Professional Documents

Culture Documents

Assembly Systems and Line Balancing

Uploaded by

Poonkuzhali ManiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assembly Systems and Line Balancing

Uploaded by

Poonkuzhali ManiCopyright:

Available Formats

Assembly Systems and Line Balancing

*Discrete products are assembled from components.

The Assembly Process

Definition: assembly involves the joining together of two or more separate parts to form a new entity

(assembly or subassembly).

*The processes used to accomplish the assembly of the components can be divided into three major

categories.

1. Mechanical Fastening Mechanical action to hold components together.

Threaded fasteners - screws, bolts, nuts etc.

Rivets, crimping and other methods

Press fits

Snap fits temporary interface of the two parts C-ring.

Sewing and stitching for soft, thin material.

2. Joining Methods welding, brazing and soldering

3. Adhesive Bonding thermoplastic, thermosetting (chemical reaction)

Assembly Systems

*There are various methods used in industry to accomplish the assembly processes. Major methods can be

classified:

1. Manual Single-StationAssembly

*Consist of a single workplace to accomplish the product or some major subassembly of the product.

*Generally used on a product that is complex and produced in small quantities, one or more workers

depending on the size of the product and the production rate.

*Such as machine tools, industrial equipment, aircraft, ships and complex consumer products (appliances,

car,...)

2. Manual AssemblyLines

*Consist of multiple workstations in which the assembly work is accomplished as the product (subassembly)

is passed from station to station along the line.

*At each workstation one or more human workers perform a portion of the total assembly work on the

product, by adding one or more components to the existing subassembly.

3. AutomatedAssemblySystem

*Use of automated methods at the workstations rather than human beings.

I. Manual Assembly Lines

Are used in high-production situations where the work to be performed can be divided into small tasks and

tasks assigned to the workstations on the line.

Key advantage of using manual assembly line is specialization of labor By giving each worker a limited

set of tasks to do repeatedly.

Transfer of Work Between Workstations

*There are two basic ways in which the work is moved on the line between operator workstations.

1. Non mechanical Lines

*No belt or conveyor is used to move the parts. The parts are passed from station to station by hand.

Problems:

Starving at stations wait for parts from the preceding station.

Blocking of station wait for the next operator to finish the task before passing along the part.

Results:

the flow of work is usually uneven

cycle time vary

buffer stocks of parts between workstations are often used to smooth out the production flow.

2. Moving Conveyer Lines

Use a moving conveyor (e.g. belt, convey, chain-in-the-floor)

Problems:

Starving can occur as with none-mechanical lines

Incomplete items are sometimes produced unable to finish the current part.

To control the feed rate of the line:

F

p

: denote feed rate

V

c

: conveyor speed

S

p

: Spacing between parts on the moving conveyor

F

p

= V

c

/ S

p

The time period (tolerance time ) T

t

L

s

: is determined largely by the operators reach at the workstation

T

t

= L

s

/ V

c

II. The Line Balancing Problem

*The line balancing problem is to arrange the individual processing and assembly tasks at the workstations so

that the total time required at each workstation is approximately the same.

*If the work elements can be grouped so that all the station times are exactly equal, we have perfect balance

on the line and we can expect the production to flow smoothly.

*In most practical situations it is very difficult to achieve perfect balance. When workstation times are

unequal, the slowest station determines the overall production rate of the line.

Terminology for Line Balancing

Minimum Rational Work Element

*Minimum rational work element is the smallest practical indivisible tasks into which the job can be divided.

These work elements cannot be subdivided further

Finished

Assembly out

Work carrier

Or Base part in

Components added at each station

Work

Flow

ASBY

MAN

ASBY

MAN

ASBY

MAN

*Example: drilling a hole, screw and nut etc.

*T

ej

: where j is used to identify the element out of the n

e

elements that make up the total work.

Total Work Content

*Total work, T

wc

, content is the aggregate of all the work elements to be done on the line.

e

n

1 j

ej wc

T T

Workstation Process Time

*Work is preformed either manually or by some automatic device. The work performed at station consists of

one or more of the individual work elements.

*T

si

: indicate the process time at station i of an n stations line.

e

n

1 j

ej

n

1 i

si

T T

Cycle Time

*Cycle time, T

c

, is the ideal or theoretical cycle time of the flow line, which is the time interval between parts

coming off the line.

*When consider efficiency, E, the ideal cycle time must be reduce.

T

c

E / R

p

Where R

p

is production rate.

*At efficiencies less than 100% the ideal cycle time must be reduced (or ideal production rate must be

increased).

* The minimum possible value of T

c

is established by the bottleneck station, the one with the largest value of

T

s

.

T

c

max. T

si

T

c

T

ej

Precedence Constraints

*Technological sequencing requirements, the order in which the work elements can be accomplished is

limited.

Precedence Diagram

*A graphical representation of the sequence of work elements as defined by the precedence constraints.

Balance Delay (Balancing Loss)

*Balance delay is a measure of the line inefficiency which results from idle time due to imperfect allocation

of work among station.

c

wc c

nT

T nT

d

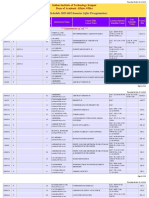

Example: Work Elements (Small electrical appliance)

No. Element Description Tej (min.) Must be

Precedence by

1 Place frame on work holder and clamp 0.2 ---

2 Assemble plug, grommet to power cord 0.4 ---

3 Assemble brackets to frame 0.7 1

4 Wire power cord to motor 0.1 1,2

5 Wire power cord to switch 0.3 2

6 Assemble mechanism plate to bracket 0.11 3

7 Assemble blade to bracket 0.32 3

8 Assemble motor to bracket 0.6 3,4

9 Align blade and attach to motor 0.27 6,7,8

10 Assemble switch to motor bracket 0.38 5,8

11 Attach cover, inspect, and test 0.5 9,10

12 Place in tote pan for packing 0.12 11

Precedence Diagram

III. Method of Line Balancing - (Manual)

*None of the methods guarantee an optimal solution, but they are likely to result in good solutions which

approach the true optimum.

1. Largest-Candidate Rule (LCR)

Procedure:

Step 1. List all elements in descending order of T

e

value, largest T

e

at the top of the list.

Step 2. To assign elements to the first workstation, start at the top of the list and work done, selecting the first

feasible element for placement at the station. A feasible element is one that satisfies the precedence

requirements and does not cause the sum of the T

ej

value at station to exceed the cycle time T

c

.

Step 3. Repeat step 2.

Example for Largest-Candidate Rule (LCR)

Step 1.

Work element T

e

Immediate

predecessor

3 0.7 1

8 0.6 3,4

11 0.5 9,10

2 0.4 ---

10 0.38 5,8

7 0.32 3

5 0.3 2

9 0.27 6,7,8

1 0.2 ---

12 0.12 11

0.12 0.5

0.38

0.27

0.6

0.32

0.11

0.3

0.1

0.7

0.4

0.2

1

3

2

4

6

5

7

8

9

10

12 11

6 0.11 3

4 0.1 1,2

Step 2, 3. If we assume T

c

= 1.00 min.

Station Element T

e

T

e

at station

1 2 0.4

5 0.3

1 0.2

4 0.1 1.00

2 3 0.7

6 0.11 0.81

3 8 0.6

10 0.38 0.98

4 7 0.32

9 0.27 0.59

5 11 0.5

12 0.11 0.62

2. Kilbridge and Wester's Method (KWM)

*It is a heuristic procedure which selects work elements for assignment to stations according to their position

in the precedence diagram.

*This overcomes one of the difficulties with the largest candidate rule (LCR), with which elements at the end

of the precedence diagram might be the first candidates to be considered, simply because their values are

large.

Procedure:

Step 1. Construct the precedence diagram so those nodes representing work elements of identical precedence

are arranged vertically in columns.

Step 2. List the elements in order of their columns, column I at the top of the list. If an element can be located

in more than one column, list all columns by the element to show the transferability of the element.

Step 3. To assign elements to workstations, start with the column I elements. Continue the assignment

procedure in order of column number until the cycle time is reached (T

c

).

Example for this method:

Step 1.

Work

Flow

Station 5 Station 4 Station 3 Station 2

Elements

3,6

Elements

8,10

Elements

9,7

Elements

11,12

Station 1

Elements

2, 5, 1, 4

0.12 0.5

0.38

0.27

0.6

0.32

0.11

0.3

0.1

0.7

0.4

0.2

1

3

2

4

6

5

7

8

9

10

12 11

I II III IV V VI

Step 2. Work elements arranged according to columns

Work element Column T

e

Sum of

Column T

e

1 I 0.2

2 I 0.4 0.6

3 II 0.7

4 II 0.1

5 II,III 0.3 1.1

6 III 0.11

7 III 0.32

8 III 0.6 1.03

9 IV 0.27

10 IV 0.38 0.65

11 V 0.5

12 V 0.12 0.62

Step 3. Work elements assigned to stations

Station Element T

e

T

e

at station

1 1 0.2

2 0.4

4 0.1

5 0.3 1.00

2 3 0.7

6 0.11 0.81

7 0.32

3 8 0.6 0.92

4 9 0.27

10 0.38 0.65

5 11 0.5

12 0.11 0.62

*Also, for stations that do have the same elements the sequence in which the elements are assigned is not

necessary identical.

*The balance delay is same as LCR d = 20%.

3. Ranked Positional Weights Method (RPW)

*Introduced by Helgeson and Birnie in 1961.

*Combined the LCR and K-W methods.

0.12 0.5

0.38

0.27

0.6

0.32

0.11

0.3

0.1

0.7

0.4

0.2

1

3

2

4

6

5

7

8

9

10

12 11

*The RPW takes account of both the T

e

value of the element and its position in the precedence diagram.

Then, the elements are assigned to workstations in the general order of their RPW values.

Procedure:

Step 1. Calculate the RPW for each element by summing the elements T

e

together with the T

e

values for all

the elements that follow it in the arrow chain of the precedence diagram.

Step 2 List the elements in the order of their RPW, largest RPW at the top of the list. For convenience,

include the T

e

value and immediate predecessors for each element.

Step 3. Assign elements to stations according to RPW, avoiding precedence constraint and time cycle

violations.

Example for this method:

Step 1. Sample calculation:

*For element 1, the elements that follow it in the arrow chain are 3, 4, 6, 7, 8, 9, 10, 11, and 12.

*The RPW for element 1 would be the sum of the T

e

s for all these elements, plus T

e

for element 1.

Step 2.

Work element RPW T

e

immediate

predecessors

1 3.3 0.2 -

3 3 0.7 1

2 2.67 0.4 -

4 1.97 0.1 1,2

8 1.87 0.6 3,4

5 1.3 0.3 2

7 1.21 0.32 3

6 1.00 0.11 3

10 1.00 0.38 5,8

9 0.89 0.27 6,7,8

11 0.62 0.5 9,10

12 0.12 0.12 11

Step 3. Work element assigned to stations

Station Element T

e

T

e

at station

1 1 0.2

3 0.7 0.9

2 2 0.4

4 0.1

5 0.3

6 0.11 0.91

3 8 0.6

7 0.32 0.92

4 10 0.38

9 0.27 0.65

5 11 0.5

12 0.11 0.62

*In the RPW line balance, the number of stations required is five, but the max. station process time is 0.92

minute, at number. According the line could be operated at a cycle time of T

c

= 0.92 rather than 1.0 minute.

Benefit:

1. Increase the production rate

R

c

= 1 / 0.92 = 1.075 units/min.

2. Balance delay

d = [5 (0.92) 4] / [5 (0.92)] = 0.13 = 13%

4. Compare LCR, K-W, and RPW

*The RPW solution represents a more efficient assignment of work elements to station than either of the two

preceding solutions.

*However, this result is accordingly by the acceptance of cycle time T

c

= 1 and make those methods

different.

*If the problem were reworked with T

c

= 0.92 minute, it might be possible to duplicate the efficiency.

5. Other Ways to Improve the Line Balance

1. Dividing work elements

*A minimum rational work element was defined as the smallest practical indivisible task.

*For example:

Drilling of a deep hole at one station was to cause a bottleneck situation should be separated into two steps.

*Advantages- eliminates the bottleneck and increases the tool life.

2. Changing work lead speeds at automatic stations

*Through a process increasing the speed/feed combinations at the stations with long process time, and

reducing the speed/feed combinations at stations with idle time.

3. Method analysis

*The study of human work activity may result in better workplace layout, redesigned tooling and fixturing or

improved hand and body motions.

4. Pre-assembly of components

*Reduce the total amount of work done on the regular assembly line by another assembly cell or by

purchasing.

a. Required process may be difficult to implement on the regular assembly line.

b. Variations in process times (adjustments or fitting)

5. Inventory buffers between stations

6. Parallel stations.

*Disregard the stations must be arranged sequentially.

*Illustrate:

a. Suppose that a five station line had station process times of 1 min at all but he fifth station is 2 minutes.

b. Then the production rate R

c

= 30 units/hr, if two station were arranged in parallel at the fifth station, the

output could be increase R

c

= 60 units/hr.

For example:

Station Element T

e

T

e

at station

1 0.2

1 2 0.4

2 3 0.7

4 0.1

8 0.6 2.00

3 5 0.3

6 0.11

7 0.32

9 0.27 1.00

4 10 0.38

11 0.5

12 0.11 1.00

Switch

Switch

Assembly

station 1

Assembly

station 2

Assembly

station 3

Assembly

station 4

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Can Test BoxDocument3 pagesCan Test Boxjulio261No ratings yet

- Assumed Modes MethodsDocument17 pagesAssumed Modes MethodsYsharath Chandramouli100% (1)

- Automotive Supplier SurveyDocument38 pagesAutomotive Supplier SurveyVINETH .RNo ratings yet

- BIMstore Bible v13 PDFDocument53 pagesBIMstore Bible v13 PDFilefante100% (1)

- NEMSDocument13 pagesNEMSChandrakiran AlapatiNo ratings yet

- Click Here, Type The Title of Your Paper, Capitalize First LetterDocument3 pagesClick Here, Type The Title of Your Paper, Capitalize First LetterYsharath ChandramouliNo ratings yet

- Solving System of Linear Equations: Y. Sharath Chandra MouliDocument32 pagesSolving System of Linear Equations: Y. Sharath Chandra MouliYsharath ChandramouliNo ratings yet

- TEQIP School On Computational Methods in Engineering ApplicationsDocument3 pagesTEQIP School On Computational Methods in Engineering ApplicationsYsharath ChandramouliNo ratings yet

- Study On Material Selection of Fuselage SkinDocument10 pagesStudy On Material Selection of Fuselage SkinYsharath ChandramouliNo ratings yet

- 1-D Beam Code: For EI (X) 1, F 1, L 1, With Boundary Conditions W 0, 0 at X 0 and M 0, V 1 at X 1.given T 0.01Document6 pages1-D Beam Code: For EI (X) 1, F 1, L 1, With Boundary Conditions W 0, 0 at X 0 and M 0, V 1 at X 1.given T 0.01Ysharath ChandramouliNo ratings yet

- Study On Material Selection of Fuselage SkinDocument10 pagesStudy On Material Selection of Fuselage SkinYsharath ChandramouliNo ratings yet

- Uni Variant MinimizationDocument15 pagesUni Variant MinimizationYsharath ChandramouliNo ratings yet

- Course Schedule2015162 PDFDocument52 pagesCourse Schedule2015162 PDFYsharath ChandramouliNo ratings yet

- IHC S70 & S90: Hydro Hammer No. 42127, No. 42128 and Power Pack No. 42129Document2 pagesIHC S70 & S90: Hydro Hammer No. 42127, No. 42128 and Power Pack No. 42129gobyshomeNo ratings yet

- 120W Ficha Tecnica Data SheetDocument1 page120W Ficha Tecnica Data Sheetjorge paredesNo ratings yet

- PSP0 Process Script Purpose Entry Criteria: - PSP0 Project Plan Summary FormDocument16 pagesPSP0 Process Script Purpose Entry Criteria: - PSP0 Project Plan Summary FormDaniela Rodriguez ZavalaNo ratings yet

- Irricad 10 ManualDocument964 pagesIrricad 10 Manualالسيد تامرNo ratings yet

- Exercise 6.1: Restful Api Access: Student@Lfs458-Node-1A0A: $ Kubectl Config ViewDocument2 pagesExercise 6.1: Restful Api Access: Student@Lfs458-Node-1A0A: $ Kubectl Config ViewtektitemoNo ratings yet

- TSC NSC SeriesDocument32 pagesTSC NSC Seriesmoh shoNo ratings yet

- User GuideDocument216 pagesUser Guideit4728No ratings yet

- Vi PEC ManualDocument62 pagesVi PEC ManualsssenakaNo ratings yet

- MODULE 2: Input / Output Organization: Courtesy: Text Book: Carl Hamacher 5 EditionDocument95 pagesMODULE 2: Input / Output Organization: Courtesy: Text Book: Carl Hamacher 5 Editionayush mittalNo ratings yet

- Executive Summary-2Document13 pagesExecutive Summary-2Ulkar AlaskarovaNo ratings yet

- IRFP240Document8 pagesIRFP240Hugo JimenezNo ratings yet

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreDocument2 pagesDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryNo ratings yet

- JSP (Java Server Page)Document54 pagesJSP (Java Server Page)ali khan0% (1)

- DNS 315 Qig en UkDocument76 pagesDNS 315 Qig en UkrcmillosNo ratings yet

- Johnson Space Center Roundup 2012-06Document12 pagesJohnson Space Center Roundup 2012-06rtphokieNo ratings yet

- Amazon Case StudyDocument26 pagesAmazon Case StudySteven JonathanNo ratings yet

- CodegiaodienDocument4 pagesCodegiaodienKhôi Nguyễn ĐìnhNo ratings yet

- 2014-12-04 - Light Duty Shock Absorber ApplicationsDocument4 pages2014-12-04 - Light Duty Shock Absorber ApplicationsVevo18No ratings yet

- 3RF24301AC45 Datasheet enDocument5 pages3RF24301AC45 Datasheet enzenagyNo ratings yet

- Iim Indore'S: Integrated Program in Business Analytics (IPBA)Document8 pagesIim Indore'S: Integrated Program in Business Analytics (IPBA)Ankit PandaNo ratings yet

- 2013 - Dimyadi - Automated Building Code Compliance Checking - Where Is It atDocument15 pages2013 - Dimyadi - Automated Building Code Compliance Checking - Where Is It atVicente MedianoNo ratings yet

- NER LabDocument65 pagesNER LabKondo CandiNo ratings yet

- Iscom Rax 711 (B) : Essential Demarcation DeviceDocument3 pagesIscom Rax 711 (B) : Essential Demarcation DeviceCarlos PazNo ratings yet

- Advanced C++ ProgrammingDocument69 pagesAdvanced C++ ProgrammingVijay KumarNo ratings yet

- Types of Processes Conversion (Ex. Iron To Steel) Fabrication (Ex.Document9 pagesTypes of Processes Conversion (Ex. Iron To Steel) Fabrication (Ex.ashishgiri67% (3)

- Computers & Education: Gi-Zen Liu, Zih-Hui Liu, Gwo-Jen HwangDocument15 pagesComputers & Education: Gi-Zen Liu, Zih-Hui Liu, Gwo-Jen HwangNoerwanty Yustitiana RidwanNo ratings yet