Professional Documents

Culture Documents

CO Parking Garage Design Guidelines

CO Parking Garage Design Guidelines

Uploaded by

Alexandru TeodorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CO Parking Garage Design Guidelines

CO Parking Garage Design Guidelines

Uploaded by

Alexandru TeodorCopyright:

Available Formats

The Right Choice

INTEC Controls

9730 Distribution Ave.

San Diego, CA 92121

info@inteccontrols.com

www.inteccontrols.com

Phone: (858) 578-7887

Fax: (858) 578-4633

Guidelines for the Design Engineer

Carbon Monoxide (CO)

Detection and Control Systems

for Parking Structures

Rev 1.11

1 General Overview ............................................................................................................ 3

1.1 Carbon Monoxide and Its Effects ........................................................................................................... 3

2 Installation and Application Codes and Standards ...................................................... 5

2.1 ASHRAE Handbook ............................................................................................................................... 5

2.2 IMC - International Mechanical Code..................................................................................................... 5

2.3 UMC - Uniform Mechanical Code .......................................................................................................... 5

2.4 UBC - Uniform Building Code................................................................................................................. 5

2.5 NFPA National Fire Protection Agency / Standard 720 ...................................................................... 5

3 Carbon Monoxide Exposure Limits................................................................................ 6

4 Detection and Control System........................................................................................ 7

4.1 Ventilation Requirements ....................................................................................................................... 7

4.2 Sensing Technology............................................................................................................................... 7

4.3 Location of Sensors and Controllers ..................................................................................................... 8

4.4 Selection of Detection and Control System Type................................................................................... 9

4.5 Basic Central Controller Recommendations ........................................................................................ 11

4.6 Controller Output Signals ..................................................................................................................... 12

4.7 System Self-Test Diagnostic with Malfunction Warning....................................................................... 12

4.8 Sample Sequence of Operations ......................................................................................................... 12

5 System Commissioning and Project Sign-off ............................................................. 13

5.1 Commissioning and Start-up................................................................................................................ 13

5.2 Performance Demonstration and Training ........................................................................................... 13

6 Calibration and Services............................................................................................... 13

6.1 Calibration ............................................................................................................................................ 13

7 Other Concerns.............................................................................................................. 14

7.1 Energy Cost & Greenhouse Savings and Return of Investment Potential........................................... 14

7.2 Time of Day Fan Scheduling................................................................................................................ 14

7.3 Diesel Fume Detection and Control ..................................................................................................... 14

7.4 Combustible Fume Detection and Control ........................................................................................... 15

7.5 Rough Environmental Conditions......................................................................................................... 15

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 2 of 15 Printed in USA 100511

Specification subject to change without notice.

1 General Overview

Carbon Monoxide (CO), one of the most toxic components of vehicle exhaust, is a significant safety

concerns in parking structures. Gas-powered vehicles make use of these structures on a regular basis and

emit CO. When concentrations of CO approach unsafe levels, the ventilation system must be activated to

normalize the parking area.

Due to energy and environment concerns, many jurisdictions across Northern America have mandated CO-

sensing control systems for new parking garages.

A wide range of gas detection and control systems is available for handling the sequence of operations for

enclosed parking structures. This guide offers detailed support for the Design Engineer in selecting and

specifying an optimal solution that will provide a safe environment and minimize energy cost. Ultimately, a

parking structures design will determine which type of gas detection and control system best fits the

application.

1.1 Carbon Monoxide and Its Effects

Carbon monoxide (CO) is a colorless, odorless and tasteless gas that is highly toxic to humans and

animals; it bonds with hemoglobin and reduces the oxygen-carrying capacity of blood in the body. Its

chemistry consists of one carbon atom and one oxygen atom. CO is produced from the partial

oxidation of carbon-containing compounds; it forms when there is not enough oxygen to produce

carbon dioxide (CO2), such as when operating a combustion engine in an enclosed space.

The level of CO concentration is measured in parts per million (ppm). For example, 100 ppm CO

means that for every 1,000,000 molecules of air, 100 of those molecules are CO.

In addition to determining the current level of CO concentration, another method used is the Time

Weighted Average (TWA). This measures a persons average exposure (in ppm) to CO over a time

span. For example, if a person were exposed to a large dose of CO in the morning but none

afterwards into the evening, the TWA for the entire day would be low. However, if a person is

continually exposed to 20 ppm CO throughout the day, the TWA will be 20 ppm for that duration.

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 3 of 15 Printed in USA 100511

Specification subject to change without notice.

The table below summarizes some health effects due to prolonged exposure to various concentrations

of CO in air. It has been compiled from reputable sources, including the NFPA:

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 4 of 15 Printed in USA 100511

Specification subject to change without notice.

CO Level Condition & Health Effects Institute

0 ppm Normal, fresh air

9 ppm Maximum allowable short-term exposure ASHRAE

10-24 ppm Possible health effects with long-term exposure

25 ppm Max TWA exposure for 8 hour work-day ACGIH

50 ppm Maximum permissible exposure in workplace OSHA

100 ppm Slight headache after 1-2 hours

200 ppm Dizziness, nausea, fatigue, headache after 2-3 hours of exposure

400 ppm Headache and nausea after 1-2 hours of exposure / Life threatening in 3 hours

800 ppm Headache, nausea, and dizziness after 45 minutes / Collapse and unconsciousness

after 1 hour of exposure / Death within 2-3 hours

1,600 ppm Headache, nausea, and dizziness after 20 minutes of exposure / Death within 1-2

hours

3,200 ppm Headache, nausea, and dizziness after 5-10 minutes / Collapse and

unconsciousness after 30 minutes of exposure / Death within 1 hour

6,400 ppm Death within 30 minutes

12,800 ppm Immediate physiological effects, unconsciousness / Death within 1-3 minutes of

exposure

2 Installation and Application Codes and Standards

Various institutions, societies, organizations and government agencies establish codes and standards to

address the limits of CO levels for parking structures. Most building codes allow for demand-based

ventilation in enclosed parking garages by monitoring CO levels. This type of design can drastically reduce

energy costs (operating of garage fans and heating system), increase fan belt and motor life and reduce

noises. Codes and standards vary by city and state. An overview of the most well known is listed below.

The design of a garage exhaust system should be based upon the codes and standards of the appropriate

local jurisdiction.

2.1 ASHRAE Handbook

To conserve energy, fan systems should be controlled by carbon monoxide meters with multiple fan or

variable speed stages for larger systems, if permitted by local codes. In multi-level parking garages or

single-level structures of extensive area, independent fan systems, each under individual control, are

recommended.

2.2 IMC - International Mechanical Code

Mechanical ventilation systems for public garages are not required to operate continuously where the

system is arranged to operate automatically upon detection of a concentration of carbon monoxide of

25 ppm by approved detection devices.

2.3 UMC - Uniform Mechanical Code

Automatic carbon monoxide-sensing devices may be employed to modulate the ventilation system to

maintain a maximum average concentration of carbon monoxide of 50 ppm during any eight-hour

period, with a maximum concentration not greater than 200 ppm for a period not exceeding one hour.

2.4 UBC - Uniform Building Code

Automatic CO sensing devices may be employed to modulate the ventilation system to maintain a

maximum average of 50 ppm CO during any eight-hour period, with a maximum average concentration

not greater 200 ppm for a period not exceeding one hour.

2.5 NFPA National Fire Protection Agency / Standard 720

Standard for Installation of Carbon Monoxide Detection & Warning Equipment Requires carbon

monoxide monitoring equipment (i.e. sensors/transmitters) to be performance tested and certified to

standard UL2075.

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 5 of 15 Printed in USA 100511

Specification subject to change without notice.

3 Carbon Monoxide Exposure Limits

Each organization has its own vocabulary to describe the type of limit or level. Here is a summary of some

common terms:

TWA - Time Weighted Average. This is the level of CO (in ppm) that a person has been exposed to on

average over some period of time (usually 8 hours).

PEL - Permissible Exposure Limit. This is the term OSHA uses for the limits it publishes. For CO, it happens

that all of OSHA's PELs are actually TWA limits.

Ceiling - An upper limit on the permissible concentration of CO at any moment. For example, a ceiling value

of 200 ppm means that the level of CO should never rise above 200 ppm.

STEL - Short Term Exposure Limit. This is a TWA defined over a short time period of 15 minutes. According

to ACGIH, it should not be exceeded during any part of a workday, even if the 8-Hour TWA is within its limit.

Excursion Limit - An ACGIH term that refers to the ceiling limit within a short duration (typically 15 - 30

minutes). This limit is used when no STEL is published, and is defined as 5 times the 8-Hour TWA limit

(Source: ACGIH Handbook of TLVs and BEIs, 2004).

The table below summarizes the alarm levels and national standards for garage CO exposure levels:

Organization

Type

CO level in

air

Alarm level

ACGIH

American Conference of Governmental

Industrial Hygienists

TWA

(8 Hours)

25 ppm

IMC

International Mechanical Code

25 ppm

Smallest CO ppm amount for

Low Alarm Level Trip/Setpoint

NIOSH

National Institute for Occupational Safety

and Health

TWA

(1 Hour)

35 ppm

EPA

Environmental Protection Agency

TWA

(1 Hour)

35 ppm

Acceptable CO ppm amount for

Low Alarm Level Trip/Setpoint

OSHA

Occupational Safety and Health

Administration

OSHA PEL

as TWA

(8 Hours)

50 ppm

Acceptable CO ppm amount for

Low Alarm Level Trip/Setpoint.

Maximum concentration for low alarm!

75 ppm

CO ppm amount for Medium Alarm

Level Trip/Setpoint

Manufacturers recommendation

100 ppm

Smallest CO ppm amount for

High Alarm Level Trip/Setpoint

ACGIH

American Conference of Governmental

Industrial Hygienists

Excursion

Limit (EL)

125 ppm

Acceptable CO ppm amount for

High Alarm Level Trip/Setpoint

NIOSH

National Institute for Occupational Safety

and Health

Ceiling 200 ppm

Acceptable CO ppm amount for

High Alarm Level Trip/Setpoint.

Maximum concentration for high alarm!

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 6 of 15 Printed in USA 100511

Specification subject to change without notice.

Manufacturers recommendation

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 7 of 15 Printed in USA 100511

Specification subject to change without notice.

4 Detection and Control System

4.1 Ventilation Requirements

A controller monitoring multiple CO sensors should be capable of zoning. The controller should have

multiple relay outputs and thresholds in order to control exhaust fans, make-up fans and supply fans.

Analog outputs from the controller can be used to ramp up variable-frequency drives (VFD) based on

the serviced area of the exhaust fan.

When the exhaust fans are stopped or operating at low speed the garage will have minimal ventilation.

On hot and humid days the controller should be able to increase the speed of the exhaust fans to

compensate for high temperature or high humidity conditions.

4.2 Sensing Technology

The International Mechanical code states that ventilation systems for enclosed parking garages are

not required to operate continuously if the system is arranged to react automatically upon detection of

a concentration of carbon monoxide of 25 ppm by approved automatic detection devices.

The accurate detection of CO at low levels is critical in garage applications. There are currently two

types of CO sensing technology available: electro-chemical and solid state. The most accurate

devices utilize an electro-chemical element. These sensors are gas specific and have an accuracy

reading of +/- 0.5 to 1 ppm. By contrast, solid state sensors approximate the CO levels and are

susceptible to temperature or humidity. Solid state sensors are also cross sensitive to other gases and

heavy solvents in the environment, and thus, prone to false alarms.

The market offers mainly two types of CO gas sensing element technologies for commercial

garage applications electrochemical and solidate state

Technology Accuracy

PPM CO

Life Span Features

Electrochemical

Type High Accuracy

< +/- 1 5+ years

Detects the true level of CO in ppm

Reduced drift

High accuracy & reduced drift

means fewer calibration intervals

Electrochemical

Type Standard

+/- 3 < 5 years

Solid State /

Semiconductors (MOS)

Type 1

+/- 7 to 15 7+ years

Solid State /

Semiconductors (MOS)

Type 2

Unknown 2.5 years

Solid state sensors:

Are cross sensitive and prone to false

alarm

Subject to drifts of readings at sizeable

space temperature and/or humidity

changes

Shorter calibration intervals

CO Guidelines for the

4.3 Location of Sensors and Controllers

Sensors shall be located in the garage area and mounted on columns at approximately 5 ft above the

floor. Each CO sensor can cover approximately 5,000 to 10,000 sq ft of open space. CO gas will

disperse and flow with natural air current and car movement.

Using the average of 7,500 sq ft per sensor and a circular radius of 49 feet, the sensors area coverage

could be scaled and placed on the garage floor plan layout to cover the open floor area.

Based on the number of CO sensors and the location of the exhaust fans and make-up air handlers,

one can determine the most cost effective CO detection equipment to minimize the total cost of

sensors, controllers, conduit, wiring, termination, startup and final commissioning.

ill. 1 Sample CO sensor placement

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 8 of 15 Printed in USA 100511

Specification subject to change without notice.

4.4 Selection of Detection and Control System Type

Single & Dual Sensor Systems are best for smaller size areas (7,500 to 15,000 sq ft). The system

monitors one or two gas types and has relay outputs for fan control. The single or dual sensor system

will also have an analog output to control one VFD.

ill. 2 Typical single- or dual-point system

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 9 of 15 Printed in USA 100511

Specification subject to change without notice.

ill. 3 Typical analog, multi-point system

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 10 of 15 Printed in USA 100511

Specification subject to change without notice.

Multi-Point Analog Systems are best for small to medium size areas (15,000 to 90,000 sq ft). The

system can monitor multiple gas sensors and control multiple relays for fan control. All sensor wiring

is home run to the multi-point controller using two-wire (three-wire for combustible gas transmitters)

shielded cable. The controller should be capable of providing multiple relay outputs for fan control and

have multiple analog outputs to control VFDs.

Digital Multi-Point Bus Systems are best for medium to large areas (90,000+ sq ft). It reduces the

total overall installation cost when using a digital daisy chain setup, where four wires are connected

to each sensor or remote relay. The conduit is minimized to since only two wires are used for

power and two twisted shielded wires for the communication. The system can monitor up to 98 digital

gas sensors. The fans can be turned on and ramped up via relays and analog outputs located in the

controller or remote relay/AO modules located anywhere along the bus.

ill. 4 Typical digital, RS-485, multi-point system

4.5 Basic Central Controller Recommendations

- The controller should not be located where water, oil etc. may influence proper operation or where

mechanical damage might be possible.

- Mount where service technicians can gain access.

- The controller shall allow five programmable stage alarm levels per sensor (four stages for stand-

alone) with each stage assignable to a control relay output. The controller shall also provide

analog outputs (4-20mA) corresponding to the real-time value of the highest gas sensor within a

sensor zone.

- Analog transmitters (AT-series) shall output a 4-20mA signal corresponding to the real-time gas

value readings and connect to the controller (or digital transmitter) via two-wire (loop powered) or

three-wire connection.

- Digital transmitter (DT5-series) shall output a digital signal that shows the real-time gas value

readings and connect to the controller via 4-wire connection (two wires for power and two wires for

RS-485 communication).

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 11 of 15 Printed in USA 100511

Specification subject to change without notice.

- The controller shall be capable of zoning the highest real-time value reading of a sensor.

- The controller shall have a digital display with keypad that is password protected and allows for

programming or changing of all system parameters and for viewing of all sensor readings.

4.6 Controller Output Signals

- The quantity of relay outputs varies depending on the system configuration. Some relay contacts

are SPDT 8A, 250VAC max. Some relay contacts are (1) SPDT 0.5A and (1) SPNO/SPNC 0.5A,

30VAC max. Systems can have up to 30 relay outputs depending on the system configuration.

The relays can be used to control fans, horns, and strobes, or provide status to the building

automation system (BAS).

- Analog Output: A sensor (or sensors) can be assigned to a particular analog output (4-20mA

signal) to show the highest sensor reading value of a zone group in real-time. The system should

be capable of 12 analog outputs. The analog outputs normally connect to variable-frequency

drives to increase or decrease fan speed as the gas ppm concentration increases or decreases.

- The controller can be provided with a BACnet, LON or Modbus coupler that provides upwards

communication to the BAS.

4.7 System Self-Test Diagnostic with Malfunction Warning

- The controller shall notify appropriate personnel when a fault has occurred.

- The controller, with the correct level password, allows manual override of the relays outputs. The

controller can be programmed to assign any of the four digital inputs to override the assigned relay

to off or on condition automatically.

- Controller can be programmed to alarm the operator of system maintenance whenever a set date

has been reached by displaying the phone number to contact for further instructions.

- The controllers integrated fault management shall keep records of the last 15 faults with date and

time stamps that can be viewed by authorized personnel with the appropriate password.

4.8 Sample Sequence of Operations

In this example, a small enclosed parking garage with a low setpoint of 25 ppm and a high of 100 ppm.

When any CO sensor exceeds a threshold (ppm level in air) the following shall happened:

- Threshold # 1 (low alarm level trip/setpoint) at 25 ppm:

Start the exhaust fan at minimum speed with relay #1 to bring in fresh air and

reduce the CO level.

- Threshold # 2 (medium alarm level trip/setpoint) at 75 ppm:

Step up the exhaust fan to high speed with relay # 2 to bring more fresh air and

reduce the CO level.

If the exhaust fans have VFDs preferably use the analog output associated with this

exhaust fan to ramp up the VFD between 25 ppm and 75 ppm proportionally to

highest speed.

- Threshold # 3 (high alarm level trip/setpoint) at 100 ppm:

Turn on with relay # 3 remote horns/strobes located in garage area or areas where

security or maintenance personnel can be warned of high ppm CO concentrations.

- Threshold # 4 (high alarm level trip/setpoint) at 100 ppm:

Notify with relay high alarm level condition to the BAS.

- Threshold # 5 (high alarm level trip/setpoint) at 100 ppm:

Activate controllers horn/buzzer and alarm LED.

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 12 of 15 Printed in USA 100511

Specification subject to change without notice.

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 13 of 15 Printed in USA 100511

Specification subject to change without notice.

5 System Commissioning and Project Sign-off

5.1 Commissioning and Start-up

- A qualified gas control system service technician should perform the following:

- Thoroughly check that onsite assembled equipment, specified cables, control unit station(s),

remote sensors/transmitters & other field control modules are properly placed and installed.

- Verify that electrical connections follow electrical and building codes. The wiring end must

terminate correctly.

- Apply calibration gases on the sensors in order to test the correct functions of the alarm setpoints

and verify the operations sequence of the carbon monoxide detection and control system.

- Issue a written report of the test results and corrective actions to be completed if required.

- The report should include the verification of all devices, i.e. remote strobe, horn, sign, other alarm

units and protective equipment, etc.

- Malfunctioning products are repaired or replaced.

5.2 Performance Demonstration and Training

The building owners maintenance personnel should be trained by a qualified gas system service

technician. This individual will be responsible for changing setpoints & operations sequence,

troubleshooting, performing scheduled maintenance, and calibrating the CO detection and control

system using the appropriate tools and test gases.

6 Calibration and Services

6.1 Calibration

- Calibration intervals must comply with the manufacturers recommendations.

- Calibration tool kit shall be provided at the time of the installed systems completion.

- Building owners may consider maintaining and calibrating the CO, as well as NO2 and

combustible, gas detection and control system periodically by a qualified gas detection service

company.

7 Other Concerns

7.1 Energy Cost & Greenhouse Savings and Return of Investment Potential

The table below is an example of the potential savings by using an appropriate gas detection demand

control system.

Underground Garage/Parking Structure of an Office Building

- 100,000 sq ft for about 350 parking spaces for automobiles

- Approximately total 75 HP (Horsepower), combined of all fans

- 12 hours/day and 7 days/week garage operation

HP (Horsepower) to Watts (Electrical Power) Conversion

(In this example the fan motor efficiency and load factor canceling out each other)

75 HP x 746 Watts/HP = 55,950 Watts divided by 1,000 = 55.95 kWatts

Without Gas Detection Demand Control

12 hours/day x 365 days x 55.95 kWatts = 245,061 kWh

Annual

Fan Power

Consumption

(kWh)

With Gas Detection Demand Control

2 hours/day x 365 days x 55.95 kWatts = 40,844 kWh

Annual

Savings

kWh Savings per Year:

No Demand Control 245,061 kWh

Demand Control - 40,844 kWh

Savings = 204,217 kWh

Electricity Cost Savings per Year:

204,217 kWh

x $ 0.175 per 1 kWh

Savings = $ 35,738

With Utility

Rebate

Immediate to 0.5 Year

- Installation Cost -

Return of

Investment

(No Rebate) 0.8 to 1.5 Year

Greenhouse

Savings

273,651 lbs CO

2

7.2 Time of Day Fan Scheduling

Some products offer a time clock in their CO detection and controls system package for actuating a

ventilation system based on the time of the day. This is unnecessary! The CO detection and control

system detects the presence of CO and actuates the fans ONLY when needed.

Overriding the ventilation system with a time switch diminished the benefits of a CO system. Instead of

using a time of day override function, integrate high temperature and/or relative humidity limit

ventilation control to facilitate and secure adequate space comfort when no CO is present.

7.3 Diesel Fume Detection and Control

Diesel-powered vehicles emit exhaust containing nitrogen dioxide (NO2), a major contaminant and

carcinogen (cancer causing agent). The monitoring of NO2 must be addressed in the design of a

ventilation system.

- Nitrogen dioxide detection and control is applied wherever numerous diesel engines are used, i.e.

train stations, bus and truck maintenance garages, rapid transit authorities, car dealerships,

ambulance bays, loading docks and diesel-powered vehicle parking structures.

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 14 of 15 Printed in USA 100511

Specification subject to change without notice.

7.4 Combustible Fume Detection and Control

When vehicles using fuel types such as methane, propane, or where gasoline spillage is of concern

then consider combustible gas detection sensors in the design of the ventilation system.

7.5 Rough Environmental Conditions

Depending on the parking structure design, type of usage, and installation location, special product

packaging requirements may apply; i.e. sensors and/or controllers exposed to:

- Dust, dirt, light water splashing

Provide optional NEMA 4X enclosure (X = Designates resistance to corrosive

agents).

- Washing cars and/or hosing down walls

Provide optional NEMA 4X enclosure with splash guard protection.

- Low temperature environment, sensor/transmitter ambient temperature below -10C (14F)

Provide optional heater, built-in sensor/transmitter enclosure, allows ambient

temperature down to -40C (-40F).

CO Guidelines for the

Design Engineer

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 9730 Distribution Ave., San Diego, CA 92121

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com Page 15 of 15 Printed in USA 100511

Specification subject to change without notice.

You might also like

- Nursing Care Plan For Risk For Aspiration NCPDocument5 pagesNursing Care Plan For Risk For Aspiration NCPderic100% (8)

- British Standard: A Single Copy of This British Standard Is Licensed ToDocument11 pagesBritish Standard: A Single Copy of This British Standard Is Licensed ToMohamed AdelNo ratings yet

- ECA Task Force CCS GuidelineDocument48 pagesECA Task Force CCS Guidelinemercedes100% (1)

- Basics of Designing MATVDocument12 pagesBasics of Designing MATVIbrahim GhannamNo ratings yet

- Pocket Guide 10 (Fire Alarms in Dwellings)Document2 pagesPocket Guide 10 (Fire Alarms in Dwellings)RudanekNo ratings yet

- 2 Fire DamperDocument28 pages2 Fire Damperntt_121987No ratings yet

- CO Parking Garage Design Guidelines PDFDocument15 pagesCO Parking Garage Design Guidelines PDFSrki MenNo ratings yet

- Cable Sizing CalculationDocument1 pageCable Sizing CalculationhafizheryNo ratings yet

- EMC Issue On HV SWGDocument9 pagesEMC Issue On HV SWGsusanto_andri_2005No ratings yet

- BEMS ManualDocument111 pagesBEMS Manual이아름No ratings yet

- Power System Engineering by R K RajputDocument3 pagesPower System Engineering by R K RajputVIGNESH T A100% (1)

- AMTED300014ENDocument84 pagesAMTED300014ENAmol KhanvilkarNo ratings yet

- Air QualityDocument31 pagesAir QualityMohammad Faizul ZainudinNo ratings yet

- Building Energy Auditing Module 3 - FinalDocument22 pagesBuilding Energy Auditing Module 3 - FinalMadhu ValavalaNo ratings yet

- LCCC, Energy Efficiency and Renewable Energy Site. Ministry of Communication, Works, Transport and Public Utilities, St. Lucia, 12-2010Document34 pagesLCCC, Energy Efficiency and Renewable Energy Site. Ministry of Communication, Works, Transport and Public Utilities, St. Lucia, 12-2010Detlef LoyNo ratings yet

- Load ForecastingDocument15 pagesLoad ForecastingRathinaKumarNo ratings yet

- ERITECH Grounding & Bonding Catalogue PDFDocument68 pagesERITECH Grounding & Bonding Catalogue PDFanji201No ratings yet

- Austin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013Document123 pagesAustin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013megamaster2010No ratings yet

- Catalogo Lutron WallboxDocument287 pagesCatalogo Lutron WallboxCecilia GonzalezNo ratings yet

- Zumtobel Health CareDocument54 pagesZumtobel Health CareDaniel SalinasNo ratings yet

- 1 Upfc ContentsDocument4 pages1 Upfc ContentsRafat ThongNo ratings yet

- Smartplant ElectricalDocument1 pageSmartplant ElectricalGEETHA PUSHKARANNo ratings yet

- ProtectionDocument16 pagesProtectionDEADMANNo ratings yet

- Medical Gas SpecDocument8 pagesMedical Gas SpecJanitha Lakmina BandaraNo ratings yet

- Interpreting IEEE STD 519 and Meeting Harmonic Limits VFDs PCIC 2003 15Document6 pagesInterpreting IEEE STD 519 and Meeting Harmonic Limits VFDs PCIC 2003 15Vinícius BaconNo ratings yet

- Help SIMARIS Project 3.1 enDocument61 pagesHelp SIMARIS Project 3.1 enVictor VignolaNo ratings yet

- g83 2 Single Premises Connection GuideDocument44 pagesg83 2 Single Premises Connection Guideabbd1990No ratings yet

- Concepts and PrinciplesDocument38 pagesConcepts and PrinciplesManjunath DsNo ratings yet

- Fault Current and The Effects On Clampstar®: Test At)Document4 pagesFault Current and The Effects On Clampstar®: Test At)Dante FilhoNo ratings yet

- Electrical Planning and Design Guide FinalDocument187 pagesElectrical Planning and Design Guide FinalSundaresan SabanayagamNo ratings yet

- Equipment Heat GainDocument6 pagesEquipment Heat GainpauloNo ratings yet

- Level3 - Application Note Earth Leakage RelayDocument4 pagesLevel3 - Application Note Earth Leakage RelayChhinPidenNo ratings yet

- EDS 06-0017 Customer Installation Earthing DesignDocument48 pagesEDS 06-0017 Customer Installation Earthing DesignelectworldNo ratings yet

- Direct Digital ControllerDocument2 pagesDirect Digital ControllerRushikesh Uttamrao patilNo ratings yet

- Getting Into The Flow Understanding Connectors in Revit MEPDocument21 pagesGetting Into The Flow Understanding Connectors in Revit MEPilikefreeNo ratings yet

- Eds 02-0041Document42 pagesEds 02-0041daegerteNo ratings yet

- IEA Grid Connected PV Power Systems PDFDocument64 pagesIEA Grid Connected PV Power Systems PDFces.alexander.cvNo ratings yet

- Demand FactorDiversity FactorUtilization FactorLoad FactorDocument15 pagesDemand FactorDiversity FactorUtilization FactorLoad FactorscribistNo ratings yet

- Electrical Design EngineerDocument3 pagesElectrical Design EngineerNikhatRizaviNo ratings yet

- Section 21-Elect Specs 08-03-08 LatestDocument98 pagesSection 21-Elect Specs 08-03-08 LatestsasikalaNo ratings yet

- Innovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987From EverandInnovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D A ReayNo ratings yet

- APA Reseach PaperDocument38 pagesAPA Reseach PaperMegi MarkuNo ratings yet

- CO2 Safety ManualDocument51 pagesCO2 Safety ManualKrishna YadavNo ratings yet

- Co Monitoring GuideDocument12 pagesCo Monitoring GuideMohammad MohammadeeNo ratings yet

- 6622 Environmental PlanningDocument16 pages6622 Environmental PlanningAlrik EYINo ratings yet

- Hot Car Baby Detector: By: Jian Gao Luis PabonDocument27 pagesHot Car Baby Detector: By: Jian Gao Luis PabonAMitBhardwajNo ratings yet

- Chalp 2009Document182 pagesChalp 2009Carlos OmarNo ratings yet

- ScrubberDocument64 pagesScrubberPrashant Rajput100% (1)

- CATS Technical BrochureDocument22 pagesCATS Technical BrochurePeter FormanNo ratings yet

- 16681Document8 pages16681Asad Abbas Amerjee0% (1)

- Hydraulic ABS For Medium-Duty Trucks, Buses and Motor Home ChassisDocument36 pagesHydraulic ABS For Medium-Duty Trucks, Buses and Motor Home ChassisMAHMOUDNo ratings yet

- Environmental SolutionsDocument92 pagesEnvironmental Solutionsmihai.banicaNo ratings yet

- International Code CouncilDocument111 pagesInternational Code CouncilCraig J Lopez AiaNo ratings yet

- Operation and Maintenance of Hospital IncineratorsDocument226 pagesOperation and Maintenance of Hospital IncineratorsElder A. Gutiérrez Villacorta100% (1)

- Standards Publication Technical Corrigendum: Doc No: QP-STD - S - 036Document24 pagesStandards Publication Technical Corrigendum: Doc No: QP-STD - S - 036samynathan_bvsNo ratings yet

- On Board Diagnostics (OBD) Scan Tool To Diagnose Emission Control SystemDocument5 pagesOn Board Diagnostics (OBD) Scan Tool To Diagnose Emission Control SystemEditor IJRITCCNo ratings yet

- Raw Milk: Product Category Classification: Un CPC 022Document26 pagesRaw Milk: Product Category Classification: Un CPC 022Nathalia Del PilarNo ratings yet

- Iron SteelDocument74 pagesIron Steelmano1574No ratings yet

- Mitigation of Internal Corrosion in Carbon Steel Gas Pipeline SystemsDocument24 pagesMitigation of Internal Corrosion in Carbon Steel Gas Pipeline Systemsakshat agrawalNo ratings yet

- Nitrogen Safety BookletDocument61 pagesNitrogen Safety BookletRauf HuseynovNo ratings yet

- Ashare 62 2001Document40 pagesAshare 62 2001Trương Văn Cường100% (2)

- Enviromental Fluid Catalytic Cracking Technology PDFDocument43 pagesEnviromental Fluid Catalytic Cracking Technology PDFNoheilly VásquezNo ratings yet

- 0702 Sound and Vibration ControlDocument7 pages0702 Sound and Vibration Controlntt_121987No ratings yet

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987No ratings yet

- 1Document3 pages1ntt_121987No ratings yet

- No. Model Selling Price USD: Bình Tank Hiệu Zilmet - Ý - 10 BarsDocument1 pageNo. Model Selling Price USD: Bình Tank Hiệu Zilmet - Ý - 10 Barsntt_121987No ratings yet

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987No ratings yet

- LH124 4ces 9yDocument4 pagesLH124 4ces 9yntt_121987No ratings yet

- Stair Pressurization - 23 5 2015Document8 pagesStair Pressurization - 23 5 2015ntt_121987No ratings yet

- FVG FVPG FD R22Document154 pagesFVG FVPG FD R22thanhlong2005No ratings yet

- 3.MECH Duct11Document2 pages3.MECH Duct11ntt_121987No ratings yet

- Pressure Relief DamperDocument1 pagePressure Relief Damperntt_121987No ratings yet

- Thu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNDocument2 pagesThu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNntt_121987No ratings yet

- Non Return DamperDocument3 pagesNon Return Damperntt_121987No ratings yet

- MechanicalDocument56 pagesMechanicalntt_121987No ratings yet

- Egg Crate: Product InformationDocument5 pagesEgg Crate: Product Informationntt_121987No ratings yet

- Linear Bar Grille - FullDocument7 pagesLinear Bar Grille - Fullntt_121987No ratings yet

- Volume Control DamperDocument8 pagesVolume Control Damperntt_121987No ratings yet

- Perforated GrilleDocument5 pagesPerforated Grillentt_121987No ratings yet

- Motorised DamperDocument3 pagesMotorised Damperntt_121987No ratings yet

- Lourve: Product InformationDocument8 pagesLourve: Product Informationntt_121987No ratings yet

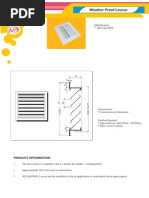

- Weather Proof Louvre MDocument6 pagesWeather Proof Louvre Mntt_121987No ratings yet

- Single DeflectorDocument7 pagesSingle Deflectorntt_121987No ratings yet

- Weather Proof LouvreDocument6 pagesWeather Proof Louvrentt_121987No ratings yet

- Air Light TrofferDocument2 pagesAir Light Trofferntt_121987No ratings yet

- Double DeflectorDocument7 pagesDouble Deflectorntt_121987No ratings yet

- Jet DiffuserDocument5 pagesJet Diffuserntt_121987No ratings yet

- Plenum BoxDocument2 pagesPlenum Boxntt_121987No ratings yet

- Round DiffuserDocument2 pagesRound Diffuserntt_121987No ratings yet

- Supply Air DiffuserDocument6 pagesSupply Air Diffuserntt_121987No ratings yet

- Encyclopedia of Depression Research - James R. FuscoDocument562 pagesEncyclopedia of Depression Research - James R. FuscoJaqueline CarvalhoNo ratings yet

- BDP (Barangay Development Plan) Part 1Document12 pagesBDP (Barangay Development Plan) Part 1Kazumi Shiori100% (5)

- CHL Ar 2020 DigitalDocument70 pagesCHL Ar 2020 DigitalSujan TumbapoNo ratings yet

- Garcinia Cowa 3Document3 pagesGarcinia Cowa 3Mostafa Al AminNo ratings yet

- Job Vacancy - WASH OfficerDocument2 pagesJob Vacancy - WASH OfficerAdham Abdulrahman AlSalehNo ratings yet

- API Brochure - Bazayan - 19 PDFDocument7 pagesAPI Brochure - Bazayan - 19 PDFashishvsNo ratings yet

- Pengajuan Order 14-03-2024Document189 pagesPengajuan Order 14-03-2024praditya24No ratings yet

- Climate Change Impacts, Adaptation and Vulnerability in The Niger Delta Region of NigeriaDocument9 pagesClimate Change Impacts, Adaptation and Vulnerability in The Niger Delta Region of NigeriaTemesgen M. MandersoNo ratings yet

- Hyperthyroidism (Thyrotoxicosis) : 郑州大学第一附院内分泌科 王守俊 Wang shou junDocument133 pagesHyperthyroidism (Thyrotoxicosis) : 郑州大学第一附院内分泌科 王守俊 Wang shou junapi-19916399No ratings yet

- RESPONDER Nitrile Exam GlovesDocument6 pagesRESPONDER Nitrile Exam Glovessandakelum AsankaNo ratings yet

- Comparison Haigis Vs SRK TDocument5 pagesComparison Haigis Vs SRK TSatya PratiwiNo ratings yet

- Web Based Appointment Management System For Out Patient Department Bukidnon Provincial Hospital Kibawe Bukidnon RRLDocument4 pagesWeb Based Appointment Management System For Out Patient Department Bukidnon Provincial Hospital Kibawe Bukidnon RRLEmar Vince OliverosNo ratings yet

- Cns InfectionsDocument141 pagesCns InfectionsReda AlyNo ratings yet

- Prevention of Injury and Overuse in Sports-2016Document178 pagesPrevention of Injury and Overuse in Sports-2016Mahdicheraghi100% (1)

- Managing Fatigue in The Workplace: A Guide For Oil and Gas Industry Supervisors and Occupational Health PractitionersDocument28 pagesManaging Fatigue in The Workplace: A Guide For Oil and Gas Industry Supervisors and Occupational Health PractitionersRaulEsparzaP100% (1)

- Protecting The Environment Is The Most Important Problem Facing The World Today (Protejarea Mediului Este Cea Mai Imporanta Problema Cu Care Se Confrunta Lumea in Ziua de Azi)Document1 pageProtecting The Environment Is The Most Important Problem Facing The World Today (Protejarea Mediului Este Cea Mai Imporanta Problema Cu Care Se Confrunta Lumea in Ziua de Azi)Ana-Maria CiobotaruNo ratings yet

- MY Persuasive SpeechDocument1 pageMY Persuasive SpeechKrishia BlascoNo ratings yet

- Social Support For The Parents of Children WithDocument5 pagesSocial Support For The Parents of Children WithLina Mahayaty SembiringNo ratings yet

- Final 1 AsdaDocument16 pagesFinal 1 Asdaapi-511390817No ratings yet

- Cardiometry No7 November 2015 PDFDocument69 pagesCardiometry No7 November 2015 PDFEmanuele DanieleNo ratings yet

- US4917890 Porceder de Fabrication Aloe Vera Et Des Produits À Base D'aloe Vera PDFDocument74 pagesUS4917890 Porceder de Fabrication Aloe Vera Et Des Produits À Base D'aloe Vera PDFNadjah YousfiNo ratings yet

- Pe1 Q2 Week 5-6Document5 pagesPe1 Q2 Week 5-6Mercy Joyce Nuque CastanedaNo ratings yet

- Service Profile Book DSS Engilish VersionDocument123 pagesService Profile Book DSS Engilish VersionMAZID TTNo ratings yet

- Referral Form Jessa 2021Document1 pageReferral Form Jessa 2021Jessa MaeNo ratings yet

- Cardiac Arrest Vs Heart Attack 2019Document1 pageCardiac Arrest Vs Heart Attack 2019Celine SuryaNo ratings yet

- 5 6073397899041964251 PDFDocument18 pages5 6073397899041964251 PDFPradosh Kumar PanigrahyNo ratings yet

- Healthy Fit & Strong - A Parent-Child Physical Activity ProgramDocument51 pagesHealthy Fit & Strong - A Parent-Child Physical Activity ProgramUsman Ahmad TijjaniNo ratings yet