Professional Documents

Culture Documents

Centrifugal Compressor - Production Manager Standing Order - Increase Gas Rate Immediately To Get More Money

Centrifugal Compressor - Production Manager Standing Order - Increase Gas Rate Immediately To Get More Money

Uploaded by

lvicencioa0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

Centrifugal Compressor - Production Manager Standing Order_Increase Gas Rate Immediately to Get More Money

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesCentrifugal Compressor - Production Manager Standing Order - Increase Gas Rate Immediately To Get More Money

Centrifugal Compressor - Production Manager Standing Order - Increase Gas Rate Immediately To Get More Money

Uploaded by

lvicencioaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Centrifugal Compressor Production Manager Standing Order : Increase Gas Rate

Immediately to Get More Money!!

Cahyo Hardo, Premier Oil Natuna Sea BV - Sr. Site Process Engineer

While a company facing a challenge to produce more gas, operation is requested to increase gas rate with the existing facilities. The first

common question is: Can our centrifugal compressor deliver more gas than current operation?

Do not rush to answer that question! We must do carefully verify what effect if we have to increase compressor rate. Suppose gas wells are

still strong enough to against current setting of suction compressor. So, the simple thing to increase the capacity of the compressor is raise up

the suction pressure of the compressor. The first step is, we have to review the present power available of the compressor. Do we still have

power spare to compress more gas? If yes, second question may be: How far current operation close to T5 of turbine? Sometimes even

though power is still available, T5 is close with shutdown setting limit. It means you must do something, detergent wash the turbine is a

common solution.

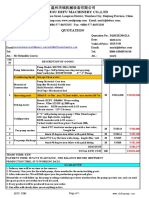

Figure above represents a common configuration of centrifugal compressor installation.

TO DELIVERY

POINT

ANTI SURGE

VALVE

COMPRESSOR

COOLER

GAS

FEED

PCV-1

LCV-2

GAS

TURBINE

SET@

XXXPSIG

SPEED

CONTROL

TO FLARE

BLOWDOWN

VALVE

PSV-2

PSV-3

PT

PSHH

LCV-1

PSV-1

SEPARATOR

Increasing the setting pressure of suction side does increasing suction pressure of the compressor. According to the gas rules, by increasing

the pressure, actual volume of the gas decreases, means the compressor will compress more actual volume of gases. Refer to the compressor

equation, increasing suction pressure, which is one of denominators of the equation, causes less power requirement for the same rate at lower

suction pressure, or for the same power input to the compressor, the gas compressed increase. If power input to compressor increased again,

more gas compressed.

Increasing setting point on PT automatically will decrease compressor speed so rate decreases. So how increasing the suction pressure can

increase the gas rate? If the condition happened, it means the gas flow to the compressor is not enough! Remember that gas rates from wells

are still slightly reduced because we increase the resistance at suction compressor. The only way to increase the speed is, increase the gas

rate. This is the time to more open choke valve or possibly, open stand-by wells. This is our manager want!

In papers, it seems good, but there are still some considerations to be aware. Increasing PT setting should be communicated to entire system

of centrifugal compressor. The centrifugal compressor systems are not just compressor and driver, but also cover suction scrubber, and inlet

separator, and off course, process/safety instrumentation (e.g.: PCV, LCV, PSV, etc). Lets explore more deeply.

Increasing the setting point sometime gives the new number too close with the PCV flare (PCV-1). If it is, so increase the setting of PCV. Okay,

but how if the new setting of the PCV is too close with PSHH setting. Then we increase the setting of the PSHH. How if the new setting of

PSHH also is too close with PSV of inlet separator (PSV-1)? Then we increase the setting. Wait the minute! We touch safety issue here. We

cant set the PSV higher than 1.1 of MAWPs separator as per API RP-520, except the PSV is fire-based. (Figure before showed PSV-1 sized

based on block discharge case). Sometimes, even though the PSVs new setting still acceptable, we may have to buy a new spring for the

PSV. Be prepared

Lets decide on that case, our PSV setting is far enough from PSHH so still acceptable. What we should worries now? I think is settling out

pressure of the compressor. What is that? It is the equilibrium pressure when compressor shutdown and anti-surge valve open. The

equilibrium pressure value is between suction and discharge pressure of the compressor. By increasing the suction pressure, settling out

pressure increases. What we should worry? Your setting pressure of PSV-2, located on suction side of compressor. Normally, this PSV is fire-

based and set at value, which is still far enough from settling out pressure. If you forgot to review this PSV, it could cause a problem by

frequently popping up during compressor shutdown.

All have been reviewed completely? I think yes, except if your systems have special features that need more consideration.

Can I increase the gas rate by reducing the setting of suction pressure of compressor? Off course. Do we need to consider another system

that may impact due to lowering the suction pressure? Off course. All details will be explained someday.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoDocument2 pagesTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1-6 Types of Pumps and FansDocument43 pages1-6 Types of Pumps and FansCirky NadleiNo ratings yet

- Air Compressor ProcedureDocument2 pagesAir Compressor ProcedurePerwez21No ratings yet

- Hydraulic Pump CalculationsDocument9 pagesHydraulic Pump CalculationsAlvin SmithNo ratings yet

- Danfoss Price ListDocument44 pagesDanfoss Price ListAhmad Hassanain100% (1)

- Francis TurbineDocument22 pagesFrancis TurbineHASSAN ARSHADNo ratings yet

- Technical Manual Diaphragm Expansion VesselsDocument40 pagesTechnical Manual Diaphragm Expansion VesselsjosecevmspNo ratings yet

- Biffi Hydraulic ActuatorsDocument28 pagesBiffi Hydraulic ActuatorsMuthu Kumar R100% (1)

- Class 1CB2S01 (Pip PN01CB2S01 - 2005)Document6 pagesClass 1CB2S01 (Pip PN01CB2S01 - 2005)Zvonko BešlićNo ratings yet

- The Value of Size ReductionDocument5 pagesThe Value of Size ReductionlvicencioaNo ratings yet

- The Solubility RulesDocument1 pageThe Solubility RuleslvicencioaNo ratings yet

- Attachment 5.3 Commissioning Steps - FinalDocument1 pageAttachment 5.3 Commissioning Steps - FinallvicencioaNo ratings yet

- JIP Compressor FoulingDocument3 pagesJIP Compressor FoulinglvicencioaNo ratings yet

- Division13 SpecialConstructionDocument14 pagesDivision13 SpecialConstructionbeo beoNo ratings yet

- TH4-Mobile Diesel Engine Pump-DeFU20230421ADocument3 pagesTH4-Mobile Diesel Engine Pump-DeFU20230421Aluisdavid01No ratings yet

- Fuel System of CI EngineDocument23 pagesFuel System of CI EngineRohit NewarNo ratings yet

- NTL 2011-n11Document9 pagesNTL 2011-n11ger80No ratings yet

- Attachment-A1 - SBB ValvesDocument3 pagesAttachment-A1 - SBB Valvesbsnegi111No ratings yet

- ERHA EXECUTIVE SUMMARY - April 24, 2014Document3 pagesERHA EXECUTIVE SUMMARY - April 24, 2014ABUBAKARNo ratings yet

- Vane Cat 2005Document62 pagesVane Cat 2005omni_partsNo ratings yet

- 10 819 Astro Express LF Valve IODocument2 pages10 819 Astro Express LF Valve IOHary FadlyNo ratings yet

- Series: Gas/Pneumatic Driven Injection PumpDocument4 pagesSeries: Gas/Pneumatic Driven Injection PumpHashemAliHashemNo ratings yet

- Gas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationDocument6 pagesGas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationscribdkhatnNo ratings yet

- TarikDocument33 pagesTarikRy-zal channel100% (1)

- EIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsDocument17 pagesEIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsPravinPMKoolNo ratings yet

- Haskel Liquid Pumps v16Document24 pagesHaskel Liquid Pumps v16Carl Moritz50% (2)

- Parker Product GuidesectionDocument51 pagesParker Product GuidesectionNicolas RibeiroNo ratings yet

- RFI-3410 - Daily Fit Up Inspection Report-OKDocument92 pagesRFI-3410 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- SPX DC PowerDocument15 pagesSPX DC PowerCentral HydraulicsNo ratings yet

- Fluid FlowDocument15 pagesFluid Flowdekra abdoNo ratings yet

- Orifice Test ExperimentDocument4 pagesOrifice Test ExperimentEmmanuel MulayiNo ratings yet

- Pages From GS3 Parts Catalog V3.4 ColorDocument7 pagesPages From GS3 Parts Catalog V3.4 ColoryossiatNo ratings yet

- Fluid Mechanics LaboratoryDocument3 pagesFluid Mechanics LaboratoryWira LiantoNo ratings yet