Professional Documents

Culture Documents

Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data Sheet

Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data Sheet

Uploaded by

kskr_440 ratings0% found this document useful (0 votes)

12 views4 pagesdehumidifier

Original Title

bry air

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdehumidifier

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views4 pagesCompact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data Sheet

Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data Sheet

Uploaded by

kskr_44dehumidifier

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

BRY-AIR (ASIA) PVT. LTD.

20, Rajpur Road, Delhi 110054

PHONE : 91-11-23906666 FAX: 91-11-23906600

E-MAIL: enquire@pahwa.com, Web site: www.bryair.com

FEATURE HIGHLIGHTS

High efficiency and reliability Easy to operate

* Certifiied as per standard ENISO12100-1:2003, * Suitable for continuous operation

EN ISO12100-2:2003,EN602041:1997 * Auto / manual selector switch.

* A totally self contained unit * Power on, heater on and fault status indications

* CNC fabricated unit(s) with powder coated finish * Independent blower and motor for each airflow

* Rotor media has high performance metal silicates (Process & Reactivation)

synthesized in situ. * Volume control damper for both (Process & Reactivation)

* Rotor incorporates robust internal structure with stainless air flow

steel perimeter flange for industrial quality, durability and Easy to install

easy serviceability. * Several mounting and installation options

* Rotor perimeter flange extends media and seal life * Small footprints; low volume/weight per CMH.

* Edge hard face coating on rotor ensures long life and Easy to maintain

good sealing for media and seals. * Quick and easy to service

* Rotor is non-flammable with organics <2%. * Rotor is water washable

* Process and reactivation air flow sectors are insulated Options

Necessary control and safeties * Humidity control through humidistat on/off

* Differential air pressure switch for providing react air flow. * Stainless steel construction

* High temperature safety thermostat cutout.

* Reactivation cool down safety device.

* Electrical interlocking of fan motors, heaters and rotor drive.

* Unique PTFE bonded bulb seal design; minimized air leakage

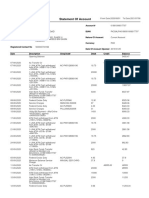

COMPACT DEHUMIDIFIER - FFB SPECIFICATION

MODEL PROCESS REACT. APPROX.

ESP ESP WEIGHT

(Pa.) (Pa.) Kg.

FFB170 150 100 63

FFB300 150 100 72

FFB600 200 150 101

FFB1000 200 150 139

FFB1500 200 150 178

FFB2000 200 150 187

* Note:- Other voltage available are 200/220/240/380/440/460 VAC, 1Ph/3Ph, 50/60 Hz

Document No. :D0004_11

Dated : J une 8, 2007

415 /3/ 50

230 /1/ 50

415 /3/ 50

415 /3/ 50

415 /3/ 50

POWER *

REQD.

(v//Hz.)

230 /1/ 50

1.5

REACT.

AIR FLOW

CMH

57

100

200

333

500

667

0.1

0.37

0.75

1.5

KW

MOTOR

REACT.

0.75

0.37

0.1

0.1

REACT.

KW

HEATER

12

7.2

3.6

2.3

18

24

0.75

0.75 2000

300

600

1000

1500

170

PROCESS

MOTOR

KW CMH

PROCESS

AIR FLOW

0.1

ALL DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 1 of 4

COMPACT DEHUMIDIFIER

FFB WITH HIGH PERFORMANCE, METAL SILICATE FLUTED

DESICCANT SYNTHESISED ROTOR

FLUTED FLAT BED - FFB SERIES

TECHNICAL

DATA SHEET

Bulletin

Effective

Supercedes

: BAA: D0004_11

: June 08,2007

: BAA: D0004_10

July 26,2006

A B C D E F G H H1 J JJ J1 K K1 L L1 w O P Q R S S1 T T1 U U1 x

FFB-170 676 470 390 146 105 228 225 152 190 112 0 96 120 175 77 93 0 110 85 230 160 118 145 120 175 77 93 0

FFB-300 736 540 445 165 115 237 265 208 190 170 0 124 120 175 98 93 0 110 85 237 170 118 145 120 175 98 93 0

FFB-600 886 630 494 195 135 300 275 264 240 226 0 160 170 225 98 128 0 142 85 300 218 182 145 170 225 98 128 0

FFB-1000 1044 730 555 220 145 365 285 320 290 280 0 208 220 220 124 150 27.5 212 125 365 265 255 225 220 220 124 150 27.5

FFB-1500 1204 890 585 250 145 375 308 376 290 170 170 208 220 220 135 150 27.5 212 125 375 265 325 225 220 220 135 150 27.5

FFB-2000 1204 880 629 250 145 375 344 376 290 170 170 208 220 220 135 163 27.5 212 125 375 255 325 225 220 220 135 150 27.5

Note : All dimensions in mm.

Document No. :D0004_11

Dated : June 08 ,2007

DIMENSIONAL DATA & DUCT CONNECTION (mm)

MODEL

UNIT

DIMENSION

DATA

(mm)

OUTLET

CONNECTION

INLET

CONNECTION

PROCESS DUCT CONNECTION (mm)

OUTLET

CONNECTION (mm)

INLET CONNECTION

150

Page 2 of 4

ALL DATA SUBJECT TO CHANGE WITHOUT NOTICE

200

200

200

V

100

CONNECTION

100

DIA.

HOSE

REACTIVATION DUCT CONNECTION (mm)

W

S

1

J

1 H

1

E

D

V

V

W

50

1

3

8

/

1

0

3

5

8

/

2

3

60 TYP.

T X

X

T

1

K

K

1

V

V

ELECTRICAL SERVICES ACCESS

PROVIDE MIN400 CLEARANCE

PERFORMANCE CHART

NOMINAL PROCESS AIR FLOW

PROCESS INLET AIR MOISTURE CONTENT wPI(g/kg)

PRESSURE DROP CHART

Model FFB-2000

% NOMINAL AIR FLOW

Document No. :D0004_11

Dated : June 08 ,2007 Page 3 of 4

ALL DATA SUBJECT TO CHANGE WITHOUT NOTICE

P

R

E

S

S

U

R

E

D

R

O

P

D

E

L

T

A

P

(

p

r

o

c

e

s

s

)

m

m

W

.

C

.

Example :-

P

R

O

C

E

S

S

O

U

T

L

E

T

A

I

R

M

O

I

S

T

U

R

E

C

O

N

T

E

N

T

w

P

O

(

g

/

k

g

)

Process air volume = 1600 m

3

/h

Air volume = 80%

DP (Process) = 8.4 mm w.c.

Chart data :-

Process outlet w PO = 5g/kg,

Process outlet T PO. = 46.5C

P

R

O

C

E

S

S

O

U

T

L

E

T

A

I

R

D

B

T

E

M

P

E

R

A

T

U

R

E

T

P

O

(

O

C

)

Process inlet w PI = 12g/kg,

Process inlet T PI. = 20C

Example :-

Conditions:

60

55

50

45

40

35

30

6

4

0

18 16 14 12 10 8

18

16

14

12

35C

30C

25

25C

35C

25C

30C

2

20C

20C

15C

10C

35C

15C

25C

30C

10C

15C

20C

4 2

10C

6 4 2 0

1

0.5

0

10

1.5

120% 80% 60% 50% 70% 100% 90% 110%

FF

B

-170

F

F

B

-3

0

0

T

h

ru

1

5

0

0

F

F

B

-

2

0

0

0

0

5

10

15

High performance metal silicate

High performance metal silicate (High RH)

High performance molecular sieve (Low RH)

High capacity metallic mesh filter

External box fitted with EU5 / filter

External box fitted with EU7 / filter

Higher static fan

High capacity metallic mesh filter

External box fitted with EU5 / filter

External box fitted with EU7 / filter

Higher static fan

Electric reactivation

External box fitted with steam reactivation

Cold rolled powder coated steel

Stainless steel

Single stage On/Off humidstat

Double stage On/Off humidstat

Proportional humidity sensor with SSR

Digital display panel

Document No. :D0004_11

Dated : June 08 ,2007

FAN PERFORMANCE CHART

Page 4 of 4

AIR FLOW m

3

/h

ALL DATA SUBJECT TO CHANGE WITHOUT NOTICE

FEATURE OVERVIEW

Items

Control :

The fan performance curve are for inlet conditions at 20

C, density 1.2kg/m

3

Standard Optional

S

T

A

T

I

C

P

R

E

S

S

U

R

E

(

P

a

)

Rotor :

Process :

Reactivation :

Energy :

Construction :

0

0

0

2

B

F

F ,

0 0 5

1 -

B F F

F

F

B

-

1

0

0

0

F

F

B

-

6

0

0

F

F

B

-

3

0

0

F

F

B

-

1

7

0

0

0

100

200

300

400

500

600

700

800

500 1000 1500 2000 2500 3000

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 'Account StatementDocument11 pages'Account StatementSikander Qazi100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ports and Marines FacilitiesDocument36 pagesPorts and Marines Facilities허윤호No ratings yet

- Methods of DehumidificationDocument4 pagesMethods of Dehumidificationprashant_mahitkar4532100% (3)

- FFB BrochureDocument4 pagesFFB Brochureprashant_mahitkar4532No ratings yet

- Bry Air QuestionarysectionDocument7 pagesBry Air Questionarysectionprashant_mahitkar4532No ratings yet

- PipingDocument9 pagesPipingannanambi100% (2)

- Heren Requain (Noble Houses of Gondor)Document25 pagesHeren Requain (Noble Houses of Gondor)RojasNo ratings yet

- 5 Great Anthropologists of India and Their Contributions in The Field of AnthropologyDocument5 pages5 Great Anthropologists of India and Their Contributions in The Field of AnthropologyVersha BansalNo ratings yet

- Chapter 1-3Document24 pagesChapter 1-3Gemar EstrellaNo ratings yet

- 2G OptimizationDocument35 pages2G OptimizationHarsha AzadNo ratings yet

- Pioneer VSX 417Document52 pagesPioneer VSX 417cristakeNo ratings yet

- IFB Agro AR-2021-22 (Full) Latest Copy On 23-07-2022Document184 pagesIFB Agro AR-2021-22 (Full) Latest Copy On 23-07-2022Ahmed KhanNo ratings yet

- PV Elite Training-MAWP Reduction PV EliteDocument8 pagesPV Elite Training-MAWP Reduction PV EliterakicbgNo ratings yet

- Education Priorities of KP (EPKP) SDG-4 (TDEA-FAFEN)Document22 pagesEducation Priorities of KP (EPKP) SDG-4 (TDEA-FAFEN)waqaNo ratings yet

- Catalogue GS Series Pump1Document26 pagesCatalogue GS Series Pump1Yohanes KrisNo ratings yet

- SKMT Tot For Ydos-2023-ProgramDocument1 pageSKMT Tot For Ydos-2023-ProgramCrafty PsycheNo ratings yet

- HarmonesDocument6 pagesHarmonesbaskarNo ratings yet

- BS en 61232-1997Document18 pagesBS en 61232-1997narinderNo ratings yet

- Riverboat CasinosDocument4 pagesRiverboat CasinosAngela BrownNo ratings yet

- All 14607Document23 pagesAll 14607davian wijayaNo ratings yet

- SDR ProjectDocument16 pagesSDR ProjectshohobiNo ratings yet

- Ps 5Document4 pagesPs 5Andres Nicolas ZartaNo ratings yet

- Farmacology Del Paro CardiacoDocument14 pagesFarmacology Del Paro CardiacoNicoSwtifNo ratings yet

- Requirements Management - V1.1Document29 pagesRequirements Management - V1.1Madhusudan VijaykumarNo ratings yet

- WeldingDocument23 pagesWeldingSuneel Kumar MeenaNo ratings yet

- Jcees 8 158Document7 pagesJcees 8 158betelhembhabtufkaduNo ratings yet

- Fault Identification and ReportingDocument2 pagesFault Identification and ReportingNoel BlancaNo ratings yet

- CPD Providers As of Feb 6, 2020Document733 pagesCPD Providers As of Feb 6, 2020John Mark ArcillaNo ratings yet

- Assignment 2 - SolutionsDocument14 pagesAssignment 2 - Solutionshassaniqbal84No ratings yet

- Form 4 Module 9 (2 WEEKS) QUESTIONDocument7 pagesForm 4 Module 9 (2 WEEKS) QUESTIONSYARIFAH SYARINA BT SHEIKH KAMARUZAMAN MoeNo ratings yet

- Ma. Nemia Lizada, M.D.: Preventive, Community, and Family MedicineDocument5 pagesMa. Nemia Lizada, M.D.: Preventive, Community, and Family MedicineJoher Jr. MendezNo ratings yet

- Ypgh 113 1695081Document12 pagesYpgh 113 1695081Pawan MishraNo ratings yet

- Embedded Images Non Verbal Reasoning Questions and AnswersDocument27 pagesEmbedded Images Non Verbal Reasoning Questions and AnswersAditya DeshmukhNo ratings yet

- LEEP System 1000 Directions For UseeDocument24 pagesLEEP System 1000 Directions For UseeFernando CosciaNo ratings yet