Professional Documents

Culture Documents

Catalog Cuplaje Eng Rom

Uploaded by

Anonymous 4MwmDaNbCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalog Cuplaje Eng Rom

Uploaded by

Anonymous 4MwmDaNbCopyright:

Available Formats

Flexible Couplings Catalog

ISO 9001 Cert.n

o

1274/0

BRAFLEX couplings

general description

The BRAFLEX flexible couplings are designed according to API, AGMA, EN international standards.

The technical solutions and design of BRAFLEX couplings allows them to work in horizontal and vertical

position. Some of the standard models offer one of the most important advantages: service without

displacement of drive or driven unit.

The main advantages of the BRAFLEX flexible couplings are as follows:

minimal moments of inertia during speed increase to nominal value, caused by low weight of the coupling;

low level of vibrations for all the rotating system, caused by their dynamic absorption over the internal

flexible arrangement;

increasing the reliability of any type of sleeves, mechanical seals and high speed or high torque gear

assemblies;

long life when primary alignment is well done, and unit maintenance is assisted by vibration analyzer;

The BRAFLEX couplings are all metallic flexible

assemblies. The arrangement is symmetrical, with

alternate flexible assemblies. The single flexing

couplings allows only angular and axial

misalignments, but the double flexing couplings

allows also radial, added to angular and axial

misalignments.

The all-metallic flexible assemblies are built in

permanent arrangements of elastic discs or lamellas

and bushings.

This type of flexible assembly allows to the

BRAFLEX couplings a predesigned torsion stiffness,

together with easy axial and radial movements which

appear during the normal function.

The integral metallic BRAFLEX couplings can be

used without restriction between 40C and +280C.

The ATK types of BRAFLEX couplings are made

mainly using hubs, flanges, spacers and flexible

assemblies. The ATS types are made using only

hubs, spacers and flexible assemblies as principal

parts.

The standard models of the BRAFLEX couplings

have minimal recommended lengths and various

technical solutions, to allow easier their specific

mounting and to allow the easier maintenance

without displacement of the drive and driven unit.

The special designed BRAFLEX couplings are made

according to the special applications and can be:

equipped with overload protection;

equipped with brake drum;

equipped with axial ball contact for vertical

function;

equipped with joint ball for high speed rotation;

The couplings components are combined to obtain different arrangements according to specific applications.

K

u

Ka=Smax-Smin

Smin

Axial movement

Angular misalignment

Parallel offset and angular misalignment

2

x

K

u

K

u

Smax

K

r

Construcia cuplajelor

flexibile BRAFLEX

Cuplajele flexibile BRAFLEX sunt realizate n conformitate cu normele internaionale API, AGMA, EN.

Soluiile tehnice i concepia cuplajelor BRAFLEX permit utilizarea lor n poziie orizontal i vertical.

Varianta standard asigur utilizatorului unul din cele mai importante avantaje: activitatea de ntreinere a

utilajelor se poate face fr deplasarea acestora.

Principalele avantaje ale utilizrii cuplajelor flexibile BRAFLEX sunt:

valoarea eforturilor ineriale dinamice este minim n timpul accelerrii spre turaia nominal, datorit

masei mici a cuplajelor;

asigur scderea nivelului de vibraii al ntregului sistem n micare de rotaie, prin absorbia dinamic a

vibraiilor n sistemul flexibil intern al cuplajului;

asigur creterea fiabilitii lagrelor de orice tip, a etanrilor mecanice i a angrenajelor de turaie

ridicat sau de putere mare;

durat de exploatare ridicat atunci cnd alinierea primar este corect, iar ntreinerea utilajelor este

asistat de aparatur de analiz a vibraiilor;

Cuplajele BRAFLEX sunt construite cu elemente

flexibile, n totalitate metalice. Sunt construcii simetrice,

n care elementele flexibile se monteaz alternativ.

Cuplajele simplu flexibile preiau numai abateri

unghiulare i axiale, iar cuplajele dublu flexibile preiau

att abateri unghiulare i axiale, ct i dezalinieri radiale

ale arborilor.

Elementele flexibile, integral metalice, se monteaz n

pachete ce constituie un ansamblu nedemontabil,

compus din discuri sau lamele, i buci de fixare.

Acest montaj al pachetului de elemente flexibile confer

cuplajelor BRAFLEX un grad controlat de rigiditate la

torsiune i permite totodat deplasri axiale, dezalinieri

unghiulare i radiale ntre arbori n timpul funcionrii.

Cuplajele BRAFLEX pot fi utilizate fr restricii n

domeniul de temperaturi cuprins ntre 40C i 280C.

Cuplajele BRAFLEX tip ATK se execut cu flane

intermediare de legtur, iar cuplajele tip ATS se

execut fr flane intermediare de legtur, uneori

lipsindu-le chiar tronsonul de legtur.

Modelele standard de cuplaje BRAFLEX au lungimi

minime recomandate i diverse variante constructive,

astfel nct montarea lor i activitatea de ntreinere s

poat fi efectuat fr deplasarea utilajelor.

Cuplajele flexibile BRAFLEX cu destinaie special

sunt construite conform cu aplicaia real i pot fi:

echipate cu protecie la suprasarcin prin limitarea

momentului de torsiune;

echipate cu tambur de frnare;

echipate cu sprijin axial sferic pentru funcionare

vertical;

echipate cu articulaii sferice pentru utilizarea la

viteze de rotaie foarte mari;

Elementele componente sunt sistematic combinate pentru realizarea cuplajelor, rezultnd modele tipice

pentru fiecare aplicaie.

Deplasare axiala

Smax

Ka=Smax-Smin

Smin

Dezaliniere radiala

K

u

K

u

K

r

2

x

K

u

Dezaliniere unghiulara

CNC

DMC

INTERMEDIATE

DND

ATK double flexing

ATK dublu flexibile

AMA

C

INTERMEDIAR

DND

INTERMEDIAR

INTERMEDIATE

ATS double flexing

ATS dublu flexibile

CMC

N

C-C

D-D

ATS single flexing

ATS

ATS simplu flexibile

D-C

D

C-D D-D

INTERMEDIATE

A

INTERMEDIAR

Coupling components

Componente cuplaj

M

INTERMEDIATE

INTERMEDIAR

Possible arrangements

CMC CMD DMD

ATK AMA AMB

ATS

ATK

B

CNC CND

DND

BMB

Combinatii posibile

Coupling components and possible arrangements

Componente cuplaj i combinaii posibile

Special designs

Construcii speciale

Special design for high speed

applications

Construcie special pentru turaii mari

Coupling with overload protection

Cuplaj cu decuplare la suprasarcin

Coupling for vertical mounting, with

pressure plate to support spacer

weight

Construcie special pentru

funcionare vertical, cu sprijin axial,

sferic, pentru preluarea greutii

tronsonului

Coupling with intermediate shaft for

bridging distances between shafts

end

Cuplaj cu arbore intermediar pentru

compensarea distanelor dintre

capetele arborilor

Naval coupling

Cuplaj naval

Selection of the BRAFLEX couplings

General information

The BRAFLEX couplings transmit continuous the

nominal torque of the rotating movement if the load is

uniform for nominal misalignments. In these

conditions, the functional prescribed characteristics

cover the normal function. Using the couplings on

overload speed and misalignment is possible if a

precise knowledge referring to the mechanical

coupling characteristics are available. In conclusion,

that kind of destination requires close manufacturer

consulting. The service factor allows establishing the

overload for all conventional drive/driven units, if they

are in constant operation, according to international

standards (AGMA, API).

Table no. 2 details typical groups of machinery and

their applications, showing the usual overload factor.

The operating factor F is established for the normal

situations when drive unit is an electrical motor or

turbine, active controlled. Table no. 3 refers to other

drive units, supplementary overloaded like piston

engines or reciprocating compressors.

Determining the coupling size

The nominal torque is reference for the coupling

design:

(1) C

N

=

n

P

10 3

N

4

C

N

= nominal system torque [Nm]

P

N

= nominal motor/engine output [kW]

n = nominal coupling rotating speed [rpm]

The nominal motor/engine output is generally higher

than the driven unit power requirement.

The correct BRAFLEX coupling size selection is

guaranteed for normal function conditions, if the

following relation is fulfilled:

(2) C

A

> C

N

F

The service factors proposed to consider according

to table no. 2 and table no. 3 take accept

influences, which may occur during normal and

constant operation, depending on the type of driving

unit. The maximum allowed coupling torque must

be greater than the theoretical maximum torque

values that may be occur.

C

A max.

> T

1

sau T

2

The catalogue specifications for C

Amax.

are

presented for a maximum of 20 starts per hour.

The maximum torque which may be occur can be

checked using the following equations:

(3) C

A max.

T

1

8 , 1

1 m

1

+

C

A max.

T

2

8 , 1

1 m

1

+

T

1

= drive-side shock [Nm]

e.g. engine pull out torque

T

2

= driven-side shock torque [Nm]

m

=

1

/

2

1

= drive-side mass inertia

2

= load-side mass inertia

Temperatures above 150C

If the surrounding increase the coupling temperatures

constantly more than 150C, then must reconsider the

BRAFLEX coupling transmittable torque. This will be

done according to the next relation:

(4) C

A

> C

N

F F

T

F

T

value is according to diagram showed in table no. 1.

If use a long spacer, then the theoretic critical rotating

speed must be checked as follows:

n

crit

~ 120

10

7

2

2 2

A

d D

i e

+

[rpm]

D

e

= pipe/tube/shaft outer diameter [mm]

d

i

= pipe/tube/shaft inner diameter [mm]

A

= distance between end shafts [mm]

The real maximum value of the rotating speed must be

lower than the critical theoretic determined value:

n

max.

< 0,8

n

crit

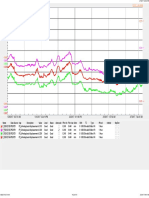

TABLE 1

" F

T

" - Thermal factor diagram

F

T

v > 150 C

1,4

1,3

1,2

1,1

1

150 200 250 300 [C]

Temperature

TABLE 2

" F " Service factor according to machine type

1,0

2,0

1,5

1,75

1,0

1,5

2,5

1,75

1,0

1,25

1,75

3,0

1,75

3,0

2,0

1,75

1,5

2,0

2,0

3,0

1,75

2,5

2,5

1,0

2,0

1,5

1,5

2,5

2,0

1,25

1,5

1,5

1,0

1,0

1,75

1,75

1,0

1,25

1,75

2,5

2,5

1,75

3,0

1,75

1,75

1,75

1,75

2,0

1,5

2,0

1,5

2,5

2,0

1,75

1,75

2,5

1,5

2,0

1,5

2,5

1,75

1,75

1,75

1,0

2,0

1,75

2,5

1,75

1,5

BLOWERS, FAN S

Centrifugal, axial and radial blowers

Cooling tower fans

Gas recirculating fans

Induced draft fans c./a. hostile environment

Light duty fans centrifugal /axial

Lobe or vane blowers

Mine ventilation fans

Rotary piston blowers

COMPRESSORS

Axial

Centrifugal

Lobe, turbocompressor

Reciprocating, with flywheel:

single acting 1, 2 or 3 cylinders

single acting 4 cylinders or more

double acting 1 or 2 cylinders

double acting 3 cylinders

double acting 4 cylinders or more

Rotary screw

CONSTRUCTION EQUIPMENT

Briquetter machines, rollers

Concreting mixers

Crushers

Elevators

Mills balls, hammers, tubes

Rotating kilns

SCREENS

Air washing

Grates

Rotary stone or Gravel

Traveling water intake

Vibratory

WATER TREATMENT

Aerators

Agitators

Sewage disposal equipment

Sewage treatment pumps

Water filters

CONVEYORS

- uniformly loaded or fed

Assembly

Band pocket conveyors

Belt conveyors (bulk material)

Bucket conveyors for flour

Chain conveyors

Circular conveyors

heavy duty not uniformly fed

Belt conveyors (piece goods)

Bucket conveyors

Chain conveyors

Live roll, shaker and reciprocating

Screw conveyors

Steel belt conveyors

HOISTS AND ELEVATORS

Ballast elevators

Bridge drive

Bucket elevators

Centrifugal discharge elevators

Freight elevators

Gravity discharge elevators

Hoist gear

Main hoists

Skip hoists

Trolley drive

DREDGERS

Bucket wheels

Capstan

Centrifugal dredge pumps

Conveyors

Cutter head drives

Maneuvering trolley

Maneuvering winches

Pumps

Rudder drive

Screen drives, Stackers

Slewing gear

Travelling gear (caterpillar)

Travelling gear (rails)

Utility winches

1,0

1,0

1,25

1,25

1,75

1,75

1,5

1,75

1,0

1,5

1,75

1,75

1,25

1,5

2,0

1,75

2,0

2,0

2,0

1,75

1,5

2,5

1,5

2,0

2,0

1,75

2,5

1,5

2,5

2,0

2,0

1,5

2,0

2,5

3,0

2,0

2,0

2,5

2,0

2,0

2,0

2,5

2,5

2,0

2,0

2,5

3,0

3,0

2,5

2,5

1,75

1,75

2,0

1,5

2,0

3,0

2,0

2,0

3,0

1,75

2,0

2,5

3,0

1,75

2,0

2,0

2,0

1,5

2,0

1,5

2,5

2,0

1,75

1,75

2,0

FOOD INDUSTRY MACHINERY

Brew kettle

Bottling, can filling machines

Cereal cooker

Cookers continuous duty

Dough mixers, meat grinders

Hammer mills

Lauter tub

Mash tub

Packaging machines

Roller mills

Scale hopper

Sugar beet washing machines

MACHINE TOOLS

Auxiliary and traverse drives

Coilers and uncoilers

Cutter mill

Main drives

Plate planners

Punch presses

Tapping machines

Wire drawing or flattening

Wire winder

METAL WORKING MACHINES

Ball mills

Car dumpers

Car pullers

Cement kilns

Chain conveyors

Continuous casting plant

Cooling beds

Descaling machines

Door opener

Draw bench carriage

Driving shafts

Dryers and coolers

Extruders

Feed rolls blooming mills

Furnace pushers

Hot and cold saws

Ingot and blooming mills

Ingot cars

Ingot pushers

Kick out (seamless tube mills)

Manipulators

Ore crushers

Plate shears

Plate straightening machines

Presses

Punch presses

Pusher or larry car traction drive

Pusher ram drive

Reciprocating feeder

Roller adjustment drives

Reel drives

Rod mills

Roller table (light duty)

Roller table (heavy duty)

Mill tables

Runout - reversing

Runout - non-reversing, non-plugging

Screwdown

Seamless tube mills piercer

Slitters, Steel mill only

Straighteners

Table conveyors non-reversing

Table conveyors reversing

Trimming shears

Tube conveyor rolls

Tube welding machines

Unscrambles (billet bundle busters)

Winding machines (strip and wire) - cold

Winding machines (strip and wire) - hot

OIL INDUSTRY

Chillers

Drilling rods

Oil well pumping

Paraffin filter press

Pipeline pumps

Rotary kilns

1,75

1,75

1,0

1,75

1,75

1,5

1,75

1,5

2,0

2,0

2,5

1,75

2,5

2,5

2,0

1,75

2.0

2,5

2,0

2,0

2,0

2,5

3,0

2,0

2,0

2,0

2,5

1,25

2,0

2,0

1,75

2,5

1,5

2,0

2,5

2,0

1,5

2,0

1,75

1,5

1,5

1,75

1,5

2,0

1,75

1,5

2,0

2,0

2.0

1,5

1,5

1,5

1,5

1,5

2,5

1,75

2,0

1,75

2,0

2,0

1,25

2,0

1,25

1,75

2,5

1,75

2,0

1,25

2,5

1,5

1,25

2,5

CHEMICAL INDUSTRY

Agitators (semi-liquid materials)

Centrifuges (heavy)

Centrifuges (light)

Crushers

Drying, cooling drums

Liquid agitators, variable density

Mixers

Muller

Plastic extruders

RUBBER INDUSTRY

Calenders

Cracker, Plasticator

Extruders

Mixers

Mixing mill, refiner or sheeter

- 1 or 2 in line

- 3 or 4 in line

- 5 or more in line

Sheeter

Tire building machines

Tubers and strainers

Warming mills

PAPER INDUSTRY

Barker auxiliaries, hydraulic

Barking drum machined spur gear

Barking drum cast tooth spur gear

Barking drum helical gear

Beater & pulper

Calenders

Chipper

Converting machines

Couches, dryers

Cutters, platters

Cylinders, dryers

Glazing cylinders

Line shaft

Log haul

Mechanical barker

Presses

Printing presses

Pulpers

Reel, rewinder, winder

Stock chests, washers, thickeners

Stock pumps, centrifugal, constant speed

Suction roll

TEXTILE MACHINES

Batchers

Calenders, card machines

Centrifuges

Cloth finishing machines

Dry cans

Laundry washers or tumbler

Laundry washers reversing

Looms

Nappers, Mangles

Printing and dyeing machines

Tender frames

WOOD WORKING MACHINES

Band resaw

Barkers drum type

Circular resaw cut-of

Log haul - incline

Planer

Planer feed chain

Planer tilting hoist

Rolls, non-reversing

Rolls, reversing

Slab conveyor

Sawdust conveyor

Saw frames

Trimmer

Trimmer feed

Woodworking machinery

GENERATORS

Frequency transformers

Hoist or railway service

Uniformly load

Welding generators

The service factor, selected from this table, can be used for driven equipment based on smooth prime movers such as electric motors and

turbines.

For reciprocating prime movers, such as diesel or gas engines, the service factor F will be increase according to table 3.

TABLE 3

Number of cylinders 1 to 6 cylinders 6 or more cylinders

Service factor TABLE 2 1,0 1,25 1,5 1,75 2,0 2,5 3,0 1,0 1,25 1,5 1,75 2,0 2,5 3,0

INCREASED Service factor 2,0 2,25 2,5 2,75 3,0 3,5 4,0 1,5 1,75 2,0 2,25 2,5 3,0 3,5

Dimensionarea cuplajelor flexibile BRAFLEX

Generaliti

Cuplajele tip BRAFLEX transmit continuu cuplul

nominal dac funcionarea este uniform, iar

dezalinierile arborilor nu depesc valorile nominale.

Valorile caracteristicilor funcionale prezentate n

catalog sunt acoperitoare pentru condiii de

funcionare normale i coeficieni de suprasarcin

unitari. Utilizarea cuplajelor la turaii i dezalinieri

care depesc valorile de catalog este posibil doar

n condiiile cunoaterii exacte a parametrilor de

utilizare i a caracteristicilor mecanice ale cuplajelor.

n consecin o astfel de folosire trebuie stabilit

conform recomandrilor productorului. Factorul de

serviciu, conform normelor internaionale (AGMA,

API), permite determinarea suprasarcinii cauzate de

mainile antrenate, la funcionare continu.

n tabelul 2 sunt prezentai factorii de serviciu

aplicabili uzual pe tipuri de agregate categorii i

utilizri.

Factorul de serviciu F este acoperitor pentru

antrenarea cu motoare electrice sau turbine cu

control activ al turaiei. Pentru alte tipuri de antrenri,

precum este cazul motoarelor cu piston, trebuie luat

n considerare tabelul 3, care recomand coeficieni

acoperitori pentru ncrcrile suplimentare.

Determinarea mrimii cuplajului

Cuplul nominal este elementul de referin pentru

dimensionarea cuplajelor:

(1) C

N

=

n

P

10 3

N

4

C

N

= Cuplul nominal absorbit [Nm]

P

N

= Puterea nominal a motorului [kW]

n = Turaia nominal [rpm]

Puterea nominal a motorului este de regul

superioar puterii necesare utilajului condus.

Se precizeaz corect mrimea cuplajului BRAFLEX

atunci cnd, n condiii normale de funcionare, este

ndeplinit condiia:

(2) C

A

> C

N

F

Factorul de serviciu propus n tabelul 2 sau n

tabelul 3 ia n considerare influena motorului i a

agregatului condus asupra funcionrii continue

normale. Cuplul maxim admis al cuplajului trebuie

s fie mai mare sau egal cu cuplul de vrf al sarcinii

transmise, innd cont de frecvena vrfurilor.

C

A max.

> T

1

sau T

2

Valorile de catalog pentru C

Amax.

sunt stabilite

pentru maxim 20 de porniri pe or.

Verificarea cuplurilor maxime care apar n exploatare se

face cu relaia urmtoare:

(3) C

A max.

T

1

8 , 1

1 m

1

+

C

A max.

T

2

8 , 1

1 m

1

+

T

1

= cuplul de oc de la utilajul conductor [Nm]

de ex. cuplul de pornire al motorului

T

2

= cuplul de vrf datorat agregatului condus [Nm]

m

=

1

/

2

1

= momentul de inerie al utilajului conductor

2

= momentul de inerie al agregatului condus

Temperaturi peste 150C

Dac temperaturile ambiante ce se transmit cuplajului se

situeaz constant peste 150C, trebuie corectat cuplul

transmis de cuplaj conform relaiei:

(4) C

A

> C

N

F F

T

F

T

se determin cu ajutorul diagramei din tabelul 1.

n cazul lungimii mari a tronsonului (A), trebuie verificat

turaia critic teoretic. Aceast verificare se efectueaz

conform relaiei:

n

crit

~ 120

10

7

2

2 2

A

d D

i e

+

[rpm]

D

e

= Diametrul exterior al elementului de torsiune [mm]

d

i

= Diametrul interior al elementului de torsiune [mm]

A

= Lungimea tronsonului [mm]

Valoarea real maxim a turaiei de lucru trebuie s fie

mai mic dect valoarea critic teoretic, conform

relaiei:

n

max.

< 0,8

n

crit

TABEL 1

Diagrama de variaie a factorului termic " F

T

"

F

T

v > 150 C

1,4

1,3

1,2

1,1

1

150 200 250 300 [C]

Temperatura

TABEL 2

" F " Factor de serviciu recomandat funcie de aplicaie

1,0

1,5

1,75

1,0

1,75

1,5

2,0

2,5

1,0

1,25

1,5

3,0

1,75

3,0

2,0

1,75

1,75

2,0

3,0

2,5

1,75

2,0

2,5

1,5

1,25

2,0

1,5

2,5

2,0

1,0

1,25

1,25

1,5

1,0

1,75

1,0

1,75

1,75

1,25

1,75

2,5

1,75

2,5

1,75

3,0

1,75

2,0

1,75

2,0

1,5

1,5

2,0

1,75

2,5

1,75

2,0

2,5

1,75

1,5

1,5

2,5

1,75

1,75

1,75

2,0

2,5

1,0

1,75

1,5

SUFLANTE I VENTILATOARE

Suflante centrifugale, axiale i radiale

Suflante cu turbin sau cu pale

Suflante cu piston rotativ

V. centrif./axiale pt. condiii uoare de lucru

V. centrif./axiale de aspiraie mediu ostil

V. cu recircularea gazelor

V. pentru turnuri de rcire

V. de aerisire galerii

COMPRESOARE

Axiale

Centrifugale

Cu melc / elicoidal

Cu pistoane i volant:

simpl aciune cu 1, 2 sau 3 cilindri

simpl aciune cu 4 cilindri sau mai mult

dubl aciune cu 1 sau 2 cilindri

dubl aciune cu 3 cilindri

dubl aciune cu 4 cilindri sau mai mult

Cu turbin, cu pale

ECHIPAMENTE DE CONSTRUCII

Amestectoare cu tambur, betoniere

Concasoare

Cuptoare rotative

Elevatoare

Maini de brichetat, de prelucrat argil, tvluguri

Mori cu bile, cu ciocane, tubulare

FILTRE (SITE)

Filtre rotative de rcire, site ptr. nisip

Filtre cu vid

Grtare

Site rotative pentru roc sau prundi

Site vibratoare

TRATAMENTUL APEI

Aeratoare

Alimentatoare chimice, filtre de ap

Amestectoare lente i rapide

Colectoare de reziduuri (nmol)

Echipament ptr. evacuare ape reziduale

CONVEIOARE

- aliment. sau ncrc. uniform

Band rulant de asamblare

Conv. circulare

Conv. cu cupe ptr. pulbere

Conv. cu band (mat. n vrac)

Conv. cu band cu buzunare

Conv. cu lan, cu plci metalice, cu raclei

cond. grele, alim. neunifor.

Conv. elicoidale / cu melc

Conv. cu cupe de mortar

Conv. cu eclise

Conv. cu band (mat. blocuri)

Conv. cu lan, cu plci metalice

Conv. cu role mobile, cu jgheab oscilant

MACARALE I ELEVATOARE

Antrenare pod rulant, sau crucior macara

Ascensoare de mrfuri

Elevatoare ptr. balast

Elevatoare cu plan nclinat, cu cupe

Elevatoare cu descrcare gravitaional

Elevatoare cu descrcare centrifugal

Mecanisme principale de ridicare

Mecanism de acionare a braului

Mecanism de deplasare macara

Vinciuri de tras

DRAGOARE (EXCAVATOARE)

Antrenare grtare, stivuitoare

Antrenare capete de scormonit, ghidaje

Antrenare tamburi cu cablu

Cabestan

Conveioare

Mecanisme de deplasare (enile)

Mecanisme de deplasare (roi pe ine)

Mecanisme de rotire

Pompe

Pompe centrifugale de dragare

Roat cu cupe

Transmisia crmei

Trolii de manevr

Vinciuri utilitare

1,75

1,0

1,25

1,25

1,5

1,75

1,75

1,0

1,75

1,0

1,75

1,5

1,25

1,75

2,0

1,5

2,0

1,5

2,0

1,75

2,0

2,5

2,5

1,75

2,0

1,75

3,0

2,0

1,5

2,0

1,5

2,0

3,0

3,0

2,0

2,5

2,0

2,0

2,0

2,0

2,5

1,75

2,0

1,75

2,0

2,5

2,0

3,0

2,5

2,0

2,5

2,5

3,0

2,5

1,5

2,0

2,0

2,0

1,5

2,5

2,0

1,5

3,0

2,5

2,0

2,0

2,0

2,0

1,75

1,5

2,0

2.0

1,75

1,75

2,5

INDUSTRIA ALIMENTAR

Cazan de borhot

Cazan de fabricat bere

Cazan de distilat - debit continuu

Cuv de amestecare (ptr. buturi)

Cuv de filtrare bere

Cuve de terciuit (zdrobitoare)

Malaxor de aluat i maini de tocat

Maini de mpachetat

Maini de splare legume, sfecl

Maini de umplere bidoane i lzi

Mori ptr. fin cu ciocane

Mori ptr. fin cu valuri

MAINI UNELTE

Antrenoare auxiliare i intermediare

Antrenoare principale

Freze de canelat

Maini de bobinat

Maini de filetat, Maini de frezat

Main de nfurat i desfurat

Main rabotat margini de tabl

Main de trefilat i aplatisat srm

Prese de perforat

INSTALAII INDUSTRIALE

Alimentatoare cu schimbare de sens

Antrenare ram extractor (cocserie)

Antrenarea stivuitoarelor cu rulouri

Antrenare necuri

Antrenare tobe de trefilat

Antrenare traciune vagonei

Arunctoare (eliminatoare) laminor evi

Arbori conductori de echipamente

Bancuri de tras / de trefilare

Ci cu role de transp. (cond. uoare)

Ci cu role de transp. (cond. grele)

Ci cu role de transp. - laminoare de lingouri

Crucior transport rame de formare

- cu schimbare de sens

- fr schimbare de sens , neacoperit

Concasoare ptr. minereu

Conveior cu role ptr. evi

Cuptoare de uscare, rotative, de ciment

Deschiztor de u (furnale)

Descifratoare (desfurtor colaci de band)

Extrudoare, Forje

Fierstru circular ptr. metale - la oelrie

Fierstraie ptr. metale calde i reci

Foarfeci de debavurat

Foarfeci de tabl, de agle

Instalaie de turnare continu

mpingtor laminor evi

Laminor de degroare

Laminoare de profile, de lingouri, de tabl

Laminor netezitor

Manipulatoare

Mas de transport fr schimbare de sens

Mas de transport cu schimbare de sens

Maini de decojire

Maini de nfurat la rece (band i srm)

Maini de nfurat la cald (band i srm)

Maini de aplatisat

Maini de sudat evi

Mecanism basculant ptr. vagonei

Moar cu bile

Prghii furnal

Paturi de rcire

Perforatoare laminor evi

Prese

Tobe de curat piese 1

Transportoare de lingouri

Vatr mobil cuptor de tr. termic

Usctoare i rcitoare

Transportoare cu lan

INDUSTRIA PETROLIER

Cristalizatoare

Cuptor rotativ de uscare

Pompe de extracie

Pompe pentru conducte

Prese filtre ptr. parafin

Tije de foraj

1,5

1,75

1,75

1,0

1,75

1,5

2,0

1,75

1,75

2,0

1,75

2,0

2,5

2,5

2,0

1,75

2,5

2,5

2,0

2.0

1,75

1,5

2,0

2,5

2,5

3,0

2,0

2,0

1,5

2,0

2,5

1,25

2,0

1,75

2,0

1,5

1,5

2,0

2,0

2,5

1,75

2,0

2,0

1,75

2,0

1,5

1,5

1,5

2.0

1,5

1,5

1,5

2,0

2,0

2,0

1,75

1,25

1,25

1,75

1,5

1,75

2,5

1,75

2,0

2,5

2,0

1,25

2,0

1,25

1,5

2,5

2,5

INDUSTRIA CHIMIC

Agitatoare lichide cu densitate variabil

Amestectoare, Calandre

Centrifuge (condiii grele)

Centrifuge (condiii uoare)

Concasoare

Kollergang

Extrudoare ptr. material plstic

Malaxoare

Tambururi ptr. rcire, ptr. uscare

INDUSTRIA CAUCIUCULUI

Calandre de cauciuc

Extrudoare, instalaii de tabletat

Extrudoare ptr. furtune i extrudoare cu site de

filtrare

Laminoare, Malaxoare

Malaxor deschis, rafinor, val de tras n foi

- 1 sau 2 valuri n linie

- 3 sau 4 valuri n linie

- 5 sau mai multe valuri n linie

Maini de confecionat anvelope

Val concasor main de plastifiat

Valuri de prenclzire

Valuri de tragere n foi

INDUSTRIA HRTIEI

Antrenarea nfurtoarelor, depntoarelor

Antrenoare intermediare

Calandru

Cilindri satinori

Cojitor cilindru cu dini drepi prelucrai

Cojitor cilindru cu dini montai

Cojitor cu tambur roat cu dini elicoidali

Defibratoare

Depozitoare, spltoare, ngrotoare

Maini de decojit auxiliare, hidraulice

Maini de decojit, mecanice

Main de mrunit

Maini de tiat hrtie, ghilotine

Mori cilindrice (cu valuri)

Prese

Prese de tiprit

Pomp de past, centrifug. avans constant

Ridictor transportor de buteni

Storctoare, usctoare

Toctor

Val de absorbie (sugar)

Volant defibrator

MAINI TEXTILE

Calandre, maini de drcit

Centrifuge

Cilindri de stors, main de uscat

Dozatoare

Echipament de vopsire i imprimare

Maini de finisat estura

Maini de splat cu schimbare de sens

Maini de scmoat, mangle

Purttoare de stendere

Rzboaie de esut

Spltoare sau storctoare

PRELUCRAREA LEMNULUI

Alimentatoare mas de tiat

Alimentatoare maini de degroat grinzi

Conveioare de lauri

Conveioare de rumegu

Echipament de prelucrat lemnul

Fierstru circular de spintecat

Fierstru cu panglic de spintecat

Mas de tiat

Maini de decojit

Main de ndreptat / de rindeluit

Mecanism de rsturnare grinzi

Rame de gater

Ridictor transp. de buteni ( tip plan nclinat)

Rulouri, fr schimbare de sens

Rulouri, cu schimbare de sens

GENERATOARE

De sarcin uniform

Ptr. macarale sau ntreinere ci ferate

Ptr. sudur

Transformatoare de frecven

Factorul de serviciu, ales din tabel, se aplic la pornire lent, cu agregat conductor motor electric, turbin sau motor hidraulic.

Antrenrile efectuate cu motoare cu ardere intern (benzin sau motorin), majoreaz factorul de serviciu F, prezentat n tabelul 2, conform

indicaiilor din tabelul 3

TABEL 3

Numr de cilindri 1 pn la 6 cilindri 6 sau mai muli cilindri

Factor de serviciu TABEL 2 1,0 1,25 1,5 1,75 2,0 2,5 3,0 1,0 1,25 1,5 1,75 2,0 2,5 3,0

Factor de serviciu MAJORAT 2,0 2,25 2,5 2,75 3,0 3,5 4,0 1,5 1,75 2,0 2,25 2,5 3,0 3,5

Dimensions Flexible coupling, discs assembly with radial removable spacer

Cuplaj flexibil. Tronson cu demontare radial.

Maximum misalignment

Dezalinierea maxim

Size

Mrime

Model

Modelul

Total weight

Masa total

Torque

Cuplul nominal

Max. speed

Turaia max.

Axial

axial

Angular

unghiular

Radial

radial

[Kg]

C

A

[Nm]

n

1)

[rpm]

ka

2)

[mm]

kw

3)

[]

kr

2)

[mm]

0005 BMB 2,65 57 5.000 0,5

0.27 /

A

min

=63mm

AMA 3,83

AMB 4,65

AMC 3,40

0011

CMC 3,30

105 32.000 1

0.271mm/

A

min

=72mm

AMA 6,77

0027

AMB 8,24

260 25.500 1.25

0.328 /

A

min

=75mm

AMA 10,51

AMB 12,57

AMC 8,97

0060

CMC 8,33

573 20.000 1.5

0.423 /

A

min

=91mm

AMA 18,32

AMB 21,18

AMC 15,87

0110

CMC 13,35

1050 18.500 2.0

0.534 /

A

min

=115mm

0180 AMA 23,52 1720 14.400 2.5

0.534 /

A

min

=124mm

0260 AMA 34,89 2.75

0.52 /

A

min

=144mm

AMA 70,50

AMB 82,50 0400

CMC 50,08

3820 10.500 3.25

0.534 /

A

min

=150mm

0750 AMA 77,52 7160 8.000 4.25

0.616 /

A

min

=155mm

AMA 131,20

1120

CMC 92.80

10700 7.000 5.0

0,5

0.716 /

A

min

=155mm

1) Starting with peripheral velocity of > 30 m/s we recommend a dynamical balancing of the coupling.

For couplings with spacer A > 250 mm or couplings with higher speeds - please inquire.

1) La viteze periferice > 30 m/s, cuplajele se livreaz echilibrate dinamic.

Pentru cuplaje cu lungimi ale tronsonului A > 250 mm sau cuplaje de turaie mare consultai productorul.

Twin-cardanic desing with minimal

overall length.

Execuie dublu articulat cu tronson de

lungime minim.

Type

Tip

ATK

Dimensions Arrangements: AMC , CMC

Combinaii: AMC , CMC

Size

Mrime

Model

Modelul

d

1

max.

d

2

max.

A

min.

L

min.

C

1

C

2

D

1

D

2

D

3

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

0005 BMB 32 32 63 140 38,5 38,5 66 66 66

AMA 40 40 72 149 38,5 38,5 56 56 90

AMB 40 52 72 149 38,5 38,5 56 90 90

AMC 40 20 46.5 117 38,5 32 56 33 90

0011

CMC 20 20 21 85 32 32 33 33 90

AMA 52 52 75 164 44,5 44,5 72 72 112

0027

AMB 52 65 75 164 44,5 44,5 72 112 112

AMA 64 64 92 193 50,5 50,5 88 88 130

AMB 64 80 92 193 50,5 50,5 88 130 130

AMC 64 40 50 151 50.5 50.5 88 57 130

0060

CMC 40 40 8 109 50,5 50.5 57 57 130

AMA 85 85 114 237 61,5 61,5 110 110 152

AMB 85 105 114 237 61,5 61,5 110 152 152

AMC 85 50 62.5 187 61,5 63 110 70 152

0110

CMC 50 50 11 137 63 63 70 70 152

0180 AMA 100 100 131 271 70 70 130 130 179

0260 AMA 100 100 144 290 78 78 137 137 185

AMA 135 135 152 368 108 108 170 170 230

AMB 135 160 152 368 108 108 170 230 230 0400

CMC 100 100 8 188 90 90 122 122 230

0750 AMA 160 160 155 371 108 108 200 200 272

AMA 200 200 155 371 108 108 246 246 330

1120

CMC 150 150 11 191 90 90 190 190 330

2) Referring to 2 packs of flexible assemblies.

Se refer la 2 pachete de lamele.

3) Referring to 1 pack of flexible assembly.

Se refer la un pachet de lamele.

Twin-cardanic desing with minimal

overall length.

Execuie dublu articulat cu tronson de

lungime minim.

Type

Tip

ATK

Dimensions Flexible coupling, discs assembly with radial removable spacer

Cuplaj flexibil. Tronson cu demontare radial.

Maximum misalignment

Dezaliniere maxim

Size

Mrime

Model

Modelul

Total weight

Masa total

Torque

Cuplul nominal

Max. speed

Turaia max.

Axial

axial

Angular

unghiular

Radial

radial

[Kg]

C

A

[Nm]

n

1)

[rpm]

ka

2)

[mm]

kw

3)

[]

kr

2)

[mm]

DMD 2,56

CMC 2,31

DMC 2,44

1

0.158mm/

A

min

=42mm

0011

DD 1,74

105 32.000

0,5 0

DMD 3,89 1.25

0.192 /

A

min

=44mm

0027

DD 2,55

260 25.500

0,62 0

DMD 6,36 1.5

0.250

A

min

=54mm

0060

DD 4,36

573 20.000

0,75 0

DMD 10,67 2.0

0.306/

A

min

=66mm

0110

DD 7,02

1050 18.500

1 0

DMD 15,05 2.5

0.340 /

A

min

=79mm

0180

DD 9,62

1720 14.400

1,25 0

DMD 38,03 3.25

0.349 /

A

min

=98mm

0400

DD 27,84

3820 10.500

1,62 0

DMD 53,14 4.25

0.401 /

A

min

=101mm

0750

DD 40,83

7160 8.000

2,12 0

DMD 111,57 5.0

0. 467/

A

min

=101mm

1120

DD 87,22

10700 7.000

2,50 0

DMD 211,34 4,40

0. 834/

A

min

=235mm

5000

DD 128,67

10700 7.000

2,20

0,5

0

1) Starting with peripheral velocity of > 30 m/s we recommend a dynamical balancing of the coupling.

For couplings with spacer A > 250 mm or couplings with higher speeds - please inquire.

1) La viteze periferice > 30 m/s, cuplajele se livreaz echilibrate dinamic.

Pentru cuplaje cu lungimi ale tronsonului A > 250 mm sau cuplaje de turaie mare consultai productorul.

Twin-cardanic desing with minimal

overall length.

Execuie dublu articulat cu tronson de

lungime minim.

Type

Tip

ATS

Dimensions Arrangements: CMC , DD

Combinaii: CMC , DD

Size

Mrime

Model

Modelul

d

1

max.

d

2

max.

A

min.

L

min.

C

1

C

2

D

1

D

2

D

3

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

DMD 28 28 42 118 38 38 42 42 86

CMC 20 20 4 70 33 33 33 33 86

DMC 28 20 23 94 38 33 42 33 86

0011

DD 28 28 7,5 83,5 38 38 42 42 86

DMD 36 36 44 134 45 45 56 56 108

0027

DD 36 36 8 98 45 45 56 56 108

DMD 42 42 54 158 52 52 66 66 123

0060

DD 42 42 8,5 112,5 52 52 66 66 123

DMD 52 52 66 192 63 63 80 80 145

0110

DD 52 52 9,5 135,5 63 63 80 80 145

DMD 75 75 79 218 72 72 104 104 172

0180

DD 75 75 13,5 152,5 72 72 104 104 172

DMD 95 95 98 318 110 110 140 140 222

0400

DD 95 95 22,5 242,5 110 110 140 140 222

DMD 140 140 101 321 110 110 180 180 264

0750

DD 140 140 24 244 110 110 180 180 264

DMD 165 165 101 321 110 110 212 212 320

1120

DD 165 165 24 244 110 110 212 212 320

DMD 150 150 235 535 150 150 220 220 410

5000

DD 150 150 30 330 150 150 220 220 410

2) Referring to 2 packs of flexible assemblies or to 1 pack of flexible assembly for model DD.

Se refer la 2 pachete de lamele sau la 1 pachet pentru modelul DD.

3) Referring to 1 pack of flexible assembly.

Se refer la un pachet de lamele.

Twin-cardanic desing with minimal

overall length.

Execuie dublu articulat cu tronson de

lungime minim

Mono-cardanic desing without overall

length.

Execuie simplu articulat fr tronson

Type

Tip

ATS

CUPLAJ FLEXIBIL / FLEXIBLE COUPLING

Formular de comand / Cerere de ofert Pag. 1 / 2

Order form / Inquiry information Page

Adresa clientului / Customer's address

Tel. / Phone:

Fax / Fax:

Data / Date:

Serv. / Dept.: Reprez./ Contact person:

A V transmitem urmtoarea comand / cerere de ofert

We hereby send the following order / inquiry information

Mrimea Tipul Modelul buc.

Size Type Model pcs.

1

2

3

Situaia la montaj se precizeaz

n pct. 4, pag. 2 / 2.

Mounting situation is precissed

in item 4, page 2 / 2

. .

Locul, Data / Place, Date Semntura / Signature

B V transmitem comanda pentru cuplaje, utilizate n urmtoarele condiiile :

We hereby send the order for couplings, used in following conditions:

1. Condiiile de funcionare / Operation conditions:

Funcionare: uniform pulsatorie ncrcri cu oc ncrcare alternant

Operation: uniform pulsating shock loadings alternating load

Funcionare intermitent nu da porniri pe zi

Intermittend operation no yes startings per day

Funcionare cu schimbare de sens nu da schimbri / or / zi

Reversing operation no yes times / hour / day

Temperatura ambiant permanent C max.: C

Ambient temperature permanent

Praf, mizerie, umezeal, mediu exploziv, izolat electric? / Dust, dirt, water, explosive, electric insulated?

Dezaliniere radial Kr mm Dezaliniere axial Ka mm Dezaliniere unghiular Kw .

Radial misalignment Axial misalignment Angular misalignment

2. Agregatul conductor / Driver:

Motor electric, Turbin, Motor hidraulic Motor cu piston 1 - 6 cilindrii peste 6 cilindrii

Electric motor, Turbine, Hydraulic motor Piston engine 1 - 6 cylinders morethan 6 ylinders

Pornire direct / Direct starting

Puterea nominal .. kW la turaia rpm

Power rating at speed

Momentul de torsiune ... Nm la turaia rpm

Operation torque at speed

Turaia max. / Max. speed rpm

ncrcri cu oc (ex. momente de pornire) Nm ct de des? / zi

Shock loadings (e.g. starting moments) how often? / day

CUPLAJ FLEXIBIL / FLEXIBLE COUPLING

Formular de comand / Cerere de ofert Pag. 2 / 2

Order form / Inquiry information Page

Pot s apar ncrcri cu oc neprevzute (ex. blocaj al rotirii) nu da

Can unforeseen shock loads occur (e.g. shock circuit-blockage moments) no yes

dac da: ct de mare este ncrcarea cu oc? Nm ct de des?

if yes: how big is shock loading? How often?

3. Tipul agregatului condus (ex. ventilator, pomp, maini unelte, mori)

Driven machine type (e.g. fan, pump, working machines, mills)

Domeniul industrial .

Industry area

Momentele de inerie kgm

2

Moments of inertia

4. Cerine constructive / Mounting situation

Echilibrare: nu da

Balancing: no yes

Turaia de echilibrare: T

1

T

2

T

3

...rpm

Balancing speed

Calitate 1 = 2 = 3 =

Quality

Butucul 1 echilibrare fr locaul penei

Hub1 balancing without keyseating

echilibrare cu locaul penei

balancing with keyseating

Butucul 2 echilibrare fr locaul penei

Hub 2 balancing without keyseating

echilibrare cu locaul penei

balancing with keyseating

Echilibrare n ansamblu: nu da

Assembly balancing: no yes

Distana ntre arbori S

1

. S

2

. S

3

...mm

Distance between shaft ends

Butuc 1 Arbore

1

.

2

.

3

..mm

Hub 1 Shaft

Lungime arbore L

1

. L

2

. L

3

.mm

Shaft length

Pan STAS nu da

Key to ISO no yes

Conicitate C

1

. C

2

. C

3

.

Taper on diameter

Lungimea de fixare W

1

W

2

. W

3

mm

Fixative length

Butuc 2 Arbore

1

.

2

.

3

.mm

Hub 2 Shaft

Lungime arbore L

1

.. L

2

. L

3

.mm

Shaft length

Pan STAS nu da

Key to ISO no yes

Flotant axial nu da

Axial float no yes

Poziia de montaj: oriz. vert.

Mounting position: horiz. vert.

X

W

Y S

L L

1

2

Conicitate

Taper on diameter

X

1

= mm

X

2

= mm

X

3

= mm

Y

1

= mm

Y

2

= mm

Y

3

= mm

5. Observaii / Remarks:

NOT: Pentru o bun i rapid informare, v rugm s completai ct mai multe rubrici ale formularului de comand /cerere de ofert.

NOTE: For correct information and rapid delivery, please fill out as more as possible fields.

Address / Adresa

2200 Braov ROMANIA

Str. G-ral Eremia Grigorescu 6

Tel: (+40) 268 324227, 331533

Fax: (+40) 268 330028, 331530

E-mail: braflex@braflex.ro

www.braflex.ro

c

o

d

C

0

0

1

/

E

d

.

A

/

A

c

t

.

1

/

2

0

0

2

You might also like

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- ISO 9001 Flexible Couplings CatalogDocument16 pagesISO 9001 Flexible Couplings CatalogAnonymous 4MwmDaNbNo ratings yet

- Autoflex Catalogue PDFDocument24 pagesAutoflex Catalogue PDFDenis AugustoNo ratings yet

- Coupling 2Document19 pagesCoupling 2tushar9810080No ratings yet

- CBA 300 Series Pneumatic ActuatorsDocument6 pagesCBA 300 Series Pneumatic ActuatorsMidzie PedroNo ratings yet

- Tolomatic Rod and Rodless Style Electric Actuators BrochureDocument36 pagesTolomatic Rod and Rodless Style Electric Actuators BrochureElectromateNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- FLENDER Standard CouplingsDocument278 pagesFLENDER Standard Couplingsalfredo_fredo_1No ratings yet

- Grundfos White PaperDocument8 pagesGrundfos White PapermishraenggNo ratings yet

- Recommended FitsDocument10 pagesRecommended FitsZiad AkmalNo ratings yet

- Bettis CBA 725Document16 pagesBettis CBA 725kutts76100% (1)

- CQ Brochure - English A4Document20 pagesCQ Brochure - English A4mrbookaniNo ratings yet

- RINGFEDER Keyless Shaft & Hub ConnectionsDocument44 pagesRINGFEDER Keyless Shaft & Hub Connectionsaiyubi2No ratings yet

- 154 Bettis Cba-Series CatalogDocument16 pages154 Bettis Cba-Series CatalogsebastianNo ratings yet

- ER-56-03 EN Packager Standards Skid Design and FabricationDocument4 pagesER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoNo ratings yet

- How to Select an Escogrid CouplingDocument10 pagesHow to Select an Escogrid CouplingdjalikadjouNo ratings yet

- Bettis Cba 300 Series Pneumatic Actuators Us DataDocument6 pagesBettis Cba 300 Series Pneumatic Actuators Us DatasusantoNo ratings yet

- Raj. S. Saitavadekar Abhishek Bhosale Santosh Gurkhe Sumeed RamtekeDocument14 pagesRaj. S. Saitavadekar Abhishek Bhosale Santosh Gurkhe Sumeed RamtekeRazi A. RahimNo ratings yet

- 327, BC A101 05 Oa As BSDocument9 pages327, BC A101 05 Oa As BSMiguel AngelNo ratings yet

- Steering SystemsDocument14 pagesSteering SystemsDhanashekar ManickamNo ratings yet

- DTS 04 UkDocument12 pagesDTS 04 UkhepcomotionNo ratings yet

- Acoplamientos TSK PDFDocument4 pagesAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesNo ratings yet

- REICH ARCUSAFLEX Rubber Disc CouplingsDocument20 pagesREICH ARCUSAFLEX Rubber Disc CouplingsfernandoalvesvnbNo ratings yet

- Tolomatic MXE Electric Rodless Actuator CatalogDocument56 pagesTolomatic MXE Electric Rodless Actuator CatalogElectromateNo ratings yet

- ARCA Fly Antriebe GBDocument6 pagesARCA Fly Antriebe GBcvfNo ratings yet

- Wartsila O P Transverse ThrusterDocument8 pagesWartsila O P Transverse ThrusterionesqNo ratings yet

- John Crane Met A StreamDocument4 pagesJohn Crane Met A StreamGNo ratings yet

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2No ratings yet

- Vibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarDocument8 pagesVibration Analysis in Reciprocating Compressors - Vassillaq Kacani, Ernst HuttarConradodaMatta0% (1)

- General Purpose Centrifugal Fan, Model USDocument32 pagesGeneral Purpose Centrifugal Fan, Model USlsaishankar100% (1)

- Arcusaflex - ReichDocument20 pagesArcusaflex - ReichFR100% (1)

- Palfinger PK 40002 EH GDocument8 pagesPalfinger PK 40002 EH Gjose lozadaNo ratings yet

- Optimize linear motion drive selectionDocument12 pagesOptimize linear motion drive selectionSammy-papa Maropeng ShikaNo ratings yet

- B TsdeDocument8 pagesB TsdeDênis DáyolNo ratings yet

- Re77502 2004-05Document20 pagesRe77502 2004-05pamururamuNo ratings yet

- Catalogo Centaflex Serie ADocument15 pagesCatalogo Centaflex Serie ACarlos Gallardo LagosNo ratings yet

- CBA-Series Scotch-Yoke Pneumatic ActuatorsDocument4 pagesCBA-Series Scotch-Yoke Pneumatic Actuatorsprihartono_diasNo ratings yet

- Jakob Metaalbalgkoppeling K Catalogus enDocument25 pagesJakob Metaalbalgkoppeling K Catalogus enFallo SusiloNo ratings yet

- Horizontal Balancing Machines: Series HM4/HM40, HM5/HM50Document4 pagesHorizontal Balancing Machines: Series HM4/HM40, HM5/HM50Samuel TanNo ratings yet

- Agitator Shaft Features and Benefits AnalysisDocument9 pagesAgitator Shaft Features and Benefits AnalysisTan Chee MingNo ratings yet

- CraneDocument80 pagesCranehoseinNo ratings yet

- HHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original FileDocument2 pagesHHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original Fileaatishsehgal94No ratings yet

- Couplings SiemensDocument139 pagesCouplings SiemensTài liệu Công ty TNHH Nam TrungNo ratings yet

- Bettis Cba300 DsDocument12 pagesBettis Cba300 DsdamicesterNo ratings yet

- Korfund Elastomeric Mounts PDFDocument66 pagesKorfund Elastomeric Mounts PDFMarko PetkovicNo ratings yet

- Centaflex DDocument7 pagesCentaflex DInu Muh NuurNo ratings yet

- Hercules Pot Type BearingDocument21 pagesHercules Pot Type BearingSunil KumarNo ratings yet

- To Falk Steel FlexDocument47 pagesTo Falk Steel FlexJose Antonio García RuízNo ratings yet

- VLATB110-Rack & Pinion & Scotch Yoke Actuators TBDocument18 pagesVLATB110-Rack & Pinion & Scotch Yoke Actuators TBBoy AlfredoNo ratings yet

- Reich Cat 2011Document149 pagesReich Cat 2011drakula85No ratings yet

- Bulletin - 610 - JUN13 BLOWERS PDFDocument8 pagesBulletin - 610 - JUN13 BLOWERS PDFJuan David Muriel CastilloNo ratings yet

- Twintors - Diaphragm Couplings For Turbo Machines: H. Birkholz, P. Dietz, E. Dehner and M. GarzkeDocument6 pagesTwintors - Diaphragm Couplings For Turbo Machines: H. Birkholz, P. Dietz, E. Dehner and M. Garzkeajiths89No ratings yet

- R999001185 2018 03 Gewindetriebe ENDocument278 pagesR999001185 2018 03 Gewindetriebe ENMarco Manuel Ascensão SilvaNo ratings yet

- Inkoma PK CouplingDocument21 pagesInkoma PK CouplingMarco ChacanaNo ratings yet

- Lancaster Flow Choke AutomationDocument6 pagesLancaster Flow Choke AutomationleonardomaoNo ratings yet

- Siemens Flender 05 BipexDocument8 pagesSiemens Flender 05 BipexDhanielNo ratings yet

- PDFDocument6 pagesPDFHicham HrslNo ratings yet

- Iwsd 51051Document84 pagesIwsd 51051Anonymous 4MwmDaNbNo ratings yet

- Temp Si Pres 7.02.17Document1 pageTemp Si Pres 7.02.17Anonymous 4MwmDaNbNo ratings yet

- Manual IndesitDocument12 pagesManual IndesitAnonymous 4MwmDaNbNo ratings yet

- Accent Travel Vara 2017 OMV PDFDocument268 pagesAccent Travel Vara 2017 OMV PDFAnonymous 4MwmDaNbNo ratings yet

- Acumulator 20l H P 002ADocument12 pagesAcumulator 20l H P 002AAnonymous 4MwmDaNbNo ratings yet

- Coupling AlignmentDocument14 pagesCoupling Alignmentkutts76No ratings yet

- Temp Si Pres 7.02.17Document1 pageTemp Si Pres 7.02.17Anonymous 4MwmDaNbNo ratings yet

- Instructions Steam Turbine Sets PDFDocument1 pageInstructions Steam Turbine Sets PDFAnonymous 4MwmDaNbNo ratings yet

- Mechanics 24Document6 pagesMechanics 24olwe90No ratings yet

- Catalogo de BandasDocument180 pagesCatalogo de BandasPaul OñaNo ratings yet

- Accent Travel Iarna 2016 PDFDocument80 pagesAccent Travel Iarna 2016 PDFAnonymous 4MwmDaNbNo ratings yet

- Deplasare Axiala Suflanta 7.02.17 PDFDocument1 pageDeplasare Axiala Suflanta 7.02.17 PDFAnonymous 4MwmDaNbNo ratings yet

- Acumulator 20l H P 002ADocument1 pageAcumulator 20l H P 002AAnonymous 4MwmDaNbNo ratings yet

- Ludeca - SoftFoot Causes Characteristics and Solutions PDFDocument27 pagesLudeca - SoftFoot Causes Characteristics and Solutions PDFAnonymous 4MwmDaNbNo ratings yet

- Pro TechDocument6 pagesPro TechAnonymous 4MwmDaNbNo ratings yet

- OPTALIGN Smart - 8-Page-Brochure - DOC-12.400 - 21-06-10 - en PDFDocument8 pagesOPTALIGN Smart - 8-Page-Brochure - DOC-12.400 - 21-06-10 - en PDFAnonymous 4MwmDaNbNo ratings yet

- Train in Main ENGDocument148 pagesTrain in Main ENGSelvakumarNo ratings yet

- OPTALIGN-smart - Operating-Handbook - ALI 9.123 - 10-10 - 1.19 - G - v5 PDFDocument187 pagesOPTALIGN-smart - Operating-Handbook - ALI 9.123 - 10-10 - 1.19 - G - v5 PDFAnonymous 4MwmDaNb33% (3)

- Ludeca-A Practical Guide To Shaft Alignment PDFDocument0 pagesLudeca-A Practical Guide To Shaft Alignment PDFDelfinsh100% (1)

- Emission Containment Seal: ForewordDocument8 pagesEmission Containment Seal: ForewordAnonymous 4MwmDaNbNo ratings yet

- ZH Centrifugal Compressor PDFDocument14 pagesZH Centrifugal Compressor PDFAldo Martinez100% (1)

- Dictionar Petrol TehnicDocument99 pagesDictionar Petrol TehnicAnonymous 4MwmDaNbNo ratings yet

- WIKA Product - Catalog (189 Pages)Document189 pagesWIKA Product - Catalog (189 Pages)Robin Bobin100% (1)

- Accent Travel Iarna 2016Document80 pagesAccent Travel Iarna 2016Anonymous 4MwmDaNbNo ratings yet

- Operating Instruction Rotary Piston GM 150SDocument46 pagesOperating Instruction Rotary Piston GM 150SAnonymous 4MwmDaNb100% (2)

- Manometru Europe PDFDocument20 pagesManometru Europe PDFAnonymous 4MwmDaNbNo ratings yet

- BR Chemical GB 6424 PDFDocument21 pagesBR Chemical GB 6424 PDFAnonymous 4MwmDaNbNo ratings yet

- BR ProductPortfolio en Co 6434 PDFDocument88 pagesBR ProductPortfolio en Co 6434 PDFAnonymous 4MwmDaNbNo ratings yet

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceFrom EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceNo ratings yet

- Learn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.From EverandLearn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.Rating: 5 out of 5 stars5/5 (34)

- Clean Code: A Handbook of Agile Software CraftsmanshipFrom EverandClean Code: A Handbook of Agile Software CraftsmanshipRating: 5 out of 5 stars5/5 (13)

- Machine Learning: The Ultimate Beginner's Guide to Learn Machine Learning, Artificial Intelligence & Neural Networks Step by StepFrom EverandMachine Learning: The Ultimate Beginner's Guide to Learn Machine Learning, Artificial Intelligence & Neural Networks Step by StepRating: 4.5 out of 5 stars4.5/5 (19)

- Python Programming For Beginners: Learn The Basics Of Python Programming (Python Crash Course, Programming for Dummies)From EverandPython Programming For Beginners: Learn The Basics Of Python Programming (Python Crash Course, Programming for Dummies)Rating: 5 out of 5 stars5/5 (1)

- Linux: The Ultimate Beginner's Guide to Learn Linux Operating System, Command Line and Linux Programming Step by StepFrom EverandLinux: The Ultimate Beginner's Guide to Learn Linux Operating System, Command Line and Linux Programming Step by StepRating: 4.5 out of 5 stars4.5/5 (9)

- ITIL 4: Digital and IT strategy: Reference and study guideFrom EverandITIL 4: Digital and IT strategy: Reference and study guideRating: 5 out of 5 stars5/5 (1)

- Nine Algorithms That Changed the Future: The Ingenious Ideas That Drive Today's ComputersFrom EverandNine Algorithms That Changed the Future: The Ingenious Ideas That Drive Today's ComputersRating: 5 out of 5 stars5/5 (7)

- Art of Clean Code: How to Write Codes for HumanFrom EverandArt of Clean Code: How to Write Codes for HumanRating: 3.5 out of 5 stars3.5/5 (7)

- Introducing Python: Modern Computing in Simple Packages, 2nd EditionFrom EverandIntroducing Python: Modern Computing in Simple Packages, 2nd EditionRating: 4 out of 5 stars4/5 (7)

- The JavaScript Workshop: Learn to develop interactive web applications with clean and maintainable JavaScript codeFrom EverandThe JavaScript Workshop: Learn to develop interactive web applications with clean and maintainable JavaScript codeRating: 5 out of 5 stars5/5 (3)

- What Algorithms Want: Imagination in the Age of ComputingFrom EverandWhat Algorithms Want: Imagination in the Age of ComputingRating: 3.5 out of 5 stars3.5/5 (41)

- Monitored: Business and Surveillance in a Time of Big DataFrom EverandMonitored: Business and Surveillance in a Time of Big DataRating: 4 out of 5 stars4/5 (1)

- Excel VBA: A Comprehensive, Step-By-Step Guide on Excel VBA Programming Tips and Tricks for Effective StrategiesFrom EverandExcel VBA: A Comprehensive, Step-By-Step Guide on Excel VBA Programming Tips and Tricks for Effective StrategiesNo ratings yet

- Agile Metrics in Action: How to measure and improve team performanceFrom EverandAgile Metrics in Action: How to measure and improve team performanceNo ratings yet

- Software Engineering at Google: Lessons Learned from Programming Over TimeFrom EverandSoftware Engineering at Google: Lessons Learned from Programming Over TimeRating: 4 out of 5 stars4/5 (11)

- Python Programming: Your Advanced Guide To Learn Python in 7 DaysFrom EverandPython Programming: Your Advanced Guide To Learn Python in 7 DaysNo ratings yet