Professional Documents

Culture Documents

Effect of Temperature On The Process of Beer Primary

Effect of Temperature On The Process of Beer Primary

Uploaded by

Jorge Sergio CondeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Temperature On The Process of Beer Primary

Effect of Temperature On The Process of Beer Primary

Uploaded by

Jorge Sergio CondeCopyright:

Available Formats

Journal of Microbiology,

Biotechnology and Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

Food Sciences

1791

REGULAR ARTICLE

EFFECT OF TEMPERATURE ON THE PROCESS OF BEER PRIMARY

FERMENTATION

Miriam Solgajov*, Helena Frankov, tefan Drb, igmund Tth

Address: Ing. Miriam Solgajov PhD.

1

Slovak University of Agriculture, Faculty of Biotechnology and Food Sciences, Department

of Storing and Plant Products Processing, Tr. A .Hlinku 2, 949 01, Nitra, Slovakia, phone

number: 037 654 4421.

*Corresponding author: miriam.solgajova@uniag.sk

ABSTRACT

Beer is a very popular and widespread drink worldwide. Beer may be defined as a

foamy alcoholic drink aerated by carbon dioxide that is formed during fermentation. Sensorial

and analytical character of beer is mainly formed during process of primary fermentation. Our

work has monitored the influence of temperature of fermentation substrate on the process of

primary fermentation during beer production. Obtained values of temperature and apparent

extract out of four brews of 10% light hopped wort has been recorded, during the process of

primary fermentation carried out in mini brewery of SPU. We have compared our results with

theoretical values of primary fermentation process commonly achieved in conditions of

industrial breweries. It was found out that our results differ in some ways, moreover they

exceed theoretically given values which was caused due to different construction of mini

brewery fermentation tank in comparison with industrial brewery technologies. Beer produced

in mini brewery of SPU showed in sensorial tests very good quality without any strange odour

and any strange taste.

Keywords: temperature, primary fermentation, beer, apparent extract, yeast, saccharization

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1792

INTRODUCTION

In brewing, the primary fermentation is one of the longest stages as well as an important

aromatic compound production step. Indeed, fermentation has the main impact on process

productivity and product quality (Landaud et al., 2001; Davis et al., 2008). The fermentation

of beer is an inherently variable process, affected by factors such as the raw ingredients

composition and the yeast characteristics. In practice, this means that fermentation times can

vary considerably between batches of the same beer quality (Siebert, 2001).

The main consideration in primary fermentation is to ferment wort to the desired gravity

(degree of attenuation) in the required period of time. This is largely achieved first by

accurate pitching of wort and secondly, by controlling the temperature of the process (Lewis,

Young, 2002). According to Brown, Hammond (2003) common practical approaches toward

fermentation intensification include use of high temperatures, high yeast pitching rates and

high wort gravities. Increases in temperature and pitching rate enhance the rate of

fermentation by promoting yeast growth. However, these straightforward approaches have a

number of disadvantages including altered beer flavor at the end of primary fermentation and

detrimental effects on yeast viability and vitality (leading to poor successive fermentation

performance) (Stewart, 2001; Pratt-Marshall et al., 2002).

Optimal fermentation temperature during bottom fermentation is in interval 5 to 16C.

Increase of temperature with regard to bottom fermentation could cause increased activity of

yeasts, deterioration of foam stability, beer colour, decrease of pH and higher lost of bitter

compounds. Optimal speed of fermentation means that decrease of extract within 24 hours

should not exceed 1.5% by weight. Temperature should not fall faster than 1C within 24

hours so that fermentation wont be interrupted (Basaov et al., 2010, Basaov, 2002).

Temperature regulation is in practice one of the most effective tool to modify speed of

fermentation. If temperature is changed from 10 to 13C and than it is tempered at 14C, in

the last stage of fermentation, the process of fermentation could be shorten about 28.8 hours,

found out epeov (2004). This change even improves sensorial properties of beer.

For yeast to live and grow, wort must contain a sufficient supply of nutrients. Yeast

needs fermentable carbohydrate, assimilable nitrogen, molecular oxygen, the vitamin biotin,

source of phosphorus and sulfur, calcium and magnesium ions, and trace elements such as

cooper and zinc ions (Lewis, Young, 2002).

The objective of our study was to monitored influence of the fermentation substrate

temperature on the process of primary fermentation during beer production.

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1793

MATERIAL AND METHODS

Beer preparation

Beer was prepared in mini brewery of Slovak University of Agriculture in Nitra. Light

hopped wort with concentration of 10% was prepared using infusion mashing system of

brewing and consequently the fermentation process of hopped wort was carried out.

Measurement

Saccharization of initial wort and apparent extract of fermented hopped wort were

measured using saccharometer. Saccharometer was dipped into sample of prepared initial

wort that was firstly rid off CO

2

bubbles. Sample of wort had 20C to be measured. Values of

saccharization and apparent extract were taken off saccharometer.

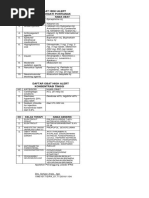

Temperature measurements of fermented hopped wort were carried out by

thermometer. From results of temperature and apparent extract diagrams of fermentation

process were arranged. We have compared our results with theoretical values of primary

fermentation process commonly achieved in conditions of industrial breweries (Figure 1).

14

17

13

22

22 22

4 4

5,5

7

8,5

10

4,2

3,2

2,8 2,8 2,7 2,7

2,6 2,6 2,6 2,6

6,8

10

0

5

10

15

20

25

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Days

A

p

p

a

r

e

n

t

e

x

t

r

a

c

t

(

%

)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Figure 1 Theoretical fermentation process - development of temperature and apparent extract

during boiling of hopped wort

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1794

RESULTS AND DISCUSSION

Figure 2 presents fermentation process of 10% light hopped wort. Initial pitching

temperature was 14C and within 24 hours it raised up to 22C. This temperature stayed at

this level within 2 days and value of apparent extract was 3.2%. Due to this temperate we

started to cool down the brew thus we regulated whole process to reach value of apparent

extract 2.6%. Minimal temperature that was achieved was 4C. As we compare process of

primary fermentation of 10% light hopped wort with theoretical process (Figure 1) we found

out some deviations in comparison with theoretical process due to strong temperature cut-

down after fourth day that fall from 22 to 12C. This problem did not affected values of

apparent extract which represented 2.8% (figure 2).

14

22 22 22

12 12

10

8 8

6

4 4

10,1

6,8

4,2

3,2

2,8 2,8 2,7 2,7 2,6 2,6 2,6 2,6

0

5

10

15

20

25

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Days

A

p

p

a

r

e

n

t

e

x

t

r

a

c

t

(

%

)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Figure 2 Development of temperature and apparent extract during hopped wort boiling the

first brew

Form figure 3 we can observe that pitching temperature represented 12C. By

spontaneous fermentation process without cooling, the temperature reached 20C in 24 hours.

We could see that lower initial fermentation temperature affected the whole process of

fermentation. In comparison with theoretical fermentation process, the pitching temperature

was about 2C lower. Values of apparent extract were not affected. According to Brown,

Hammond (2003) increases in temperature and pitching rate enhance the rate of fermentation

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1795

by promoting yeast growth. However, these approaches have a number of disadvantages

including altered beer flavor at the end of primary fermentation.

12

20

22 22

14

12 12

10

6 6 6 6 9,9

6,6

4,2

3,4

2,9 2,9 2,8 2,8 2,8 2,8 2,8 2,8

0

5

10

15

20

25

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Days

A

p

p

a

r

e

n

t

e

x

t

r

a

c

t

(

%

)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Figure 3 Development of temperature and apparent extract during hopped wort boiling the

second brew

Initial fermentation temperature (16C) of boiled and cooled hopped wort presents

figure 4. During 24 hours the temperature of fermentation medium increased to 22C. This

temperature remained stable 48 hours and during this time value of apparent extract reached

3.2%. This value is considered as optimal value because after finalization of fermentation

process the value of 2.6% of apparent extract should be reached. In our case the value of

apparent extract represented 2.7% that is about 0.1% higher as theoretical process even if

temperature of fermentation was 6C. However, this difference is minimal. As we compare

process of primary fermentation of figure 4 with theoretical process, we could notice only

minimal deviation in comparison with theory. Despite this fact, the final product (beer)

achieved very good qualitative parameters. According to Basaov et al., (2010) temperature

regulation is in practice one of the most effective tool to modify speed of fermentation and

final sensorial properties of beer.

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1796

16

22 22 22

14

12 12

10

6 6 6 6

10,2

6,8

4,4

3,2

2,8 2,8 2,7 2,7 2,7 2,7 2,7 2,7

0

5

10

15

20

25

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Days

A

p

p

a

r

e

n

t

e

x

t

r

a

t

(

%

)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Figure 4 Development of temperature and apparent extract during hopped wort boiling the

third brew

Next brew fermentation process presents figure 5. Initial fermentation temperature was

15C and second day it raised, without cooling the fermentation medium, up to 22C. During

next two days it reached 23C. Value of apparent extract was 3.3%. Next day we started with

cooling down the hopped wort.

If we spontaneously leave temperature to increase, in the first phase of primary

fermentation, we could reach the value of 23C. One of the arrangements to protect against

pressure collision is to open the tap on blocking device that assure outflow of generating CO

2

into space and this prevent against increase of pressure in tank. On the other hand we can

confirm findings of Kelner et al. (2000) who claims that amount of vicial dicetons expressed

by limited value of diacetyl 0.1 mg.dm

-3

decreases by using such higher temperatures. This

value of diacetyl is given by threshold sensitivity of human body to feel its presence in

evaluated samples. Also according to Kosa and Prochdzka (2000) an important element

that lowers number of diacetyl during fermentation is the temperature.

In comparison with theoretical process, during first days of fermentation, we recorded

small increase in temperature just about 1C and moreover values of apparent extract were

higher only about 0.1%.

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1797

15

22

23 23

14

10 10

6 6 6 6 6

9,8

6,4

4,3

3,3

2,7 2,7 2,7 2,7 2,7 2,7 2,7 2,7

0

5

10

15

20

25

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

Days

A

p

p

a

r

e

n

t

e

x

t

r

a

c

t

(

%

)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Figure 5 Development of temperature and apparent extract during hopped wort boiling the

fourth brew

According to obtained results, if we compare real process of primary fermentation with

theoretical process we can observe that increase of pitching temperature just about 1 or 2C

means increase of maximal value of whole fermentation process about 1C. At the end of

fermentation process it was reached 23C instead of 22C. This little deviation did not have

any influence on the fermentation process whereas values of apparent extract relatively to

great extent mapped values of theoretical fermentation process. According to Basaov et al.,

(2010) optimal speed of fermentation means that decrease of extract within 24 hours should

not exceed 1.5% by weight. Temperature should not fall faster than 1C within 24 hours so

that fermentation wont be interrupted.

Form our results we can state that recorded deviation not even affected final sensorial

and analytical quality of beer made in mini brewery of SPU. Presented fact needs to be

constantly controlled mostly by sensorial evaluation of produced beer which is an important

criteria of its quality.

CONCLUSION

With development of new technologies in brewing industry it is important to care

about quality that relates to yeast nutrition as well as to fermentation. Therefore it is necessary

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1798

to provide standard wort for the fermentation process with balanced amount of positive

compounds entering the process of primary fermentation.

From our results we can conclude that even maximal value of pitching substrate

(14C) that is limited for industrial breweries was not kept, we manage to create new

(different) technological diagram. This diagram was arranged by approach to keep maximal

temperature mostly in the first stage of fermentation. We managed to produce final product

(beer) with very good sensorial quality which was one of the most important goals of our

work. At the base of hopped wort fermentation process we created theoretical diagram of

fermentation process (10% hopped wort) that could be used as pattern for future brews

produced in conditions of SPU mini brewery due to different construction of mini brewery

fermentation tank in comparison with industrial technologies.

Acknowledgments: This work has been supported by KEGA project (KEGA 015/SPU-

4/2011).

REFERENCES

BASAOV, G. 2002. Vvoj teorie kvaen a dokvaovn piva. In Kvasn prmysl, vol. 48,

2002, p. 61-65.

BASAOV, G. AVEL, J. BASA, P. LEJSEK, T. 2010. Pivovarstv : Teorie a praxe

vroby piva. Praha : Vysok kola chemicko-technologick, 2010. 904 p. ISBN 978-80-7080-

734-7

BROWN, A. K. HAMMOND, J. R. M. 2003. Flavour control in small-scale beer

fermentations. In Trans IChemE, vol. 81, 2003, p. 40-49

DAVIS, B. LOCKWOOD, A. PANTELIDIS, I. ALCOTT, P. 2008. Food a beverage

mangement. Elsevier Ltd., 2008, 421 p., ISBN 978-0-7506-6730-2

KELNER, V. ULK, J. et al. 2000. Stanoven chlorovanch alifatickch uhlovodku

v pivu. In Kvasn prmysl, vol. 46, 2000, no. 7-8, p. 512-514.

KOSA, K. PROCHDZKA, S. 2000. Technologie vroby sladu a piva. 1vyd. Praha:

Vzkumn stav pivovarsk a sladsk, 2000. 389-402 p., ISBN 80-902658-6-3.

LANDAUD, S. LATRILLE, E. CORRIEU, G.. 2001. Top Pressure and Temperature

Control the Fusel Alcohol/Ester Ratio through Yeast Growth in Beer Fermentation. In Journal

of the Institute of Brewing, vol. 107, 2001, no. 2, p. 107-117

JMBFS / Solgajova et al. 2013 : 2 (Special issue 1) 1791-1799

1799

LEWIS, M. J - YOUNG, T. W. 2002. Brewing. Kluwer Academic/Plenum Publishers, 2002,

398 p., ISBN: 0-306-47274-0.

PRATT-MARSHALL, P.L. - BREY, S.E. - DE COSTA, S.D. - BRYCE, J.H. - STEWART,

G.G. 2002. High gravity brewing-an inducer of yeast stress. In Brewers Guardian, vol. 131,

2001, no. 3, p. 2226.

STEWART, G.G. 2001. Fermentation of high gravity worts-its influence on yeast metabolism

and morphology. In Proceedings of the 28th Congress of the European Brewery Convention,

Budapest, paper number 36.

SIEBERT, K. J. 2001. Chemometrics in brewing A review. In. Journal of the American

Society of Brewing Chemists, vol. 59, 2001, no. 4, p.147156.

EPEOV, G. CVENGROOV, M. MOGROVIOV, D. 2004. Fakulta chemickej

a potravinrskej technolgie STU. In Kvasn prmysl, 2004.

You might also like

- ImprovingBrewhouseEfficiency HavigDocument40 pagesImprovingBrewhouseEfficiency HavigJaime Andres Villegas MansillaNo ratings yet

- 01.30.55.110-Yeast Propagation and Management 2008 PDFDocument23 pages01.30.55.110-Yeast Propagation and Management 2008 PDFÁnhXuânPhạmNo ratings yet

- Make Yeast StarterDocument2 pagesMake Yeast StarterAlexandraNo ratings yet

- Ferment IsDocument56 pagesFerment IsCarlos UriaNo ratings yet

- Enzymes in Brewing - Biokemisk ForeningDocument9 pagesEnzymes in Brewing - Biokemisk ForeninggutaviedNo ratings yet

- HINDMAN, Hillbilly Yeast Propagation ProjectDocument40 pagesHINDMAN, Hillbilly Yeast Propagation ProjectDoug HindmanNo ratings yet

- MS For Deflection Test-Rev.03Document9 pagesMS For Deflection Test-Rev.03anishdev6100% (1)

- The Theory of MashingDocument6 pagesThe Theory of MashingVohinh NgoNo ratings yet

- Lallemand Brewing - TechPaper Lagering Made Easy 23Document22 pagesLallemand Brewing - TechPaper Lagering Made Easy 23FabioNo ratings yet

- 2014 MBAA Chris White Yeast ManagementDocument30 pages2014 MBAA Chris White Yeast ManagementAdrián LampazziNo ratings yet

- Malt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupDocument33 pagesMalt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupOleg Burlac100% (1)

- Brewing ScienceDocument36 pagesBrewing ScienceVohinh NgoNo ratings yet

- Brewing With WheatDocument16 pagesBrewing With WheatGustavo MicheliniNo ratings yet

- 408103442.xlsx: Grain Bill Hop Bill & Schedule Grain % Type Species IBU Amount (LB) Time (Min) Alpha (%) Qty (Oz)Document10 pages408103442.xlsx: Grain Bill Hop Bill & Schedule Grain % Type Species IBU Amount (LB) Time (Min) Alpha (%) Qty (Oz)GeoNo ratings yet

- Forty Years of Brewing ResearchDocument27 pagesForty Years of Brewing ResearchAngélica Durán MuñozNo ratings yet

- 2010 SOQ 3 Belgian StrongDocument5 pages2010 SOQ 3 Belgian StrongJoao Carlos MaximianoNo ratings yet

- Yeast Management PropagationDocument39 pagesYeast Management PropagationPatricio LazcanoNo ratings yet

- Light Beer "Forbidden Fruit"Document2 pagesLight Beer "Forbidden Fruit"Angel CarpioNo ratings yet

- Loma Brewing Company MenuDocument2 pagesLoma Brewing Company MenuEaterNo ratings yet

- Turbidity of BeerDocument39 pagesTurbidity of BeerManuel PlataNo ratings yet

- Mangrove Jacks CatalogoDocument13 pagesMangrove Jacks CatalogolhcorreaNo ratings yet

- 1.5 Grist ComponentDocument11 pages1.5 Grist Componenthung tranNo ratings yet

- Malting Process PDFDocument9 pagesMalting Process PDFRay TaipeNo ratings yet

- Cat's Meow Home Brewing 05 Stout PorterDocument48 pagesCat's Meow Home Brewing 05 Stout PorternawickNo ratings yet

- YeastStarter PDFDocument6 pagesYeastStarter PDFHiran GonçalvesNo ratings yet

- Brewing Recipe Template v3 4Document63 pagesBrewing Recipe Template v3 4Gonzalo Ortega100% (1)

- Chemical Composition in Barley Grains and Malt Quality: July 2010Document37 pagesChemical Composition in Barley Grains and Malt Quality: July 2010Roberta AguiarNo ratings yet

- Beer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealDocument8 pagesBeer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealFarhaan MohammedNo ratings yet

- Waste Water Treatment For Brewery and Winery IndustryDocument31 pagesWaste Water Treatment For Brewery and Winery IndustryNational WaterNo ratings yet

- Beer Brewing ProcessDocument4 pagesBeer Brewing ProcessprodebmicrooNo ratings yet

- Recipes for Brewing Different Types of Beers and AlesFrom EverandRecipes for Brewing Different Types of Beers and AlesNo ratings yet

- Hand Out Home BrewingDocument9 pagesHand Out Home BrewingJuan Martin GiménezNo ratings yet

- Yeast Production ProcessDocument1 pageYeast Production Processboonsom100% (1)

- 32005mashing Unmalted 109Document15 pages32005mashing Unmalted 109Pulbere NeagraNo ratings yet

- Arduino Controlled BrewingDocument5 pagesArduino Controlled BrewingJuliana ChavesNo ratings yet

- Enzymes in BrewingDocument8 pagesEnzymes in BrewingAlexandru TarțianNo ratings yet

- Fermentedtreasures Ginger Beer BrewingDocument3 pagesFermentedtreasures Ginger Beer BrewingguennikNo ratings yet

- Beer Brewing Fact SheetDocument4 pagesBeer Brewing Fact SheetAsh88640% (1)

- Enhancing Yeast Alcoholic FermentationDocument43 pagesEnhancing Yeast Alcoholic FermentationNoob chơi game100% (1)

- Mangrove Jack's BREWER'S YEASTS FOR CRAFT BREWINGDocument13 pagesMangrove Jack's BREWER'S YEASTS FOR CRAFT BREWINGLois99No ratings yet

- Right Hand Milk StoutDocument1 pageRight Hand Milk StoutSteven MancineNo ratings yet

- Understanding YeastDocument1 pageUnderstanding YeastEmbdenNo ratings yet

- High Gravity BrewingDocument4 pagesHigh Gravity BrewingMohd SuhailNo ratings yet

- Sustainable Brewing Concept LRDocument5 pagesSustainable Brewing Concept LRAndalusia Martha Novaline SiboroNo ratings yet

- Ratio Recipes BDocument1 pageRatio Recipes Bapi-287224366No ratings yet

- Brewing: Reported By: Relvis Josh DG. LauretaDocument11 pagesBrewing: Reported By: Relvis Josh DG. LauretamelalabsyouNo ratings yet

- Late Hop & Hop OilsDocument3 pagesLate Hop & Hop OilsBill LimaNo ratings yet

- Ref PlanDocument4 pagesRef Planアルビン ベネNo ratings yet

- Grains and Adjuncts Chart English Grain Malto PDFDocument7 pagesGrains and Adjuncts Chart English Grain Malto PDFDavide NicolisNo ratings yet

- Malting BarleyDocument58 pagesMalting Barleylordniklaus100% (1)

- Yeast SubstitutionsDocument7 pagesYeast SubstitutionsJuan ToledanoNo ratings yet

- 01 - Beer Stabilisation Part 1 PDFDocument2 pages01 - Beer Stabilisation Part 1 PDFNelcy LatorreNo ratings yet

- BeerRecipe 37 PDFDocument2 pagesBeerRecipe 37 PDFAngel CarpioNo ratings yet

- Enzyme InformationDocument7 pagesEnzyme InformationLong ThuậnNo ratings yet

- As Part of Big Brew 2015 and Receive A Copy Of: Join The AhaDocument1 pageAs Part of Big Brew 2015 and Receive A Copy Of: Join The AhaYerco UrquizaNo ratings yet

- Bavarian Weizen All GrainDocument7 pagesBavarian Weizen All GrainDavide NicolisNo ratings yet

- Megazyme Brewing Flyer 2011Document2 pagesMegazyme Brewing Flyer 2011Megazyme International IrelandNo ratings yet

- AC 18th EBC Standard Malt FVDocument3 pagesAC 18th EBC Standard Malt FVNguyễn Văn ThảoNo ratings yet

- Emerging: Brewing Is The Production ofDocument16 pagesEmerging: Brewing Is The Production ofSheerin SulthanaNo ratings yet

- 15 American IPAs1Document17 pages15 American IPAs1JohnRykerNo ratings yet

- 5 - National Clinical Guideline of Dengue Timor Leste - Clean - Final 12 Dec 2022Document93 pages5 - National Clinical Guideline of Dengue Timor Leste - Clean - Final 12 Dec 2022Ahmad FaizNo ratings yet

- Six Ways To Refresh Your MindDocument3 pagesSix Ways To Refresh Your MindBhupesh D. SahareNo ratings yet

- Arcroma Luprintol Soft F-SIG Liq CDocument10 pagesArcroma Luprintol Soft F-SIG Liq CClub classic 350No ratings yet

- Updated phq9 TestDocument3 pagesUpdated phq9 Testapi-528322409No ratings yet

- Sad StoriesDocument8 pagesSad StoriesEvonne LawNo ratings yet

- Community Wishbook 2019-2020Document40 pagesCommunity Wishbook 2019-2020Darlyn ReddyNo ratings yet

- Over 1,000 Health Experts Release Letter of Support To BLM Protesters But Conservative Must Stay HomeDocument15 pagesOver 1,000 Health Experts Release Letter of Support To BLM Protesters But Conservative Must Stay HomeJim Hoft100% (4)

- لحل مشكلة كتابة الروشتات للأطفال PDFDocument253 pagesلحل مشكلة كتابة الروشتات للأطفال PDFOmarAly100% (4)

- CPR Evaluation SheetDocument2 pagesCPR Evaluation SheetCatoNo ratings yet

- Waste Management Laws PDFDocument7 pagesWaste Management Laws PDFrohit kumar0% (1)

- FormDocument5 pagesFormpuput utomoNo ratings yet

- Personality Disorders - A Brief OverviewDocument2 pagesPersonality Disorders - A Brief OverviewMaria- AndreeaNo ratings yet

- TRA 13 Loading or Unloading Chems With ForkliftDocument2 pagesTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- Desfibrilador s3 s5Document219 pagesDesfibrilador s3 s5Ailen Lazarte100% (1)

- Clinical Nursing Skills and Techniques 6th Edition Perry Test BankDocument11 pagesClinical Nursing Skills and Techniques 6th Edition Perry Test BankAnnetteOliverrbwcx100% (12)

- Yin and YangDocument39 pagesYin and YangRadina Bi RanNo ratings yet

- Questionnaire Development: An Examination of The Nordic Musculoskeletal QuestionnaireDocument5 pagesQuestionnaire Development: An Examination of The Nordic Musculoskeletal QuestionnaireAchmad Syukron100% (2)

- NeliswaDocument7 pagesNeliswaAnonymous KD9GcvdaoMNo ratings yet

- Juvenile CataractDocument44 pagesJuvenile CataractArvindan SubramaniamNo ratings yet

- Quality Control in Occupational Safety and HealthDocument27 pagesQuality Control in Occupational Safety and HealthNecklal SoniNo ratings yet

- Nursing Care Plan: Risk For Ineffective Airway Clearance Related To Bleeding From Tonsillectomy Short TermDocument4 pagesNursing Care Plan: Risk For Ineffective Airway Clearance Related To Bleeding From Tonsillectomy Short TermErika Danalle ArceoNo ratings yet

- 2 - SERIES 2023 Updated-2Document8 pages2 - SERIES 2023 Updated-219ucs175No ratings yet

- Manpower Planning at Different LevelsDocument13 pagesManpower Planning at Different Levelsdr_shilpa11No ratings yet

- TLCM Group Assignement BriefDocument16 pagesTLCM Group Assignement BrieftinoNo ratings yet

- Anes - Premedication and PositioningDocument7 pagesAnes - Premedication and PositioningChristine MendozaNo ratings yet

- 11-Iv Admixture 0Document20 pages11-Iv Admixture 0udinNo ratings yet

- Orthopedic Cast, Braces, and Traction ApplicationDocument86 pagesOrthopedic Cast, Braces, and Traction ApplicationMiss medNo ratings yet

- Daftar Obat High Alert - FIXDocument2 pagesDaftar Obat High Alert - FIXDonny HartawinataNo ratings yet

- CAE Use of English Part 5 - Key Word TransformationDocument5 pagesCAE Use of English Part 5 - Key Word TransformationAndreaGarciaRuzNo ratings yet