Professional Documents

Culture Documents

De Husker

De Husker

Uploaded by

Mithun MohanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

De Husker

De Husker

Uploaded by

Mithun MohanCopyright:

Available Formats

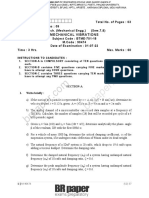

INTERIM PROJECT PRESENTATION

ON

COCONUT DEHUSKER

.

ABSTRACT

Coconut dehusker is a machine that uses electric

power for coconut dehusking. The main components

of this machine are 1HP motor, belt, pulley, gears,

shaft with blades, bearings etc. The expected

number of coconuts to be dehusked by this machine

is about 900 per hour. This machine can result in a

great revolution in agro based industries .

PERSONAL VISITS

Village officer: Mr. Suresh Babu

Purpose : To have a discussion on the problems

related to automatic coconut dehusking and

currently available technologies in it.

Agricultural engineer : Mr. Jayakrishnan

Purpose:

To get a technical guidance related to

coconut dehusker.

The power requirement, speed ratio etc

were discussed in detail.

VISIT

Kelappaji college of agricultural engineering,

Thavannur.

PURPOSE: To have a knowledge about the already

existing machineries used for coconut dehusking.

PERSONS MET: Dr Shivsubramaniam (Dean)

Dr Jayan (Assistant dean)

BENEFITS:

Understood that dehusking of coconuts is one of

the major problems faced in agro based industries.

Understood the basic working principles of

dehusking machines .

Problems identified.

DESIGN

Force calculation:

Force calculated using UTM

Result: dehusking force = 8 Kgf ( tender coconut)

= 10 Kgf(dry coconut)

CALCULATION

Power requirement

=

2

60

=

22009.81

60

=205.46 W

=0.27 hp

Hence , 1 hp slow speed motor

is selected

Shaft design

3

=

16

(

)

2

+(

)

2

=

16

290 10

5

(3 3)

2

+(3 3.63)

2

=2.45 10

6

= 0.0135

= 1.35

The diameter of shaft selected is 7 cm

BEARING DESIGN:

F=10Kgf

S=1.2(service factor)

Equivalent Load(P)=FS

= 101.2= 12Kgf

Dynamic capacity(C)=(L) P^(1/K),

(K=3 for ball bearings.)

Life of bearing(L)= (2006083655)/10^6

= 175.2 million revolutions

C= 175.20(12)^(1/3)= 401.1 Kgf

Bearing selection: Self aligning ball bearing

SPECIFICATIONS:

SKF NO:2206,

d=30mm,

D=62mm,

static capacity(

)=560Kgf,

dynamic capacity(C)=1200kgf,

maximum permissible speed=13000 rpm.

PULLEY AND V-BELT DESIGN:

d=75mm,N=200rpm

D=i*d= 3.6*75= 270mm

equivalent pitch diameter (De)=85.5mm

Belt cross-section symbol is A

Belt speed (s)=( DN)/60= 2.356 m/s

Rated power for belt cross-section A=1.559 KW

Design power=

(rated power service factor)

(length factorangle correction factor)

=(1.5591.11.02)/(.97)

=1.803 KW

No of belts= design power/ rated power

=1.15

1

Centre distance(C)=700mm

Length of belt=2C+/2(D+d)+((D-d)^2)/4C

=1872mm

Top Width of belt= 13mm

Thickness= 8mm

DIMENSION OF V-GROOVED PULLEY:

Groove cross-section=A

Pitch width=11mm

Minimum depth below pitch line=8.7mm

Slope design

Coefficent of friction for coconut= 0.522

For coconut to slide=

sin > cos

tan >

> 27.56

Selected value of slope=28.072

MANUFACTURING

DETAILS

Items purchased:

Blade:30mm10mm flat, length 4000mm.

Pipe:3 inch diameter-bush pipe, length 1000mm.

Shafts:35mm diameter, length 850mm and

650mm.

Dummy piece:2 inch diameter, thickness 50 mm.

Angle:1/4 inch5/4 inch-length 4000mm.

Bearing: UCP 206.

COST ESTIMATION

MATERIAL COST:RS 2000/-

BEARING COST:RS 1250/-

MOTOR COST:RS 2000/-

BELT AND PULLEY:RS 2500/-

GEARS:RS 1500/-

MANUFACTURING COSTS:RS 7500/-

OTHER COSTS:RS 1250/-

TOTAL COST ESTIMATE:RS 18000/-

WORK COMPLETED

THANK YOU

You might also like

- HDLT12300 Device Instruction ManualDocument88 pagesHDLT12300 Device Instruction ManualJulio Cesar Hernandez Trujillo100% (6)

- Design of A Modified Hand Operated Maize ShellerDocument18 pagesDesign of A Modified Hand Operated Maize ShellergemeeNo ratings yet

- Electrical Workshop ManualDocument30 pagesElectrical Workshop Manualjosephjohn20360% (5)

- 2010 (Q2) - Tables For Eccentrically Loaded WT Shapes in CompressionDocument10 pages2010 (Q2) - Tables For Eccentrically Loaded WT Shapes in CompressionCesar RjszvlNo ratings yet

- Mechanical ProjectDocument14 pagesMechanical ProjectMP HNo ratings yet

- Design and Fabrication of Coconut de HuskingDocument5 pagesDesign and Fabrication of Coconut de HuskingKenneth LorenzoNo ratings yet

- Ijsetr Vol 4 Issue 5 1269 1273Document5 pagesIjsetr Vol 4 Issue 5 1269 1273naqeeb na3No ratings yet

- Redesign and Fabrication of Coconut Dehusking MachineDocument52 pagesRedesign and Fabrication of Coconut Dehusking MachineBassey Etim0% (1)

- Coconut Fair ReportDocument25 pagesCoconut Fair ReportMithun Mohan100% (2)

- Performance Characteristics of A CoconutDocument14 pagesPerformance Characteristics of A CoconutNeil TaneoNo ratings yet

- Design and Fabrication of Pedal Powered Lawn Mower CycleDocument2 pagesDesign and Fabrication of Pedal Powered Lawn Mower CycleVinayaga ProjectinstituteNo ratings yet

- Advanced Pepper Separator Machine: A Project ReportDocument42 pagesAdvanced Pepper Separator Machine: A Project ReportSports GalleryNo ratings yet

- Fabrication of Low-Cost Manualcrop Harvesting MachineDocument9 pagesFabrication of Low-Cost Manualcrop Harvesting Machinepratik g100% (1)

- Prashant Seminar ReportDocument18 pagesPrashant Seminar ReportPrashant RajoleNo ratings yet

- A Review of Coconut Husking MachinesDocument11 pagesA Review of Coconut Husking MachinesjonjonnyNo ratings yet

- Final Write Up - Dehusking Machine-2020Document55 pagesFinal Write Up - Dehusking Machine-2020Zainal MohdNo ratings yet

- Industrial Visit ReportDocument3 pagesIndustrial Visit ReportBarzeen Mehr AfareenNo ratings yet

- Design and Fabrication of Groundnut Thresher MachineDocument5 pagesDesign and Fabrication of Groundnut Thresher MachineBhanu Hi100% (1)

- Tender Coconut Cutting MachineDocument1 pageTender Coconut Cutting MachineRavindraNo ratings yet

- Design and Fabrication of A Motorized Rice HullingDocument11 pagesDesign and Fabrication of A Motorized Rice HullingridwanmuhammadtajudeenNo ratings yet

- Coconut DehuskingDocument37 pagesCoconut Dehuskinghaiod100% (1)

- New Microsoft PowerPoint PresentationDocument11 pagesNew Microsoft PowerPoint PresentationShubham PatilNo ratings yet

- Coconut DehuskingDocument50 pagesCoconut DehuskingRaghavendra NaikNo ratings yet

- Design and Fabrication of Groundnut Pods and Shell StripperDocument5 pagesDesign and Fabrication of Groundnut Pods and Shell StripperSanket WaradeNo ratings yet

- Design and Fabrication of An Economical Coconut Dehusking MachineDocument9 pagesDesign and Fabrication of An Economical Coconut Dehusking MachineMohamed SaleemNo ratings yet

- Design of An Innovative Coconut Grating Machine Using TinkercadDocument5 pagesDesign of An Innovative Coconut Grating Machine Using TinkercadChristopher Ysit100% (1)

- Development Coconut Dehusking Machine PDFDocument7 pagesDevelopment Coconut Dehusking Machine PDFRamiro JancoNo ratings yet

- Bud Chpper Machine DetailsDocument18 pagesBud Chpper Machine DetailsSanket Malunje100% (1)

- Tender Coconut Extracting MachineDocument17 pagesTender Coconut Extracting MachineMANJUNATHA K H100% (2)

- Conceptual Design of Coconut Dehusking MachineDocument10 pagesConceptual Design of Coconut Dehusking Machineசிங்கக்குட்டி சின்னக் கவுண்டர்No ratings yet

- Multi Agri Cutter - AbstractDocument4 pagesMulti Agri Cutter - AbstractShankar G75% (4)

- Shaft Design Bearing SelectionDocument2 pagesShaft Design Bearing Selectionfma381bNo ratings yet

- Multicrop Harvesting MachineDocument9 pagesMulticrop Harvesting MachineIJRASETPublicationsNo ratings yet

- T.E - I (English) - N SchemeDocument353 pagesT.E - I (English) - N SchemeSakthiVelMNo ratings yet

- Solar Rice Dehusking Machine 2 PHASEDocument16 pagesSolar Rice Dehusking Machine 2 PHASEDeiva K100% (1)

- Hydraulic Cutting MachineDocument19 pagesHydraulic Cutting Machineanon_776112819100% (1)

- Fabrication of Sugarcane Bud ChipperDocument37 pagesFabrication of Sugarcane Bud ChipperAakash DindigulNo ratings yet

- Automatic Rice Transplantation Machine PDFDocument4 pagesAutomatic Rice Transplantation Machine PDFHidden Face01No ratings yet

- Design of Seed Sowing MachineDocument7 pagesDesign of Seed Sowing MachinePranshu GuptaNo ratings yet

- Design and Implementation of Automatic Lawn CutterDocument6 pagesDesign and Implementation of Automatic Lawn CutterIJSTENo ratings yet

- Groundnut ThrasherDocument27 pagesGroundnut ThrasherBoopathi KalaiNo ratings yet

- Design and Fabrication of Crop Cutting Machine IJERTV8IS060212 PDFDocument6 pagesDesign and Fabrication of Crop Cutting Machine IJERTV8IS060212 PDFHaritha ChowdaryNo ratings yet

- 4.journal of Arecanut Tree ClimberDocument3 pages4.journal of Arecanut Tree ClimberPranith K VNo ratings yet

- Cam Based Sand FilterDocument56 pagesCam Based Sand FilterANAND KRISHNAN100% (1)

- 64 Development of Power Operated Coconut Dehusker (2014) (Patil S.R)Document88 pages64 Development of Power Operated Coconut Dehusker (2014) (Patil S.R)Suresh NatarajanNo ratings yet

- Agricultural Based Projects PDFDocument3 pagesAgricultural Based Projects PDFChandra Sekar100% (2)

- Paddy TransplanterDocument24 pagesPaddy TransplanterMuhammad Ali100% (4)

- Design and Fabrication of Multi-Purpose Sieving MachineDocument6 pagesDesign and Fabrication of Multi-Purpose Sieving MachineMICHEL RAJ MechNo ratings yet

- Design & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostDocument8 pagesDesign & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostIJIRSTNo ratings yet

- Coconut Dehusking MachineDocument16 pagesCoconut Dehusking MachineArjuncv100% (4)

- Pedal Operated Flour Mill MachineDocument27 pagesPedal Operated Flour Mill MachineAshwani dubey100% (1)

- Mais Thresher PDFDocument6 pagesMais Thresher PDFHenry DatangelNo ratings yet

- Agriculture Fertilizer Feeding MachineDocument30 pagesAgriculture Fertilizer Feeding MachineEr Dinesh TambeNo ratings yet

- Weeder SynopsisDocument8 pagesWeeder SynopsisParas ChauhanNo ratings yet

- Fabrication of Portable Noodle Making Ma Fd82a2eeDocument4 pagesFabrication of Portable Noodle Making Ma Fd82a2eeankush belkarNo ratings yet

- Automatic Coconut Cutting MachineDocument10 pagesAutomatic Coconut Cutting Machineakrofi percy obengNo ratings yet

- Design of Crop Cutter Machine Ijariie5257Document6 pagesDesign of Crop Cutter Machine Ijariie5257Vijay PulavarthiNo ratings yet

- Pnumatic Ramming and Punching Machine ReportDocument28 pagesPnumatic Ramming and Punching Machine ReportSun SriNo ratings yet

- Design and Fabrication of Onion Seed Sowing Machine 1433826027 PDFDocument10 pagesDesign and Fabrication of Onion Seed Sowing Machine 1433826027 PDFGuiiNo ratings yet

- MV (7th&8th) May2022Document3 pagesMV (7th&8th) May2022Amit AngralNo ratings yet

- A Report On The Attachment at KengenDocument28 pagesA Report On The Attachment at KengenmelissakiptooNo ratings yet

- INTRODUCTIONDocument24 pagesINTRODUCTIONnaveeen chackoNo ratings yet

- Abrasive Cut Off Machine Mini ProjectDocument49 pagesAbrasive Cut Off Machine Mini ProjectdurendranNo ratings yet

- PN 2300Document95 pagesPN 2300cresjohn100% (1)

- Furnace & Ovens WP (Original)Document38 pagesFurnace & Ovens WP (Original)Mumahmmad Rizwan RNo ratings yet

- Non Metallic Materials Used For Machine Elements2Document42 pagesNon Metallic Materials Used For Machine Elements2RajanikantJadhavNo ratings yet

- ELECTROCHEMISTRYDocument67 pagesELECTROCHEMISTRYGOVIND RANJANNo ratings yet

- Indicador Áudio Visual Ex DDocument2 pagesIndicador Áudio Visual Ex Dmrcunha_brNo ratings yet

- Potency of Sugarcane Bagasse Ash Partial Substitution of Cement in ConcreteDocument5 pagesPotency of Sugarcane Bagasse Ash Partial Substitution of Cement in ConcreteAnteneh GeremewNo ratings yet

- An Overview of Scheduled Wastes Management in Malaysia: October 2019Document5 pagesAn Overview of Scheduled Wastes Management in Malaysia: October 2019Sharifah Hannan AinaNo ratings yet

- Factory A - Item # 1 - Crane Data: 1 GeneralDocument3 pagesFactory A - Item # 1 - Crane Data: 1 GeneralSubuk NgaboNo ratings yet

- Industrial Waste Abatement SeafoodDocument27 pagesIndustrial Waste Abatement SeafoodTuróczy EmőkeNo ratings yet

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- Contitech Conveyor Belt Splicing ManualGoodyearBeltingDocument27 pagesContitech Conveyor Belt Splicing ManualGoodyearBeltingseba101986100% (1)

- SKF Plain BearingDocument36 pagesSKF Plain Bearinga04205No ratings yet

- BILL OF MATERIALS SampleDocument2 pagesBILL OF MATERIALS SampleARIESNo ratings yet

- LIFECO Fire BlanketDocument1 pageLIFECO Fire BlanketkuraimundNo ratings yet

- Steam Distribution and UtilizationDocument79 pagesSteam Distribution and UtilizationRanggaAnastasiusNo ratings yet

- XLPE Insulated Low Voltage CablesDocument40 pagesXLPE Insulated Low Voltage CablesAnzad AzeezNo ratings yet

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 pagesWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhNo ratings yet

- MVS Hydrogen Generator Product CatalogueDocument4 pagesMVS Hydrogen Generator Product CatalogueRachit VemulaNo ratings yet

- DPWH Adopts New Standards For Pavement ThicknessDocument3 pagesDPWH Adopts New Standards For Pavement ThicknessBlesselda San Jose Mangcoy100% (1)

- FAO DeltametrineDocument101 pagesFAO DeltametrinemercuriusNo ratings yet

- Lec - 8 Mix Design Applications PDFDocument68 pagesLec - 8 Mix Design Applications PDFAZIMERAWNo ratings yet

- Psychrometric Chart ReadingDocument10 pagesPsychrometric Chart ReadingEzakiman OtanimNo ratings yet

- Pulls Plates Escutcheons Catalogue SectionDocument22 pagesPulls Plates Escutcheons Catalogue SectionOwenNo ratings yet

- Branson 3510 UltrasonicDocument34 pagesBranson 3510 Ultrasoniccav4444No ratings yet

- Part 1: Introduction To Managerial AccountingDocument7 pagesPart 1: Introduction To Managerial AccountingJoemel F. RizardoNo ratings yet

- Xanthan MSDSDocument5 pagesXanthan MSDShuythai2011No ratings yet

- FL - Glazing.agc Glass - Update 1 1Document44 pagesFL - Glazing.agc Glass - Update 1 1Le Manh CuongNo ratings yet