMATE LOAD

(= ULS Load = S*)

Geotechnical Engineer:

ULTIMATE CAPACITY

(= R

ug

)

S* R

ug

* =

g

.R

ug

=> Out by a factor of

= 0.4 to 0.8?

Confusions In Terminology

Geotechnical Engineer:

ALLOWABLE LOAD

(= R

ug

/FOS)

Confusions In Terminology

Geotechnical Engineer:

ALLOWABLE LOAD

(= R

ug

/FOS)

Structural Engineer:

???

(S or S* ?)

Confusions In Terminology

Geotechnical Engineer:

ALLOWABLE LOAD

(= R

ug

/FOS)

Structural Engineer:

???

(S or S* ?)

.S = S* R

ug

* =

g

.Rug

Out by a factor of

= 1.2 to 1.5?

Quick Recap:

Limit State Design Requirements

Part 1 - Strength Limit State

R

ug

* S* R

ug

* S*

g

R

ug

S

Failure mechanism does not

form due to deflections

The Limit State Design Requirements

Part 2 - Serviceability Limit State

Under the serviceability loading, the resulting deflection Under the serviceability loading, the resulting deflection

does not exceed the tolerable limit.

Shallow Square Pad Footing Problem on a Stiff Clay

S and S*

Comparison with Working Stress

Comparison with Working Stress

Working Stress:

R

ug

/ FoS S

e.g. R

ug

/ 3.0 S for a shallow footing

Limit State:

R

ug

* S* R

ug

* S*

g

R

ug

S

R

ug

/ (/

g

) S

For typical = 1.3 and

g

= 0.7, (/

g

) = 1.86

R

ug

/ 1.86 S

But the design is not quite finished !

Serviceability Limit State

R

ug

Shallow Square

Pad Footing

Load

For the this example:

S = 1200kN

S* = 1.3 x 1200 = 1560kN

Rug = 600kPa

Working stress:

Rug/3 = 200kPa

B = 2.45m

E at working stress = 20MPa

Settlement = 22mm

Limit State:

S

s

Deflection

Limit State:

Rug* = Rug x 0.7 = 420kPa

B = 1.95m

Serviceability stress = 316kPa

E at this stress level = 16MPa

Settlement = 35mm (may need

to increase footing width if

settlement is unacceptable)

In both methods, likely settlement should

be assessed but rarely done in Working

Stress Design

Deformation is a Key Design Issue

Why?

Case Study Barangaroo South (the site)

Case Study Barangaroo South (site plan)

~ 4 ha

Case Study Barangaroo South (geotech conditions)

Case Study Barangaroo South (Rock Levels)

(top of rock RL0m to -28mAHD)

1. Geotechnical investigation commissioned on a

competitive basis

2. Standard brief requested the provision of design

parameters

Case Study Barangaroo South (design parameters)

3. Report provided geotechnical design parameters

based on well known guide used in Sydney (Pells et

al, 1998)

4. Both Limit State and Serviceability design values

provided in geotechnical investigation report

Case Study Barangaroo South (design parameters)

V

Sand-

stone

Rock

Class

V

IV

III

II

Note FOS ranges

from 3 to 10

Case Study Barangaroo South (Pile Design Loads)

Building

C4

Case Study Barangaroo South (Pile Design Loads)

Building C4 Typical Loads & Settlement Limits

Pile Diameter

(m)

ULS (MN) SLS (MN)

Pile Toe

Settlement

Limit at SLS

(mm)

1 9.4 to 17.5 7.2 to 14.4 3

1.18 20.5 to 28 16.7 to 23 3.5

1.5 26.9 to 32 24.2 to 25.9 4.5

2.4 90.5 to101.4 72.6 to 81.4 7.2

1. Preliminary design using allowable design values

resulted in long socket lengths (e.g.10m in Class II for

2.4m diameter piles)

2. Detailed design using Limit State Design method, with

rock socket settlement performance analysed using

numerical methods:

Case Study Barangaroo South (Design)

Base alone would achieve adequate Strength for the

ULS load

Design was governed by serviceability limits

Rock socket required to provide sufficient stiffness

Rock socket lengths reduced to 50% to 60% of the

preliminary design lengths

Case Study Barangaroo South (Design)

Why is there a

difference?

Case Study Barangaroo South (Design Example)

Case Study Barangaroo South (Design Example)

1. Rough side walls and clean pile bore base

considered to be vital to achieve design stiffness and

capacity

2. Contractor method statement critically reviewed

Case Study Barangaroo South (Construction)

2. Contractor method statement critically reviewed

3. Independent site monitoring by geotechnical staff

4. Pile load testing to validate design assumptions

Case Study Barangaroo South (Load Testing)

Prototype Pile Load

Testing using O-Cells

2 x 0.75m dia piles

designed to be loaded designed to be loaded

to 17.4MN

bi-directionally (i.e.

total 34.8MN)

Case Study Barangaroo South (test pile BAR-19)

Test pile

designed to

mobilise ~75%

of estimated

ultimate shaft

resistance, and resistance, and

~50% of

estimated

ultimate base

resistance

Case Study Barangaroo South (great project for big toys)

Case Study Barangaroo South (rock auger tool)

Case Study Barangaroo South (boring bucket)

Case Study Barangaroo South (boring bucket)

Case Study Barangaroo South (cleaning bucket)

Case Study Barangaroo South (Happy snaps with O-Cell)

Case Study Barangaroo South (O-Cell being lowered)

Case Study Barangaroo South (O-Cell installed)

Case Study Barangaroo South (O-Cell Test Results)

Final load was 26MN

(i.e. 52MN total) at

65mm shaft deflection

but O-Cell not calibrated

beyond 17.4MN

Mobilised values in

Class II Sandstone: Class II Sandstone:

End bearing

pressure > 59MPa

Shaft friction >

2,000kPa, but non-

linear beyond

1,200kPa

Conclusions

1. The design principles for both Working Stress and

Limit State methods are similar, if done properly .

2. Limit State Method has the following advantages:

Partial factors for different levels of uncertainties

Designers are reminded, or forced to consider

the key issues of Deformation as well as the key issues of Deformation as well as

Strength, and hopefully also Uncertainties

Ability to optimise design based on both strength

and serviceability criteria rather than lumping

these together using an arbitrary FOS

Conclusions (Cont)

3. Standard geotechnical investigation and reporting

commissioned under competitive bidding

arrangement is more likely to result in conventional

or ordinary results

4. Better results can be achieved by collaborative

approach between the structural and geotechnical

engineers, with the latter providing input on detailed engineers, with the latter providing input on detailed

foundation assessment, validation testing, and

construction monitoring.

5. I am not advocating reducing safety factors - I am

advocating replacing arbitrary safety factors

Prof. Malcolm Bolton, Cambridge University - 52

nd

Rankine Lecture 2012

Clear communication and close

working relationship between

geotechnical and structural

engineers is essential

Acknowledgement

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Option Ii: Collector Beam Detail Scale 1:20Document1 pageOption Ii: Collector Beam Detail Scale 1:20Kuber BogatiNo ratings yet

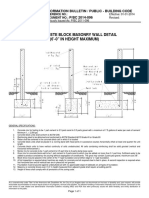

- 6" Concrete Block Masonry Wall Detail (6'-0" in Height Maximum)Document1 page6" Concrete Block Masonry Wall Detail (6'-0" in Height Maximum)Kuber BogatiNo ratings yet

- Retrofit CourseDocument34 pagesRetrofit CourseKuber BogatiNo ratings yet

- Advances in Engineering Software: M.J. Esfandiari, G.S. Urgessa, S. Sheikholare Fin, S.H. Dehghan ManshadiDocument12 pagesAdvances in Engineering Software: M.J. Esfandiari, G.S. Urgessa, S. Sheikholare Fin, S.H. Dehghan ManshadiKuber BogatiNo ratings yet

- Model TOR For DPR Preparation of Road and Bridge ProjectsDocument6 pagesModel TOR For DPR Preparation of Road and Bridge ProjectsKuber BogatiNo ratings yet

- Temporary Spoil: Car Park SpecificationDocument1 pageTemporary Spoil: Car Park SpecificationKuber BogatiNo ratings yet

- Consulting Engineers ManualDocument50 pagesConsulting Engineers ManualFungai M ChitsikeNo ratings yet

- 7.1 Isolated Footing Example: 7.1.1 Creating A New General Foundation ProjectDocument9 pages7.1 Isolated Footing Example: 7.1.1 Creating A New General Foundation ProjectKuber BogatiNo ratings yet

- Dde Mov Ersio N Ense Dde Mov Ersio N: Design DetailDocument3 pagesDde Mov Ersio N Ense Dde Mov Ersio N: Design DetailKuber BogatiNo ratings yet

- Non-Linear Seismic Analysis of A Reinforced Concrete Building With FRP Jacketed ColumnsDocument6 pagesNon-Linear Seismic Analysis of A Reinforced Concrete Building With FRP Jacketed ColumnsKuber BogatiNo ratings yet