Professional Documents

Culture Documents

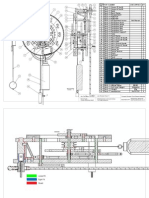

Dial Removed For Clarity: Item QTY Part No. Description

Uploaded by

Thanh BinhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dial Removed For Clarity: Item QTY Part No. Description

Uploaded by

Thanh BinhCopyright:

Available Formats

13

2 3

17 1 8 7 4 18

19

16

14

15

9

20 21

29

22 23

12

12

43

42

31 33 32

39 41

37

38

6 13

40 22

25

28 30

26

22 25

44

24

21

45

3

6

34

35

24

29

Dial removed for clarity

SHT 1 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

General Assembly 1

ITEM QTY PART NO. DESCRIPTION

1 1 Back

2 1 Front

3 3 Spacer top

4 1 Pendulum hanger

5 1 Clock dial 6mm Perspex

6 2 Dial spacer

7 1 Pendulum head

8 1 Pendulum pivot

9 1 Pendulum rod

10 1 Pendulum bob

11 1 Pendulum nut

12 7 Shaft cover

13 3 Screw

14 1 Shaft 151 Steel

15 1 Yoke

16 1 Escape

17 1 Pallet 2

18 1 Pallet 1

19 1 Yoke spacer

20 1 Timing wheel

21 3 Shaft 140 Steel

22 3 Sleeve 119

23 1 Gear 16 teeth

24 1 Shaft185 Steel

25 2 Pawl

26 1 Sleeve 70

27 1 Drum

28 1 Ratchet

29 3 Gear 60 teeth

30 2 Pawl pin

31 1 Gear 32 teeth

32 1 Gear 10 teeth

33 1 Sleeve 18

34 1 Rope

35 1 Weight

36 1 Gear 16 teeth DP6

37 1 Shaft 30 Steel

38 1 Gear 8 teeth

39 1 Gear 30teeth

40 2 Gear 15 teeth

41 1 Key shaft

42 1 Minute hand

43 1 Hour hand

44 1 Gear 12teeth DP6

45 1 Winder support

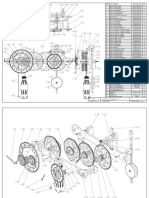

15

12 24

20

4

36

27 30 22

22

22

3

Back plate removed for clarity

35

10

9

11

5

SHT 2 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

General Assembly 2

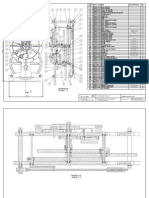

3

5

350

290

1

8

0

9

0

8

1

8

9

.4

3

86.60

5

5

1

2

.7

0

6

.3

5

6

.3

5

6.35

6.35

6.35

12.70

4

3

0

R

1

7

5

R

2

0

70

R20

R

2

0

112.04

R

1

2

R

2

5

0

Front plate 1-off

1

1

Back plate 1-off

76.81

76.32

95

1

4

0

1

4

0

4

0

8

9

.4

3

4

6

.

6

0

9

0

8

1

5

5

76.32

12.70

1

2

.7

0

364

290

3

5

86.60

2

59.20

23.12

76.81

30.38

SHT 3 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

Frames

355

4

6

.2

0

23.12

1

8

0

2

6

1

3

59.20

R

1

7

7

.5

0

290

Dial 1-off

8

5

30

A

A

120

A-A

3

0 1

2

.7

0

1/2" thread

3

0

12.70

C

C

21

C-C

D

D

3

1

8

D-D

10

30

6

9

55

7

5

E

E

10

6

E-E

4

0

6

3

0 Pendulum pivot 1-off

1

2

0

5

9

3

0

6

.5

0

R

3

7

0

Pendulum bob 1-off

10

28

20

F

F

2

0

F-F

M6 x 50 deep

1076 6

Minute Hand 1-off

Pendulum rod 1-off

30

G

G

120 10

1

2

.

7

0

50 G-G

42

Hour hand 1-off

43

12 48

35

H

H

90

2

H-H

Thread M6

3 Spacer 1-off

3 Spacer 2-off

4 Pendulum hanger 1-off

6 Dial spacer 2-off

12 Shaft cover 7-off

13 Screw 3-off

7 Pendulum head 1-off

11 Pendulum nut 1-off

SHT 4 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

Frame details

1

3

19.50

10

6

.

1

0

1

3

28

37

1

0

6

.1

0

6

23 Gear 16 teeth 1-off 40 Gear 15 teeth 1-off

37 Shaft 37 1-off

33 Sleeve 28 1-off

31 Gear 32 teeth 1-off

31 Gear 10 teeth 1-off

38 Gear 8 teeth 1-off

39 Gear 30 teeth 1-off

27 Drum 1-off 28 Ratchet 1-off

36 Gear 16 teeth DP61-off

44 Gear 12 teeth 1-off

20 Timing wheel 1-off

40 Gear 15 teeth 1-off

SHT 5 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

Gears 1

1

0

1

0

I

I

6

6

6

106

6

.

1

0

R

5

4

4

.

2

7

36.96

51.44

10

6

1

0

20.25

I-I

25 Pawl 2-off

30 Pawl pin 2-off

29 Gear 60 teeth 3-off

SHT 6 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

Gears 2

23.80 20.83

39.50 39.60

R

5

6

7

4

.

3

0

R

7

.5

0

20

1

0

8.61

40

1

2

.

7

0

R

1

6

.3

5

3

2

9

.

5

0

9.50

1

2

.

7

0

151

140

119.50

185

6

1

0

6.10

6

70

1

0

6.10

6

1

0

6

10

16 Escape 1-off

17 Pallet 2 1-off

18 Pallet 1 1-off

15 Yoke1-off

26 Sleeve 70 1-off

22 Sleeve 119 3-off

21 Shaft 140 3-off

14 Shaft 151 1-off

24 Shaft 185 1-off 41 Key shaft 1-off

45 Winder support 1-off

SHT 7 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

Details

SHT 8 OF 8 SHTS

NTS

LAW WOODEN CLOCK 2

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/ - 0.5

J AN 2001

Designed by:

BRLAW

www.woodenclocks.co.uk

Instructions

Woodenclock Clock 2

Notes

Use close-grained timber such as Beech planed down to a thickness of 1

10 mm for all components unless otherwise stated.

All shafts for spindles should be made from 6 mm diameter bar.

Any suitable material can be used for the weight. The mass of the weight

will need to be established by experiment, but a good starting point would

be 6 lbs.

Details of the dial numerals are shown for guidance only, the actual form

of the numerals is left to your own discretion.. They can be applied by

painting or as relief numerals cut from thin sheet.

The hands are again given for guidance only, although in this instance

they are drawn to size so that you can copy these if you wish. They should

in any event be cut from thin sheet.

Where the components are drawn to 1:1 scale you can attach the drawing

to the timber using a low tack adhesive, and cut around the profiles. Great

care should be taken with this approach when cutting the gear teeth

because they need to be cut very accurately to avoid problems when

assembling the clock.

The frame is held together using 3 threaded screws into spacers (3)glued

into the back plate. Alternatively pins fitted into holes cross drilled after

assembly can be used.

Care should be taken to adjust the pallets (17 & 18) relative to the timing

wheel. They should operate to allow the timing wheel to move

incrementally forward when swinging through a small arc of movement of

the pendulum. (<10).

The pitch of the gears is controlled by the drilling of the hole centres in the

front and back frames. It may help to delay the drilling of these holes in

the frames until after the gears are first cut and then linished to size. At

this point it would help to mount them on two separate pieces of wood and

test there free movement one to the other and measure the centre

distance between them, so that the hole centres can be drilled at this

dimension rather than the theoretical dimension on the drawing.

The winder used is not drawn on the plans but a simple 'T' bar with a

square hole in the end to engage over the end of the square end of the

shaft holding the winding gears.

You might also like

- Clock 45 Instructions Iss1Document17 pagesClock 45 Instructions Iss1David TkalčičNo ratings yet

- The Modern Clock: A Study of Time Keeping Mechanism; Its Construction, Regulation and RepairFrom EverandThe Modern Clock: A Study of Time Keeping Mechanism; Its Construction, Regulation and RepairNo ratings yet

- Complete Guide to Making Wooden Clocks, 3rd Edition: 37 Woodworking Projects for Traditional, Shaker & Contemporary DesignsFrom EverandComplete Guide to Making Wooden Clocks, 3rd Edition: 37 Woodworking Projects for Traditional, Shaker & Contemporary DesignsNo ratings yet

- Wooden Gear ClocksDocument157 pagesWooden Gear ClocksFranco Mauricio87% (240)

- Clock 40 InstructionsDocument20 pagesClock 40 Instructionsabraham maldonadoNo ratings yet

- Woodenclock Gears-Pl PDFDocument8 pagesWoodenclock Gears-Pl PDFstaticfactory928178% (9)

- A D2wwwgaescription of A Clepsydra or Water-Clock (1753)Document14 pagesA D2wwwgaescription of A Clepsydra or Water-Clock (1753)Fernando PereyraNo ratings yet

- 01-02-1 Assembly, Gears Ratio Clock WoodDocument1 page01-02-1 Assembly, Gears Ratio Clock Woodjgokey100% (1)

- Wooden Gear Clock - Clock Instructions 9Document66 pagesWooden Gear Clock - Clock Instructions 9bird100% (1)

- HorlogeDocument12 pagesHorlogearwa bouazaouiNo ratings yet

- Clock 38 InstructionsDocument20 pagesClock 38 InstructionsCanNo ratings yet

- Dial Removed For Clarity: Item QTY Part No. DescriptionDocument8 pagesDial Removed For Clarity: Item QTY Part No. DescriptionDaniel Andres Bolaños Gonzalez100% (1)

- Book Woodenclock Design and Build Imperial SampleDocument24 pagesBook Woodenclock Design and Build Imperial Sampleariel marinNo ratings yet

- Watch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyFrom EverandWatch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyNo ratings yet

- Worlds Simplest Clock Assy 6may04 PDFDocument3 pagesWorlds Simplest Clock Assy 6may04 PDFLucianoAlmeidaNo ratings yet

- Envisionlabs Wood ClocksDocument22 pagesEnvisionlabs Wood ClocksAlfonso100% (1)

- Ascent Plan ManualDocument48 pagesAscent Plan Manualkaka_0246878% (9)

- Build Your Own Wooden Clock PlansDocument12 pagesBuild Your Own Wooden Clock Planszotsenko85% (20)

- Compact Wooden Clock AssemblyDocument11 pagesCompact Wooden Clock Assemblykreitzz100% (1)

- Desktop Manufacturing Use Machine Above This To Make ProductsFrom EverandDesktop Manufacturing Use Machine Above This To Make ProductsNo ratings yet

- Clock6 1PRDocument0 pagesClock6 1PRMarco Muñoz ANo ratings yet

- Woodenclocks Journal-V1Document173 pagesWoodenclocks Journal-V1jekRaffio100% (1)

- Herramientas para Trazar y MedirDocument51 pagesHerramientas para Trazar y MedirFranco Mauricio50% (6)

- Hackaday Io Project 163814 3d Printed Pendulum ClockDocument17 pagesHackaday Io Project 163814 3d Printed Pendulum ClockMihai Daniel100% (1)

- Wooden Gear ClockDocument10 pagesWooden Gear ClockLuca Alberti0% (1)

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCarlos Gabriel Estergaard100% (1)

- Clock 31-Drawings Iss 2Document9 pagesClock 31-Drawings Iss 2Gmayuso Gma Gma0% (1)

- Wooden Gear Clock Instructions 10-2 PDFDocument78 pagesWooden Gear Clock Instructions 10-2 PDFLuca Alberti50% (2)

- Easy To Make Wooden SundialsDocument46 pagesEasy To Make Wooden SundialsJosé João Roseira80% (10)

- Clock 7Document21 pagesClock 7Jose Antonio Torres del Rio100% (3)

- Wooden clock assembly drawingsDocument24 pagesWooden clock assembly drawingsJose Antonio Torres del Rio100% (2)

- Wooden Clock PlansDocument12 pagesWooden Clock Plansnk186980% (5)

- The Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairFrom EverandThe Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairRating: 5 out of 5 stars5/5 (1)

- The Lever Escapement - A Guide to the Many Variations of this Crucial Element of Clock WorkFrom EverandThe Lever Escapement - A Guide to the Many Variations of this Crucial Element of Clock WorkNo ratings yet

- Mystery ClockDocument88 pagesMystery ClockVương Ngọc Khánh100% (1)

- Clock 5Document0 pagesClock 5jjtex100% (5)

- Wooden Clock 1Document21 pagesWooden Clock 1strokealpha80% (5)

- Wooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockDocument25 pagesWooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockKovačević Darko100% (1)

- How to Build a Wooden ClockDocument9 pagesHow to Build a Wooden Clockpejotage100% (2)

- Penguin Clock Assembly DrawingsDocument25 pagesPenguin Clock Assembly Drawingsbird100% (8)

- Assembly (Rev 1)Document31 pagesAssembly (Rev 1)Ceci_SunshineNo ratings yet

- French 8-Day Posted-Frame Clock with Restored AlarmDocument6 pagesFrench 8-Day Posted-Frame Clock with Restored AlarmbahchovanskiNo ratings yet

- CW5 TotalDocument101 pagesCW5 TotalPierre799es88% (26)

- Clock 4Document10 pagesClock 4pejotage100% (1)

- Clock 12 Skeleton-Wind Up-Detail Drawings-PRDocument14 pagesClock 12 Skeleton-Wind Up-Detail Drawings-PRTimothy Clark80% (5)

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- Turret Clock GuidelinesDocument48 pagesTurret Clock Guidelinesmaccione431150% (4)

- Clock 9Document12 pagesClock 9Jose Antonio Torres del Rio100% (8)

- Wooden Clock 1 PDFDocument21 pagesWooden Clock 1 PDFAntonio Antonio NuñezNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCristian Silva100% (1)

- The Watch Adjuster's Manual - A Practical Guide for the Watch and Chronometer Adjuster in Making, Springing, Timing and Adjusting for Isochronism, Positions and TemperaturesFrom EverandThe Watch Adjuster's Manual - A Practical Guide for the Watch and Chronometer Adjuster in Making, Springing, Timing and Adjusting for Isochronism, Positions and TemperaturesNo ratings yet

- Clock 4Document10 pagesClock 4Jose Antonio Torres del Rio100% (1)

- Clockmaking - Past And Present: With Which Is Incorporated The More Important Portions Of 'Clocks, Watches And Bells,' By The Late Lord Grimthorpe Relating To Turret Clocks And Gravity EscapementsFrom EverandClockmaking - Past And Present: With Which Is Incorporated The More Important Portions Of 'Clocks, Watches And Bells,' By The Late Lord Grimthorpe Relating To Turret Clocks And Gravity EscapementsNo ratings yet

- Hanging Gear Clock GuideDocument10 pagesHanging Gear Clock Guideeescudero FFyLNo ratings yet

- The Tower Clock and How to Make it - A Practical and Theoretical Treatise on the Construction of a Chiming Tower Clock, with Full Working Drawings Photographed to ScaleFrom EverandThe Tower Clock and How to Make it - A Practical and Theoretical Treatise on the Construction of a Chiming Tower Clock, with Full Working Drawings Photographed to ScaleNo ratings yet

- Brian Law's wooden clock blueprintDocument9 pagesBrian Law's wooden clock blueprintNatalia Elizabeth RamosNo ratings yet

- Clock 27 FDM DrawingsDocument2 pagesClock 27 FDM DrawingsAli Shodiqin100% (1)

- QcadCAM Tutorial enDocument12 pagesQcadCAM Tutorial enartisanicviewNo ratings yet