Professional Documents

Culture Documents

Underfloor Air Distribution (UFAD) Application Guide: Titus

Underfloor Air Distribution (UFAD) Application Guide: Titus

Uploaded by

Miguel MancillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underfloor Air Distribution (UFAD) Application Guide: Titus

Underfloor Air Distribution (UFAD) Application Guide: Titus

Uploaded by

Miguel MancillaCopyright:

Available Formats

AG-UFAD-02

December 5, 2007

Titus

Underfloor Air Distribution (UFAD)

Application Guide

Air Distribution Technologies

605 Shiloh Road

Plano, Texas 75074

972.212.4800

www.titus-hvac.com

Titus, the Titus Spiral, The Leader in Air Management is a trademark of Titus.

All other trademarks, noted or not, are the property of their respective owners.

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

3 of 9

Contents Page

General.............................................................. 3

Introduction...................................................... 3

UFAD System Overview.................................. 3

Design Basics .................................................. 3

Plenum Design .............................................. 3

Perimeter Systems ........................................ 4

Conference Rooms & Other Areas of Varying

Load............................................................... 5

Return Air....................................................... 6

Humidity Issues ............................................. 6

Sizing Jobs..................................................... 6

System Economics.......................................... 6

First Costs & Installation Costs...................... 7

Higher HVAC Equipment Efficiency .............. 7

Lower Horsepower Fans................................ 7

Better Heat and Pollutant Removal ............... 7

Easy Installation and Relocation.................... 8

Lower Life Cycle Costs.................................. 8

UFAD and LEED............................................... 8

Optimize Energy ............................................ 8

Building Reuse............................................... 9

Controllability of Systems .............................. 9

Abbreviations................................................... 9

General

This document provides application and design

highlights for underfloor air distribution (UFAD)

systems.

Additional information may be found at the Titus

website, www.titus-hvac.com.

Introduction

The interest in underfloor air distribution (UFAD)

has increased significantly over the last decade.

There is currently several million square feet of

access floor air distribution systems being

designed across the country.

In 1997 Titus introduced the TAF-R diffuser and

the TAF-G grommet, which were installed in the

Owens Corning World Headquarters. Since then,

Titus, ASHRAE, and the engineering community

have continued to learn about UFAD systems.

In the decade that Titus has participated in UFAD

designs in the US, we have continued to introduce

new products to meet the needs of this unique

application.

UFAD System Overview

UFAD systems utilize the space under an access

floor as an air plenum. Properly designed UFAD

systems take advantage of thermal stratification.

ASHRAE recommend that, for comfort, the

temperature in the occupied zone be between 73

o

and 77

o

F, relative humidity be between 25 - 60%,

and the maximum velocity in occupied zone be 50

fpm in cooling or 30 fpm in heating.

The key to successful access floor systems is the

ability of the access floor diffuser to rapidly mix

room air into the supply air at low velocities.

Because supply air is introduced directly into the

occupied zone, it is important that the supply air

reach the ASHRAE recommended temperature

and velocity, mixing of the supply air into the

space should happen rapidly.

The typical application for a UFAD system is the

open plan office. Floor space is at a premium in a

cubicle so a smaller clear area around the diffuser

will allow more usable space in the cubicle. The

UFAD diffuser manufacturer defines the required

clear area that their diffuser needs to achieve the

ASHRAE recommended temperature and velocity.

Originally UFAD systems were for computer

rooms. The design intent was to cool computer

equipment and not to provide comfort. The

computer room design concept typically provides

too cold of a space for comfort.

There has been a growth of UFAD systems used

in offices and headquarters in U.S. It is estimated

that 10% of U.S. construction will utilize access

floors within few years.

The growing interest in UFAD systems is primarily

due to companies need to easily rearrange office

layouts, information and communications based

offices, economics of ownership, and green

building programs such as LEED.

Design Basics

Plenum Design

The raised floor office can be supplied with

conditioned air from below the floor in two ways

pressurized plenum or neutral plenum.

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

4 of 9

Pressurized Plenums

The pressurized plenum (the area between the

slab and the raised floor) is essentially a large

duct maintained at a constant pressure differential

to the room above; typically between 0.05 and

0.10 in. pressure (w.g.).

This pressure is maintained through the supply of

conditioned air from a number of supply duct

terminations. The spacing and location of these

ducts are dependent on the air supply

requirement and the plenum depth, with shallow

plenums and / or high air quantities requiring more

air supply duct outlets under the floor. UFAD

diffusers are specially designed grilles with a user

adjustable damper to regulate flow.

Sealing the underfloor plenum is critical to

optimizing the operation of a UFAD system. Air

leaking through the floor tiles into the occupied

zone is of minimal concern because it is leaking

into the occupied space. Air leaking into the space

between the walls, however, is wasted energy. All

knockouts and holes in the drywall below the

raised floor must be sealed during construction.

The advantages of pressurized plenums include

low first cost and easily changed layouts. This is

the most commonly used plenum design.

Neutral Plenums

With the neutral plenum design, the same layout

as the pressurized plenum may be used, but the

pressure difference between the plenum and the

room is kept as close as possible to zero.

Floor diffusers either contain integral fans, are

ducted from a central source, or both. In many

cases, these closely resemble conventional

ceiling supply systems.

Advantages include the possibility of multiple

small zones (as with multiple tenants) and

insensitivity to construction details. Disadvantages

include higher first costs due to ducting and/or fan

connections under the floor, lower flexibility as the

grilles are individually ducted, and potentially

higher noise levels.

This design is rarely used, but may be effective in

tenant buildings where the utilities will be paid by

the tenant.

Plenum Details

Plenum heights typically range from 14 to 18,

occasionally going as low as 12. The plenum

height is usually determined by the height

requirements of other equipment that will be

located under the floor. The number of inlets

required to supply the plenum with sufficient air to

run the diffusers is dependent upon the plenum

size and the number of diffusers, which in turn is

determined by the load of the space.

As a general rule, the longest distance from the

supply air outlet in the plenum and the farthest

diffuser should not exceed 50-65 feet. Distances

longer then this are subject to thermal losses and

the discharge temperature of the diffuser may be

too high.

If zone control is desired from the underfloor

plenum, the plenum can be partitioned into

separate zones. The zones in the underfloor

plenum should correspond to building zones

having similar load requirements. However, it is

not necessary to partition the underfloor plenum

into zones and doing so can make future office

layout changes more difficult. If an office layout

must be changed, the partitioned plenum will need

to be changed to match the new layout.

Because of the special heating and cooling

requirements of the perimeter of the building, it

may be necessary to create a perimeter zone in

the underfloor plenum to run a separate perimeter

system. Typically only the perimeter is zoned from

the core. The perimeter will be discussed in more

detail next.

Perimeter Systems

The perimeter is typically the most difficult area of

an underfloor system to design. The perimeter is

often handling much larger loads and require the

most equipment. In the past, the best way to

handle the perimeter was to use fan powered

terminals with reheat ducted to linear bar grilles.

There are a couple challenges with this design

concept. The throw of a linear bar grille ducted to

the discharge of a fan powered terminal is very

long, possible as long as 15-20 feet. Designing

long throws at the perimeter contradicts the

concept of stratification in a UFAD system. Not

only does the long throw from the grille mix the air

above the stratified layer into the occupied zone,

wasting energy, but it also may roll up the glass

and across the ceiling, where it drop into the

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

5 of 9

occupied zone causing discomfort for the

occupants.

Although the concept of UFAD systems is to be

modular, the function of handling perimeter loads

is not modular. Those loads come with the

building envelope, which is always a line of some

sort. The TAF-L Perimeter System was designed

to address all of these considerations.

Perimeter Cooling

The perimeter cooling system should combine

induction, buoyancy and displacement ventilation

models, handles high thermal loads such as 225

CFM per 4 length at 0.07 wg, engage the

occupied zone, but not the stratified ceiling layer.

This avoids occupant complaints from air rolling

back, dumping into interior space and saves

energy by not mixing the warm ceiling air into the

occupied zone.

The TAF-L perimeter system provides this ideal

air pattern. The TAF-L system consists of a

modular cooling plenum, the TAF-L-V, and

heating plenum, the TAF-L-W, designed to be

integrated with the CT-TAF-L multi-deflection

linear bar diffuser.

The TAF-L system provides a continuous look

around the perimeter. The TAF-L-V cooling

plenum used with the CT-TAF-L has an

engineered throw pattern that never breaks

through the stratification layer created by the

UFAD diffusers in the core. The dual aperture

plate design allows the TAF-L-V / CT-TAF-L

assembly to maintain this engineered throw

pattern while modulating the airflow volume.

Perimeter Heating

Perimeter heating cannot be accomplished with

the same system as the interior load cooling

system. Ideally, since ASHRAE 90.1 states that

you should not simultaneously cool and heat, the

perimeter heating system should be completely

independent of the cooling system. Separate

ducting of hot or reheated air, hydronic systems,

or perimeter fan powered systems are often used

to condition the skin load on the building.

The TAF-L-W, self contained fin tube perimeter

heating plenum utilizes room air to heat the

perimeter instead of supply air. The TAF-L-W

heating plenum also uses the CT-TAF-L to create

a continuous linear look from the occupied space.

The TAF-L-W works by allowing the denser cold

air to flow down a window or exterior wall into the

TAF-L-W plenum while also inducing room air into

the plenum. A finned tube heater in the plenum

reheats this cold air and room air, returning the

warmer air to the window or exterior wall through

natural convection.

Typically the TAF-L-V, cooling plenums, and TAF-

L-W, heating plenums are alternated as needed

throughout the perimeter.

The TAF-L system allows you to remove the fan

powered terminals, and their associated energy

and maintenance costs, from the UFAD system.

However, in the event where the system cannot

achieve consistent plenum pressure, a fan

powered terminal may be necessary.

The PFC was designed to be used as a booster

unit for perimeter applications. The PFC fan

powered terminal unit is designed to be installed

between the pedestals in an underfloor system

and installed in a floor 12 to 18 in height.

The PFC is usually ducted to linear bar diffusers,

such as the CT, or diffuser and plenum units, such

as the TAF-D. The airflow of the diffusers is

directed at the glass like a typical ceiling system.

Modulating the fan speed to vary the amount of air

supplied to the zone is the most common control

sequence used for the PFC. The PFC controller

will determine the speed of the fan based on zone

temperature. For example, the fan would run

100% when the zone is 75

o

F and modulated down

to 30% as the zone approaches 70

o

F.

Conference Rooms & Other

Areas of Varying Load

Much like the perimeter, conference rooms must

be handled separately to adjust for the varying

load conditions. The LHK fan powered terminal

was designed for this application. Like the PFC,

the LHK fits within the modular pedestal systems

of the raised floor and is available in various

heights to fit under 12 through 18 raised floors.

With the exception of its unique dimensions, the

LHK is like any other series fan powered terminal.

The LHK has a supply inlet with a damper

modulated by a controller and actuator. The LHK

has an induced air inlet which pulls air from the

underfloor plenum or from the room depending on

how the LHK is applied.

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

6 of 9

The LHK supply inlet would be open to the

plenum with the induced air inlet ducted to the

room as the return. The discharge would then be

flex ducted to TAF-Rs in the room.

Return Air

Due to the upward air flow, returns should be

located at the ceiling or on a high side wall. This

allows the heat from ceiling lights to be returned

before it is able to mix with the conditioned air in

the occupied zone. There will also be a small

amount of free cooling due to the natural

buoyancy of hot air.

If the system must use 55

o

F supply air for

humidity reasons, some of the return air can be

recirculated from the ceiling to the underfloor

plenum to raise the temperature of the air to 63

o

F

to 68

o

F.

Another option is to take the return air back to the

air handling unit where it can be filtered and

dehumidified before re-entering the underfloor

plenum. With this option, you can more accurately

control the air temperature at the diffuser and you

gain the cost benefits of the warmer supply air

temperature.

Humidity Issues

A potential problem with the higher supply

temperatures used in underfloor supply systems is

the higher potential moisture content of the

warmer supply air used in these systems.

The supply system must reduce relative

humidities to less than 60% to meet IAQ

concerns, and this requires dew points less than

65

o

F. This implies either reheat or blending of air

to achieve a 65

o

F supply, 55

o

F dew point

condition.

System designs utilizing condenser water reheat,

run-around coils, face & bypass, and other

strategies can be employed to solve these

potential design problems. Other possible

solutions include the use of a separate system to

dry outside air or the use of desiccant

dehumidification.

Climate and building operation are important

considerations when designing a UFAD system.

In humid climates, it may be necessary to operate

the HVAC system 24 hours a day to maintain

acceptable humidity levels in the building.

Sizing Jobs

The optimum design point for the TAF-R is 80 -

100 CFM when a 10

o

F room / supply differential is

used. At this point, the noise is negligible and the

pressure required is less than 0.10.

Throw will be less than 6 ft., preserving the

desired ceiling stratification layer. Our testing

shows that there is 100% mixing in the occupied

zone under these conditions.

The stratification in this installation results in a

supply - exhaust T similar to the typical 18

o

F to

20

o

F T common in most conventional systems.

For example, with 64

o

F supply air in a 74

o

F room,

the room exhaust, at the ceiling, will probably be

about 82

o

F, for an 18

o

F T.

This means that one diffuser can handle:

18

o

F T x 100 CFM x 1.08 = 1944 BTUH or

1944 BTUH 3.41 = 570 watts of internal load.

Lights are typically 0.75 W/sq.ft, but with ceiling

stratification are probably not a part of the room

load (but are seen by the air handler). If

computers and printers supply about 1W/sq.ft.

load and occupants add about 1.2 W/sq.ft, this

translates to:

1.0 W/sq.ft. (computers and printers)

+ 1.2 W/sq.ft. (occupants)

= 2.2 W/sq.ft. (room load)

This corresponds to one TAF-R every:

570 Watts of internal heat

2.2 W/sq.ft. room load

= 260 sq.ft. floor space sensed interior zone load.

As a general rule, one TAF-R should be provided

for each occupant.

System Economics

The main economic considerations for a UFAD

system are reduced first costs & installation costs,

higher HVAC equipment efficiency, lower

horsepower fans, better heat and pollutant

removal, quick to install and easy to rearrange

office layouts, and lower life-cycle building costs.

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

7 of 9

First Costs & Installation Costs

UFAD systems can be designed with plenum

returns using the same floor to floor height as

conventional systems by shifting the occupied

zone up into where the ceiling plenum would

normally be.

The cost of the raised floor, typically $5-7 per

sq.ft., is offset by the fact that less ductwork is

required. The installation costs are usually lower

because the HVAC and data / power work is done

at floor level.

In a conventional system, ductwork must go to

every diffuser. UFAD systems use a pressurized

plenum to supply each diffuser, so less ductwork

is required. In a UFAD system, the only ducting in

the underfloor plenum is the ductwork required to

supply the diffusers that are more than 50-65 feet

away from the dampers or the separation for the

perimeter.

Figure 1. Conventional system ductwork

Figure 2. UFAD system plenum

A 1996 study in Building Design & Construction

magazine showed a $2.13/sq.ft. first cost savings

using UFAD systems.

Higher HVAC Equipment

Efficiency

In an UFAD system, supply air enters directly into

the occupied zone at the floor level. In a

conventional system, the supply air temperature is

usually 55

o

F because it must mix with the warm

air at the ceiling before it enters the occupied

zone.

UFAD systems typically use 63-68

o

F supply air

temperatures. This warmer supply air can reduce

energy consumption of the HVAC equipment.

Some DX equipment cannot supply air at this high

temperature, so this must be considered when

selecting the HVAC equipment.

Lower Horsepower Fans

UFAD systems move a larger volume of air with

overall lower pressure drops. The diffusers used

in UFAD systems operate with less than 0.1 wg,

so lower horsepower fan can be used, reducing

energy costs.

Better Heat and Pollutant

Removal

Heat from overhead ceiling lights is removed

before it enters the occupied zone and lateral

mixing in the occupied zone is reduced. A

Main Duct Loop

Branch Ducts

Air handler

Core VAV box

Diffusers

Air is

supplied to

the center

of the floor

Fan powered

terminals

handle the

perimeter

Air is

supplied to

the center

of the floor

Fan powered

terminals

handle the

perimeter

Air is

supplied to

the center

of the floor

Fan powered

terminals

handle the

perimeter

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

8 of 9

Lawrence Berkeley National Laboratory field study

found that pollutant removal efficiency for carbon

dioxide was 13% higher than expected in a space

with well-mixed air, suggesting a 13% reduction in

exposures to occupant generated pollutants.

Easy Installation and Relocation

UFAD diffusers are installed through the floor

panel after flooring and carpet installation is

complete. Little attention needs to be placed on

diffuser location until office furniture layout is

finalized.

Typical churn in an office is 33%, meaning that

everyone moves every three years. Diffusers are

rearranged by moving entire floor panel to a new

location. This reduces the time and labor costs of

relocation and renovation in an office.

Lower Life Cycle Costs

Several factors of the UFAD system contribute to

potential life cycle savings. The building should

have an energy savings from the use of lower

horsepower fans. The owner should see reduced

costs for office layout changes.

In addition to these, the concrete structural slab

can be used to lower peak cooling demand. The

use of the underfloor plenum as a supply duct

allows the use of the thermal mass of the

structure as an energy flywheel.

By ventilating the underfloor plenum with cool air

at night, the structure can be cooled to the point

where the load during the early part of the day is

significantly lowered. A number of strategies can

be employed to take advantage of the potential for

stored cool, resulting in lowered energy use and

off-peak energy use. However, there is a potential

for overcooling the occupied space during the

night requiring addition morning warm up, costing

energy.

There are also costs savings associated with

increased thermal comfort for occupants. Because

the diffusers are occupant adjustable, the facility

staff should see fewer complaints about thermal

comfort.

Increased employee satisfaction potentially results

in increased productivity. Labor costs are typically

10 times the cost of property. A 1% productivity

improvement is the equivalent of 22 hours, or

almost three days, of gained productivity.

For a company with 115 employees earning

$35,000 a year, 30 employees earning $60,000 a

year, and 5 employees earning $80,000 a year, a

1% improvement would worth be almost $70,000.

This is a substantial payback for a building owner.

UFAD and LEED

The United States Green Building Council

(USGBC) developed the Leadership in Energy &

Environmental Design (LEED

TM

) Green Building

Rating System. The LEED council is a

voluntary, consensus-based national standard

board for developing high-performance,

sustainable buildings. USGBC members

represent all segments of the building industry

and update the program continuously.

The growing interest in green buildings and LEED

certification has increased the interest in UFAD

systems. The table below shows the LEED credits

that could be achieved with UFAD systems.

Criteria Classification Points

Energy & Atmosphere

Credit 1 - Optimize Energy

Performance

Up to 10

Materials & Resources

Credit 1 - Building Reuse 1 3

Indoor Environmental Quality

Credit 6 Controllability of

Systems, Thermal Comfort

1

Credit 7 Thermal Comfort 1

Optimize Energy

Credit 1 is Optimize Energy Performance. The

intent of this credit is to achieve increasing levels

of energy performance above the prerequisite

standard to reduce environmental impacts

associated with excessive energy use. Credits are

based on percentage of reduction and range from

10.5% reduction (1 Point) to 42% reduction (10

Points) for new buildings.

The requirement for optimizing energy

performance credit is to reduce the design

energy cost compared to the energy cost budget

for systems regulated by ASHRAE/IESNA

Standard 90.1-2004. Per LEED, regulated energy

systems include HVAC, service hot water and

interior lighting.

Underfloor Air Distribution (UFAD)

Application Guide

AG-UFAD-02

December 5, 2007

9 of 9

All LEED projects registering after June 26, 2007

are required to achieve at least two (2) Optimize

Energy Performance points

One way to achieve energy optimization credit is

with an underfloor system. An underfloor system

may have higher HVAC equipment efficiency as

access floor air systems use warmer supply air

(63

o

to 68

o

F) than conventional systems that use

55

o

F supply air. Raising the discharge

temperature of many system types reduces

energy consumption.

Underfloor systems can move a larger

volume of air with overall lower pressure drops.

The underfloor plenum needs less than 0.1 wg

of water pressure or less for proper diffuser

performance. This results in less fan horsepower

needed for underfloor systems resulting in lower

energy usage.

The energy savings of an underfloor system

should be considered as part of the system to

receive an Optimize Energy Performance credit.

ECM motors are another option that should be

considered for the Optimize Energy Performance

credit. The ECM motor has efficiencies of up to

70% across its entire operating range (300-1200

rpm) and 80% over 400 rpm. The ECM motor is

available in the Titus LHK and PFC UFAD fan-

powered terminals. See the ECM Application

Guide, AG-ECM, for more information.

Building Reuse

If the project is a renovation, Credit 1.1, 1.2, or

1.3, Building Reuse, may be applicable.

Credit 1.1 is for maintaining at least 75%, based

on surface area, of existing building structure and

envelope. Credit 1.2 is for maintaining an

additional 20%. Credit 1.3 is for maintaining 50%

of existing interior non-structural elements such as

interior walls, doors, floor coverings and ceiling

systems.

Each credit qualifies for one point, meeting the

criteria for all three credits nets a maximum of

three points for the Material & Resources section.

Utilizing access floors systems can update a

building for meet current technology needs

without demolishing the current building structure.

In situations where the architect wants to leave an

ornamental ceiling open, access floor air

distribution may be the perfect solution.

Controllability of Systems

Credit 6, Controllability of Systems, has two parts:

6.1 Lighting and 6.2 Thermal Comfort. The intent

of Credit 6.2 is to provide individual comfort

controls for 50% of the building occupants to

enable adjustments to suit individual task needs

and preferences.

The credit states that, Individual adjustments may

involve individual thermostat controls, local

diffusers at floor, as potential strategies to

achieve this credit. VAV diffusers, such as the

Titus T

3

SQ would also qualify for this credit as

well as access floor diffusers such as the TAF-R.

Abbreviations

The following table lists abbreviations used within

this document.

Abbrev. Term

ASHRAE American Society of Heating,

Refrigerating and Air-Conditioning

Engineers

UFAD Underfloor Air Distribution

LEED Leadership in Energy & Environmental

Design

USGBC U. S. Green Building Council

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Howard Terzigni Presentation and HandoutsDocument129 pagesHoward Terzigni Presentation and HandoutsMiguel MancillaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Case 621C Wheel Loader: Help Improve This Specification Print SpecificationDocument2 pagesCase 621C Wheel Loader: Help Improve This Specification Print SpecificationTerry Malone100% (1)

- Method Statement For Under CrossingDocument24 pagesMethod Statement For Under CrossingSaifur RahmanNo ratings yet

- Method Statement For Demolition of Pile Cap of Existing Dolphin JettyDocument5 pagesMethod Statement For Demolition of Pile Cap of Existing Dolphin JettyPriodeep ChowdhuryNo ratings yet

- Subject: Work at Height: Unit: Maihar Cement WorksDocument3 pagesSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Structural Design Calculation SampleDocument17 pagesStructural Design Calculation Sampleihpeter83% (6)

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- Mineral and Synthetic Lubricating Oil Used in Steam or Gas TurbinesDocument8 pagesMineral and Synthetic Lubricating Oil Used in Steam or Gas TurbinesJicheng PiaoNo ratings yet

- Gabion Wall Design SheetDocument3 pagesGabion Wall Design SheetTej Bdr. paliNo ratings yet

- Safety Integrity Level (Basra)Document44 pagesSafety Integrity Level (Basra)Husnain BasraNo ratings yet

- UOP Method 46-85 Ceras de ParafinaDocument6 pagesUOP Method 46-85 Ceras de ParafinaAngel MurilloNo ratings yet

- Datos Técnicos RefrigeradorDocument25 pagesDatos Técnicos RefrigeradorMiguel Mancilla100% (2)

- Datos Técnicos RefrigeradorDocument25 pagesDatos Técnicos RefrigeradorMiguel Mancilla100% (2)

- Diagrama Simba m4 - C PDFDocument122 pagesDiagrama Simba m4 - C PDFFrancisco Parada OrellanaNo ratings yet

- Compair Fluid Force 4000 IndonesiaDocument3 pagesCompair Fluid Force 4000 Indonesiaindolube75% (4)

- Hot Work PTWDocument2 pagesHot Work PTWHSSE AL THAIL GROUPNo ratings yet

- Air Distribution Selection For SchoolsDocument55 pagesAir Distribution Selection For SchoolsMiguel MancillaNo ratings yet

- Magirus MAN Descriptivo Tecnico 1Document32 pagesMagirus MAN Descriptivo Tecnico 1Jose Alexander Varas Arriaza100% (1)

- EBT730 731 ManualDocument80 pagesEBT730 731 ManualMiguel MancillaNo ratings yet

- BAC Tab OpenCoolingTowers ENv00Document2 pagesBAC Tab OpenCoolingTowers ENv00Miguel MancillaNo ratings yet

- Product Dimensions: SDV Basic UnitDocument1 pageProduct Dimensions: SDV Basic UnitMiguel MancillaNo ratings yet

- Varitrac Changeover Bypass VavDocument52 pagesVaritrac Changeover Bypass VavMiguel MancillaNo ratings yet

- Varitrac Changeover Bypass VavDocument52 pagesVaritrac Changeover Bypass VavMiguel MancillaNo ratings yet

- Evolution of Stirling Cycle Final DraftDocument13 pagesEvolution of Stirling Cycle Final DraftMiguel MancillaNo ratings yet

- Building and Construction CSI SpecificationsDocument3 pagesBuilding and Construction CSI SpecificationsJessica PerezNo ratings yet

- Electrical Circuit Lab ReportDocument9 pagesElectrical Circuit Lab Reportapi-239929566No ratings yet

- NTTDocument8 pagesNTTIon FloareaNo ratings yet

- PSD 09 2018 30RB RQ 017-040 30rby 017 033Document26 pagesPSD 09 2018 30RB RQ 017-040 30rby 017 033Constantin294No ratings yet

- Alcatel SDH For Sale From Powerstorm 4SI10190981Document10 pagesAlcatel SDH For Sale From Powerstorm 4SI10190981samNo ratings yet

- Lecture Notes On StaticsDocument121 pagesLecture Notes On StaticsAhmet BenliNo ratings yet

- PSpice TutorialDocument25 pagesPSpice TutorialJuan RojasNo ratings yet

- Cebex 031Document4 pagesCebex 031Moatz HamedNo ratings yet

- Saddle StandardDocument1 pageSaddle StandardRajeev KhantwalNo ratings yet

- Toll Free (800) 445-4155 - Fax (631) 348-7160Document100 pagesToll Free (800) 445-4155 - Fax (631) 348-7160Jorge Luis Galezo MuñozNo ratings yet

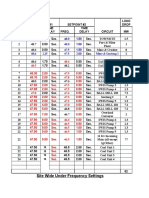

- LOAD SHED Under Frequency - Rev1Document1 pageLOAD SHED Under Frequency - Rev1Alpha AgustinusNo ratings yet

- Systematic Intel Ind. (P) Ltd. Survey No. 269 Sayali, SilvassaDocument6 pagesSystematic Intel Ind. (P) Ltd. Survey No. 269 Sayali, Silvassasantosh_thorat1234No ratings yet

- Cone of Confusion - When To Stop Chasing The NeedleDocument1 pageCone of Confusion - When To Stop Chasing The NeedleJay GalangNo ratings yet

- Statistical Analysis of The Stability NumberDocument9 pagesStatistical Analysis of The Stability Numberroger jhonarNo ratings yet

- ComlinDocument13 pagesComlinSammar AdhikariNo ratings yet

- ProblemsDocument6 pagesProblemsKABILA RNo ratings yet