Professional Documents

Culture Documents

AWS Vs CSA

AWS Vs CSA

Uploaded by

A.R.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AWS Vs CSA

AWS Vs CSA

Uploaded by

A.R.Copyright:

Available Formats

COMPARATIVE REVIEW OF AWS D1.1 VS CSA W59 & W47.

1

CANADIAN WELDING BUREAU

A Division of the CWB Group Industry Services

7250 West Credit Avenue, Mississauga, Ontario, L5N 5N1.

Tel: (905) 542-1312 Fax: (905) 542-1318

AWS D1.1:2004 Structural Welding Code Steel

CSA Standard W59-03 Welded Steel Construction (Metal Arc Welding)

CSA Standard W47.1-03 Certification of Companies for Fusion Welding of Steel

July 2004

Introduction:

The purpose of this comparative review is to provide the users of these Standards an

overview, which may take hours of thorough study of each individual Standard to find

their similarity and differences.

It should be pointed out the AWS D1.1 covers: welding design, welding procedure

qualification, fabrication, inspection, stud welding, and strengthening and repairing

existing structures. In the CSA Standards, W59 covers similar subjects and W47.1

covers the subjects pertaining to welding procedure qualification, welding personnel

qualification and company certification. The latter two subjects constitute the major

difference between AWS D1.1 and CSA Standards.

The CSA W47.1 Standard is administered by the Canadian Welding Bureau, which is

mandated to certify fabricators and monitor their conformance to Standards

requirements. Whereas the AWS D1.1 is a voluntary conformance Standard and AWS

does not monitor or enforce the conformance.

While great effort is made to compare these Standards clause by clause, some clauses

of general nature may be omitted. Some clauses are shown for their comparative

differences and fundamental importance.

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 1

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

1

General Requirements

1

Scope

1

Scope

2

Definitions and Reference

Publications

2

Reference Publications

3

General Requirements

3

Definitions

EQ

No EQ Clause 4

Administration

Canadian Welding Bureau

administers this standard,

certifies companies, plants and

qualifies welding personnel.

Certified companies are

monitored by the Bureau to

ensure that the requirements of

this Standard are being met.

Major difference

(also see P.17 and

P.18)

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 2

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

2

Design of Welded

Connections

Part A

Common Requirements for

Design of Welded

Connections

4

Design of Welded

Connections

2.1

Scope

2.2

Contract Plans and

Specifications

4.1

General Requirements

EQ

2.3

Effective Areas

4.3

Effective, Weld Area, Length,

Throat and Fillet Size

EQ

D1.1 specifies the

reduction coefficient for

end-loaded long fillet

weld.

Part B

Specific Requirements

for Design of

Non-tubular Connections

4.1.1.1

Design Drawings

2.4

General

Clauses 11 and 12

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 3

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

2.5

Stresses

Clauses 11 and 12

Table 2.3

Allowable Stresses

Tables 11.2(a), 12.2(a)

Allowable Stresses

Table 11.2(b), 12.2(b)

Limit States Design

EQ

D1.1 Allowable

Stress Design

CSA W59 Allowable

Stress Design and

Limit States Design

2.6

Joint Configuration

and Details

Clauses 10

11.4

12.4

EQ

2.6.7

Welds with Rivets or Bolts

Clauses 11.4.3

12.4.3

EQ

2.7

Joint Configuration

and Details

Groove Welds

Clauses 10

11

12

Fig. 10.1 to 10.8

EQ

2.8

Joint Configuration

and Details

Fillet Welded Joints

4.3.2

4.4

11.4.6

12.4.6

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 4

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

2.9

Joint Configuration

and Details

Plug and Slot Welds

4.4.2

Plug and Slot Weld Details

EQ

2.10

Filler Plates

4.6

Fillers

EQ

2.11

Built-Up Members

11.4.13

12.4.13

Connection of Components

of Built-Up Members

EQ

2.12 to 2.16

Specific Requirements

for Design of

Non-tubular Connections

(Cyclically Loaded)

Clause 12

Table 12.2(a)

Allowable Stress

Table 12.2(b)

Limit States

EQ

D1.1 provides more

design formulas.

2.17

Prohibited Joints and Welds

12.4.14

Prohibited Types of

Joints and Welds

EQ

2.18

Inspection

12.5.4

Quality of Welds

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 5

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

Part D

Specific Requirements

for Design of

Tubular Connections

Appendix L

Hollow Structural Section

(HSS) Connections

Appendix R

Fatigue Life of Structures

D1.1 provides detail

design formulas.

CSA W59 provides

general consideration

and references are

given for detail design.

Clauses 19 to 26

Table 2.1

Effective Weld Size of

Flare Groove Welds

4.3.16

Flare Groove Welds

Table 4.1

Table 4.2

EQ

Table 2.2

Loss Dimension

Fig. 4.8

Welds in Skewed Joints

EQ

Table 2.4

Fatigue Design Parameters

Table 12.4 and

Fig. 12.1

EQ

D1.1 shows more joint

details.

Table 2.5

Allowable Stresses in

Tubular Connection Welds

No EQ.

Table 2.6

Stress Categories for

Circular Sections

No EQ.

See CSA S473

Offshore Design

Standard which covers

tubular connections.

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 6

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

Table 2.7

Fatigue Category Limitations

(Tubular Connections)

No EQ.

Table 2.8

Z Loss Dimensions for

Tubular Connections

No EQ.

See CSA S473-04

Offshore Design

Standard

Table 2.9

Terms for Strength

of Connections

(Circular Sections)

No EQ.

3

Prequalification of WPS

10

Details and Welding

Procedure Requirements for

Prequalified Joints

3.1

Scope

10.1

General

EQ

3.2

Welding Processes

3.1.3

10.1.3

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 7

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

3.3

Base Metal / Filler Metal

Combinations

Table 3.1

Prequalified Base Metal /

Filler Metal Combinations for

Matching Strength

Table 11.1

EQ

D1.1 Table 3.1 Lists

more Grades of Steel

3.4

Engineers Approval for

Auxiliary Attachments

2.1.1

EQ

3.5

Min. Preheat and Interpass

Temperature Requirements

Clauses 5 and 10

Table 3.2

Min. Preheat and

Interpass Temperature

Table 5.3

Min. Preheat and

Interpass Temperatures

EQ

3.6

Limitation of WPS Variables

5.5

Details of Welding

10

Welding Procedure Specifications

(WPS)

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 8

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

3.7

General WPS Requirements

3.8

Common Requirements for

Parallel Electrode and

Multiple Electrode SAW

5.5.3.3

Procedures for Welding with

Parallel Electrodes

5.5.3.4

Procedure for Welding with

Multiple Electrodes

EQ

3.9

Fillet Weld Requirements

4.3.2

Fillet Welds

EQ

3.10

Plug and Slot Weld

Requirements

4.3.3

4.4.2

Appendix B

EQ

3.11

Common Requirements of

PJP and CJP Groove Welds

4.3

EQ

3.12

PJP Requirements

4.3

EQ

3.13

CJP Groove Weld

Requirements

4.3

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 9

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

3.14

Postweld Heat Treatment

5.12

Stress Relief Heat Treatment

EQ

Fig. 3.3

Prequalified PJP Groove

Welded Joint Details

Fig. 3.4

Prequalified CJP Groove

Welded Joint Details

Fig. 10.1 to Fig. 10.8

EQ

Fig. 3.5

Prequalified Joint Details for

PJP T-, Y-, and K-

Tubular Connections

See CSA S473-04

Offshore Design

Standard.

Fig. 3.6

Prequalified Joint Details for

CJP T-, Y-, and K-

Tubular Connections

Fig. 10.1 to Fig. 10.8

Fig. 7 to Fig. 11

Location, Definitions and

Details of Tubular CJP

Connections

Fig. 10.1 to Fig. 10.8

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 10

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

4

Qualification

Part A

General Requirements

4.1

General

1

Scope

EQ.

4.2

Common Requirements for

WPS and Welding Personnel

Performance Qualification

8

Welding Personnel

EQ

Part B

Welding Procedure

Specification (WPS)

10

Welding Procedure Specifications

(WPS)

EQ

4.4

Type of Qualification Tests

11.4

Types of Test Groupings of Welds

EQ

4.5

Weld Types for

WPS Qualification

10

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 11

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

4.6

Preparation of WPS

11.5

Test Assembly, Position and

Specimens

EQ

4.7

Essential Variables

5.5

Details of Welding Procedures

Table 11

(See Essential Variables for all

Welding Processes)

EQ

4.8

Methods of Testing and

Acceptance Criteria for

WPS Qualification

11.4

Type of Test Groupings of Weld

11.6

Test Methods and Acceptance

Criteria Soundness Tests

11.7

Test Methods and Acceptance

Criteria Mechanical Tests

11.8

Welding Consumables

EQ

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 12

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

4.9

CJP Welds for

Nontubular Connections

Table 13

Procedure Qualification CJP

Groove Welds, Range of Thickness

and Diameters Qualifications

EQ

4.10

PJP Groove Welds for

Nontubular Connections

Table 14

(Clause 11.4.5 and Table 11)

Procedure Qualification

PJP Groove Welds

Range of Thickness Qualified

EQ

4.11

Fillet Welds for Tubular and

Nontubular Connections

Table 15 (Clause 11.4.5)

Procedure Qualification

Fillet Welds

Range of Weld Sizes Qualified

EQ

4.12

CJP Groove Welds for

Tubular Connections

See CSA S473-04

Offshore Design

Standard

4.13

PJP Tubular Connections

See CSA S473-04

Offshore Design

Standard

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 13

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

4.14

Plug and Slot Welds

(Also see 4.29)

4.3.3

Plug and Slot Welds

4.4.2

Plug and Slot Weld Details

CSA W47.1

Procedure Qualification

test is required.

D1.1 Groove Weld

Qualification qualifies

plug and slot welds.

4.15

Welding Processes

Requiring Qualification

5.5

(Describes processes

requiring qualification)

EQ

4.16

WPS Requirement (GTAW)

5.5

(Describes processes

requiring qualification)

Both D1.1 and CSA

W59 require procedure

qualification.

4.17

WPS Requirements

(ESW/EGW)

5.5.5

(Procedure qualification

required)

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 14

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

Part C

Performance Qualification

4.18

General:

Welders, Welding Operators

and Tack Welder

Qualification

4.19

Type of Qualification Tests

Required

4.20 to 4.29

Weld Types for Welder and

Welding Operator

Performance Qualification

8

Welding Personnel

8.2

Qualification Process for Welding

Personnel

8.3

Period of Effectiveness

8.4

Renewal of Qualification

8.5

Extent of Qualification

8.6

Record of Qualification

9

Qualification of Welding Personnel

9.6

Welding Personnel Qualification

(also see Clause 9.14 requirements)

EQ

CSA W47.1

Classification of

Welding Personnel

S, T, FW, WT, ASW

See Clause 3

Definitions

D1.1 No such

classification system

4.30

Methods of Testing and

Acceptance Criteria for

Welder and Welding

Operator Qualification

9.10

Test Methods

(including radiographic

examination, root-, face-, side-bend

tests, macro-etch examinations)

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 15

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

4.31

Methods of Testing and

Acceptance Criteria for Tack

Welder Qualification

9.14.4

WT Classification

CSA W47.1

WT Tack Welder

No EQ

(See AWS D1.3 Structural

Welding Code Sheet Steel)

9.14.5

ASW Classification

CSA W47.1

ASW Arc Spot

Welder

4.32

Retest

Clauses 9.12,

9.14.4.6, 9.14.5.9

EQ

Table 4.1

WPS Qualification

Table 16

Procedure Qualification

EQ

Table 4.2

WPS Qualification

Range of Thick.

and Diam. Qualified

Tables 13 and 14

Procedure Qualification

Range of Thick.

and Diam. Qualified

EQ

Table 4.5

PQR Essential Variables

Table 11

Soundness Test Essential

Variables

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 16

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

Table 4.9

Welder Qualification

Table 4 and 19

S and T Classification

Plate Test Assemblies

Tables 5 and 20

T-Classification

Pipe Test Assemblies

Not EQ

Not EQ

Table 4.10

Welder and Welding

Operator Qualification

Number and Type of

Specimens and Range of

Thickness and Diameter

Qualified

Table 4 to 8

Qualification Tests

(Reference made to Figures with

test plate thicknesses given)

Not EQ

Table 4.11

Welding Personnel

Performance

Essential Variable Changes

Requiring Requalification

Table 11 Not EQ

Table 4.12

Electrode Classification

Groups

Table 1

Group Designation of SMAW

Electrodes

EQ

Sizes of Test Assemblies

and preparation of tests

specimens are similar.

However, CSA W47.1

requires welders to progress

through a hierarchy of

welding positions starting

with the flat position with no

one position qualifying the

other (unlike AWS). In

addition, CSA W47.1

requires fillet welding tests

depending on the complete

joint geometry tested (AWS

does not require this).

Finally, CSA W47.1 requires

welders to be check tested

every two years to ensure

they maintain the required

welding skills (AWS D1.1

does not require

this).Therefore, CSA W47.1

is tougher in all these areas.

In addition, a major

difference is:

W47.1:

All qualification tests must

be witnessed by the CWBs

representative.

D1.1:

The Company records the

welding parameters without

independent witnessing.

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 17

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

The following comments highlight

the major difference between D1.1

and W47.1:

Major difference.

Independent

verification

No EQ (a) Certification of Fabricators

(see Note (1))

No EQ (b) Qualify Welding Engineers:

- Define duties of welding

engineers

- Outline experience and

education requirements

See Clause 6 and Appendices

A, B, C.

No EQ (c) Qualify welding supervisors

See Clause 7.

- Outline experience and

education requirements.

EQ

(Test Record, No Certificate)

(d) Test Welders and welding

operators

- Issue certificates to qualified

welding personnel.

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 18

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

No EQ (e) Regular visits to certified

fabricators

- Monitor conformance to

Standard by the Bureaus

regional representatives from

regional offices throughout the

country.

- Visit to all companies certified

to W47.1 by the Bureau.

Major differences.

EQ

(By Fabricator)

(f) Qualify and approve welding

procedures.

No EQ Note (1)

See Clause 5.2

The company can be certified in

one of the following Divisions:

Div. 1: shall employ full-time

qualified welding engineer.

Div. 2: shall retain the services of

qualified welding engineer

Div. 3: No engineer is required.

All certified companies are required

to employ full-time qualified

supervisors.

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 19

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

No EQ See Clause 5.3

Application for Certification

(Information required to satisfy CSA

W47.1 for certification)

Major differences.

5

Fabrication

5

Electrodes, Workmanship

and Technique

5.1

Scope

5.1

General

EQ

5.2

Base Metal

3.2

Base Metal

EQ

D1.1 Lists more

grades of steels

5.3

Welding Consumables and

Electrode Requirements

5.2

Electrodes

EQ

5.4

ESW and EGW Processes

5.2.5

Electrodes, Fluxes and

Gases for ESW and EGW

EQ

5.5

WPS Variables

5.2.1.5

(Covers all Welding

Processes)

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 20

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

5.6

Preheat and Interpass

Temperatures

5.7

Preheat, Interpass

Temperature, and

Heat Input Control

EQ

5.7

Heat Input Control for

Quenched and

Tempered Steels

5.5.1.6

Welding Quenched and

Tempered Steels

EQ

5.8

Stress Relief Heat Treatment

5.12

Stress Relief Heat Treatment

EQ

5.9

Backing, Backing Gas

and Inserts

5.5.1.1

Material for Extension Bars,

Run-Off Plates and backings

EQ

5.10

Backing

5.4.9

Backing

EQ

D1.1 shows thickness

of backing bars for

different welding

processes.

5.11

Welding and

Cutting Equipment

5.3

Preparation of Material

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 21

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

5.12

Welding Environment

See Notes of Table 5.3

EQ

5.13

Conformance with Design

4.1

Design of Welded

Connections

General Requirements

EQ

5.14

Min. Fillet Weld Sizes

Table 4.4

Min. Fillet Weld Size

EQ

5.15

Preparation of Base Metal

5.3

Preparation of Material

EQ

5.16

Re-entrant Corners

5.3.6

Re-entrant Corners

EQ

5.17

Beam Copes and Weld

Access Holes

5.3.7

Beam Codes and Weld

Access Holes

5.3.8

Weld Access Hole

Dimensions

EQ

D1.1 Fig. 5.2 and

W59 Fig. 5.1 are

identical.

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 22

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

5.17.2

Group 4 and 5 Shapes

5.3.9

Group 4 and 5 Shapes

EQ

These shapes are

heavy rolled or built-up

shapes.

5.18

Temporary and Tack Welds

5.4.7

Tack Welds

5.4.8 and 12.5.5

Temporary Welds

EQ

5.19

Camber in Built-Up Members

11.4.13 and 12.4.13

Connection of Components

of Built-Up Members

EQ

5.20

Splices in Cyclically

Loaded Structures

12.4.10

Splices in

Compression Members

12.4.11

Splices in Tension Members

EQ

5.21

Control of Distortion

and Shrinkage

5.6

Control of Distortion and

Shrinkage Stresses

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 23

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

5.22

Tolerance of Joint

Dimensions

5.23

Dimensional Tolerance of

Welded Structural Members

5.8, 11.5.3, 12.5.3

Dimensional Tolerances

EQ

5.24

Weld Profiles

Fig. 5.4

Fig. 14

Acceptable and Unacceptable

Weld Profiles

(Clauses 9.10.3.2)

EQ

5.25

Technique for Plug

and Slot Welds

4.4.2

Plug and Slot Weld Details

Appendix B

Plug and Slot Welds

EQ

5.26

Repairs

5.10

Corrections

EQ

5.26.5

Welded Restoration of Base

Metal with Mislocated Holes

No EQ

No EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 24

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

5.27

Peening

5.11

Peening

EQ

5.28

Calking

No EQ

No EQ

5.29

Arc Strike

5.14

Arc Strikes

EQ

5.30

Weld Cleaning

5.13

Cleaning of Welds

EQ

5.31

Weld Tabs

11.5 and 12.5

Workmanship

EQ

6

Inspection

Part A

General Requirements

7

Welding Inspection

6.1 Scope 7.1

General

EQ

6.2

Inspection of Materials

7.2

Inspection of Materials

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 25

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

6.3

Inspection of WPSs

and Equipment

(See Annex IV

and Appendix E)

CWB certified companies adhere to

W47.1 certification requirements

10

Welding Procedure Specifications

(WPS) (See Appendix D)

11

Welding Procedure Data Sheets

(WPDS) (See Appendix C)

CSA W47.1 shows

WPS and WPDS in

separate formats.

D1.1 WPS covers

WPS and WPDS.

Part B

Contractor Responsibilities

3.1.1

Contractor

7.3

Obligation of Contractor

EQ

Part C

Acceptance Criteria

6.9

Visual Inspection

11.5.4.1

12.5.4.1

EQ

6.10

Liquid Penetrant and MPT

PT and MT

7.4.4

7.4.5

EQ

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 26

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

6.11

Non Destructive Testing

7.4

EQ

6.12

Radiographic Inspection

8.1

Radiographic Examination

of Welds

EQ

D1.1:

Shows more figures

Reference Images

Figs. 6.1 to 6.6 Tables 14 to 16

6.13

Ultrasonic Inspection

8.2

Ultrasonic Inspection of

Groove Welds

EQ

PART D

Non Destructive

Testing Procedure

PART E

Radiographic of Testing

8.1

EQ

D1.1 shows more detail

figures.

PART F

Ultrasonic Testing of

Groove Welds

8.2

COMPARATIVE REVIEW OF AWS D1.1, CSA W59 & W47.1

ID: MEANS THE TWO CLAUSES ARE IDENTICAL, WORD BY WORD

EQ: MEANS THE CONTENTS ARE SIMILAR BUT THE WORDING IS DIFFERENT Page 27

AWS D1.1:2004

Structural Welding

Code - Steel

CSA W59-03

Welded Steel Construction

(Metal Arc Welding)

CSA W47.1-03

Certification of Companies for

Fusion Welding of Steel

Identical (ID)

or

Equivalent (EQ)

Remarks

Clause No. Clause No. Clause No.

7

Stud Welding

5.5.6

Stud Welding

Annex IX

Manufacturers Stud Base

Qualification Requirements

Appendix H

Material Requirements for

Stud and Stud Base

Qualification Requirements

EQ

8

Strengthening and Repairing

Existing Structures

9

Strengthening and Repair of

Existing Structures

EQ

ANNEXES I to XII

Mandatory Information

APPENDICES A to R

Non-mandatory Information

except Appendix H which is

mandatory

APPENDICES A to E

Non-mandatory Information

ANNEXES A to O

Non-mandatory Information

The AWS D1.1, CSA

W59 and CSA W47.1

contain information to

assist users to these

Standards.

You might also like

- Welding Panel-AWS D1.1 Structural Welding Code-Wes OliphantDocument27 pagesWelding Panel-AWS D1.1 Structural Welding Code-Wes OliphantVijay Gurav100% (3)

- Thermal Process Information BookDocument15 pagesThermal Process Information Book45 Aadhya RoyNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 4 out of 5 stars4/5 (8)

- Aws B4.0 (2000)Document113 pagesAws B4.0 (2000)Ganesh Yadav100% (1)

- CWB W47.1 Study Guide PDFDocument33 pagesCWB W47.1 Study Guide PDFalexayala515193% (15)

- AWS A5.12 Tungsten Electrodes For Arc Welding and CuttingDocument22 pagesAWS A5.12 Tungsten Electrodes For Arc Welding and CuttingFernando LoboNo ratings yet

- CSA Standards W47.1 & W59 and AWS D1.1: The Similarities and DifferenceDocument1 pageCSA Standards W47.1 & W59 and AWS D1.1: The Similarities and DifferenceGuillermo BaltazarNo ratings yet

- CSA Welding Standards Feb 2014Document57 pagesCSA Welding Standards Feb 2014AlexanderTomasik100% (1)

- AWS SWPS Matrix PDFDocument2 pagesAWS SWPS Matrix PDFAli SASSINo ratings yet

- Aws B2.5 - B2.5M-2021Document34 pagesAws B2.5 - B2.5M-2021Noe NuñezNo ratings yet

- Aws QC-12Document32 pagesAws QC-12Faisal NaeemNo ratings yet

- Asme Sa Csa-G40.21 PDFDocument2 pagesAsme Sa Csa-G40.21 PDFarly0% (2)

- Aws B1.10Document41 pagesAws B1.10Tam Huynh Thanh100% (1)

- AWS G2.3M-G2.3-2012 - Guide For The Joining of Solid Solution Austenitic Stainless SteelsDocument108 pagesAWS G2.3M-G2.3-2012 - Guide For The Joining of Solid Solution Austenitic Stainless SteelsLuis VargasNo ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet

- AWS D1.1 Structural Welding CodeDocument27 pagesAWS D1.1 Structural Welding CodeNickesh ShahNo ratings yet

- Aws C5.5 (2003) Rp-GtawDocument131 pagesAws C5.5 (2003) Rp-GtawIsmail Karmana100% (2)

- WPS A2.4-2007Document140 pagesWPS A2.4-2007wahyu_mokoNo ratings yet

- AWS B2.1.002 - 1990 Standard Welding Procedure Specification (WPS) For PDFDocument12 pagesAWS B2.1.002 - 1990 Standard Welding Procedure Specification (WPS) For PDFmasv792512100% (1)

- 0301e - Welding Inspector Application Guide 2020Document17 pages0301e - Welding Inspector Application Guide 2020neelapu mahesh reddy0% (1)

- Kobelco Welding Special Stainless Steel SingleDocument44 pagesKobelco Welding Special Stainless Steel SingleAhmed Gamal100% (1)

- AWS A5.32-1997 Specification For Welding Shielding GasesDocument26 pagesAWS A5.32-1997 Specification For Welding Shielding GasesIngrid Elena Pardo CadenasNo ratings yet

- Aws D10.9Document73 pagesAws D10.9scrib93420No ratings yet

- AWS B2.1-1-011 - Ed.2002 SWPS Shielded Metal Arc Welding of Galvanized Steel in The As-Welded CondiDocument19 pagesAWS B2.1-1-011 - Ed.2002 SWPS Shielded Metal Arc Welding of Galvanized Steel in The As-Welded CondiRonaldo NunezNo ratings yet

- SCWI StudyguideDocument21 pagesSCWI Studyguideahugandkiss77071No ratings yet

- AWS D17.1 GuidesDocument1 pageAWS D17.1 GuidesTAGUI100% (1)

- Aws Eg4 0 1996Document150 pagesAws Eg4 0 1996Mario MendozaNo ratings yet

- Guide For The Fusion Welding of Titanium and Titanium AlloysDocument14 pagesGuide For The Fusion Welding of Titanium and Titanium AlloysA SoniNo ratings yet

- Stereonet of 32 Crystal Class: Mustak Ali M.Sc. I Sem. University of Rajasthan JaipurDocument16 pagesStereonet of 32 Crystal Class: Mustak Ali M.Sc. I Sem. University of Rajasthan JaipurYogesh Sharma100% (2)

- CSA Standard W178.2-01: Certification of Welding InspectorsDocument2 pagesCSA Standard W178.2-01: Certification of Welding InspectorsramalingamNo ratings yet

- CSA W47.1 W59 13 Guides WeldCanadaDocument5 pagesCSA W47.1 W59 13 Guides WeldCanadamehdi810100% (2)

- Aws D10.12-00Document45 pagesAws D10.12-00Erick GoyesNo ratings yet

- Preview AWS+A2.4 2012Document16 pagesPreview AWS+A2.4 2012Abdul HamidNo ratings yet

- Astm A240 - 15Document13 pagesAstm A240 - 15Nguyễn Xuân TrườngNo ratings yet

- Specification For Stainless Steel Flux Cored and Metal Cored Welding Electrodes and RodsDocument8 pagesSpecification For Stainless Steel Flux Cored and Metal Cored Welding Electrodes and Rodszakki akbar100% (1)

- B2.1 8 024 2001 (R2012) PVDocument8 pagesB2.1 8 024 2001 (R2012) PVJaime50% (2)

- Comparativereviewofawsd 11 Csaw 471 Andcsaw 59Document25 pagesComparativereviewofawsd 11 Csaw 471 Andcsaw 59qc_531040655No ratings yet

- September 10, 1999 06:51:57 Information Handling Services, 1999Document128 pagesSeptember 10, 1999 06:51:57 Information Handling Services, 1999Yesid Medina A100% (1)

- American: Assurance For FabricatorsDocument12 pagesAmerican: Assurance For FabricatorsessnelsonNo ratings yet

- Generalized Guidelines For Structural Steel Welding InspectionDocument19 pagesGeneralized Guidelines For Structural Steel Welding InspectionHariPrasath100% (1)

- Specification For AWS Certification of Welding InspectorsDocument34 pagesSpecification For AWS Certification of Welding InspectorsInwon Kim100% (1)

- Aws D15.2Document38 pagesAws D15.2Kamalakannan1234100% (2)

- Asme, Aws CodesDocument21 pagesAsme, Aws CodesemmanueljosephNo ratings yet

- CWB Acboa April 2008Document29 pagesCWB Acboa April 2008bountymaniNo ratings yet

- Aws A5.8-A5.8m-2004Document47 pagesAws A5.8-A5.8m-2004HenryNo ratings yet

- TACOM Weld Code - Alumn (12472301A)Document123 pagesTACOM Weld Code - Alumn (12472301A)mtcengineeringNo ratings yet

- Q1, Module 1, Lesson 2Document10 pagesQ1, Module 1, Lesson 2Jerome A. GomezNo ratings yet

- Shieldinggases Aws 5.32 PDFDocument3 pagesShieldinggases Aws 5.32 PDFessnelsonNo ratings yet

- Aws B2.1-001 PDFDocument10 pagesAws B2.1-001 PDFAli SASSINo ratings yet

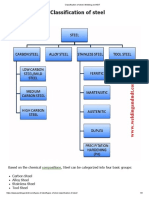

- Classification of Steel - Welding and NDTDocument3 pagesClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- List of Welding CodesDocument10 pagesList of Welding CodesBharath KumarNo ratings yet

- List of Welding CodesDocument11 pagesList of Welding CodesÀngel RodriguezNo ratings yet

- Some Pitfalls in Welding Duplex Stainless Steels PDFDocument5 pagesSome Pitfalls in Welding Duplex Stainless Steels PDFsusanwebNo ratings yet

- Hot Dip GalvanizingDocument6 pagesHot Dip GalvanizingjpkedahNo ratings yet

- Sample Questions & Practice Examination For D1.1Document21 pagesSample Questions & Practice Examination For D1.1Earl HarbertNo ratings yet

- API 571+à+ç+å+Document7 pagesAPI 571+à+ç+å+Bilal Ghazanfar100% (1)

- Astm A473-99Document5 pagesAstm A473-99NadhiraNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariablesAnonymous rYZyQQot55No ratings yet

- Filler MetalsDocument28 pagesFiller MetalsPeerasak ArunNo ratings yet

- Astm A484-A484m-00Document12 pagesAstm A484-A484m-00Razvan Andrei GiuscaNo ratings yet

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- AWS C5.10 - Sheilding Gas PDFDocument6 pagesAWS C5.10 - Sheilding Gas PDFBoby ThomasNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Comparative Review of Aws D1 1 VS Csa W5Document29 pagesComparative Review of Aws D1 1 VS Csa W5Rick Henbid100% (1)

- ASMECodesDocument7 pagesASMECodesEng UlaNo ratings yet

- Usefull List Welding CodeDocument8 pagesUsefull List Welding CodeWael MansourNo ratings yet

- 6.2 Aircraft Material - Non Ferrous - Unsurya 2019Document78 pages6.2 Aircraft Material - Non Ferrous - Unsurya 2019Raihan Farhan RamadhanNo ratings yet

- Astm A322-91Document4 pagesAstm A322-91Anıl ZiylanNo ratings yet

- Hardness Testing On Metallic MaterialsDocument1 pageHardness Testing On Metallic MaterialsThe KeymasterNo ratings yet

- Copper Alloy C14200 PDFDocument9 pagesCopper Alloy C14200 PDFNut AssanaiNo ratings yet

- Biomineralization and BiominingDocument4 pagesBiomineralization and BiominingkanishkaNo ratings yet

- Namma Kalvi 12th Chemistry Reduced Syllabus Guide em 219848Document102 pagesNamma Kalvi 12th Chemistry Reduced Syllabus Guide em 219848CHARUMATHE NNo ratings yet

- ChirayuDocument15 pagesChirayuDevashish JoshiNo ratings yet

- ME8351 Manufacturing Technology I Syllabus Regulation 2017Document2 pagesME8351 Manufacturing Technology I Syllabus Regulation 2017Dr.S.Ravi CITNo ratings yet

- Density Table of Verious MaterialsDocument1 pageDensity Table of Verious MaterialsscemanjuNo ratings yet

- Comparatii Si Echivalente Branduri Sarma TubularaDocument4 pagesComparatii Si Echivalente Branduri Sarma TubularaAnonymous LpKY4pNo ratings yet

- Lecture 3 - Minerals and MatterDocument44 pagesLecture 3 - Minerals and MatterAytach IskandarovaNo ratings yet

- Chap-1 - Introduction To AMPDocument25 pagesChap-1 - Introduction To AMPAmilin HatiaraNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- EcapDocument2 pagesEcapM SaravananNo ratings yet

- Gold Recovery Using Cyanide Free TechnologyDocument13 pagesGold Recovery Using Cyanide Free TechnologyLounie MarananNo ratings yet

- Sintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)Document13 pagesSintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)volkanNo ratings yet

- Topic 5 PP 4 QPDocument22 pagesTopic 5 PP 4 QPKineticbtwNo ratings yet

- Surf Sci Eng - Course FileDocument6 pagesSurf Sci Eng - Course FileAdnan MaqboolNo ratings yet

- Fulltext PDFDocument151 pagesFulltext PDFAhmed GomaaNo ratings yet

- Welding Quiz 1Document2 pagesWelding Quiz 1Thanga PandiNo ratings yet

- The Size of The Sensitization Zone in Stainless Steel Welds: N. S. Tsai TDocument5 pagesThe Size of The Sensitization Zone in Stainless Steel Welds: N. S. Tsai T江宸宸No ratings yet

- El Rosario Charcas Ni 43 101Document91 pagesEl Rosario Charcas Ni 43 101FrancoPaúlTafoyaGurtzNo ratings yet

- TDS A183n 750 EngDocument3 pagesTDS A183n 750 EngVigneswaranNo ratings yet