Professional Documents

Culture Documents

Square Pile

Square Pile

Uploaded by

vincent_rko0 ratings0% found this document useful (0 votes)

8 views2 pagesSquare

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSquare

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesSquare Pile

Square Pile

Uploaded by

vincent_rkoSquare

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

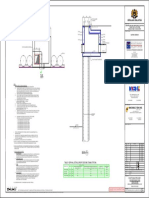

PRECAST RC SQUARE PILE

The aim of pile design is to provide a footing which will safely

support the superstructure over its design life. The footing

shall be durable, and of adequate strength and the footing

performance shall be compatible withthe superstructure so that it

remains serviceable and can perform its intended function.

Piles are considered of displacement type and they shall be

designed for both structural and geotechnical strength

requirements. As geotechnical design involves pile - soil

interaction the capacity then shall be usually assessed vide

static pile load testing. Once the piles are driven to their fnal

position the stresses caused by foundation loading are likely to

be much lower than those caused by handling and driving.

The reinforcement requirements are predominantly catered

for handing during manufacture, storage, transport and on

site as appropriate.

SPECIFICATION AND DESIGN

Piles shall be designed to BS 8110 or CP 116 and to MS 1314

(see table 1, 2 and 3). Any special design criteria or to other

relevant codes, specifcations and requirements can be

fulflled if required.

The ultimate bearing capacity for a pile shall be calculated vide

empirical dynamic pile formula or by a static formula and

conclusively determinedby test loading.

APPLICATION

Civil Engineering and building structures on land or immediate

inshore locations intended for use as permanent structures.

CONCRETE MATERIAL

AGGREGATE

Coarse aggregates shall comply with MS 29. The nominal

maximum size shall not exceed 20mm.

ADMIXTURES

Admixtures when used shall comply with MS 922. Calcium

choride or admixture based on calcium choride shall not be

used.

CONCRETE

The fully compacted concrete shall have a minimum cement

content of 350 kg/cu.m for normal and easy driving conditions

and the characteristic strength of concrete shall be 45

N/sq.mm. However for hard and very hard driving condition

and in marine works a minimumcement content of 400Kg/cu.m

is recommended to be used.

REINFORCEMENT

Reinforcing steel shall comply to MS 146 for main longitudinal

bar and MS 144 for the lateral links.

MANUFACTURE

Steel forms are employed to manufacture the piles in a

factory-controlled environment. After the concrete has

been placed, vibrated by internal vibrators and cured the

products are stripped from the stationery steel forms and

the production cycle is then repeated.

TABLE 1

ACP BRAND`STANDARD PRECAST REINFORCEDCONCRETE SQUARE PILES - GRADE OF CONCRETE 45MPa

PILE NOMINAL DIMENSIONS AND REINFORCEMENT DETAILS

Nominal

size

(mmxmm)

Main Longitudinal

Reinforcement

No. Dia.(mm)

Mild Steel

Wire Size

(mm)

Lateral Reinforcement (Links)

P

(mm)

S2

(mm)

Q

(mm)

S3

(mm)

R

(mm)

150x150

175x175

200x200

225x225

250x250

300x300

350x350

380x380

400x400

4

4

4

4

4

4

4

4

8

8

9

10

12

10

16

20

20

20

4

4

5

5

5

6

6

6

6

S1

(mm)

57

52

50

45

42

53

46

44

42

450

525

600

675

750

900

1050

1145

1200

450

525

600

675

750

900

1050

1145

1200

57-72

52-85

50-100

45-112.5

42-125

53-145

46-145

44-125

42-125

72

85

100

112.5

125

125

125

145

145

4200

3900

6600

6300

9000

8400

7800

7420

7200

Note 1 :

R - refer to recommended maximumlength at middle transition section of pile.

MildSteel joint plateshall beinaccordancewithTable2for dierent applicationas approciate, other details remainunchanged

as inTable 1.

TABLE 2 TABLE 3

Note 2:

* MaximumAxial Working Load is in accordance with BS 8004/CP 116.

** Ultimate Axial Load

2

is in accordance with BS 8110.

Formula to determine maximum axial load working load*

Reference

Where

Formula to determine ultimate axial load**

Reference

Where

Note : Specifcation and details shown in brochure subject to change without prior notice due to product development, changing customer and industry requirements.

MILD STEEL JOINT PLATE THICKNESS (mm)

ACP BRAND `STANDARD

(mm)

ACP BRAND `MS 1314

(mm)

TYPE

Nominal Size

(mmxmm)

150x150

175x175

200x200

225x225

250x250

300x300

350x350

380x380

400x400

4.5

4.5

5

6

6

8

8

9

9

6

6

9

9

9

9

12

12

12

Nominal

Size

(mmxmm)

150x150

175x175

200x200

225x225

250x250

300x300

350x350

380x380

400x400

PILE STRUCTURAL CAPACITY

Longitudinal

Reinforcement Area

(mm2)

201

254

314

452

628

804

1256

1256

1256

Maximum

Axial Working Load*

(Tonnes)

31

42

55

71

88

125

173

200

219

Ulitimate

Axial Load**

(Tonnes)

47

64

83

107

134

190

264

303

331

1. BS 8004 : 1986 Clause 7.4.2.3.2

2. CP 116, Clause 321.b, equation 17 & table 8

Po = Pcc Ac + PscAsc

Po = Permissible axial load as a short column

Pcc = Permissible stress for the concrete in direct

compression (0.27fcu)

Ac = Cross sectional area of concrete excluding

accessories and reinforcing steel

Psc = Permissible compressive stress for longitudinal

steel (0.55fy and > 175 N/mm2)

Asc = Cross sectional area of the longitudinal steel.

fy = Guaranteed yield or proof stress.

1. BS 8004 : 1986 Clause 7.4.2.3.2

2. BS 8110 : Pt 1 : 1985 clause 3.8.4, equation 38

N = 0.4fcuAc + 0.75fyAsc

N = Ultimate Axial load

fcu = Characteristic strength of concrete at 28 days.

Ac = Cross sectional area of concrete excluding

accessories and reinforing steel.

fy = Characteristic yieldstrengthof longitudinal steel

Asc = Cross sectional area of the longitudinal steel.

SURFACE FINISH

Small blemishes caused by entrapped air or water may be

expected but the surface shall be free from voids, honey

combing or other large blemishes.

MARKING

Each unit shall be clearly indentifed and position for lifting as

in use shall be indicated by lifting hooks.

DIMENSION

The maximum permissible derivations from the manufacturing

meandimensionshall not exceedBS 8110:Pt 1:1985requirements.

QUALITY ASSURANCE

QualityAssuranceinthemanufactureof theproducts is provided

vide established MS ISO 9001 Quality Management System.

PILE DRIVING

Pile can be installed commonly by hammering, pushing,

jacking, screwing, vibrating or other means to force them into

the ground so as to transmit loads to the soil or rock. These

piles can be easily extended by splicing additional length of

piling.

Pile preparation for testing shall generally involve all practical

steps to ensure that the hammer and pile are aligned to prevent

bending of the pile during the test blows, and that the hammer

strikes a fush sound surface perpendicular to the pile axis.

Test driving is recommended as it provides a clue to the strata,

load bearing capacity leading to valuable informations for

selection of the best pile driving plant and of the best pile type.

As to stresses induced during installation they may be obtained

from a wave equation analysis or directly measured during pile

driving, using dynamic pile testing equipment. As a rule of

thumb and from lessons of experience also from successful

applications the maximum calculated stress in piles during

driving shall not exceed 0.8fcu in compression and in tension

0.8sqrt(fcu) where fcu is the compressive strength of cube in

MPa at the time of driving.

Experience shows that even during properly executed driving

of reinforced concrete piles, hair line cracks cannot always be

avoided. They are unobjectionable as long as they do not

exceed a certain number and a certain crack width. Relevant

global industry standards permit cracks up to a width of

0.15mm which has proven, according to the present knowldge

to be harmless.

LIFTING AND STORAGE ARRANGEMENTS

Units shall be lifted at designated lifting points provided along

the pile and preferably by means of a spreader beam to avoid

and undue stresses. All units shall be stored on an unyielding

ground and stacked with timber.

JOINTS

In lengthening of piles the mild steel and plates are butt (blunt

point), jointed centerally and axially and subjected to feld full

penetration butt welding. Cast iron shoes are usually required

only when driven into rocks, coarse gravel and othersoils liable

to damage the concrete at the tip of the pile. (fg 1)

You might also like

- Drilling Programme TemplateDocument15 pagesDrilling Programme TemplateJason MournsAlways100% (1)

- Summary FoS On SNI 8460-2017Document3 pagesSummary FoS On SNI 8460-2017BambangHutapeaNo ratings yet

- CBP Wall - DWGDocument1 pageCBP Wall - DWGsambasivammeNo ratings yet

- Steel Wire Rope For Lifting AnalysisDocument4 pagesSteel Wire Rope For Lifting AnalysisCHIKARANo ratings yet

- 3chapter SOILS AND FOUNDATIONS - BNBC 2020 CommentaryDocument95 pages3chapter SOILS AND FOUNDATIONS - BNBC 2020 CommentaryTarif Aziz Maruf100% (1)

- FCE 411 - Geotechnical Engineering II 2019-2020-1Document58 pagesFCE 411 - Geotechnical Engineering II 2019-2020-1Dennis OG100% (1)

- 45CDocument8 pages45Cjhacademyhyd100% (4)

- Drawing Spun PileDocument5 pagesDrawing Spun Pile2C Nur Izzati Binti RamleeNo ratings yet

- 300mm Microhtbar RevDocument2 pages300mm Microhtbar RevAlsonChinNo ratings yet

- Differential Settlement Bh7Document9 pagesDifferential Settlement Bh7Zhi Ming CheahNo ratings yet

- Esq 540 - Piling Operation-AssignmentDocument11 pagesEsq 540 - Piling Operation-AssignmentMoffat KangombeNo ratings yet

- JKR-Mackintosh Probe ChartDocument1 pageJKR-Mackintosh Probe ChartNurmuliana Abdul WahabNo ratings yet

- MNEDocument15 pagesMNEDavid PuenNo ratings yet

- Precast Pile Analysis & Design.350Document2 pagesPrecast Pile Analysis & Design.350প্রিয়দীপ প্রিয়মNo ratings yet

- 01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefDocument144 pages01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefFreddie KooNo ratings yet

- Deep FoundationsDocument75 pagesDeep FoundationsMuhd SyahidNo ratings yet

- Analysis of Irregular Shaped BeamsDocument1 pageAnalysis of Irregular Shaped BeamsCaitlinNo ratings yet

- PC PilesDocument12 pagesPC PilesBobby SetiawanNo ratings yet

- Project: Date: Location: Job Ref: Column:: Column Design SUN - U, Phase1 Part 2 7-12-21 ACE.09.206Document15 pagesProject: Date: Location: Job Ref: Column:: Column Design SUN - U, Phase1 Part 2 7-12-21 ACE.09.206Lem TeohNo ratings yet

- Penang Bridge International Marathon 2010Document1,972 pagesPenang Bridge International Marathon 2010stelzertNo ratings yet

- Hilley's FormulaDocument4 pagesHilley's FormulaFaeez ZainNo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- How Do Fixed and Pinned Connections Between Piles and Pile Caps Affect The Load Carrying Capacity of PilesDocument1 pageHow Do Fixed and Pinned Connections Between Piles and Pile Caps Affect The Load Carrying Capacity of PilesthakrarhitsNo ratings yet

- Genaral Catalogue Sheet Piling 2019Document64 pagesGenaral Catalogue Sheet Piling 2019santanu mukherjeeNo ratings yet

- Vertical Reinforcement For Wall DesignDocument5 pagesVertical Reinforcement For Wall DesignSamuel AntobamNo ratings yet

- RC Raft Foundation (Bs8110) : Project Job RefDocument5 pagesRC Raft Foundation (Bs8110) : Project Job RefsitheeqNo ratings yet

- Prestressed Centrifugal Reinforced Concrete Pile Phc-D600A: Key PlanDocument1 pagePrestressed Centrifugal Reinforced Concrete Pile Phc-D600A: Key PlanChhour CENo ratings yet

- Schmidt Hammer Type N L NR LR ManualDocument21 pagesSchmidt Hammer Type N L NR LR ManualLee Tai100% (1)

- Early Thermal Cracking CalculationsDocument1 pageEarly Thermal Cracking Calculationsmassive85No ratings yet

- Steel Sheet PilesDocument6 pagesSteel Sheet PilesbanuardiNo ratings yet

- Model Bills of Quantities: Federation of Piling SpecialistsDocument9 pagesModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioNo ratings yet

- BoqDocument24 pagesBoqDilshad AhemadNo ratings yet

- Prestressed Concrete Design (SAB 4323) : Dr. Roslli Noor MohamedDocument22 pagesPrestressed Concrete Design (SAB 4323) : Dr. Roslli Noor MohamedJerryYanNo ratings yet

- Crack Width by Bs8110Document2 pagesCrack Width by Bs8110Mohammed100% (1)

- Aci 224.3r-95 (Joints in Concrete Construction)Document44 pagesAci 224.3r-95 (Joints in Concrete Construction)Arnold VercelesNo ratings yet

- Piles IntroductionDocument38 pagesPiles IntroductiondiaidrisNo ratings yet

- Notes On Hy-RibDocument20 pagesNotes On Hy-RibMohd Faizal100% (1)

- Rib Beam 1Document2 pagesRib Beam 1sabahpmNo ratings yet

- Pile Cap DesignDocument4 pagesPile Cap DesignMohamed RifdyNo ratings yet

- Concrete Pull Out Check PDFDocument1 pageConcrete Pull Out Check PDFMaliki MuhammedNo ratings yet

- Front Elevation Rear Elevation Side Elevation: Reception Table 01Document1 pageFront Elevation Rear Elevation Side Elevation: Reception Table 01Niyati ThakarNo ratings yet

- Concrete Sheet Pile Drawingdrawing06040Document4 pagesConcrete Sheet Pile Drawingdrawing06040ASKOKONo ratings yet

- Pile Load Capacity Calculation - Single Pile and Group PileDocument3 pagesPile Load Capacity Calculation - Single Pile and Group PilelaikienfuiNo ratings yet

- Design of Pilecaps - Extract From Reinforced Concrete Design (Limit State) by Varghese P.CDocument18 pagesDesign of Pilecaps - Extract From Reinforced Concrete Design (Limit State) by Varghese P.Cprabhu81No ratings yet

- Rebar Chair Designr1Document3 pagesRebar Chair Designr1John Vincent MusngiNo ratings yet

- Proposed Bridges To Replace Existing Ferry ServicesDocument25 pagesProposed Bridges To Replace Existing Ferry ServicesRoziman Hj Hajon100% (1)

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 pagePile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiNo ratings yet

- LYSAGHT BONDEK II Design & Constuction GuideDocument52 pagesLYSAGHT BONDEK II Design & Constuction GuideHazel Liow HYNo ratings yet

- RC Piles APIDocument5 pagesRC Piles APIGnabBangNo ratings yet

- Verification Manual British CodesDocument32 pagesVerification Manual British CodeshutuguoNo ratings yet

- Detention Design SD01 - OSD SwinburneDocument2 pagesDetention Design SD01 - OSD SwinburneTony PedaNo ratings yet

- QES PEVC-ENG262 - Checklist For Tower Foundation Design & DrawingDocument2 pagesQES PEVC-ENG262 - Checklist For Tower Foundation Design & DrawingRupesh KhandekarNo ratings yet

- Skin Friction and Pile DesignDocument7 pagesSkin Friction and Pile DesignNaveen RNo ratings yet

- GLT Engineers Private, Singapore: Foundation DesignDocument2 pagesGLT Engineers Private, Singapore: Foundation DesignRio HandokoNo ratings yet

- Flexible Pavement Thickness Design JKR MethodDocument3 pagesFlexible Pavement Thickness Design JKR MethodMohamad Shahrizal AliasNo ratings yet

- Jis Sm490yb PDFDocument1 pageJis Sm490yb PDFAcraz Muhammad BahrumNo ratings yet

- Design Formula For EC2 Version 04 UTMDocument23 pagesDesign Formula For EC2 Version 04 UTMJackieSimNo ratings yet

- Inspection of Foundation Works.1Document73 pagesInspection of Foundation Works.1Marvin Velasquez100% (1)

- Novospt enDocument29 pagesNovospt enSalvatore Miranda0% (1)

- TechSpan Brochure PDFDocument6 pagesTechSpan Brochure PDFuet22No ratings yet

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Maribel Isaura Cunurana YapuchuraNo ratings yet

- Contoh Dokumen CalculationDocument103 pagesContoh Dokumen CalculationTriana Rosma Fikriyati Dina100% (2)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Crawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, ChinaDocument10 pagesCrawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, Chinadepi_rachmanNo ratings yet

- (PDS) Lokfix EpDocument2 pages(PDS) Lokfix Epdepi_rachman100% (1)

- GFRC Admix Mix DesignDocument5 pagesGFRC Admix Mix Designdepi_rachmanNo ratings yet

- LTM1200 en PDFDocument10 pagesLTM1200 en PDFdepi_rachmanNo ratings yet

- SF Marina English Brochure 2015-04-30Document16 pagesSF Marina English Brochure 2015-04-30depi_rachmanNo ratings yet

- Sheet and Plate - Steel DataDocument1 pageSheet and Plate - Steel Datadepi_rachmanNo ratings yet

- Cebex Cable Grout-1Document4 pagesCebex Cable Grout-1depi_rachmanNo ratings yet

- Method Statement - Sikagard 670 W MYDocument1 pageMethod Statement - Sikagard 670 W MYdepi_rachman100% (1)

- Steel Bars: High Yield DeformedDocument1 pageSteel Bars: High Yield Deformeddepi_rachmanNo ratings yet

- Mekanika Tanah I: Dr. Ir. Ahmad RIFA'I, M.T. Bagian - 2Document28 pagesMekanika Tanah I: Dr. Ir. Ahmad RIFA'I, M.T. Bagian - 2Vicco TanadyNo ratings yet

- Nozel: Jurnal Pendidikan Teknik MesinDocument10 pagesNozel: Jurnal Pendidikan Teknik MesinADITYA RAHMANNo ratings yet

- InterviewDocument2 pagesInterviewJhames Marck AblanNo ratings yet

- Soil Investigation Report: Name of WorkDocument17 pagesSoil Investigation Report: Name of WorkGeetha MaNo ratings yet

- Lesson 09-Chapter 9 Deep Foundations - Part 4 (Shafts)Document56 pagesLesson 09-Chapter 9 Deep Foundations - Part 4 (Shafts)mrnaeem100% (1)

- Design and Construction of The Deepest Diaphragm Walls in CairoDocument8 pagesDesign and Construction of The Deepest Diaphragm Walls in CairofreezefreezeNo ratings yet

- Case Study of The Changi East Land Reclamation Project SingaporeDocument13 pagesCase Study of The Changi East Land Reclamation Project SingaporeVictoria JungNo ratings yet

- Undrained Shear Strength in Clay Slopes - Influence of Stress ConditionsDocument220 pagesUndrained Shear Strength in Clay Slopes - Influence of Stress ConditionsMuhammad SafdarNo ratings yet

- GT 1 of 4Document298 pagesGT 1 of 4Nileshkumar HapaliyaNo ratings yet

- VPDI PHD SubjectsDocument23 pagesVPDI PHD SubjectsAvisheak PalNo ratings yet

- Shoring Calculation Report 20211118Document37 pagesShoring Calculation Report 20211118Oshin RajapakshaNo ratings yet

- Geologic Site Characterization Report West Hackberry Salt Dome, LouisianaDocument294 pagesGeologic Site Characterization Report West Hackberry Salt Dome, Louisianaetchplain100% (1)

- Deep FoundationDocument93 pagesDeep FoundationDavid HongNo ratings yet

- Soft Copy Laporan Sandcone Gudang - JIIPEDocument2 pagesSoft Copy Laporan Sandcone Gudang - JIIPEardaloevera_63818328No ratings yet

- Geotehcnical AnalysisDocument61 pagesGeotehcnical AnalysisZakee KazmeeNo ratings yet

- J K Mitchell K Soga Fundamentals of Soil BehaviourDocument42 pagesJ K Mitchell K Soga Fundamentals of Soil BehaviourNabilla ZaheraNo ratings yet

- Earthworks Cut and FillDocument42 pagesEarthworks Cut and FillTheyen NaidooNo ratings yet

- Lab Quiz 18bnciv0977Document4 pagesLab Quiz 18bnciv0977Ameer HamzaNo ratings yet

- Ground InvestigationDocument84 pagesGround InvestigationFarah Diba Pos-PosNo ratings yet

- Jaydeep WaghDocument54 pagesJaydeep Waghankit kadamNo ratings yet

- Geotech Investigation Scope of WorkDocument3 pagesGeotech Investigation Scope of Worksamirbendre1100% (1)

- Bearing Capacity Improvement of Soil Using Bamboo MicropilesDocument14 pagesBearing Capacity Improvement of Soil Using Bamboo MicropilesIsrael AdegboyegaNo ratings yet

- PBL ManualDocument23 pagesPBL ManualSamir SoussiNo ratings yet

- Concrete Mat 7Document14 pagesConcrete Mat 7Gert-Jan RoelevinkNo ratings yet

- CFA Piling MethodDocument4 pagesCFA Piling MethodAnonymous 1HFV185Sl4No ratings yet