Professional Documents

Culture Documents

Fire Resistant Cables

Fire Resistant Cables

Uploaded by

dhandiwa0 ratings0% found this document useful (0 votes)

8 views11 pagesFire Resistant Cable Cataloque

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFire Resistant Cable Cataloque

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views11 pagesFire Resistant Cables

Fire Resistant Cables

Uploaded by

dhandiwaFire Resistant Cable Cataloque

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

Fire Resistant Cables

Ducab (Abu Dhabi) Factory

P.O. Box 9171, Abu Dhabi, UAE

Tel: (971-2) 502 7777 Fax: (971-2) 502 7888

email: ducab@ducab.com

Ducab Connect

P.O. Box 11529, Dubai, United Arab Emirates

Tel: (971-4) 808 2500 Fax: (971-4) 808 2599

E-mail: sales@ducab.com

P.O. Box 683, Dubai, United Arab Emirates

Tel: (971-4) 266 7400 Fax: (971-4) 266 8955

E-mail: sales@ducab.com

P.O. Box 39171, Abu Dhabi, United Arab Emirates

Tel: (971-2) 644 1155 Fax: (971-2) 644 3338

E-mail: kalazzani@ducab.com

Ducab-Oman

P.O. Box 3542, 112 Ruwi, Muscat, Sultanate of Oman

Tel: (968) 24565 177 Fax: (968) 24564 302

E-mail: ducabomn@omantel.net.om

JBK-BICC W.L.L.

P.O. Box 14039, Doha, Qatar

Tel: (974) 442 1924 Fax: (974) 441 9003

E-mail: jbkbicc@qatar.net.qa

BICC MET W.L.L.

P.O. Box 11413, Manama, Bahrain

Tel: (973) 1772 7071 Fax: (973) 1772 8027

E-mail: bicc@batelco.com.bh

1. Areas where people will remain in occupation for short time e.g. schools, shopping malls, cinemas etc.

2. Mass transit system e.g. metro, airport terminals etc.

3. High-rise buildings

4. Places where evacuation of people cannot be done immediately in case of fire

e.g. large hospitals

5. Services where circuit integrity is of paramount importance under fire conditions

6. Essential safety circuits e.g. fire detection, alarm and evacuation

7. Power supply to equipment used in fire fighting e.g. sprinkler pumps,

smoke extractors and fire shutters etc.

BS7846 LOW VOLTAGE 600/1000V

Areas of application for fire resistant cables include:

High Rise Buildings

Metro and Underground Tunnels

Hospitals Airports

BS 7846 LOW VOLTAGE 600/1000V

Cable Features

Red-Black Red-Yellow-Blue Red-Yellow-Blue-Black

Brown-Blue Brown-Black-Grey Blue-Brown-Black-Grey

*Available on special orders.

- Standard

INSTALLATION GUIDELINES

Cables Installed in Air

It is anticipated that many of the in air installations will be in buildings, and the ratings are therefore given in accordance with

IEE Wiring Regulations for Electrical Installations, BS 7671.

It should be noted that all ratings for cables run in free air have been based on the assumption that they are shielded from the

direct rays of the sun without restriction of ventilation. The rating for cables subjected to direct sunlight should be reduced to

take account of this factor and further guidance on this subject is available on request.

In order to maintain circuit integrity under fire conditions, it should be ensured that accessories used with cables

are also fire rated.

Rating factor for ambient air temperatures

Air Temperature 25C 30C 35C 40C 45C 50C 55C

Rating Factors 1.02 1.0 0.96 0.91 0.87 0.82 0.76

offers complete cable components and accessories selection for cables.

Fire Resistant Cable Construction

1 Copper conductor

2 Dual insulation - Mica glass - XLPE

3 LSF Bedding (Low Smoke & Fume. Also known as Low Smoke Zero Halogen - LSZH)

4 Galvanised steel wire armoured

5 LSF outer sheath

Core identification

- Alternative*

Technical Data

Ducab, established in 1979, is the leading manufacturer of electric cables in the Middle East. It is today equally owned by the

Government of Abu Dhabi and Government of Dubai. Ducab's aim is to provide electric cables of the highest quality and

provide customer service that is unequalled worldwide.

Ducab's product range also covers Ducab Smokemaster low smoke and fume cables, Ducab Powerplus MV cables upto 33

kV, LV cables, Instrumentation and Pilot cables, Control and Auxiliary cables, Wiring cables, Lead sheathed cables for the oil,

gas, and petrochemical sector. Ducab also offers a complete range of cable components and accessories.

Ducab is committed to providing the customer with total quality. Ducab's quality management system conforms to

ISO 9001 : 2000 standards and certified by BASEC. Also, Ducab is the first cable manufacturer in the region to achieve

certification to ISO 14001, the international environmental management standard by BASEC.

cables:

cables are fire resistant armoured cables intended for applications requiring circuit integrity during a fire. Since these

cables are used in critical applications, the approval process and certification are vital to ensure necessary performance.

cables comply with BS 7846 category F1 and F2 and are LPCB (Loss Prevention Certification Board) approved to

the full British Standard. Ducab has taken the view that using LPCB to approve only the basic fire tests such as CWZ and F2

classifications is not sufficient. By seeking full BS7846 approval from LPCB Ducab has proved that it is committed to go beyond

these tests and deliver a superior product with approved materials and manufacturing processes, as well as regular

independent assessment and product testing. This ongoing commitment to quality is one of the reasons why our customers

have complete faith in Ducab products.

In addition to maintaining circuit integrity under fire conditions, cables generate very low smoke and are Halogen

free in accordance with BS7846, thus helping to save human life and provide protection for the sensitive equipment.

cables also have type approval for the complete range by Lloyd's Register, UK.

Key fire performance requirements

BS 7846 cable is designed to meet:

1. Flammability:

IEC 60332-1 and IEC 60332-3 categories A, B & C.

2. Resistance to fire:

C-W-Z of BS: 6387, IEC: 60331 and F-2 of BS: 7846

3. Smoke Emission:

IEC 61034 - 1 & 2

4. Acid Gas Content:

IEC 60754 - 1 & 2, BSEN 50267- 1 & 2

Special Features

a. Maintains Circuit Integrity for

3 hours under fire condition.

b. Zero halogen, low smoke

and resistance to flame propagation.

BS 7846 LOW VOLTAGE 600/1000V

Introduction

* Circular conductors, all others are sector shaped

Installation conditions for above rating:

Ambient Air Temperature 30

o

C

Conductor operating temperature 90

o

C

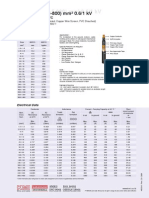

BS 7846 2-Core

Fire resistant cables. Two Core Armoured Cables 600/1000 V Grade with stranded copper conductors

Nominal

conductor

area

mm2

Approximate

cable weight

kg/km

Maximum cond-

uctor resistance

at 20

o

C

Ohm/km

Maximum armour

resistance

at 20

o

C

Ohm/km

Current rating on

perforated cable

trays / free air

Amp

Voltage drop

(1 C)

mV/A/m

Under armour

mm

Over armour

mm

Overall dia

mm

600/1000 V Copper power and control cables

1.5* 8.7 10.5 12.4 315 12.1 10.2 29 31

2.5* 9.9 11.7 13.8 385 7.41 8.8 39 19

4* 11.1 12.9 15.0 460 4.61 7.9 52 12

6* 12.1 13.9 16.0 535 3.08 7.0 66 7.9

10* 13.9 15.7 18.0 690 1.83 6.0 90 4.7

16* 15.7 18.2 20.5 920 1.15 3.7 115 2.9

25* 19.7 22.2 24.7 1270 0.727 3.7 152 1.9

35* 21.9 25.1 27.8 1720 0.524 2.6 188 1.35

50 19.5 22.6 25.4 1810 0.387 2.3 228 1

70 22.1 25.2 28.2 2305 0.268 2.0 291 0.69

95 24.5 28.4 31.6 3105 0.193 1.4 354 0.52

120 29.1 33.0 36.4 3820 0.153 1.3 410 0.42

150 31.1 35.0 38.6 4475 0.124 1.2 472 0.35

185 33.4 38.3 42.2 5675 0.0991 0.82 539 0.29

240 38.0 42.9 47.0 7090 0.0754 0.73 636 0.24

300 43.0 47.8 52.2 8570 0.0601 0.67 732 0.21

Approximate Diameter

* Circular conductors, all others are sector shaped

Installation conditions for above rating:

Ambient Air Temperature 30

o

C

Conductor operating temperature 90

o

C

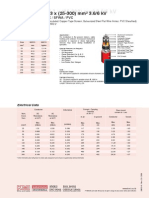

BS 7846 3-Core

Fire resistant cables. Three Core Armoured Cables 600/1000 V Grade with stranded copper conductors

Nominal

conductor

area

mm2

Approximate

cable weight

kg/km

Maximum cond-

uctor resistance

at 20

o

C

Ohm/km

Maximum armour

resistance

at 20

o

C

Ohm/km

Current rating on

perforated cable

trays / free air

Amp

Voltage drop

(3 AC)

mV/A/m

Under armour

mm

Over armour

mm

Overall dia

mm

Approximate Diameter

600/1000 V Copper power and control cables

1.5* 9.2 11.0 12.9 345 12.1 9.5 25 27

2.5* 10.5 12.3 14.4 425 7.41 8.2 33 16

4* 11.8 13.6 15.7 515 4.61 7.5 44 10

6* 12.9 14.7 16.8 610 3.08 6.7 56 6.8

10* 14.8 17.3 19.6 910 1.83 4.0 78 4.0

16* 16.8 19.3 21.8 1110 1.15 3.5 99 2.5

25* 21.1 24.3 27.0 1720 0.727 2.5 131 1.65

35* 23.5 26.7 29.6 2105 0.524 2.3 162 1.15

50 24.9 28.0 30.8 2480 0.387 2.0 197 0.87

70 26.9 30.0 33.0 3145 0.268 1.8 251 0.60

95 30.6 34.5 37.9 4310 0.193 1.3 304 0.45

120 33.9 37.8 41.4 5170 0.153 1.2 353 0.37

150 37.8 42.7 46.5 6555 0.124 0.78 406 0.30

185 42.2 47.1 51.0 7915 0.0991 0.71 463 0.26

240 46.4 51.3 55.6 9815 0.0754 0.63 546 0.21

300 52.8 57.6 62.1 12030 0.0601 0.58 628 0.185

400 58.0 62.8 67.7 14740 0.0470 0.52 728 0.165

BS 7846 4-Core

Fire resistant cables. Four Core Armoured Cables 600/1000 V Grade with stranded copper conductors

* Circular conductors, all others are sector shaped

Installation conditions for above rating:

Ambient Air Temperature 30

o

C

Conductor operating temperature 90

o

C

Nominal

conductor

area

mm2

Approximate

cable weight

kg/km

Maximum cond-

uctor resistance

at 20

o

C

Ohm/km

Maximum armour

resistance

at 20

o

C

Ohm/km

Current rating on

perforated cable

trays / free air

Amp

Voltage drop

(3 AC)

mV/A/m

Under armour

mm

Over armour

mm

Overall dia

mm

Approximate Diameter

600/1000 V Copper power and control cables

1.5* 10.1 11.9 13.8 390 12.1 8.8 25 27

2.5* 11.5 13.3 15.4 480 7.41 7.7 33 16

4* 13.0 14.8 16.9 590 4.61 6.8 44 10

6* 14.2 16.7 19.0 825 3.08 4.3 56 6.8

10* 16.4 18.9 21.2 1065 1.83 3.7 78 4.0

16* 18.6 21.1 23.6 1335 1.15 3.1 99 2.5

25* 23.4 26.6 29.3 2070 0.727 2.3 131 1.65

35* 26.1 29.3 32.2 2550 0.524 2.0 162 1.15

50 26.5 29.6 32.6 3015 0.387 1.8 197 0.87

70 30.7 34.6 38.0 4240 0.268 1.2 251 0.60

95 34.5 38.4 42.0 5420 0.193 1.1 304 0.45

120 38.1 43.0 46.8 6935 0.153 0.76 353 0.37

150 42.8 47.7 51.6 8270 0.124 0.68 406 0.30

185 47.2 52.1 56.4 10000 0.0991 0.61 463 0.26

240 52.5 57.3 61.8 12485 0.0754 0.54 546 0.21

300 58.2 63.0 67.9 15175 0.0601 0.49 628 0.185

400 66.5 72.6 78.0 19800 0.0470 0.35 728 0.165

BS 7846 Multi-Core

600/1000 V Copper auxiliary control cables

Nominal

conductor

area

mm

2

Number of

cores

Approximate

cable weight

kg/km

Maximum

conductor

resistance

at 20

o

C

Ohm/km

Maximum

armour

resistance

at 20

o

C

Ohm/km

Current rating

on perforated

cable trays

/ free air

(Multi circuit

operation)

Amp

Current rating

on perforated

cable trays

/ free air

(Single circuit

operation)

Amp

Voltage

drop

(3 AC)

mV/A/m

Under

armour

mm

Over

armour

mm

Overall

dia

mm

Fire resistant cables. Armoured Auxiliary Cables 600/1000 V Grade with stranded copper conductors

* Multi circuit means all conductors are loaded equally and operating in close vicinity

Installation conditions for above rating: Ambient Air Temperature 30

o

C Conductor operating temperature 90

o

C

Approximate Diameter

7 1.5 12.0 13.7 15.9 485 12.1 7.5 19 29 27

12 15.8 18.3 20.6 820 12.1 4.0 16 29 27

19 18.6 21.1 23.6 1060 12.1 3.5 14 29 27

27 22.4 25.6 28.3 1525 12.1 2.3 12 29 27

37 25.2 28.4 31.1 1840 12.1 2.0 11 29 27

48 29.0 32.2 35.1 2240 12.1 1.8 10 29 27

7 2.5 13.8 15.5 17.7 610 7.41 6.3 25 39 16

12 18.3 20.8 23.3 1040 7.41 3.5 21 39 16

19 21.6 24.8 27.5 1525 7.41 2.3 18 39 16

27 26.1 29.3 32.2 1980 7.41 1.9 17 39 16

37 29.4 32.6 35.5 2425 7.41 1.7 15 39 16

48 33.9 37.9 41.1 3260 7.41 1.2 14 39 16

7 4 15.6 18.0 20.3 885 4.61 4.0 33 52 10

12 20.8 24.0 26.5 1450 4.61 2.3 28 52 10

19 24.6 27.8 30.5 1940 4.61 2.0 24 52 10

27 29.8 33.0 36.0 2560 4.61 1.7 22 52 10

37 33.6 37.6 40.8 3445 4.61 1.2 19 52 10

48 38.8 42.8 46.2 4240 4.61 1.0 17 52 10

Precautions to be observed for extensions or alterations with existing & new color scheme.

Single Phase

Three Phase

Red Brown

Black Blue

Red Brown

Yellow Black

Blue Grey

Black Blue

L L

N N

L1 L1

L2 L2

L3 L3

N N

Existing Color Code New Harmonised Color Code

I nstal l ati on Gui del i nes

You might also like

- KT Factor CalculationDocument1 pageKT Factor CalculationDEADMANNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- GC CatalogDocument130 pagesGC CatalogAhmad SalahNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Thiruvasagam Sila SinthanaigalIiDocument409 pagesThiruvasagam Sila SinthanaigalIiDEADMANNo ratings yet

- N2 XFGB YDocument4 pagesN2 XFGB YRinda_RaynaNo ratings yet

- N2XCYDocument5 pagesN2XCYRinda_RaynaNo ratings yet

- N2XSYDocument5 pagesN2XSYRinda_RaynaNo ratings yet

- NA2XSKB (AL) Y 1 X (25-630) MM 3.6/6 KVDocument5 pagesNA2XSKB (AL) Y 1 X (25-630) MM 3.6/6 KVRinda_RaynaNo ratings yet

- RV-K KabelisDocument4 pagesRV-K KabelismaterkyNo ratings yet

- PHELPS DODGE Superflex Pdic01214Document5 pagesPHELPS DODGE Superflex Pdic01214unividenteNo ratings yet

- N2XYDocument5 pagesN2XYRinda_RaynaNo ratings yet

- Botas de Salida Multiple CBRDocument2 pagesBotas de Salida Multiple CBRFaVCM100% (1)

- FP 400Document6 pagesFP 400kiranvankudre5802No ratings yet

- 09 Technical TablesDocument8 pages09 Technical TablesRuban Vijaya SinghNo ratings yet

- PVC Cables FinolexDocument8 pagesPVC Cables FinolexMaria DenetNo ratings yet

- NA2XSKYDocument5 pagesNA2XSKYRinda_RaynaNo ratings yet

- XTEInterfaceServlet PDFDocument2 pagesXTEInterfaceServlet PDFWalterNo ratings yet

- Olex Nexan HandbookDocument112 pagesOlex Nexan Handbook322399mk7086No ratings yet

- Nuhas BrochureDocument71 pagesNuhas BrochuremealysrNo ratings yet

- Single Core & Multicore Flexible CablesDocument12 pagesSingle Core & Multicore Flexible Cablesdh24992499No ratings yet

- Anixter - Teck90Document18 pagesAnixter - Teck90Michele BacocchiaNo ratings yet

- Barrier Glands CMP PX2K Barrier Cable GlandsDocument1 pageBarrier Glands CMP PX2K Barrier Cable GlandsrocketvtNo ratings yet

- Caledonian: BS 6346 PVC Insulated, Armored Power and Control CablesDocument28 pagesCaledonian: BS 6346 PVC Insulated, Armored Power and Control CablessurenediyaNo ratings yet

- Monolithic Insulating JointsDocument5 pagesMonolithic Insulating JointsTran Thanh TungNo ratings yet

- 0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionDocument2 pages0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionIvan Nur BhaktiNo ratings yet

- Silflex Ewkf/ Ewkf +C: Heavy Duty, Tear Resistant, High Temperature Silicone Control CableDocument2 pagesSilflex Ewkf/ Ewkf +C: Heavy Duty, Tear Resistant, High Temperature Silicone Control CableM J VoraNo ratings yet

- Adv of XLPE Over PVC in DetailDocument1 pageAdv of XLPE Over PVC in Detailaravin9786No ratings yet

- Single Core Cables Xlpe Insulated Cables Mv-90Document20 pagesSingle Core Cables Xlpe Insulated Cables Mv-90AWG AMGCNo ratings yet

- Type ST-C Cables: DescriptionDocument51 pagesType ST-C Cables: DescriptiongilmarquijanoNo ratings yet

- Low Voltage Range of Cables - June 2014Document80 pagesLow Voltage Range of Cables - June 2014Irfan Ari PNo ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- MESC Power Cable CatalogueDocument76 pagesMESC Power Cable Catalogue1youssefsNo ratings yet

- GlosterDocument5 pagesGlosterbalabhaviniNo ratings yet

- Power Control 08Document44 pagesPower Control 08kingmltNo ratings yet

- Explosion Proof Cable Glands Prysmian Barrier Glands (424TX) For SWB Steel Wire Braided CableDocument2 pagesExplosion Proof Cable Glands Prysmian Barrier Glands (424TX) For SWB Steel Wire Braided CablerocketvtNo ratings yet

- Outdoor Composite Termination From 123 KV Up To 170 KV Ohvt: ApplicationDocument2 pagesOutdoor Composite Termination From 123 KV Up To 170 KV Ohvt: ApplicationbahramhooNo ratings yet

- ConduitsDocument10 pagesConduitsSiddiqui Abdul KhaliqNo ratings yet

- N2XSERYDocument5 pagesN2XSERYRinda_RaynaNo ratings yet

- Cable Cleat Catalogue 2014Document28 pagesCable Cleat Catalogue 2014carlosmandopintoNo ratings yet

- Explosion Proof Cable Glands Prysmian Barrier Glands (424TW) For SWA Steel Wire Armour CableDocument2 pagesExplosion Proof Cable Glands Prysmian Barrier Glands (424TW) For SWA Steel Wire Armour CablerocketvtNo ratings yet

- LG Bus Duct System: Leader in Electrics & AutomationDocument51 pagesLG Bus Duct System: Leader in Electrics & AutomationRajneesh KatochNo ratings yet

- Imsa Catalog Imsa CatDocument16 pagesImsa Catalog Imsa CatDaniel TelloNo ratings yet

- Plastic-Insulated Winding Wires: Norddeutsche Seekabelwerke GMBH & Co. KGDocument6 pagesPlastic-Insulated Winding Wires: Norddeutsche Seekabelwerke GMBH & Co. KGcesar007chNo ratings yet

- Cable TestingDocument4 pagesCable TestingArvind_Chaudha_6686100% (1)

- NA2XSEKRY 3 X (25-300) MM 3.6/6 KVDocument5 pagesNA2XSEKRY 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- MVcables DesignDocument40 pagesMVcables DesigniyyaniNo ratings yet

- N2XSEKBYDocument5 pagesN2XSEKBYRinda_RaynaNo ratings yet

- 12-Lumino - Covered ConductorDocument7 pages12-Lumino - Covered Conductorvishnu ojhaNo ratings yet

- Na2Xsefgby 3 X (25-300) MM 3.6/6 KVDocument5 pagesNa2Xsefgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- M E S C: Power / Control CableDocument2 pagesM E S C: Power / Control CablerajuNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Handbook of 3D Integration, Volume 1: Technology and Applications of 3D Integrated CircuitsFrom EverandHandbook of 3D Integration, Volume 1: Technology and Applications of 3D Integrated CircuitsPhilip GarrouNo ratings yet

- Broadband Access: Wireline and Wireless - Alternatives for Internet ServicesFrom EverandBroadband Access: Wireline and Wireless - Alternatives for Internet ServicesNo ratings yet

- Transformer Oil TestingDocument29 pagesTransformer Oil TestingDEADMAN100% (1)

- 110V DC Station Battery and Charger Calculations: 1 Input DataDocument2 pages110V DC Station Battery and Charger Calculations: 1 Input DataDEADMAN100% (1)

- Simple Methods For Calculating Short Circuit Current Without A ComputerDocument4 pagesSimple Methods For Calculating Short Circuit Current Without A ComputerDEADMANNo ratings yet

- Transformer Name Plate Details: Short Circuit Current Calculation For Transformer (Short Cicuit Test)Document1 pageTransformer Name Plate Details: Short Circuit Current Calculation For Transformer (Short Cicuit Test)DEADMANNo ratings yet

- SPD Design StepDocument1 pageSPD Design StepDEADMANNo ratings yet

- Busbar Protection SlidesDocument2 pagesBusbar Protection SlidesDEADMANNo ratings yet

- Earth Fault Protection - Part-1Document9 pagesEarth Fault Protection - Part-1DEADMAN100% (1)

- 12.es-10 Capcitor BankDocument5 pages12.es-10 Capcitor BankDEADMANNo ratings yet

- Busbar ProtectionDocument16 pagesBusbar ProtectionDEADMANNo ratings yet

- Source Impedance CalculationDocument1 pageSource Impedance CalculationDEADMANNo ratings yet

- KT FactorDocument1 pageKT FactorDEADMANNo ratings yet

- TCS SchematicDocument1 pageTCS SchematicDEADMANNo ratings yet

- Relay Sim TestDocument10 pagesRelay Sim TestDEADMANNo ratings yet

- ETAP IPP Load Flow ExampleDocument122 pagesETAP IPP Load Flow ExampleDEADMAN80% (5)