Professional Documents

Culture Documents

Series: Hydraulic Excavator

Series: Hydraulic Excavator

Uploaded by

Agus Soy YoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series: Hydraulic Excavator

Series: Hydraulic Excavator

Uploaded by

Agus Soy YoCopyright:

Available Formats

HYDRAULIC EXCAVATOR

EX-6 series

Model Code : EX3600

-6

Engine Gross Power : 1 450 kW (1 944 HP)

Operating Weight : Loading Shovel : 361 000 kg

Backhoe : 359 000 kg

Loading Shovel Bucket : PCSA Heaped : 21.0 m

3

23.0 m

3

Backhoe Bucket : PCSA Heaped : 22.0 m

3

CECE Heaped : 19.2 m

3

2 3

Ultra Large Sized Production

from the Hitachi Gigantic

Excavators

The Hitachi Giants Yield Amazing

Mining Production

Setting a New Standard

4 5

Powerful SingleEngine Readyforthetask.

Time-proven Cummins diesel engine produces a total of 1 450 kW (1 944 HP) for

handling the big excavation jobs.

1 450 kW (1 944 HP)

EmissionControl Engine Helpingtoprotectourenvironment.

Conforms to U.S. EPA Tier emission regulations.

EfcientE-PControl Adjustspoweroutputtotheworkbeingperformed.

Hitachi's computer-aided Engine-Pump Control (E-P Control) coaxes optimum

efciency fromthe engine and hydraulic pumps. This innovative systemsenses load

demand and controls engine and pump output for maximumoperating efciency.

LargerBucketProvidesHighWorkCapacity.

Loading shovel bucket : 21.0 m

3

Backhoe bucket : 22.0 m

3

MaximumExcavatingForce.

Loading shovel : Arm crowding force : 1 200 kN (122 000 kgf)

Breakout force : 1 130 kN (115 000 kgf)

Backhoe : Arm crowd force : 951 kN (97 000 kgf)

Bucket digging force : 1 050 kN (107 000 kgf)

LargeBucket Designedtoenhanceefciency.

The large bucket has been shaped specically

to enhance scooping and loading operations. Its

sharp tilt angle helps boost operating efciency.

Productivity-BoostingAuto-LevelingMechanism One-leverlevelingcontrol.

This is another unique Hitachi function developed exclusively for more efcient

leveling operations.

70

Tiltangle

Note: Photos inthis catalog mayincludeoptional equipment.

Giant-Sized Productivity

Based on Hitachi's

Theory of Evolution.

Bucket Passes toDumpTrucks

Loading Shovel 21.0 m

3

Backhoe 22.0 m

3

5 6

5 6

or

or

HITACHI

EH3500

115.1m

3

Load Capacity (

SAE 2:1

)

173 ton Nominal Payload

Heaped

GIANT

Each Hitachi generation listens

to the needs of the work site

and gives birth to an even-better

new generation.

SOLUTION

6 7

StrategicallyPositionedOil Coolers

Helpskeepoil temperatures

Four oil coolers are used for optimal

cooling efciency. They are positioned

far fromthe engine radiator for even

better cooling potential.

High-MountedCompactTravel Motors

andOptional Travel MotorGuard Help

toboostdurabilityatruggedworksites.

This design helps protect the travel

motors fromdamage by rocks.

RuggedTrackLinks Shoesinclude

rollerguidesforextendedservicelife.

This design has proven itself on

Hitachi's popular Giant EX Series. The

roller guides have been added to help

extend service life.

ConstantCorrectTrackTension

Nitrogengasaccumulatorsabsorb

abnormal tracktension.

Helps prevent abnormal track tension

fromcausing damage. Travel is

automatically stopped if accumulator

pressure exceeds a preset level.

RigidBoxDesign Resistsbending

andtwistingforces.

Computer-assisted analysis was

used to check that the frame box can

withstand heavy-duty excavation work.

SolidCastTrackFrame Morestrength

forthiskeyarea.

The track frame

is cast as a

solid unit and

includes a ange

for improved

reliability. This non-welded design

is used exclusively on large Hitachi

models.

Track

frame

Rollerguide

GIANT

Built-in toughness means the

Hitachi will continue to get

giant-sized jobs done fast.

SOLUTION

More Than Durable

J ust Plain Tough

9

HighVisibility6.83MeterCabHeight

Providingaclearviewoftheworkarea.

Gives the operator a clear view, even

when a large 200 US ton class dump

truck is being loaded. This high height

and forward-sloping cab provides a

view that boosts productivity.

Electric JoystickLevers Provides

pleasantcontrol withlessfatigue.

Electric joystick control levers have a

feather-touch allowing long periods of

effortless operation. Its stroke is much

shorter than that of hydraulic control.

AirSuspensionSeatwithAutoOperator

WeightAdjuster.

The operator seat cushion can

automatically be adjusted according to

the operator weight. This is convenient

for a machine operated by two or more

operators.

AdjustableSlidingCockpit Movesto

thebestpositionfortheoperator.

The operator can adjust the position of

the levers and the seat to customt his

size and operating style.

Constant-Cab-ComfortAirConditioner Keepsthecabpressurizedtokeepoutdust

whilemaintainingcomfortabletemperature.

IntelligentMulti-DisplayMonitorprovidesmachinedata

andoperatingstatusataglance.

The operator can monitor machine conditions and

operating status with a 10.5-inch color LCD. The

controller provides instant fault diagnosis through all

sensors, displaying warnings and countermeasures if

failure arises.

Major Functions:

Multiple meters, and alert symbols indication

Alert/failure status, and countermeasures indication

Snap-shot function that stores operating data, including

veminute operating data immediately before alerting, and

succeeding one-minute data (temperatures, pressures,

and more)

Setting oil change intervals with alerting

Much more functions are provided to ease

maintenance and servicing.

OutsideCameras(Option) Enhancesoperatingsafety.

The operator can monitor around the machine, using

four cameras (option) to eliminate blind spots.

GIANT

Comfortable operator space

and simplified maintenance,

backed by Hitachi technologies

and experience.

SOLUTION

Designed to Offer Comfort

and Intelligence

RuggedComfortableCab Protects

theoperatorfromfallingobjects.

Fluid lled elastic mounts help absorb

vibration to provide durability and

a comfortable ride. The top guard,

conforming to OPG*level II (ISO), is

provided on the cab roof.

*Operator Protective Guard

EfcientCabLayout All controls

withinnatural reachofoperator.

The ergonomic layout of the cab means

the operator will do less stretching and

reaching when operating the controls.

This adds up to less operator fatigue

and greater operating efciency.

*Illustrationshows a sampleof the

EmergencySwitch.

8

10 11

GIANT

Carefully engineered to allow

full 24-hour operation.

SOLUTION

Designed to be

Maintenable

TheCentralized

Lubrication

System:Fast

FillingSystem

LowMaintenanceDustEjector

Automaticallyexpelsdustfromtheair

cleaner.

This is one less time-consuming task

during routine maintenance.

Contaminationsensor Alertstheopera-

torofexcessivecontaminantsintheoil.

This systemdetects accumulated

contaminants

that could

cause damage

and alerts the

operator before

trouble occurs.

AutoLubricationSystemEliminatesthe

needformanual lubrication.

This systemautomatically lubricates the

front joint pins and swing circle. This

eliminates cumbersome daily lubrica-

tion.

Easy-to-ReplaceGreaseDrumCan

Designedtoprovidequickandeasy

greasedrumcanchanges.

The compartment

oor slides down

to lower a drum

for simple, easy

replacement.

ConvenientCentralizedFilterSystem

Designedtomakelterinspectionand

maintenanceeasier.

Centralized posi-

tion means that

inspection and

maintenance can

be performed

quickly and easily.

MultipurposeCounterweight Easier

accessformaintenance.

A walkway around the entire counter-

weight provides easy access to key

rear areas. This means faster and safer

inspection and maintenance.

FoldingStairswithWideSteps.

Folding stairs is designed for easy ac-

cess to the machine for servicing and

maintenance.

Wide-OpenServiceAreaProvidesthe

spaceneededforquickandeasyinspec-

tionandmaintenance.

This area is conveniently located at the

center of the body and provides access

to the engine as well as the hydraulic

and electrical systems.

21 18

24

14

10

12

13

11

20

25

22

4

5

6

8

7

1

2

3

15

19

23

16

17

26

9

EasyAccessandMaintenance

Easyaccessspeedsinspectionsandmaintenance.

1 Engine

2 Engine Radiator

3 LTA Radiator

4 Fan Motor x 4

5 Air Filter x 4

6 Hydraulic Pump x 8

7 High-Pressure Strainer x 8

8 Battery Unit

9 Engine-Pump Bulkhead

10 Muffler

11 Swing Device x 4

12 Control Valve x 4

13 Center J oint

14 Hydraulic Oil Tank

15 Fuel Tank

16 Hydraulic Oil Cooler x4

17 Hydraulic Oil CoolingFanMotor

18 Lubricator

19 Cab

20 FoldingStairs

21 Ladder

22 Reservetank(engineoil)

23 Pump Transmissionoil cooler

24 Fuel cooler

25 Reservetank(coolant)

26 Engine-Radiator Bulkhead

MACHINE MACHINE SATELLITES SATELLITES PC & PDA PC & PDA INTERNET INTERNET

*PDA:Palm m-Series

Reports

(Option)

Customer Dealers

PC

Upon Request

PDA*

DATALogger

MMS

DLU

Transmit Downloaded Data

Download

via Cable

Download Program

[Server]

Data Viewer Program

Upload

via Internet

MICMining

The MIC Mining

comprises the

DLU (Data-

logging unit) on

the machine DLU

continuously

records

performance of

the engine and the

hydraulic system.

The record can be

download by PC

and PDA.

SPECIFICATIONS

07.11 (SA / HP, MT3)

Printed in J apan

KS-EN056P

These speci cations are subject to change w ithout notice.

Illustrations and photos show the standard m odels, and m ay or m ay not include optional equipm ent,

accessories, and all standard equipm ent w ith som e differences in color and features.

B efore use, read and understand the O perators M anual for proper operation.

Hitachi Construction Machinery

www.hitachi-c-m.com

ENGINE

M odel .......................... C um m ins Q SKTA60-C E

R ated pow er

D IN 6271,net ........... 1 450 kW (1 968 PS) at 1 800 m in

-1

(rpm )

SAE J1995, gross ... 1 450 kW (1 944 H P) at 1 800 m in

-1

(rpm )

Piston displacem ent .... 60.0 L

Fuel tank capacity ....... 7 450 L

HYDRAULIC SYSTEM

M ain pum ps ................ 8 variable-displacem ent,axial piston

pum ps for front attachm ent,travel and

sw ing

Pressure setting .......... 29.4 M Pa (300 kgf/cm

2

)

M ax. oil ow ................ 8 x 500 L/m in

UPPERSTRUCTURE

Sw ing speed ............... 3.2 m in

-1

(rpm )

UNDERCARRIAGE

Travel speeds .............. H igh: 0 to 2.2 km /h

Low : 0 to 1.7 km /h

M axim um traction force ... 1 760 kN (179 500 kgf)

G rade ability ................ 60 % (30 degree) m ax.

WEIGHTS AND GROUND PRESSURE

Loading Shovel

Equipped w ith 21.0 m

3

(PC SA heaped) bottom dum p bucket

Shoe width Operating weight Ground pressure

1 270 m m 361 000 kg

189 kPa

(1.93 kgf/cm

2

)

Backhoe

Equipped w ith 9.6 m B E-boom , 4.5 m B E-arm and 22.0 m

3

(PC SA heaped) bucket

Shoe width Operating weight Ground pressure

1 270 m m 359 000 kg

188 kPa

(1.92 kgf/cm

2

)

ATTACHMENTS

Loading Shovel

Bucket Capacity (PCSA 2:1 heaped)

21.0 m

3

: M aterials density 1 800 kg/m

3

23.0 m

3

: M aterials density 1 600 kg/m

3

Backhoe

Bucket Capacity (PCSA 1:1 heaped)

22.0 m

3

: M aterials density 1 800 kg/m

3

The number of wear plates and their installation positions on the

bucket of loading shovel or backhoe vary depending on applications

at job site. The installation of wear plates is indispensable.

Consult your nearest Hitachi or Hitachi dealer for datails.

DIMENSIONS

WORKING RANGES

EH3500

EH3500

Ground Line

Ground Line

Loading Shovel

A Min. digging distance

5 850 mm

B Min. level crowding distance

8 870 mm

C Level crowding distance

5 050 mm

D Max. digging reach

15 220 mm

E Max. cutting height

16 300 mm

E' Max. dumping height

10 990 mm

F Max. digging depth

3 910 mm

G Working radius at max.

dumping height

8 650 mm

H Max. bucket opening width

1 950 mm

Arm crowding force (SAE)

1 200 kN (122 000 kgf)

Breakout force (SAE)

1 130 kN (115 000 kgf)

Backhoe

9.6 m BE-boom

4.5 m BE-arm

A Max. digging reach

18 190 mm

A' Max. digging reach (on ground)

17 600 mm

B Max. digging depth

8 580 mm

B' Max. digging depth (8' level)

8 490 mm

C Max. cutting height

17 690 mm

D Max. dumping height

11 590 mm

E Max. vertical wall

4 060 mm

Bucket digging force

ISO

1 050 kN (107 000 kgf)

SAE: PCSA

932 kN (95 000 kgf)

Arm crowd force

ISO

951 kN (97 000 kgf)

SAE: PCSA

922 kN (94 000 kgf)

8 700

2 440

7 830

905

2 305

6 660 5 500

1 270

6 770

9 420 R 6 780

6 650

U nit: m m

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alligator and Fractals of Bill WilliamsDocument5 pagesAlligator and Fractals of Bill WilliamsVibhats Vibhor100% (1)

- Compras - ProveedoresDocument158 pagesCompras - ProveedorestristhanNo ratings yet

- Vgati 2324 304Document2 pagesVgati 2324 304thisbaghelNo ratings yet

- Cpa Review School of The Philippines Manila Auditing Problems Audit of Inventories Problem No. 1Document11 pagesCpa Review School of The Philippines Manila Auditing Problems Audit of Inventories Problem No. 1Angelou100% (1)

- Effect of Relationship Marketing On Customer Satisfaction in BanksDocument6 pagesEffect of Relationship Marketing On Customer Satisfaction in Banksv dheenadhayalanNo ratings yet

- The Maharashtra Public Trusts Act 1950Document73 pagesThe Maharashtra Public Trusts Act 1950Girish Deshmukh100% (1)

- EE1Document22 pagesEE1Jeiel ValenciaNo ratings yet

- Methods of Investment in Mutual FundDocument30 pagesMethods of Investment in Mutual FundGanesh DNo ratings yet

- REPORTDocument122 pagesREPORTStarlightNo ratings yet

- 003 PDF CRUX Negotiable Instruments Act 1881 Lecture 2 English HDocument33 pages003 PDF CRUX Negotiable Instruments Act 1881 Lecture 2 English Hcricketprediction8271No ratings yet

- Level III SS3 Essay Quiz 1Document4 pagesLevel III SS3 Essay Quiz 1MujahidNo ratings yet

- Bar QA Taxation 2010-2015Document238 pagesBar QA Taxation 2010-2015poontin rilakkuma100% (2)

- ATR-17 (2015 Revised)Document3 pagesATR-17 (2015 Revised)Fahad Dehbar, ACCA100% (3)

- Interest Rate FuturesDocument22 pagesInterest Rate FuturesHerojianbuNo ratings yet

- RFBT Topics CpaleDocument4 pagesRFBT Topics CpaleRuffa TagalagNo ratings yet

- Option Chain Analysis With Examples - Dot Net TutorialsDocument9 pagesOption Chain Analysis With Examples - Dot Net TutorialsMandi100% (1)

- Working Capital ManagementDocument72 pagesWorking Capital ManagementKING KARTHIKNo ratings yet

- Bank and NBFC Mehal PDFDocument38 pagesBank and NBFC Mehal PDFPrasun AgarwalNo ratings yet

- Cocofed CaseDocument58 pagesCocofed CaseMae Siapno100% (1)

- Banking Principles - NHAE302 (1-1920) .1 - LT - Nhóm 2 - BANK RISK MANAGEMENT LIQUIDITY RISK MANAGEMENT IN VIETNAM COMMERCIAL BANKSDocument20 pagesBanking Principles - NHAE302 (1-1920) .1 - LT - Nhóm 2 - BANK RISK MANAGEMENT LIQUIDITY RISK MANAGEMENT IN VIETNAM COMMERCIAL BANKSFTU Le Gia KhanhNo ratings yet

- Company Profile: Bajaj Capital's Mission StatementDocument9 pagesCompany Profile: Bajaj Capital's Mission Statementadani9No ratings yet

- Factbook 2018 0Document92 pagesFactbook 2018 0Yves-donald MakoumbouNo ratings yet

- Indian SpicesDocument64 pagesIndian SpicesIfrah Khan100% (1)

- Bhavani Final Project 1Document75 pagesBhavani Final Project 1vishnu PalvaiNo ratings yet

- 2016 Financial Mathematics AssignmentDocument1 page2016 Financial Mathematics AssignmentDfcNo ratings yet

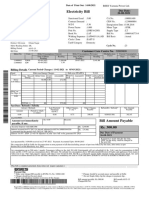

- Bill Electric of BSES Delhi GovermentDocument1 pageBill Electric of BSES Delhi Govermentpintukumar rameshbhaiNo ratings yet

- Responsibitlity Centre, RI, ROI, EVA, Balance Score CardDocument36 pagesResponsibitlity Centre, RI, ROI, EVA, Balance Score Cardkingscorp100% (1)

- HRD2315 - Economics For Civil EngineersDocument34 pagesHRD2315 - Economics For Civil EngineersMark NalNo ratings yet

- Chapter 11 and 12Document3 pagesChapter 11 and 12Jourdanette TarucanNo ratings yet

- API FP - CPI.TOTL - ZG DS2 en Excel v2 2252550Document79 pagesAPI FP - CPI.TOTL - ZG DS2 en Excel v2 2252550Abdul wahabNo ratings yet