Professional Documents

Culture Documents

AISC Structural Shapes

AISC Structural Shapes

Uploaded by

chivas_rodeoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC Structural Shapes

AISC Structural Shapes

Uploaded by

chivas_rodeoCopyright:

Available Formats

By Charles J.

Carter, PE

T

HE MATERIALS AND PRODUCTS USED

IN BUILDING DESIGN AND CONSTRUC-

TION are almost universally desig-

nated by reference to an appropriate

ASTM specification. This simplifies the

design and construction process because

all characteristics of the product speci-

fied are defined by simple reference to

an approved standard. However, with

dozens of ASTM specifications applica-

ble in steel building construction alone

and several new ones now available, it

can be challenging to keep the standard

designations in contract documents cur-

rent.

This article (Part One) is a summary

of the common ASTM specifications

used for structural members in building

design and construction. Parts Two and

Three will focus on plate and fastening

products, respectively.

The common structural shapes are

either hot-rolled cross sections (such as

W-shapes, channels and angles), steel

pipe or hollow structural sections. The

generally applicable ASTM specifica-

tions for each are given in Table 1.

Also included is a discussion of the

usual and other applicable ASTM speci-

fications for each type of structural

shape. The usual ASTM specifications

are summarized by product in Table 2.

W-SHAPES

The usual material specification for

W-shapes is ASTM A572 grade 50 with

special requirements per AISC

Technical Bulletin #3, dated March

1997 (See box on page 50). A572 Grade

50 with special requirements is cur-

rently being phased in while both ASTM

A36 and A572 grade 50 are being

phased out (for wide-flange shapes

only). This modified ASTM specification,

which will eventually bear the simpler

name ASTM A992, covers only W-

shapes and has specified minimum val-

ues for F

y

and F

u

of 50 ksi and 65 ksi,

respectively.

W-shapes with higher yield and ten-

Modern Steel Construction / January 1999

sile strength can be obtained by specify-

ing ASTM A572 grade 60 (applicable to

tensile group 1 and 2 W-shapes only),

ASTM A572 grade 65 (applicable to ten-

sile group 1 W-shapes only) or ASTM

A913 grades 60, 65 or 70. W-shapes

with atmospheric corrosion resistance

(weathering) characteristics can be

obtained by specifying ASTM A588

grade 50. Other material specifications

applicable to W-shapes include ASTM

A529 grade 42 (tensile group 1 W-

shapes only), A529 grade 50 (tensile

groups 1 and 2 W-shapes only), A572

grade 42 and A913 grade 50. However,

the availability of W-shapes in grades

other than ASTM A572 grade 50 with

special requirements per AISC

Technical Bulletin #3, dated March

1997 should be confirmed prior to their

specification.

Regardless of the material specifica-

tion chosen, the cross-sectional dimen-

sions and production tolerances for W-

shapes are given in ASTM A6.

M-SHAPES

The usual material specification for

M-shapes is ASTM A36 (F

y

= 36 ksi; F

u

= 58 ksi), although ASTM A572 grade

50 (F

y

= 50 ksi; F

u

= 65 ksi) is increas-

ingly very common.

M-shapes with higher yield and ten-

sile strength can be obtained by specify-

ing ASTM A572 grade 42, 50, 60 or 65,

or A529 grade 42 or 50. M-shapes with

atmospheric corrosion resistance

(weathering) characteristics can be

obtained by specifying ASTM A588

grade 50. However, the availability of

M-shapes in grades other than ASTM

A36 should be confirmed prior to their

specification.

Regardless of the material specifica-

tion chosen, the cross-sectional dimen-

sions and production tolerances for M-

shapes are given in ASTM A6.

S-SHAPES

Also known as American Standard

beams, the usual material specification

for S-shapes is ASTM A36 (F

y

= 36 ksi;

ARE YOU PROPERLY

SPECIFYING MATERIALS?

Part one

in a

three-

part

series:

structural

shapes

Modern Steel Construction / January 1999

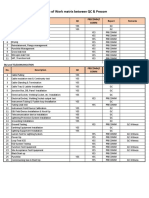

Table 1. ASTM specifications and their product-specific applicability

Product Applicable ASTM specifications Notes:

Hot-rolled structural shapes A36, A529, A572, A588, A913, A992 1, 2, 3

Steel pipe A53 grade B --

HSS A500, A501, A618, A847 --

Notes:

1. ASTM A992 is also known as ASTM A572 grade 50 with special requirements

per AISC Technical Bulletin #3, dated March 1997 and is only applicable to wide-

flange shapes.

2. ASTM A529 is most commonly used as a specification in the metal building indus-

try, but can be obtained in many smaller shape sizes (tensile groups 1 or 2) for

hot-rolled structural shapes.

3. ASTM A913 is a relatively new product specification that covers hot-rolled struc-

tural shapes produced by the quenching and self-tempering process.

So what is ASTM A572 grade 50 with special requirements per AISC

Technical Bulletin #3, dated March 1997 anyway?

In the early 90s, wide-flange steel producers began a practice called dual-certification, tar-

geting their production of wide-flange material for the window of overlap between the

mechanical, chemical and other requirements in both ASTM A36 and A572 grade 50. Among

other factors, the lack of an upper limit on yield strength in ASTM A36 made this possible.

Steel producers benefited because the resulting product could be stocked universally and

sold as either A36 or A572 grade 50. The consumer benefited because price differentials

between ASTM A572 grade 50 and A36 quickly eroded. Alas, there was often confusion

about the product being supplied because it usually carried both names.

To eliminate confusion and facilitate the shift to a single grade material for wide-flange

shapes, AISC proposed the material specification ASTM A572 grade 50 with special

requirements per AISC Technical Bulletin #3, dated March 1997 Since that time, it has been

approved by ASTM as specification A992.

Note however, that ASTM A992 has not yet been incorporated into all industry docu-

ments, including AWS D1.1. Thus, to avoid the otherwise unnecessary project-specific quali-

fication of ASTM A992 material for welding, call it by its longer name in this interim period

until the codes catch up.

To get a copy of Technical Bulletin #3, please fax a request to Jeri Irwin at 312-670-5403.

F

u

= 58 ksi), although ASTM A572 grade

50 (F

y

= 50 ksi; F

u

= 65 ksi) is increas-

ingly very common.

S-shapes with higher yield and ten-

sile strength can be obtained by specify-

ing ASTM A572 grade 42, 50, 60 or 65

(tensile group 1 S-shapes only), A529

grade 42 (tensile group 1 S-shapes only)

or 50. S-shapes with atmospheric corro-

sion resistance (weathering) character-

istics can be obtained by specifying

ASTM A588 grade 50. However, the

availability of S-shapes in grades other

than ASTM A36 should be confirmed

prior to their specification.

Regardless of the material specifica-

tion chosen, the cross-sectional dimen-

sions and production tolerances for S-

shapes are given in ASTM A6.

HP-SHAPES

Also known as bearing piles, the

usual material specification for HP-

shapes is ASTM A36 (F

y

= 36 ksi; F

u

=

58 ksi), although ASTM A572 grade 50

(F

y

= 50 ksi; F

u

= 65 ksi) is increasingly

very common.

HP-shapes with higher yield and ten-

sile strength can be obtained by specify-

ing ASTM A572 grade 42, 50 or 60 (ten-

sile group 2 HP-shapes only) or A529

grade 50 (tensile group 2 HP-shapes

only). HP-shapes with atmospheric cor-

rosion resistance (weathering) charac-

teristics can be obtained by specifying

ASTM A588 grade 50. However, the

availability of HP-shapes in grades

other than ASTM A36 should be con-

firmed prior to their specification.

Regardless of the material specifica-

tion chosen, the cross-sectional dimen-

sions and production tolerances for HP-

shapes are given in ASTM A6.

CHANNELS

The usual material specification for

American Standard Channels (C-

shapes) and miscellaneous channels

(MC-shapes) is ASTM A36 (F

y

= 36 ksi;

F

u

= 58 ksi), although ASTM A572 grade

50 (F

y

= 50 ksi; F

u

= 65 ksi) is increas-

ingly very common.

Channels with higher yield and ten-

sile strength can be obtained by specify-

ing ASTM A572 grade 42, 50, 60 or 65

(tensile group 1 channels only) or A529

grade 42 (tensile group 1 channels only)

or 50. Channels with atmospheric corro-

sion resistance (weathering) character-

istics can be obtained by specifying

ASTM A588 grade 50. However, the

availability of channels in grades other

than ASTM A36 should be confirmed

prior to their specification.

Regardless of the material specifica-

tion chosen, the cross-sectional dimen-

sions and production tolerances for

channels are given in ASTM A6.

ANGLES

The usual material specification for

angles is ASTM A36 (F

y

= 36 ksi; F

u

= 58

ksi).

Angles with higher yield and tensile

strength can be obtained by specifying

ASTM A572 grade 42, 50, 60 (tensile

groups 1 and 2 angles only) or 65 (ten-

sile group 1 angles only) or A529 grade

42 (tensile group 1 angles only) or 50

(tensile groups 1 and 2 angles only).

Angles with atmospheric corrosion

resistance (weathering) characteristics

can be obtained by specifying ASTM

A588 grade 50. However, the availabili-

ty of angles in grades other than ASTM

A36 should be confirmed prior to their

specification.

Regardless of the material specifica-

tion chosen, the cross-sectional dimen-

sions and production tolerances for

angles are given in ASTM A6.

STRUCTURAL TEES

Structural tees are split from W-, M-

and S-shapes to make WT-, MT- and

ST-shapes, respectively. For the usual

materials specification, as well as other

suitable material specifications, for

structural tees, refer to the foregoing

discussions in the sections on W-, M- or

S-shapes, as appropriate.

STEEL PIPE

The sole material specification for

steel pipe is ASTM A53 grade B (F

y

= 35

ksi; F

u

= 60 ksi). Note that steel pipe as

a product is different from round HSS.

So it is also designated differently (see

box). The cross-sectional dimensions

and production tolerances for steel pipe

are also given in ASTM A53.

ROUND HSS

The usual material specification for

round HSS is ASTM A500 grade B (F

y

=

42 ksi; F

u

= 58 ksi), although ASTM

A500 grade C (F

y

= 46 ksi; F

u

= 62 ksi) is

increasingly more common.

Round HSS with atmospheric corro-

sion resistance (weathering) character-

Table 2. Structural shapes and their usual ASTM specifications

Min. F

y

Min. F

u

Structural Shapes Usual ASTM Specification (ksi) (ksi)

W-shapes

1

ASTM A572 grade 50 with special 50 65

requirements per AISC Technical

Bulletin #3, dated March 1997

(ASTM A992)

M-, S- and HP-shapes A36 36 58

A572 grade 50 50 65

Channels A36 36 58

A572 grade 50 50 65

Angles A36 36 58

Steel pipe A53 grade B 35 60

Round HSS A500 grade B 42 58

A500 grade C 46 62

Square and A500 grade B 46 58

rectangular HSS A500 grade C 50 62

Notes:1. ASTM A572 grade 50 with special requirements per AISC Technical Bulletin #3,

dated March 1997 is also known as ASTM A992.

istics can be obtained by specifying

ASTM A847. Other material specifica-

tions applicable to round HSS include

ASTM A501 and A618. However, the

availability of round HSS in grades

other than ASTM A500 grade B should

be confirmed prior to their specification.

The cross-sectional dimensions and

production tolerances for round HSS are

also given in the selected material speci-

fication.

SQUARE AND RECTANGULAR HSS

The usual material specification for

square and rectangular HSS is ASTM

A500 grade B (F

y

= 46 ksi; F

u

= 58 ksi),

although ASTM A500 grade C (F

y

= 50

ksi; F

u

= 62 ksi) is increasingly more

common.

Square and rectangular HSS with

(weathering) atmospheric corrosion

resistance characteristics can be

obtained by specifying ASTM A847.

However, the availability of square and

rectangular HSS in grades other than

ASTM A500 grade B should be con-

firmed prior to their specification.

The cross-sectional dimensions and

production tolerances for square and

rectangular HSS are also given in the

selected material specification.

Charles J. Carter, PE, is Director of

Manuals with the American Institute of

Steel Construction, Inc. and an occasion-

al contributor of articles to Modern Steel

Construction.

Designating Steel Pipe, Round HSS and Square and

Rectangular HSS Properly.

Steel pipe is designated as follows:

1. By NPS designation through NPS 12 (e.g., Pipe 5 Std., Pipe 5

x-strong or Pipe 5 xx-strong). Note that this notation has com-

monly been abbreviated as follows for the examples given: P5,

PX5 and PXX5, respectively.

2. In the format Pipe followed by diameter x nominal wall thick-

ness, each expressed three decimal places, to for NPS desig-

nations greater than NPS 12 and other non-NPS sizes (e.g.,

NPS 14 Standard is designated Pipe 14.000x0.375)

A round HSS is designated by nominal diameter and wall thick-

ness, each expressed to three deci mal pl aces, e,g,, HSS

5.563x0.258

A square or rectangular HSS is designated by nominal outside

dimensions and wall thickness, each in rational numbers, e.g.,

HSS 5x3x3/8

By Charles J. Carter, PE

T

HE MATERIALS AND PRODUCTS USED

IN BUILDING DESIGN AND CONSTRUC-

TION are almost universally desig-

nated by reference to an appropriate

ASTM specification. This simplifies the

design and construction process because

all characteristics of the product speci-

fied are defined by simple reference to

an approved standard. However, with

dozens of ASTM specifications applica-

ble in steel building construction alone

and several new ones now available, it

can be challenging to keep the standard

designations in contract documents cur-

rent.

This article (Part Two) is a summary

of the common ASTM specifications

used for structural plates, bars and

other plate products in building design

and construction.

Part One (see January 1999 Modern

Steel Construction) covered structural

members. Part Three will focus on fas-

tening products.

The generally applicable ASTM speci-

fications for structural plates are given

in Table 1. Following is a discussion of

the usual and other applicable ASTM

specifications for structural plates and

other plate-type products. The usual

ASTM specifications are summarized by

product in Table 2.

STRUCTURAL PLATES

The usual material specification for

structural plates is ASTM A36 (F

y

= 36

ksi; F

u

= 58 ksi). Note that the yield

strength given is applicable when the

plate thickness is equal to or less than

8. Above 8 thickness, F

y

= 32 ksi.

Structural plates with higher yield

and tensile strength can be obtained by

specifying ASTM A572 grade 42, 50, 60

or 65, ASTM A529 grade 42 or 50,

ASTM A514 grade 90 or 100, or ASTM

A852. Structural plates with atmospher-

ic corrosion resistance (weathering)

characteristics can be obtained by speci-

fying ASTM A588 grade 42, 46, or 50.

However, the availability and cost effec-

Modern Steel Construction / February 1999

tiveness of structural plates in grades

other than ASTM A36 should be con-

firmed prior to their specification. Note

also that the availability of grades other

than ASTM A36 varies through the

range of thickness.

Regardless of the material specifica-

tion chosen, the production tolerances

for structural plates are given in ASTM

A6.

STRUCTURAL BARS

The foregoing comments for structur-

al plates apply equally to structural

bars, except that neither ASTM A514

and nor A852 is applicable. So again,

the usual material specification for

structural bars is ASTM A36 (F

y

= 36

ksi; F

u

= 58 ksi).

Actually, it should be highlighted

that there is very little, if any, structur-

al difference between flat bars and

plates. Consequently, plate is becoming

a universally applied term today and a

PL x 4 x 1 -3, for example, might

be fabricated from plate or bar stock.

From AISC s A Guide to Engineering

and Quality Criteria for Steel

StructuresCommon Questions

Answered (AISC Publication S323), the

historical classification system for flat

bars and plates would suggest that

there is only a physical difference

between them that centers on size (see

Table 3) and production procedure. In

raw form, flat stock has historically

been classified as a bar if it is less than

or equal to 8 wide and as a plate if it is

greater than 8 wide. Flat bars are

rolled between horizontal and vertical

rolls and trimmed to length by shearing

or flame cutting on the ends only. Plates

are generally produced using one of

three methods: (1) sheared plates are

rolled between horizontal rolls and

trimmed to width and length by shear-

ing or flame cutting on the edges and

ends; (2) universal mill (UM) plates are

rolled between horizontal and vertical

rolls and trimmed to length by shearing

or flame cutting on the ends only; and,

(3) stripped plates are sheared or flame

cut from wider sheared plates.

ARE YOU PROPERLY

SPECIFYING MATERIALS?

Part two

in a

three-

part

series:

structural

plates

Modern Steel Construction / February 1999

Table 1. ASTM specifications and their product-specific applicability

Product Applicable ASTM specifications Notes:

Structural plate A36, A514, A529, A572, A588, A852 1

Structural bar A36, A529, A572, A588 1

Raised-pattern floor plate A786 2

Sheet and strip A570, A606, A607

Notes:

1. Availability varies through the range of thickness.

2. Ordered as "commercial grade" or to plate material specification,

such as ASTM A36, A572 or A588. "Commercial grade," per ASTM A786 Section

5.1.2, means "the product will be supplied 0.33 percent carbon and without speci-

fied mechanical properties."

Specifying Plates

for Detail Materials

Plates for detail materials, such as shear plates, flange plates, gusset plates,

transverse stiffeners and web doubler plates, are commonly designated with the let-

ters PL followed by thickness x width x length. The thickness and width are speci-

fied as fractional inch dimensions and the length is specified in feet and inches.

Thus, a -thick flange plate with 8 width and 16 length would be specified as

PL x 8 x 1-4. Similarly, a -thick gusset plate with 18 width and 36 length

would be specified as PL x 18 x 3-0.

While structural plates and bars can be produced in thickness increments far

smaller, it is recommended that thicknesses be selected for detail materials in

1

/8-in

increments. That is, use thickness increments such as

3

/8 and rather than

5

/16

and

7

/16, respectively. Fabricators will rarely stock plates in 1/16 thickness incre-

ments.

Table 2. Plate products and their usual ASTM specifications

Min. F

y

Min. F

u

Product Usual ASTM Specification (ksi) (ksi)

Structural plate A36 36 58

Structural bar A36 36 58

Raised-pattern floor plate A786 see Note 2 see Note 2

Other plate products varies with application varies varies

Notes:

1. F

y

= 32 ksi for ASTM A36 material over 8 thick.

2. If ordered as "commercial grade", no minimum strength is applicable. If ordered to a

plate material specification such as ASTM A36, A572 or A588, F

y

and F

u

are as specified

therein. "Commercial grade," per ASTM A786 Section 5.1.2, means "the product will

be supplied 0.33 percent carbon and without specified mechanical properties."

Modern Steel Construction / February 1999

Table 3. Classification of Plate Products

Width (in.)

over 3

1

/2 over 6 over 8 over 12 over 48

Thickness (in.) to 3

1

/2 to 6 to 8 to 12 to 48

0.2300 and over bar bar bar plate plate plate

0.2031 to 0.2299 bar bar strip strip sheet plate

0.1800 to 0.2030 strip strip strip strip sheet plate

0.0449 to 0.1799 strip strip strip strip sheet sheet

0.0344 to 0.0448 strip strip

0.0255 to 0.0343 strip

to 0.0254

Hot-rolled sheet and strip not generally

produced in these widths and thicknesses

Charles J. Carter, P.E., is Director of

Manuals with the American Institute of

Steel Construction, Inc. and an occasion-

al contributor of articles in Modern Steel

Construction.

RAISED-PATTERN FLOOR PLATES

ASTM A786 is the standard specifica-

tion for rolled steel floor plates. As floor-

plate design is seldom controlled by

strength considerations, ASTM A786

commercial grade is commonly speci-

fied. If so, per ASTM A786 Section 5.1.2,

the product will be supplied 0.33 per-

cent maximum carbon and without

specified mechanical properties.

Alternatively, if a defined strength level

is desired, ASTM A786 raised-pattern

floor plate can be ordered to a defined

plate specification, such as ASTM A36,

A572, or A588; see ASTM A786 Sections

5.1.2 and 8 and Appendix Table X1.1.

OTHER PLATE PRODUCTS

Sheet and strip products, which are

generally thinner than structural plate

and bar products (see Table 3), are pro-

duced to such ASTM specifications as

A570, A606 or A607. Skelp is a general

term for the plate products used in the

production of hollow structural sections

(HSS).

By Charles J. Carter, PE

T

HE MATERIALS AND PRODUCTS USED

IN BUILDING DESIGN AND CONSTRUC-

TION ARE ALMOST UNIVERSALLY DES-

IGNATED by reference to an appropriate

ASTM specification. This simplifies the

design and construction process because

all characteristics of the product speci-

fied are defined by simple reference to

an approved standard. However, with

dozens of ASTM specifications applica-

ble in steel building construction alone,

it is often a challenge to keep the stan-

dard designations in contract docu-

ments current. Compounding this chal-

lenge, there have been several recent

additions to the roster of available

ASTM specifications of which many

specifiers may be unaware.

This article (Part Three) provides a

summary of the common ASTM and

other specifications used for fastening

products in building design and con-

struction. The usual and other applica-

ble ASTM specifications are addressed.

Parts One (January 1999 MSC) and

Two (February 1999 MSC) focused on

structural shapes and plate, respective-

ly.

BOLTS

The usual material specification for

conventional (heavy-hex) high-strength

bolts in steel-to-steel structural connec-

tions is ASTM A325, although ASTM

A490 can be specified when higher

strength is desired. In either case, Type

1 is most commonly specified. When

atmospheric corrosion resistance is

desired, Type 3 can be specified.

For some time now, alternative-

design fasteners have been specified as

described in Section 2(d) of the Research

Council on Structural Connections

Specification for Structural Joints Using

ASTM A325 or A490 Bolts. Recently,

ASTM published its specification F1852,

which formalizes the material and prod-

uct requirements for these twist-off-type

tension-control bolt assemblies in a

strength-level that is equivalent to

Modern Steel Construction / March 1999

ASTM A325. For convenience, the

marking system for these fasteners is

the more familiar A325 to avoid confu-

sion.

While still formally permitted in the

AISC Specification for Structural Steel

Buildings, the use of other material

specifications in steel-to-steel structural

bolting applications has become quite

uncommon. ASTM A307 is almost as

uncommonly specified today as are

ASTM A501 and A502 rivets, perhaps

only in structurally nominal connections

such as those at the ends of girts and

purlins.

NUTS

The usual material specification for

heavy-hex nuts is ASTM A563. The

appropriate grade and finish is specified

per ASTM A563 Table X1.1 according to

the bolt or threaded part with which the

nut will be used. For steel-to-steel struc-

tural bolting applications, the appropri-

ate grade and finish is summarized in

RCSC Specification Section 2(c).

Although ASTM A194 is permitted as

an alternative in some applications,

they are generally more expensive and

less available than ASTM A563 nuts.

WASHERS

The usual material specification for

hardened steel washers is ASTM F436.

This specification provides for both flat

and beveled washers. While standard

ASTM F436 washers are sufficient in

most applications, there are several spe-

cific applications when special washers

are required. Refer to RCSC Spec-

ification Sections 7(c)(6) and 7(c)(7),

which outline the special washer

requirements that apply when oversized

and slotted holes are used in outer plies

of steel-to-steel structural bolting appli-

cations. In anchor-rod and other embed-

ment applications, hole sizes are gener-

ally larger than those for steel-to-steel

structural bolting applications (see

LRFD Manual Table 11-3 for maximum

anchor-rod hole sizes). Accordingly,

washers used in such applications may

ARE YOU PROPERLY

SPECIFYING MATERIALS?

Part

three in a

three-

part

series:

fastening

products

require design consideration for proper

force transfer, particularly when the

anchorage is subject to tension.

COMPRESSIBLE-WASHER-TYPE DIRECT-

TENSION INDICATORS

Four methods of installation are rec-

ognized in RCSC Specification Section

8(d) for high-strength bolts in preten-

sioned bearing joints, slip-critical joints

and joints subject to tension or com-

bined shear and tension: turn-of-nut

installation, calibrated wrench installa-

tion, alternative-design-fastener instal-

lation and direct-tension-indicator

installation. When the direct-tension-

indicator installation method is used,

ASTM F959 compressible-washer-type

direct-tension indicators are specified.

Type A325 is used with ASTM A325

high-strength bolts and type A490 is

used with ASTM A490 high-strength

bolts.

ANCHOR RODS

(SEE BOXOPPOSITE PAGE)

The usual material specification for

anchor rods is ASTM F1554, a new

material specification that covers

hooked, headed and threaded and nut-

ted anchor rods in three strength

grades: 36, 55 and 105. Grade 55 is most

commonly specified. The weldability

supplement S1 (with the carbon equiva-

lent formula in ASTM F1554 Section

S1.5.2.1) is recommended as compara-

tively inexpensive insurance for a more

flexible solution set should the anchor

rods be placed incorrectly in the field.

ASTM F1554 grades 36 and 105 are

essentially the anchor-rod equivalents

of the generic rod specifications ASTM

A36 and A193 grade B7, respectively.

ASTM F1554 grade 55, when specified

with the weldability supplement, is sim-

ilar to an ASTM A572 material that is

intermediate between grades 50 and 60.

Although ASTM F1554 is expected to

rapidly become the specification of

choice for anchor rods, several other

ASTM Specifications can also be used.

For applications involving unheaded

rods, ASTM A36, A193, A307, A354,

A449, A572, A588 and A687 can be

specified. For applications involving

headed rods, ASTM A307, A354 and

A449 can be specified.

THREADED RODS

The usual material specification for

threaded rods, whether provided with

plain or upset ends, is ASTM A36.

Other material specifications that can

be specified include ASTM A193, A307,

Modern Steel Construction / March 1999

Did you say rods? I say bolts. Youre

not from around here, are you?

Anchor bolt is a nearly universal term in structural steel design and construc-

tion. However, it is all too common that requirements for steel-to-steel structural

bolting applications are mistakenly applied to steel-to-concrete anchorage applica-

tions. Even worse, inclusion of the word bolt in the term has misled many an engi-

neer to erroneously specify the anchorage material as ASTM A325 or A490, some-

times even in applications when a hooked rod was specified. Fortunately, their

friendly neighborhood fabricator knew that ASTM A449 and A354 provide the

respective strength equivalents in a rod material and are available in the range of

lengths that are commonly specified for anchorage devices.

To differentiate between steel-to-steel structural bolting applications and steel-to-

concrete anchorage applications, AISC has changed terminology to anchor rod.

Dont worry though if you still say anchor bolt from time to time, we know what you

mean (and we still say it sometimes too!).

A354, A449, A572, A588, and A687.

FORGED STEEL STRUCTURAL HARDWARE

Forged steel structural hardware

products, such as clevises, turnbuckles,

eye nuts, and sleeve nuts, are occasion-

ally used in building design and con-

struction. These products are generally

provided to AISI material specifications.

AISI C-1035 material is commonly used

in the manufacture of clevises and turn-

buckles. AISI C-1030 material is com-

monly used in the manufacture of steel

eye nuts and steel eye bolts. AISI C-

1018 grade 2 material is commonly used

in the manufacture of sleeve nuts. Other

products, such as steel rod ends, steel

yoke ends and pins, cotter pins and cou-

pling nuts are commonly provided

generically as carbon steel. In any

case, the dimensional and strength

characteristics of these devices are fully

described in the literature provided by

their manufacturer.

WELD METAL

The appropriate weld metal is as

summarized in ANSI/AWS D1.1-98

Table 3.1 for the various combinations

of base metal specification and grade

and electrode specification. Weld metal

with a tensile strength F

EXX

= 70 ksi is

most common.

SHEAR STUD CONNECTORS

As specified in ANSI/AWS D1.1-98

Chapter 7 (Section 7.2.6 and Table 7.1),

Type B shear stud connectors made

from ASTM A108 material are used for

the interconnection of steel and concrete

elements in composite construction.

STEEL CASTINGS AND FORGINGS

Steel castings are specified as ASTM

A27 grade 65-35 or ASTM A148 grade

80-35. Steel forgings are specified as

ASTM A668.

ACKNOWLEDGEMENTS

The author thanks Mike Friel of

Haydon Bolts Inc., Philadelphia, PA

and Bud Parka of Cleveland City Forge,

Wellington, OH for their input during

the preparation of this part.

Charles J. Carter, PE, is Director of

Manuals with the American Institute of

Steel Construction, Inc. and an occasion-

al contributor of articles in Modern

Steel Construction.

OOPS!!

Please note that an error occured in

the electronic printing process for the

February 1999 MSC (Are You

Properly Specifying Materials?, Part II:

structural plates). In several places,

such as in the box on page 38 and in

the text on page 39, the characters "fi"

and "fl" mistakenly appear; "fi" should

be "

1

/2" and "fl" should be "

3

/4".

You might also like

- ASTM A792-10 Specification GalvalumeDocument6 pagesASTM A792-10 Specification GalvalumeSaurabh Gupta0% (1)

- Safe Distance Stored Energy Calculator - Pneumatic TestingDocument3 pagesSafe Distance Stored Energy Calculator - Pneumatic TestingKarthikeyan ShanmugavelNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Astm A653 15 PDFDocument13 pagesAstm A653 15 PDFDaniel Vasquez100% (2)

- A 36 - A 36M - 19Document3 pagesA 36 - A 36M - 19AAY100% (1)

- Astm A36 PDFDocument3 pagesAstm A36 PDFrahmath nawazNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Method Statement For Hydrant As Per PVN CommentsDocument23 pagesMethod Statement For Hydrant As Per PVN CommentsAbcd efgh100% (1)

- Are You Properly Specifying MaterialsDocument7 pagesAre You Properly Specifying Materialsrslama_lecturesNo ratings yet

- A Y P S M ?: RE OU Roperly Pecifying AterialsDocument7 pagesA Y P S M ?: RE OU Roperly Pecifying AterialswjdvNo ratings yet

- Especificaciones de MaterialesDocument6 pagesEspecificaciones de MaterialesArturo AppleyxrdNo ratings yet

- SteelWise Specifying MaterialsDocument6 pagesSteelWise Specifying Materialsv100% (1)

- Are You Properly Specifying MaterialsDocument8 pagesAre You Properly Specifying MaterialssanjuanshekinahNo ratings yet

- Steelwise: Are You Properly Specifying Materials?Document9 pagesSteelwise: Are You Properly Specifying Materials?Muhammad AhsunNo ratings yet

- AISC 13th - Material GradesDocument5 pagesAISC 13th - Material GradesUpadrasta HarishNo ratings yet

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- Data Sheet ASTM A572 Grade 50 2019-05-20Document1 pageData Sheet ASTM A572 Grade 50 2019-05-20Andrés RamírezNo ratings yet

- Metallurgy and Welding PDFDocument18 pagesMetallurgy and Welding PDFPatrick DominguezNo ratings yet

- Do You 992Document2 pagesDo You 992dgkmurtiNo ratings yet

- Astm A992Document1 pageAstm A992Jaime RobertoNo ratings yet

- A792a792m 28998Document6 pagesA792a792m 28998sasdfsadasdasNo ratings yet

- Astm-A79210pdf PDFDocument6 pagesAstm-A79210pdf PDFLian HoaNo ratings yet

- Steel SpecificationsDocument6 pagesSteel SpecificationsinsidereaderNo ratings yet

- Steel Material Guide AstmDocument3 pagesSteel Material Guide Astmjworder100% (1)

- Carbon Structural Steel: Standard Specification ForDocument3 pagesCarbon Structural Steel: Standard Specification ForMr.Hnin WaiNo ratings yet

- Astm A36 A36m 14pdfDocument4 pagesAstm A36 A36m 14pdfRocio AriasNo ratings yet

- Carbon Structural Steel: Standardspecification ForDocument4 pagesCarbon Structural Steel: Standardspecification ForlinaNo ratings yet

- Structural Steel MaterialsDocument3 pagesStructural Steel MaterialsinsidereaderNo ratings yet

- SDI, Steel Deck.Document13 pagesSDI, Steel Deck.Miguel LuqueNo ratings yet

- A 792 GalvalumeDocument5 pagesA 792 GalvalumeKapa SandeepNo ratings yet

- Astm A36 A36m 14 PDFDocument3 pagesAstm A36 A36m 14 PDFWah Khaing0% (1)

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessJosé Ramón GutierrezNo ratings yet

- Carbon Structural Steel: Standard Specification ForDocument3 pagesCarbon Structural Steel: Standard Specification ForGabriel VelasteguíNo ratings yet

- Astm A36 Acero Al CarbonDocument3 pagesAstm A36 Acero Al CarbonMajo BárcenasNo ratings yet

- Steel Sheet Piling: Standard Specification ForDocument2 pagesSteel Sheet Piling: Standard Specification ForDarwin DarmawanNo ratings yet

- Astm A36 19Document3 pagesAstm A36 19Renan SouzaNo ratings yet

- ASTM A36 EdDocument3 pagesASTM A36 EdBharani DharanNo ratings yet

- Astm A792 PDFDocument6 pagesAstm A792 PDFOswaldo Enrique Adame67% (3)

- STANDARD - ASTM A792 - Brief DescriptionDocument3 pagesSTANDARD - ASTM A792 - Brief DescriptionSeyong ParkNo ratings yet

- Carbon Structural Steel: Standard Specification ForDocument3 pagesCarbon Structural Steel: Standard Specification ForSol AngelNo ratings yet

- Astm A1065-09Document6 pagesAstm A1065-09ing_fernandogalvez2015No ratings yet

- Cold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDocument3 pagesCold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDanZel DanNo ratings yet

- Metallurgy & WeldingDocument10 pagesMetallurgy & WeldingMominé VeNo ratings yet

- Carbon Structural Steel: Standard Specification ForDocument3 pagesCarbon Structural Steel: Standard Specification ForudayNo ratings yet

- Specification of ElectrodeDocument28 pagesSpecification of ElectrodeAnonymous nKOyHbNo ratings yet

- Astm A 463-A 463M-02Document6 pagesAstm A 463-A 463M-02Anton Thomas Punzalan100% (4)

- Astm A36 A36m 19Document2 pagesAstm A36 A36m 19bruno.abuafNo ratings yet

- A6/a6m A27/a27m A307 A325 A325m A500 A501 A502 A563 A563m A668/a668m A1011/a1011mDocument4 pagesA6/a6m A27/a27m A307 A325 A325m A500 A501 A502 A563 A563m A668/a668m A1011/a1011mRocio AriasNo ratings yet

- Astm A792Document7 pagesAstm A792MJ100% (2)

- A653.1501849-1 - Hot Dipped Steel GalvanizationDocument13 pagesA653.1501849-1 - Hot Dipped Steel Galvanizationsubhaschandranath1No ratings yet

- Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDocument8 pagesCorrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDarwin DarmawanNo ratings yet

- General Provisions: Chapeer ADocument9 pagesGeneral Provisions: Chapeer AJerry M. Davila MartelNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- AUTOMATIC PIPE CUTTING MACHINE EditedDocument25 pagesAUTOMATIC PIPE CUTTING MACHINE EditedrajeshNo ratings yet

- Cceer10 01Document583 pagesCceer10 01Ulissipo1955No ratings yet

- Equivalent Length of Pipe Fittings Table PDF - Google SearchDocument2 pagesEquivalent Length of Pipe Fittings Table PDF - Google SearchzoksiNo ratings yet

- Water Hammer in Steam LinesDocument5 pagesWater Hammer in Steam LinesVijaita Vikas GandhiNo ratings yet

- Specifications: I. General ProvisionsDocument4 pagesSpecifications: I. General Provisionsemem CatzNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- Bulletin 153E ATC-E 1220Document44 pagesBulletin 153E ATC-E 1220Tin KalderonNo ratings yet

- PIP - Control de ProcesosDocument9 pagesPIP - Control de ProcesosJacob Nicolas Montanares JaraNo ratings yet

- Bio-Solv ProductDocument96 pagesBio-Solv ProductArif Fahmi TurinNo ratings yet

- Tata Projects Internship ReportDocument28 pagesTata Projects Internship ReportSushant Kase0% (3)

- 31.3 Open QBDocument13 pages31.3 Open QBAnonymous Somc4sDNo ratings yet

- PVC Pipe Conduit Bends SCH 40Document2 pagesPVC Pipe Conduit Bends SCH 40Comstar Supply100% (5)

- Hydraulic Testing of PVC Pipe Laboratory and Field Tests Confirm Flow CoefficientsDocument12 pagesHydraulic Testing of PVC Pipe Laboratory and Field Tests Confirm Flow CoefficientsManish PatelNo ratings yet

- QC Vs Precom SOW MatrixDocument2 pagesQC Vs Precom SOW Matrixsc0urg3No ratings yet

- FlowGuard CPVC ME General PresentationDocument75 pagesFlowGuard CPVC ME General Presentationanwer_quadriNo ratings yet

- Quotation: S/N Parts Destription Parts Number QTY UnitDocument2 pagesQuotation: S/N Parts Destription Parts Number QTY UnitRahmat TaufikNo ratings yet

- 646w PHMD TB ZC 00oo001 D PDFDocument56 pages646w PHMD TB ZC 00oo001 D PDFalvaroNo ratings yet

- 14-11-35-GSP-FP Adden (02-08-19) FULLDocument150 pages14-11-35-GSP-FP Adden (02-08-19) FULLKhang TrầnNo ratings yet

- Concrete Pipes and Portal Culverts HandbookDocument52 pagesConcrete Pipes and Portal Culverts HandbookKenya Ayallew Asmare100% (3)

- Agilent G3471A Pneumatic Control Module (PCM) : Parts SuppliedDocument10 pagesAgilent G3471A Pneumatic Control Module (PCM) : Parts Suppliedعماد عامریNo ratings yet

- A660Document4 pagesA660Amreusit SaschimbnumeleNo ratings yet

- Fire Sprinkler System Pipe Material: The Pros and Cons of Copper and CPVCDocument8 pagesFire Sprinkler System Pipe Material: The Pros and Cons of Copper and CPVCAmar kobitaNo ratings yet

- ARMSTRONG - Pressure Reducing ValvesDocument48 pagesARMSTRONG - Pressure Reducing ValvesAdam AvalosNo ratings yet

- Approach and MethodologyDocument14 pagesApproach and Methodologykaustavmukherjee19780% (1)

- TR-DM-MI-0218: Issued For ConstructionDocument2 pagesTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNo ratings yet

- Property Case ReviewerDocument33 pagesProperty Case ReviewerJanz Serrano100% (4)

- Din 2393-2Document0 pagesDin 2393-2Yalavarthi ChandrasekharNo ratings yet

- Acg8 PumpDocument28 pagesAcg8 PumperolNo ratings yet