Professional Documents

Culture Documents

Canudas de Wit Innsbruck

Canudas de Wit Innsbruck

Uploaded by

José Luis GómezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Canudas de Wit Innsbruck

Canudas de Wit Innsbruck

Uploaded by

José Luis GómezCopyright:

Available Formats

Control Design for

X-By-Wire Components

C. Canudas-de-Wit

Laboratoire

dAutomatique

de Grenoble, FRANCE

CNRS-INRIA Projet

P / 2

Class of Systems

Air-scooters

Balancing

Scooters

Systems with

a Driver in the

loop

Drive-by-Wire

Systems

P / 3

A Motivating Example

Stabilization of

not

not explicitly

regulated

Balance Scooter is

similar to a cart-

pendulum

Differences:

P / 4

How motion is produced ?

Forward motion is induced as a

reaction of the feedback system to

changes in the tilt angle arising from

forces produced by the rider

P / 5

Control Paradigm

Seville home made

Balancing scooter

Commercial

Segway scooter

How to design controllers resulting in:

Comfortable,

Safe,

Pleasant riding

Outline

1. Introduction

Challenges

Product Evolution

Breakthroughs

2. Examples

Clutch Synchronization

Steer-by-Wire

3. Conclusions

Outline

1. Introduction

Challenges

Product Evolution

Breakthroughs

2. Examples

Clutch Synchronization

Steer-by-Wire

3. Conclusions

P / 8

Conceptual Challenges

Different driver skills:

Different levels of: perceptual abilities, physical skills, and

technological understanding,

Decision partition between Driver & Automated system:

Little control: Increases workload

Decreases drivers awareness,

comfort & safety

Too much control Confidence excess: false safety perception

A notion of driving pleasure, whose primary

goal is to safely promote comfort

(Goodrich & Boer 01)

Fun-to-Drive:

P / 9

Technical Challenges

Lack of well defined metrics

How to measure comfort ?,

How to define safety ?

Transfer of standard control notions is not always

straightforward

How to integrate in the control specs the comfort metrics (if

any) ?

Are all stable systems safe ?

How to select/define a few tuning parameters with

subjective meaning (pleasant, hard, nice, tiring, etc.) ?

u

+

-

Mechanical

Subsystem

Inner

feedback

loop

Driver

y

Y

H

P / 10

Problem

Main difficulty:

How to translate subjective vehicle specs into control

specs?

Subjective

Vehicle Specs:

Maneuverability,

Perceived quality,

& security,

Brio,

Etc.

Control Specs:

Precision,

Damping,

Stability,

Passivity,

Etc.

P / 11

Examples of Vehicle Control Problems

Implying Jointly Comfort & Safety Specs

Automatic Clutch

Smooth synchronization (C),

Engine stall (S).

Steer-by-wire & Electric Power Steering Systems

Steering wheel vibrations, Tire/road sensations (C),

Driver interaction with an active system (S).

Chassis Control

Reject road vibrations (C),

Vehicle stability (S).

Adaptive Cruise Control (ACC)

Smooth distance/velocity regulation (C),

Vehicle front collisions (S).

Etc

P / 12

Car Product Design Evolution

ESP, ABS, TC,

Airbags, etc.

By base functions:

Suspension,

Lighting, etc.

By field of expertise:

Acoustics,

Passive safety, etc

By customer-perceived performance:

Drivability,

Quality, etc.

Distinctive features

Fun-to-Drive

(something more)

Basic features

Perceived as a due

P / 13

Trade-offs due to the Introduction

of Distinctive Features

Solutions to increase torque clutch capacity:

Higher pre-constraint forces

Larger friction plates

Multi clutch plates

Example: High torque diesel engines

Clutch torque = 1.2 Peak Engine Torque

0

100

200

300

400

500

600

700

Torque [Nm]

Laguna 2.2 D

(1994)

Laguna 2.2 DT

(1996)

Laguna 2.2 dCi

(2002)

Laguna 2.0 dCi

(2005)

Ferrari Enzo

P / 14

Trade-offs due to the introduction

of Distinctive Features

Solution 1: Higher pre-constraint spring force Fn

Constraints:

Driving ergonomy

(for passenger comfort)

Passenger space

(for passenger comfort)

Crash test foot injuries

J

v

k

t

t

J

e

e

c

J

g

Side effects:

Increase of pedal effort

Lengthening of pedal

travel

Fn

P / 15

Trade-offs due to the introduction

of Distinctive Features

Solution 2: Larger plate disks

Constraints:

Constraint on power-train

packaging

Under hood dead volume (~20cm)

(Thatcham & Danner crash tests)

Gear shifting quality

J

v

k

t

t

J

e

e

c

J

g

Side effects:

Increase of effective

volume

Increase moment of

inertia

P / 16

Trade-offs due to the introduction

of Distinctive Features

Solution 3: Multi disk clutch

Constraints:

Constraint on power-train

packaging

Gear shifting quality

J

v

k

t

t

J

e

e

c

J

g

Side effects:

Increase of lateral

vehicle volume

Increase momentum

of inertia

P / 17

Breakthrough Solutions

Integrate a force assistance device

Clutch-by-wire System

Outline

1. Introduction

Challenges

Product Evolution

Breakthroughs

2. Examples

Clutch Synchronization

Steer-by-Wire

3. Conclusions

Outline

1. Introduction

Challenges

Product Evolution

Breakthroughs

2. Examples

Clutch Synchronization

Steer-by-Wire

3. Conclusions

P / 20

Clutch-by-Wire Benefits

Clutch-by-Wire:

Improves comfort

Increase engine duty life

Avoid motor stall,

P / 21

Setups

Hardware Setups:

Clutch-by-Wire (CbW), and

Automated Manual Transmission (AMT)

inexpensive and efficient solutions

Control setups:

Both engine and clutch torque as control inputs

Clutch torque as the only controlled input, considering the

engine torque as a known input

CbW

AMT

P / 22

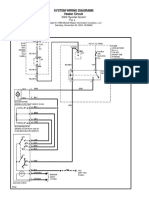

Clutch & Driveline Components

k

J

e

e

k

dmf

dmf

J

dmf

J

tl

J

wl

tl

tl

d

/2

wl

tire

LuGre

J

wr

J

tr

k

tr

tr

d

/2

wr

D

i

f

f

e

r

e

n

t

i

a

l

d F

xl

F

xr

tire

LuGre

F

n

c

J

g

Vehicle

Clutch & Dual Mass

Flywheel with

nonlinear stiffness

Separate left and right

transmission branches

Tire/Ground contact

Engine

Engine torque

(known input)

Clutch normal force

Control input:

P / 23

Simple Model for Control

J

tl

J

wl

k

tl

tl

d

/2

wl

tire

LuGre

J

wr

J

tr

k

tr

tr

d

/2

wr

D

i

f

f

e

r

e

n

t

i

a

l

d

M

F

xl

F

xr

J

e

e

c

J

g

F

n

k

dmf

dmf

J

dmf

tire

LuGre

Assuming right-left symmetry

Ignoring DMF dynamics

Ignoring tire dynamics

Equivalent moment of inertia and

stiffness

P / 24

Simple Model for Control

J

tl

J

w

k

tl

tl

w

tire

LuGre

M

F

x

J

e

e

c

J

g

F

n

k

dmf

dmf

J

dmf

Assuming right-left symmetry

Ignoring DMF dynamics

Ignoring tire dynamics

Equivalent moment of inertia and

stiffness

P / 25

Simple Model for Control

J

tl

J

w

k

tl

tl

w

tire

LuGre

M

F

x

J

e

e

c

J

g

F

n

Assuming right-left symmetry

Ignoring DMF dynamics

Ignoring tire dynamics

Equivalent moment of inertia and

stiffness

P / 26

Simple Model for Control

J

tl

J

v

k

tl

tl

J

e

e

c

J

g

F

n

Assuming right-left symmetry

Ignoring DMF dynamics

Ignoring tire dynamics

Equivalent moment of inertia and

stiffness

P / 27

Simple Model for Control

J

v

k

tl

tl

J

e

e

c

J

g

F

n

Assuming right-left symmetry

Ignoring DMF dynamics

Ignoring tire dynamics

Equivalent moment of inertia

and stiffness

P / 28

Engagement problem

1. Synchronization

3. Avoid residual

Oscillations

(Comfort)

Engine

speed

Vehicle & Gearbox

speed

2. Avoid Engine Stall (safety)

4. Minimize the

Dissipated Energy

Slipping time

P / 29

Clutch Engagement:

No-Lurch condition (Glielmo SAE 2000):

Synchronization & Comfort

necessary conditions

Je

Je

J

v

Engine

Vehicle

P / 30

Synchronization & Comfort

conditions

Je

Je

J

g

Engine

Gearbox

J

v

Vehicle

Clutch Engagement:

No-Lurch condition (Glielmo SAE 2000):

Extended ideal synchronisation & comfort conditions:

P / 31

Problem:

Analytic Solution: Under the hypothesis of constant the TPBVP

has an analytic solution

Energy Minimization: Embedded in the optimization problem via

the weighting matrices

Optimal trajectory planning

Under:

P / 32

Weighting parameters choice

ensuring Safety

Engine Stall: A posteriori Search of Safe Trajectory as a function of

the weighting matrices, i.e.

Critical Speed

P / 33

Results (Simulation & Experiments)

Simulations

Standing start on a flat track

Experiments

Engine Speed

Engine Speed

Gearbox

Speed

Gearbox

Speed

RPM RPM

P / 34

Results (Experimental setup)

Clio II AMT

1.5 dCi 85hp

equipped with dSpace

Tests performed on the

track test at Renault

Lardy Technical Centre

(South of Paris)

Nov. 2005

P / 35

Experiments (Pietro in Action)

Italian

Start

Starting with

Optimal Control

Inside

P / 36

Summarizing

Issues:

Oscillation reduction below the human perception threshold,

Open-loop trajectories, implemented in closed-loop

Clutch Friction estimation

Applied to standing-start, but also useful for gear shifting

Clutch Synchronization assistance (CbW)

Outline

1. Introduction

Challenges

Product Evolution

Breakthroughs

2. Examples

Clutch Synchronization

Steer-by-Wire

3. Conclusions

P / 38

Trade-offs due to the introduction

of Distinctive Features

Possible solutions :

Hydraulic Power Steering + Electronic Pomp Assist

Electric Power Steering

Active Front Steering

Example: Advanced Power Steering System

Electric actuators

Steering

Assisted

Power Steering

PIGNON

Steering Gear

BIELLETTE

Variable force amplification

Variable gear ratio

Active safety systems

Packaging and Environmental constraints

P / 39

Trade-offs due to the introduction

of Distinctive Features

Solution 1: HPS + Electronic Pomp Assist

Constraints:

Cost

Constraint on power-train

packaging

Environmental

Active safety not easy

Side effects:

Pomp assistance

dimensioning and control

Increase of effective volume

Presence of fluid

No control of steering angle

ECU

P / 40

Trade-offs due to the introduction

of Distinctive Features

Solution 2: EPS

Constraints:

Constraint on power-train

packaging

No optimal customer benefit

Side effects:

Steering column

Separate Torque Feedback

(comfort) or Active Steering

(Safety) are not possible

Steering

PIGNON

Steering Gear

BIELLETTE

DC motor

P / 41

Trade-offs due to the introduction

of Distinctive Features

Solution 3: Active Front Steering (AFS)

Constraints:

Constraint on power-train

packaging

Trade off in customer features

(comfort and active safety) and

Cost

Side effects:

Increase of effective

volume

Passive or Active

Torque Feedback

and Active Safety

possible

P / 42

Trade-offs due to the introduction

of Distinctive Features

Breakthrough Solutions

Integrate a force assistance and a steering

devices

Steer-by-wire System

P / 43

Steer-by-Wire: Benefits

Steer-by-Wire benefits:

Steering columns disappears

Easy-to-package (left & right models)

Improves active vehicle control

P / 44

Steer-by-Wire: Technology

P / 45

Steer-by-Wire: Control Set-up

Components:

Steering column

Steering gear

Driver impedance

Tire/road impedance

Controller

P / 46

Control Specs:

Steering Comfort & Safety

Comfort (Transparency): Ability of minimizing the extent to

which the steer-by-wire system alters the sensation felt by the

driver,

Comfort (Steerability): Provide power amplification to the

Steering wheel to make it easy to steer,

Safety (Passivity): A passive system is inherently safer since it

does not generate energy, but only stores, dissipates and releases it

(Li & Horowitz 99).

E

H

P / 47

Control Specs: Alternatives

Comfort (Transparence, Steerability):

Separate Force/position scaling,

Hybrid formulation: impedance/admittance shaping

Impedance

Admittance

Nonlinear maps

Safety (Passivity):

Bilateral/Unilateral

Coupled/Uncoupled

Control alternatives:

Exact Matching

Approximate matching (Multi-criteria optimization)

P / 48

Idealizing Comfort:

Power Scaling

Power Scaling

Environment

Impedance

Separate Force/Position Scaling

Apparent

Impedance

Seen by

the Driver

Power Scaling

P / 49

Two port ideal

Impedance model

Idealizing Comfortcont.

Impedance (Admittance) Shaping

Hybrid Force/Position Specs

Admittance

Representation

Equivalent Admittance model

E

Apparent

Impedance

P / 50

Idealizing Comfortcont.

Nonlinear admittance

Two-Stage model from physics laws (structure)

Driver-perceived

performance:

Auto-alignment torque,

(virtual, or true)

Steering wheel friction

Torque amplification

(booster stage)

Hydraulic-like behavior

Speed vehicle dependency

Torque booster

Mechanics

Apparent

Admittance

P / 51

Idealizing Comfortcont.

Nonlinear admittance

Subjective Parameters Assessment

a-fastness

b-softness/hardness

(flow leakage)

c-amplification

Cmax-Saturation

b-dependency

c=f(a, Cmax)-dependency

Torque booster stage

P / 52

Enforcing Safety (linear setting)

Passivity

Uncoupled (Bilateral) Passivity

Passive

Apparent

Admittance

PROs:

very safe

Allows connection with

non-passive environments

CONs:

Conservative design

Power amplification

forbidden

P / 53

Enforcing Safety (linear setting)

PassivityCont.

PROs:

Less

conservative

CONs:

Knowledge of :

E, H

Coupled Unilateral Passivity

Coupled Bilateral Passivity

P / 54

Control Problem: Exact Matching

(Linear setting)

PROBLEM: find K(s) such that

Exact idealized comfort is meet,

The closed-loop apparent admittance results in one of the

selected passivity constraints:

Uncoupled bilateral passivity

Coupled bilateral passivity

Coupled unilateral passivity

Limitations: Solutions may not always exist.

Relaxation of this problem via optimization

P / 55

Control Problem: Approximated

Matching (Linear setting)

Problem 1: Uncoupled bilateral passivity

Matrix

Transformation

Non Convex Optimization Problem

P / 56

Control Problem: Approximated

Matching (Linear setting)

Problem 2: Coupled unilateral passivity

Convex Optimization Problem

Known

passive

operator

Apparent

Admittance

P / 57

Control Problem: Approximated

Matching (Robustness)

Problem 3: Coupled Bilateral passivity

Convex Multi-criteria Optimization Problem

is a sector bounded nonlinearity,

G

K

u

y

v

H

E

F

P / 58

Summarizing

Linear setting:

Model matching (Exact or approximate) is tractable,

Control Specs are somewhat limited

Nonlinear setting:

Richest specifications

Exact Model matching may not be tractable:

Real system dimension higher than model

Approximated Model matching (non linear optimization):

Outline

1. Introduction

Challenges

Product Evolution

Breakthroughs

2. Examples

Clutch Synchronization

Steer-by-Wire

Adaptive Cruise Control

3. Conclusions

P / 60

ACC: 3-Levels of Complexity

Front/Rear longitudinal

inter-vehicular control

+ Multi-lane control

+ infrastructure

exchange of information

& collaborative control.

P / 61

Some Data

The French National Observatory of Road Security has reported 90220

car accidents during the year 2003.

28% correspond to accidents resulting in rear-end collisions:

Causes of accidents:

Misestimated vehicular inter-distance

Badly adapted or insufficient braking

Approaching speed too high

Erroneous estimation of the road

conditions

Statistics:

55 % Drivers do not respect the minimum 2 sec safety time

25% Drivers do not respect the minimum 50 m safety distance

P / 62

Constant and similar braking capacity for both vehicles

Does not account for any comfort criteria.

Example of safety distance :

Constant Time-Headway rule

Relative braking

distance

Reaction time

distance

Threshold

distance

Newtonian motion equation

Stationary solution

P / 63

Typical Safety & Comfort Specs

Safety:

Constant time headway (Chien and Ioannou, 1992),

Variable time headway (Yanakiev and Kanellakopoulos, 1995),

Potential forces (Gerdes et. al., 2001).

Comfort:

Drivers behavior model (Persson et. al., 1999),

Human perception-based model (Fancher, et. al. 2001),

Design of braking and jerks profiles (Yi & Chung, 2001).

New Specs Combining Safety & Comfort are needed

P / 64

Inter-distance Vehicle Policy

Desired Properties:

Avoid collisions (safety)

Limit Jerk (comfort)

Respect Braking Capabilities

Leader

Free zone Collision zone

Follower

Safe zone

P / 65

Inter-distance Vehicle Policycont.

Leader

Free zone Collision zone

Follower

Safe zone

Given:

Maximum velocity,

deceleration & Jerk:

Minimum inter-distance

Design goals:

Define the Safe zone

Made the orange zone

invariant

Respecting the velocity,

deceleration & jerk

constraints

P / 66

Inspiration from Compliant Contact Models

Genesis:

Hertz 1881

Marhefka & Orin, 1996

Nonlinear damping

Integral curves of

P / 67

Family of Integral

curves as a function of

the paramer c

Problem Formulation

c* = 0.025

c* = 0.025

c* = 0.025

P / 68

Stop & Go Scenario

Italian Driver

Model

P / 69

Comparison with the constant

time-headway policy

Advantages:

Less conservative safe distance

Better matches the drivers average inter-vehicular distance at low

velocities.

P / 70

Control Scheme: Model Tracking

Inter-distance

Dynamics

d

w

Reference Model

d

^

u d

r

Inter-distance

Controller

d

Warning Mode

+

+

PARAMETERS:

safety (anti-collision)

comfort (jerks)

vehicle

characteristics

road conditions

traffic conditions, etc.

Sensors

P / 71

Jerks

Experimental Results:

Hard stop (ARCOS-Program)

Thanks to : Axel Von-arnim (LCPC) & Cyril Royre (LIVIC)

Test Track : Satory (France).

Vehicle : LOLA (LIVIC-LCPC-INRETS)

Inter-distance

P / 72

Summarizing

Nonlinear dampers:

More flexibility (integral curve shapes)

Continuous acceleration & Jerks (comfort assessment)

On-line adaptability:

Road & traffic conditions

Model is not a true exosystem:

Model is driven by leader vehicle acceleration,

Provides bounded solutions (integral curves)

Warning mode:

Use the model to provide driver assistance only

Switching Controllers are welcomed:

Switching between different sensors.

Aiming at...

More and more applications

with subjective Specs

Complexity limits reached.

Industry needs:

further tools and unified

views for relating

subjective & control

specs

tools and general views

for components

integration, i.e. all-by-

wire

Conclusions

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 3406E Engine: Electrical Circuit DiagramDocument8 pages3406E Engine: Electrical Circuit DiagramPhil B.50% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BOSCH FUEL INJECTOR List-Fuel Injectors PDFDocument47 pagesBOSCH FUEL INJECTOR List-Fuel Injectors PDFEd Morales100% (3)

- Sukhoi-33: Flight ManualDocument19 pagesSukhoi-33: Flight ManualMarcio N AmaralNo ratings yet

- Catalogue Sheet Nortec - EVO - ENG - 1.1 PDFDocument2 pagesCatalogue Sheet Nortec - EVO - ENG - 1.1 PDFbojan_eNo ratings yet

- 5-1. Mechatronics SystemDocument144 pages5-1. Mechatronics SystemApo ghasan Al shargapiNo ratings yet

- BMW Engines m50.Htm4 m50Document3 pagesBMW Engines m50.Htm4 m50Daniel Neves PereiraNo ratings yet

- Elon Musk SpaceXDocument5 pagesElon Musk SpaceXSamiullah Awan100% (2)

- 052CDMDS20210320Document46 pages052CDMDS20210320mahmuda levianiNo ratings yet

- Suspension - Spring Preload&Race SagDocument4 pagesSuspension - Spring Preload&Race Sagmakazica100% (2)

- YamahaPartsG9 AGDocument49 pagesYamahaPartsG9 AGroleskyNo ratings yet

- Unmatched Boldness. Unrivaled Dominance.: Presenting The Imposing New Innova CrystaDocument8 pagesUnmatched Boldness. Unrivaled Dominance.: Presenting The Imposing New Innova CrystaSatya JiNo ratings yet

- Audi A1 2012Document6 pagesAudi A1 2012carlosNo ratings yet

- Nordic Tug 26 SpecificationsDocument3 pagesNordic Tug 26 SpecificationsWilde YachtsNo ratings yet

- DPWH Region Iva Aadt (2018-2022)Document50 pagesDPWH Region Iva Aadt (2018-2022)frtanay12No ratings yet

- Man Hydrodrive: More Traction. More Exibility. More SafetyDocument12 pagesMan Hydrodrive: More Traction. More Exibility. More SafetyDanielNo ratings yet

- PROJECTDocument11 pagesPROJECTAkash singhNo ratings yet

- TM 9-2330-271-14PDocument444 pagesTM 9-2330-271-14PAdvocateNo ratings yet

- CQD20-XD2-JI Operation and MaintenanceDocument106 pagesCQD20-XD2-JI Operation and MaintenanceEnrique GarcíaNo ratings yet

- D350 607 2 RevDDocument20 pagesD350 607 2 RevDBruno Alonso PachecoNo ratings yet

- Ship Machineries: by Group 2Document54 pagesShip Machineries: by Group 2Wilfred Joseph T. Casas100% (1)

- ItM 2009 ENDocument415 pagesItM 2009 ENjorge Angel LopeNo ratings yet

- Hyundai Accent 2002Document48 pagesHyundai Accent 2002jaroNo ratings yet

- Stol CH 701 Control Systems SchematicDocument1 pageStol CH 701 Control Systems SchematicTomas Ortiz Laverde100% (2)

- Clark SM 555 Service ManualDocument20 pagesClark SM 555 Service ManualTimothy100% (55)

- Boeing 727 Tech DetailsDocument6 pagesBoeing 727 Tech DetailsPourya100% (1)

- IC EngineDocument20 pagesIC Enginemebratu AssefaNo ratings yet

- Yamaha XS650 XS 650 Service Repair ManualDocument213 pagesYamaha XS650 XS 650 Service Repair Manualandy miller100% (4)

- Body and Accessory Fitment Guide 04 - 2020Document30 pagesBody and Accessory Fitment Guide 04 - 2020meduzaNo ratings yet

- 2 Wheel Drive Hybrid Motorcycle Final PresentationDocument21 pages2 Wheel Drive Hybrid Motorcycle Final PresentationJOHN JOSEPHNo ratings yet

- Wa0033.Document1 pageWa0033.LupitaNo ratings yet