Professional Documents

Culture Documents

t91 Welding Procedure BHEL

t91 Welding Procedure BHEL

Uploaded by

Ahmad K RazaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

t91 Welding Procedure BHEL

t91 Welding Procedure BHEL

Uploaded by

Ahmad K RazaCopyright:

Available Formats

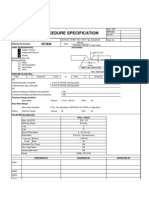

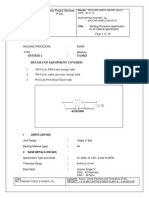

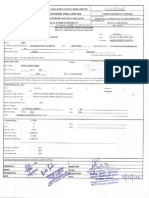

BHARAT HEAVY ELECTRICALS LIMITED

WELDING TECHNOLOGY CENTRE

Tiruchirappalli-620014

WELDING PROCEDURE SPECIFICATION

Page 1 of 2

Form No. 101-401

WPS No.:

1050

Date: 30.11.06

Rev.

:01

Date: 07.12.06

Supporting PQR No.: 1181

Welding Process: GTAW +SMAW

Type: Manual

(Auto,Semi-Auto,Manual,Machine)

Application: Groove welding of 9Cr 1 Mo 0.25 V (T91/P91) steel Tubes/ Pipes for

thickness up to 20.00 mm with pre heat & PWHT.

JOINTS (QW-402)

Joint Design

: As per production Drg.

Backing (Yes/No)

: GTAW: No; SMAW: Yes.

Backing Material (type)

: GATW: Nil; SMAW: Metal.

Metal/Non fusing metal/

Non metallic/Others

BASE METAL (QW-403)

P. No.: 5B

Group No.: 2

to

P. No.: 5B

Spec. Type & Grade

: SA 213 T91 or equivalent.

Chem. Analysis & Mech. Prop

Group No.: 2

Thickness Range

Groove: 5.0 to 20.0mm

Fillet: N.A.

Pipe Dia. range: Unlimited

Others: Nil

FILLER METALS (QW-404)

GATW

SMAW

AWS No. (Class):

E 90S-B9

E9018-B9/E9015-B9 Size of filler metal: Refer table

Specn. No. (SFA):

5.28

5.5

Flux Trade Names:

N.A

F. No.:

Consumable insert:

N.A.

A. No.:

Electrode |Flux (Class): N.A.

Deposited weld metal thickness range

Groove: 5-20 mm max. GTAW: 4.0 mm max. (Max.2 mm per pass) SMAW: Balance (Max.5 mm /

pass)

Fillet: Nil.

POSITION (QW-405)

Position of Groove:

Position of fillet:

Weld Progression:

(Up / Down)

Others:

All

N.A.

Vertical up.

Nil

PREHEAT (QW-406)

Preheat temp (min). :

220Oc

Inter pass temp. (Max.): 350oC

Pre heat maintenance: 220Oc (Min)

Other: Insulate while cooling to 80-100degc

and keep the job dry. Maintain at 80-100deg

c for 1 hr. and conduct PWHT immediately.

BHARAT HEAVY ELECTRICALS LIMITED

WELDING TECHNOLOGY CENTRE

Tiruchirappalli-620014

WELDING PROCEDURE SPECIFICATION

Form No. 101-401

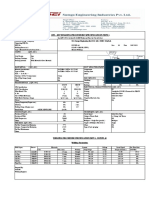

GAS (QW-408)

PWHT (QW-408)

Temp. Range:

760 10oC

Time Range

2.5-mts/ mm (Thickness of weld)

(Min.120 Minutes.)

Others:

Page 2 of 2

WPS No.: 1050 Rev 01

Rate of heating / cooling above 350oC

110O C/Hr maximum

Gases

Purity% Flow Rt.

Shielding

Argon

99.99

6-14 LPM

Trailing

N.A.

----

----

Backing

Argon

99.99

10-20 LPM

(For root welding)

ELECTRICAL CHARACTERISTICS (QW-409)

Current (AC/DC):

See table

Amps. (Range):

See table

Tungsten Electrode type and size:

Mode of metal transfer for (GMAW):

Electrode wire feed speed range:

Pulsing current (GTAW):

Polarity: See table

Volts: See table

EWTh-2/EWCe-2, 2.4 mm.

N.A.

N.A.

Nil.

TECHNIQUES (QW-410)

String or Weave Bead:

Orifice or Gas cup size:

Initial and inter pass cleaning:

Method of back Gouging:

Oscillation:

Contact tube to work distance:

Multiple or single pass (per side):

Multiple or single electrode:

Electrode spacing:

Peening:

String

6/9

Brushing/Chipping/Grinding

Nil.

N.A

N.A

Multiple

Single

N.A.

Nil.

Others:

Nil

Filler

Current

Others

(hot wire,

torch

angle

etc.)

Class

Dia.

mm

Type

Amps.

Volt

Range

Travel

speed

range

GTAW

ER 90S-B9

2.4

DCEN

70-100

N.A.

N.A.

Nil

Others

Layers

SMAW

E9018-B9

Or

E9015-B9

2.5

DCEP

70-100

N.A.

N.A.

Nil

-Do-

SMAW

-Do-

3.2

DCEP

90-130

N.A.

N.A.

Nil

-Do-

SMAW

-Do-

4.0

DCEP

140-160

N.A.

N.A.

Nil

Weld

Layer

Process

Root

Prepared by:

Reviewed by:

Approved by:

(Kankar Narzary)

(Dr K.P.Dhandapani)

(B.Natarajan)

Welding Engineer / WTC

DGM/ WTC & WCMC

SDGM/ WTC & WCMC

You might also like

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS PQR-01Document9 pagesWPS PQR-01Ranjan Kumar50% (2)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam87% (15)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- ASME P Material NumbersDocument1 pageASME P Material Numbersmahi1437100% (1)

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (2)

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- VDI 3400 Surface Finishes Definition & Technology Info: Grade Definition of RoughnessDocument1 pageVDI 3400 Surface Finishes Definition & Technology Info: Grade Definition of RoughnessvenkateswaranNo ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam75% (4)

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- Concast WPS - REV-01Document28 pagesConcast WPS - REV-01meena34No ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Shell Petroleum Development Company: (Implemented/Issued For Review/Complete)Document17 pagesShell Petroleum Development Company: (Implemented/Issued For Review/Complete)Siva RamNo ratings yet

- Eqt RecordDocument41 pagesEqt RecordShaikh sohilNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- PQRDocument2 pagesPQRalokbdas100% (1)

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocument1 pageIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNo ratings yet

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Document1 pageWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- Welding Procedure Specification: Bharat Heavy Electricals LimitedDocument2 pagesWelding Procedure Specification: Bharat Heavy Electricals LimitedMakhdum Muhardiana PutraNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Attendance FormatDocument1 pageAttendance FormatAshish GuptaNo ratings yet

- Very Important TopicDocument10 pagesVery Important TopicAshish GuptaNo ratings yet

- Acknowledgement: Ravneet KaurDocument1 pageAcknowledgement: Ravneet KaurAshish GuptaNo ratings yet

- Ik Kone Mein Tha BaithaDocument1 pageIk Kone Mein Tha BaithaAshish GuptaNo ratings yet

- ITP Tank Nozzle ModificationDocument1 pageITP Tank Nozzle ModificationAshish GuptaNo ratings yet

- Guest House ListDocument5 pagesGuest House ListAshish GuptaNo ratings yet

- SSPC Surface Preparation StandardsDocument7 pagesSSPC Surface Preparation StandardsAshish GuptaNo ratings yet

- ISO Audit 31Document1 pageISO Audit 31Ashish GuptaNo ratings yet

- Industrial Radiography Image Forming TechniquesDocument99 pagesIndustrial Radiography Image Forming TechniquesAshish GuptaNo ratings yet

- 5 Years HSE PerformanceDocument2 pages5 Years HSE PerformanceAshish GuptaNo ratings yet

- WWW - Hssc.gov - In: Closing Date For Deposit of Fee 31.03.2014Document22 pagesWWW - Hssc.gov - In: Closing Date For Deposit of Fee 31.03.2014Ashish GuptaNo ratings yet

- ConsultantsDocument30 pagesConsultantsAshish Gupta100% (1)

- FlowersDocument3 pagesFlowersAshish GuptaNo ratings yet

- Characterisation of AluminiumDocument8 pagesCharacterisation of AluminiumsathishjeyNo ratings yet

- Another DWG of Vessel No 3Document1 pageAnother DWG of Vessel No 3Nomi KhanNo ratings yet

- Learning ObjectivesDocument11 pagesLearning ObjectivesSharifur RehmanNo ratings yet

- Pulp & PaperDocument5 pagesPulp & PaperMontasir ShantoNo ratings yet

- Interior Vertical Surfacing Installation-CorianDocument18 pagesInterior Vertical Surfacing Installation-CorianAbhishek SankerNo ratings yet

- Class 12 Chemistry CH 2Document53 pagesClass 12 Chemistry CH 2Deep ChaudhariNo ratings yet

- Is 2770Document12 pagesIs 2770Ankur SinghNo ratings yet

- 7.12-States of Matter-2 IITDocument5 pages7.12-States of Matter-2 IITNikhilesh PrabhakarNo ratings yet

- DLL Grade Science 10 Quarter 3Document8 pagesDLL Grade Science 10 Quarter 3Harold GarcellanoNo ratings yet

- Properties of Relay Contact SystemDocument3 pagesProperties of Relay Contact Systemsaga2000cnNo ratings yet

- Carlos Allende and His Philadelphia ExperimentDocument14 pagesCarlos Allende and His Philadelphia Experimentdarls08No ratings yet

- Sources of SulphurDocument3 pagesSources of SulphurMadonnaAdanna UdokaluNo ratings yet

- VibrationDocument30 pagesVibrationvin4343No ratings yet

- Code Requirements For Evaluation, Repair, and Rehabilitation of Concrete Buildings (ACI 562M-13) and CommentaryDocument8 pagesCode Requirements For Evaluation, Repair, and Rehabilitation of Concrete Buildings (ACI 562M-13) and CommentaryOscar FernándezNo ratings yet

- DB Alform M-Series E 14112012Document3 pagesDB Alform M-Series E 14112012Puđa TomicaNo ratings yet

- Composite Structures: José A. Gonilha, João R. Correia, Fernando A. BrancoDocument11 pagesComposite Structures: José A. Gonilha, João R. Correia, Fernando A. BrancoAntnio5No ratings yet

- BE184P Exercise 2.1 Chromatographic Analysis - HPLCDocument10 pagesBE184P Exercise 2.1 Chromatographic Analysis - HPLCDen CelestraNo ratings yet

- Grasp 0Document28 pagesGrasp 0Diep DaoNo ratings yet

- Mat Sci Problems and Solution - Group-8 PDFDocument15 pagesMat Sci Problems and Solution - Group-8 PDFGerard Toby CalixtoNo ratings yet

- Undertaking A Dissertation From Start To Finish The Process and The ProductDocument6 pagesUndertaking A Dissertation From Start To Finish The Process and The ProductCustomWrittenPaperLittleRockNo ratings yet

- BC1020F SAYTEX Rb-7980 DatasheetDocument2 pagesBC1020F SAYTEX Rb-7980 DatasheetAsghar MahmoodNo ratings yet

- Solutions and Colligatives MHT CET Synopsis PDFDocument4 pagesSolutions and Colligatives MHT CET Synopsis PDFAbhishek Mandlik80% (5)

- Generic PID DefinitionsDocument4 pagesGeneric PID DefinitionsNicoara Stoica Paul FlorinNo ratings yet

- Pipe Freezing StudyDocument8 pagesPipe Freezing StudymirekwaznyNo ratings yet

- WS Services Pipe Fittings & Its Reference PDFDocument1 pageWS Services Pipe Fittings & Its Reference PDFbilal almelegyNo ratings yet

- wch12 01 Que 20230117Document28 pageswch12 01 Que 20230117Sigh TutorNo ratings yet

- Optical FiberDocument16 pagesOptical FiberRinju DuttNo ratings yet

- Metric Measurements Prelab CHEM 130 PDFDocument4 pagesMetric Measurements Prelab CHEM 130 PDFVu LuongNo ratings yet

- MSDS Accelerator MBT 2-Mercaptobenzothiazole KemaiDocument7 pagesMSDS Accelerator MBT 2-Mercaptobenzothiazole KemaicarlosNo ratings yet