Professional Documents

Culture Documents

Case For Advanced HRG

Case For Advanced HRG

Uploaded by

rancam070 ratings0% found this document useful (0 votes)

3 views4 pagesHigh Resistance Grounding design.

Original Title

Case for Advanced HRG

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHigh Resistance Grounding design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views4 pagesCase For Advanced HRG

Case For Advanced HRG

Uploaded by

rancam07High Resistance Grounding design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

I -Gard Advanced HRG Whi tepaper 1

The Case for Advanced High Resistance Grounding

Andrew Cochran

December 14, 2013

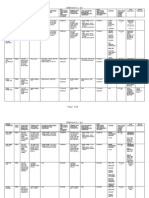

The decision on which grounding system to employ has a direct and quantifiable impact on electrical safety

and reliability. As the table below indicates, High Resistance Grounding is the superior choice as it provides

process continuity even under a single fault condition, it limits destructive transient over-voltages, it

empowers the user to quickly and safely locate the fault and it reduces the arc flash hazard.

Productivity Impact

System Type

Ungrounded

System

Solidly

Grounded

System

Low

Resistance

Grounded

System

High

Resistance

Grounded

System

Equipment

Damage

Overvoltages Severe None Limited Limited

Over current

Damage at point of

fault

Unknown Severe Minimal None

Maintenance Costs High Reasonable Reasonable Low

Downtime

Continuous

Operation with

Ground Fault

Possible; not

recommended

Not Possible Not Possible Ideal

Relay Coordination

(Equipment

Tripped, Ease of

Fault Location)

Difficult Difficult Good Excellent

Personnel Safety to Personnel Poor Poor Reasonable Excellent

High Resistance Grounding provides all the continuity benefits of an ungrounded system without the

drawbacks of transient over-voltages and inability to locate the ground fault.

IEEE 242-1986 Recommended Practice for Protection and

Coordination of Industrial and Commercial Power Systems, Clause

7.2.5 compares the two technology options:

Ungrounded systems offer no advantage over high-resistance

grounded systems in terms of continuity of service and have the

disadvantages of transient over-voltages, locating the first fault and

burn-downs from a second ground fault. For these reasons, they

are being used less frequently today than high-resistance grounded

systems, and existing ungrounded systems are often converted to

high-resistance grounded systems by resistance grounding the

neutral. Figure 1: Ungrounded System burn-down damage.

I -Gard Advanced HRG Whi tepaper 2

High Resistance Grounding like Solidly Grounded controls transient over-voltages but

significantly reduces the likelihood of an arc flash as fault current is limited to a low and

safe level that inhibits an arc from re-striking.

In the IEEE 141-1993, Recommended Practice for Electrical Power Distribution for Industrial

Plants section 7.2.4, it states that, The solidly grounded system has the highest probability of

escalating into a phase-to-phase or three-phase arcing fault, particularly for the 480 and 600V systems. A safety

hazard exists for solidly grounded systems from the severe flash, arc burning, and blast hazard from any phase-

to-ground fault.

There is a significant difference between basic HRG technology, industry standard HRG and advanced HRG.

The latter addresses many, if not all, of the concerns associated with HRG as a technology and the end result is

a safer and more reliable electrical distribution system.

Basic High Resistance Grounding is a simple resistor added to an

ungrounded system that limits the fault current and controls the

transient over-voltages. It is a simple and economical upgrade to

any ungrounded system. However, the simplicity of the solution,

limiting the fault through a basic resistor, also limits the solution

the inability to find the ground fault and to take corrective action.

While this is the simplest and most economical option it is rarely

utilized.

The industry standard HRG adds pulsing capability to the basic

option and it is this feature that empowers the user to find the

location of the ground fault and to take corrective action at a

suitable time.

Figure 2: Arc flash on a Solidly Grounded System.

Despite the obvious benefits of High Resistance Grounding its application has not yet become widespread due

to operational concerns that can easily be addressed. Most common excuses for not choosing High Resistance

Grounding are:

The need to service line-to-neutral loads

Concern over intermittent ground faults

Loss of neutral path

Leaving a ground fault on the system indefinitely

Concern over a second ground fault before the first fault has been cleared

Line-to-Neutral Loads

It is prohibited to service line-to-neutral loads when using a high resistance grounding system but in most

industrial facilities the line-to-neutral loads are 15% or less of the total system load. The installation of a simple

isolation transformer would also enable the user to continue to service these loads, typically lighting, and yet still

receive the reliability and safety benefits of an HRG system.

Given that the solidly grounded system has the highest probability of being subjected to an arc flash and given

that the magnitude of the arc flash is directly proportional to the available fault current, employing a smaller

transformer to supply only neutral loads reduces the arc flash potential and magnitude on the secondary side.

I -Gard Advanced HRG Whi tepaper 3

Intermittent Ground Faults

To find a ground fault there must be an active ground fault present on the

system. If the ground fault is intermittent or cyclical then it will be a challenge to

find. This is the major drawback with visual indication products such as ground

fault meters. If the found fault is active, the meter needle indicates its presence.

If the maintenance personnel are not present at the time, then no-one will know

there is an intermittent fault on the system.

The solution is upgrade to a relay that at a minimum has a latching indicator to

advise of an intermittent fault and has some data logging function that can be

analyzed to determine if the ground fault coincides with a particular piece of

electrical equipment cycling in the system.

Loss of Neutral Path

Neutral Grounding resistors limit the maximum fault current to a value which will not damage generating,

distribution or other associated equipment in the power system, yet allow sufficient flow of fault current to

operate protective relays to clear the fault. The neutral-to-ground path, which includes the resistor, wiring,

and connections, must be in good condition for an HRG system to work properly. Good working condition is

typically between 75 and 125% of desired resistance value.

When the desired resistance decreases below 75%, the system is trending toward a solidly grounded

system and as we know a solidly grounded system has the highest incident level of arc flash issues. When

the resistance surpasses 125%, the system is trending toward an ungrounded system and as we know

ungrounded systems are susceptible to transient over-voltages and burn-downs.

The solution is to monitor the neutral-to-ground path. When there is a change in resistance for whatever

reason, loose or improper connection, missing or compromised ground wire, foreign object etc. the neutral-

grounding resistor (NGR) monitor will detect the change and provide an alarm.

Although monitoring the resistor and providing an alarm for an

abnormal condition is only half of the solution, it is not sufficient

to have an alarm that a possibly dangerous trend is in process

without the means to provide protection if the resistor fails either

open or short. The full solution is a monitoring relay combined

with a parallel resistor circuit that provides fail-safe protection.

Should the integrity of either resistor path be compromised, the

second path continues to provide ground fault protection while

an alarm is raised.

I -Gard Advanced HRG Whi tepaper 4

Leaving a Ground Fault on the System Indefinitely

When there is a ground fault on a High Resistance Grounded system the un-faulted phase is subject to full

line-to-line voltage and there is a concern that this could lead to insulation degradation and a phase-to-

phase fault. The first line of defence in this regard is insulation ratings and typically 600V systems are

protected by 1000V rated cables and therefore there is no issue.

The second factor to consider is the time required to actually locate the ground

fault. With pulsing technology this is typically a matter of only a few hours. It is

worth noting that the more advanced HRG systems available today also include

phase and feeder indication. With this knowledge it not only takes significantly

less time to find the fault, but given that the search starts at the feeder level, it is a

safer option as the available fault current at the feeder level is much lower than at

the main branch, resulting in the incident energy level to be lower and more safe.

Another benefit with advanced HRG systems is feeder time delay trip functionality. The

user can select the timeframe anywhere from 1 minute to 99 hours that they are willing

to accept the process operating with an active ground fault on the system before the

want to isolate the faulted feeder. In this case, only the faulted feeder is isolated, not the

entire system and this functionality ensures that maintenance personnel must locate the

fault within the timeframe mandated or the feeder will isolate.

Concern over a Second Ground Fault before the First Fault is Cleared

With the basic or industry standard HRG technology, a second ground fault on a different phase from the

first will result in a phase-to-phase fault and the over-current protection on the main circuit will trip and the

entire system will isolate.

With advanced HRG technology there is the option to pre-select up to 50 feeders with priority from the

lowest to highest (16 different settings are available) so that in the event of a second ground fault the least

important feeder will trip within 100ms. This allows process continuity of the more important feeder. With this

feature the most important process in your facility will remain operational at all times.

High Resistance Grounding provides the highest level of reliability and safety when comparing system

grounding options. Advanced HRG technology effectively addresses the concerns and excuses typically

brought forth as justification for not specifying this option. With Advanced HRG technology, the user receives

all of the safety benefits, free from transients, reduction in arc flash hazard, all of the reliability benefits in

terms of process continuity and the added benefits of locating the fault faster and safer. The user also

receives the isolation faults in a pre-determined timeframe, if they are not cleared and of continuing to

operate their most important processes even under second ground fault conditions.

This is a clear case to upgrade from Ungrounded or Solidly Grounded to High Resistance Grounded and just

as clear of a case to make the jump to Advanced High Resistance Grounding.

---

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- L3000DTDocument311 pagesL3000DTpongsinpunNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 5000 HR TestDocument1 page5000 HR TestmrhomNo ratings yet

- Substation Automation Systems SLD PM5-0403-WBX - Final - PPT (Compatibility Mode) - FileDocument82 pagesSubstation Automation Systems SLD PM5-0403-WBX - Final - PPT (Compatibility Mode) - FilemrhomNo ratings yet

- 24kV Distribution TransformerDocument37 pages24kV Distribution TransformermrhomNo ratings yet

- Tested Transformer (kVA) %Z Absorbed Power at Short Circuit (Kva/%z) 0.3 X Absorb Power 1.3 X Absorb PowerDocument2 pagesTested Transformer (kVA) %Z Absorbed Power at Short Circuit (Kva/%z) 0.3 X Absorb Power 1.3 X Absorb PowermrhomNo ratings yet

- Mea MapsDocument1 pageMea MapsmrhomNo ratings yet

- Ip 68Document1 pageIp 68mrhomNo ratings yet

- Distribution TRDocument37 pagesDistribution TRmrhomNo ratings yet

- Short Circuit CalculationDocument8 pagesShort Circuit CalculationmrhomNo ratings yet

- Questionnaires To MEA: Questions or TopicsDocument2 pagesQuestionnaires To MEA: Questions or TopicsmrhomNo ratings yet

- Technical Report:: Electrical Power System: Dr. Pariya CumperayotDocument37 pagesTechnical Report:: Electrical Power System: Dr. Pariya CumperayotmrhomNo ratings yet

- 115 KV GIS RequirementsDocument3 pages115 KV GIS RequirementsmrhomNo ratings yet

- ADDAX Solutions GD Dvs2Document28 pagesADDAX Solutions GD Dvs2mrhom100% (1)

- Training Calendar: Empower Your FutureDocument6 pagesTraining Calendar: Empower Your FuturemrhomNo ratings yet

- Power System ProtectionDocument17 pagesPower System ProtectionmrhomNo ratings yet

- EE00300CDocument247 pagesEE00300CjorgedwinNo ratings yet

- Fastener BrochureDocument8 pagesFastener BrochureSugumarNo ratings yet

- Spare Parts Catalogue Type VM32Document288 pagesSpare Parts Catalogue Type VM32Tamer Elsayed100% (3)

- SamplesDocument5 pagesSamplesZe LotfiNo ratings yet

- EN ACS880-37 HW Man B A4Document258 pagesEN ACS880-37 HW Man B A4zain shafiqNo ratings yet

- ZENNER ISO9001 - Zenner - EnglischDocument2 pagesZENNER ISO9001 - Zenner - EnglischzaidNo ratings yet

- Datasheet Limit SwitchDocument21 pagesDatasheet Limit SwitchMuhammad Nasrudin LatiefNo ratings yet

- FusesDocument8 pagesFusesLugo Aldair Cobeñas PereyraNo ratings yet

- Hangman DocumentaryDocument8 pagesHangman DocumentaryChinmayee Gullapalli0% (2)

- C, C++ and JAVA: The Magic of Computer Programming LanguageDocument3 pagesC, C++ and JAVA: The Magic of Computer Programming LanguageInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Definition of Information, Data Vs InformationDocument21 pagesDefinition of Information, Data Vs InformationVineetSharmaNo ratings yet

- 2006trans13 CDocument26 pages2006trans13 Ceurospeed2No ratings yet

- Ficha Ténica Software Balanceo Bently NevadaDocument5 pagesFicha Ténica Software Balanceo Bently NevadaCAGERIGONo ratings yet

- 1.) Actually Who Uses AS400 Servers?Document3 pages1.) Actually Who Uses AS400 Servers?aviNo ratings yet

- RP-29FA40 Service Manual FADocument57 pagesRP-29FA40 Service Manual FAJorge Fernando de TivantaNo ratings yet

- Vidya GaemsDocument33 pagesVidya GaemspimpolioNo ratings yet

- Vtu Ece Schemes RejinpaulDocument10 pagesVtu Ece Schemes RejinpaulMatthew BattleNo ratings yet

- The Difference Between The Internet and World Wide WebDocument3 pagesThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- Broadband PPT Presentation MTNL BSNLDocument35 pagesBroadband PPT Presentation MTNL BSNLtechcare123No ratings yet

- Sagem ErrorsDocument4 pagesSagem ErrorsmilitaryhistoryNo ratings yet

- Reconfigurable Computing ES ZG554 Session 1: BITS PilaniDocument18 pagesReconfigurable Computing ES ZG554 Session 1: BITS PilaniroykvincentNo ratings yet

- Abrites J2534 Passthru Driver User ManualDocument37 pagesAbrites J2534 Passthru Driver User ManualRalph WamaeNo ratings yet

- UNIT-5: 1: Explain About Storage Oscilloscope With Block Diagram?Document13 pagesUNIT-5: 1: Explain About Storage Oscilloscope With Block Diagram?Sumarani KpNo ratings yet

- System Imaging and SW Update Admin v10.6Document102 pagesSystem Imaging and SW Update Admin v10.6tseiple7No ratings yet

- Current Transformers (CTS)Document34 pagesCurrent Transformers (CTS)Don ThanadonNo ratings yet

- VERITAS Storage Foundation 5.0 For Linux - FundamentalsDocument400 pagesVERITAS Storage Foundation 5.0 For Linux - FundamentalsMaria Ghazalia CameroonNo ratings yet

- Steps For Handling Page Fault - Easy NotesDocument4 pagesSteps For Handling Page Fault - Easy NotesanuNo ratings yet

- Ponyprog Circuit For AVR& PIC16F84Document6 pagesPonyprog Circuit For AVR& PIC16F84tiensinh1No ratings yet