Professional Documents

Culture Documents

Relief Holes in Custom Tray (Dentistry)

Uploaded by

deekshampdcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Relief Holes in Custom Tray (Dentistry)

Uploaded by

deekshampdcCopyright:

Available Formats

Effects of relief space and escape holes on pressure characteristics of

maxillary edentulous impressions

Osamu Komiyama, DDS, PhD,a Hiroyuki Saeki, DDS, PhD,b Misao Kawara, DDS, PhD,c

Kihei Kobayashi, DDS, PhD,d and Shigeo Otake, DDS, PhDe

Nihon University of Dentistry at Matsudo, Matsudo City, Chiba, Japan

Statement of problem. The selective pressure technique has been recommended for making impressions of

maxillary edentulous residual ridges. Although various methods for making impressions have been reported,

a definitive procedure has not been clearly elucidated.

Purpose. This in vitro study evaluated changes in impression pressure produced by different types of relief

space and escape holes in the impression tray for making an impression of a simulated maxillary edentulous arch.

Material and methods. Silicone impression material (Exadenture) and a maxillary edentulous acrylic cast

were used. A miniature pressure sensor was embedded at the mid-palatal suture (point-P) and at the left first

molar area on the edentulous ridge (point-R). Three types of tray relief were used: no spacer (NS), a 0.36-mmthick sheet of wax (SS), or a 1.40-mm-thick base plate wax (BS). Four types of escape holes were made: no hole

(NH), or escape holes of 0.5, 1.0, or 2.0 mm in diameter (05H, 10H, and 20H, respectively) in the area

opposing point-P. Twelve trays were formed using these relief space and escape hole combinations. The cast and

tray were attached to a rheometer for applying a continuous isotonic force of 5.0 kgf and compressive speed of

120 mm/min. Impressions were made and measurement of pressure (kPa) began immediately prior to

compression and continued until the materials had polymerized for 2 minutes, with a sampling time of 5 Hz.

Measurements were performed 5 times for each tray. The data were analyzed using 3-way analysis of variance

and the Bonferroni test (a=.05).

Results. At initial pressure, the data obtained at point-P showed significantly higher values for NSNH, NS05H,

SSNH, and SS05H (range: 22.29 6 1.58 kPa to 29.96 6 1.41 kPa) than those at point-R (range:

18.61 6 1.12 kPa to 22.71 6 2.11 kPa). At end pressure, the data obtained from NSNH at point P showed

a significantly higher value (25.36 6 1.69 kPa) than that of point-R (15.36 6 0.99 kPa) (P\.001), whereas

data from NS10H and NS20H at point-P showed a significantly lower value (6.32 6 0.84 kPa and 4.50 6 0.42

kPa) than at point-R (15.50 6 0.49 kPa and 14.98 6 0.88 kPa) (P\.001). The data obtained from SS05H,

SS10H, and NS20H at point-P showed significantly lower values (range: 3.72 6 0.44 kPa to 9.10 6 0.26 kPa)

than those at point-R (range: 13.40 6 1.31 kPa to 14.40 6 0.98 kPa). Moreover, the data obtained from

BSNH, BS05H, BS10H, and BS20H at point-P showed significantly lower values (range: 3.24 6 1.96 kPa to

10.20 6 1.84 kPa) than those of point-R (range: 11.69 6 1.01 kPa to 14.04 6 2.08 kPa).

Conclusion. For making impressions of an edentulous maxilla, the data suggest that a tray with an escape hole

1.0 mm or larger or a spacer thickness of base plate wax (1.40 mm) be used. (J Prosthet Dent 2004;91:570-6.)

CLINICAL IMPLICATIONS

The results of this in vitro study suggest that when making an impression of an edentulous

maxillary arch using the selective pressure technique, optimal pressure can be obtained using

a tray with escape holes 1.0 mm or larger or a 1.40-mm thickness of base plate wax as a spacer.

B

a

Assistant Professor, Department of Comprehensive Clinical

Dentistry.

b

Lecturer, Department of Complete Denture Prosthodontics.

c

Professor and Chair, Department of Comprehensive Clinical

Dentistry.

d

Professor and Head, Department of Complete Denture Prosthodontics.

e

Professor and Head, Department of Comprehensive Clinical

Dentistry.

570 THE JOURNAL OF PROSTHETIC DENTISTRY

oucher recommended the use of the selected

pressure technique for impressions of edentulous residual ridges.1 The outer surface of the bone in the

region of the crest of the maxillary residual ridge is

compact in nature, because it is made up of Haversian

systems.2 Histologically, compact bone, in combination

with the tightly attached mucous membrane, makes the

crest of the maxillary residual ridge most suitable to

provide primary support for the maxillary denture.3

VOLUME 91 NUMBER 6

KOMIYAMA ET AL

Clinicians should take advantage of the nature of this

tissue when making definitive impressions.4-6

The soft tissue covering the hard palate varies significantly in consistency and thickness among different

locations.7 Anterolaterally, the submucosa of the hard

palate contains adipose tissue, and posterolaterally, the

submucosa contains glandular tissue. These tissues

should be recorded in a resting condition, because when

displaced in the impression procedure, these tissues tend

to return to their normal form within the completed

denture base, creating an unseating force on the denture

or soreness.8,9 The submucosa in the region of the

median palatal suture of the maxillary bones is extremely

thin, and the mucosal layer is almost in contact with the

underlying bone.10 Little or no stress should be placed

in this region when making definitive impressions.1

Otherwise, the denture may rock over the center of

the palate when vertical forces are applied to the artificial

teeth. In addition, this part of the mouth is highly

sensitive,1 and excess pressure can be painful. Due to

these variations, the authors recommend selectively

placing pressure on the mucous membrane and bone

in amounts that are compatible with the histologic

tolerances of the supporting tissues for each patient

during impression making.11,12

Although various methods for making selective pressure impressions for edentulous patients have been

reported, a definitive procedure has not been clearly

elucidated.13-15 Minimal pressure impressions16-18 and

selective pressure methods, to obtain the support of

occlusal pressure,15 have been reported to control

pressure to the edentulous ridge. However, success with

these techniques varies according to the clinicians

experience using different impression materials and tray

designs.

The question remains as to the amount of force that

should be applied when using the selective pressure

technique. Frechette19 reported that the load of a denture on the oral mucosa was 50 to 200 kPa during

mastication. In addition, Kydd et al9 reported that it

took up to 4 hours for the residual ridge to completely

recover from a moderate load, approximately 50 kPa,

that lasted for 10 minutes. The authors further stated

that a small amount of occlusal force (2 kPa) could

compress the denture-bearing mucosa to approximately

20% of its thickness at rest. Lindan20 also found that

denture-bearing mucosa might be deformed to 95% of

its usual thickness at rest when occlusal force was

applied.

Frank21 simulated and measured impression pressure

using trays with 5 escape holes placed equidistant from

each other and 0.25 inches from the center of each

pressure gauge with a round bur (number 6), along with

relief provided by a base plate wax spacer. That tray

produced a pressure of 15 to 16 kPa, compared with

approximately 29 kPa in trays without holes and relief.

JUNE 2004

THE JOURNAL OF PROSTHETIC DENTISTRY

Rihani22 measured impression pressure in the edentulous maxilla using zinc oxideeugenol paste and suggested that the primary pressure regions during

impression making were near the center of the palate

and pressure diminished toward the buccal borders.

This in vitro study evaluated changes in impression

pressure produced by various designs of relief space

and escape holes in the impression tray for making an

impression of a simulated maxillary edentulous arch.

MATERIAL AND METHODS

A miniature pressure sensor was embedded into

a maxillary acrylic resin cast, and the 12 impression trays

were formed for each combination of 3 types of relief

space and 4 types of escape hole combinations. The cast

and tray were attached to a rheometer for applying

a continuous compressive isotonic force. Impressions

were made with silicone impression material, and measurement of pressure began immediately prior to compression and concluded when the materials had

polymerized for 2 minutes.

Edentulous cast

A standard maxillary edentulous acrylic resin cast

(G10-402K; Nissin Dental Products Inc, Kyoto,

Japan) was used after eliminating the undercut in the

anterior labial region. Two measuring points were

selected. The first was at the sagittal mid-point (pointP) on the mid-palatal suture and the second at the left

first molar point of the crest on the edentulous residual

ridge (point-R) (Fig. 1). A miniature pressure sensor

(PS-1KD; Kyowa Electronic Instruments Co, Tokyo,

Japan) was embedded into the cast at these points, so

that the surface of the sensor formed a continuous plane

with the cast (Fig. 2).

Impression trays

Each impression tray was fabricated with autopolymerizing acrylic resin (Ostron 100; GC Co, Tokyo,

Japan) using a conventional method.1 The thickness of

the tray at the palatal portion was approximately 3 mm,

and the border of the tray was in contact with the cast.

Three types of tray relief were used: no wax spacer (NS);

sheet wax (No. 28 Sheet Wax; GC Co; 0.36 mm thick)

(SS), or base plate wax (Base Plate Wax, GC Co; 1.40

mm thick) (BS). Four types of escape holes were tested:

no hole (NH) or escape holes of 0.5, 1.0, or 2.0 mm in

diameter (05H, 10H, and 20H, respectively) opposite

point-P. Twelve trays were fabricated for each relief

space and hole-type combinations. Five measurements

were made for each tray, resulting in 60 values (Table I)

per group.

571

THE JOURNAL OF PROSTHETIC DENTISTRY

KOMIYAMA ET AL

Fig. 2. Simulation cast with rheometer. Two pressure sensors

at sagittal center point on mid-palatal suture and at first molar

point of crest on edentulous ridge.

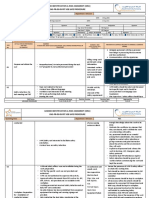

Table I. Abbreviations of tray design used in study

Fig. 1. Maxillary edentulous cast and tray. Miniature pressure

sensor embedded into cast at sagittal mid-point (point-P) on

mid-palatal suture and at first molar point of crest on

edentulous ridge (point-R).

Escape Hole

Spacer

Impression material

Light body silicone impression material (Exadenture,

6.0 g; GC Co) was used for making impressions. The

manufacturer purports the setting time of the material

to be 120 seconds. A cartridge and dispenser were used

to evenly mix and distribute the impression material

throughout the tray, taking care to avoid trapping air

within the materials.

Compression and measurement

The cast and tray were attached to a rheometer (CR200D; SUN Scientific Co. Ltd, Tokyo, Japan) for

application of a continuous isotonic force. For equalization of pressure while compressing the impression

materials to the tray, the plane formed by connecting the

incisive papilla point with the right and left first molar

points was positioned parallel to the floor. The compression force was set at 5.0 kgf and the press speed at

120 mm/min as reported by Frank.21 Measurement

began immediately prior to compression and continued

for 2 minutes with a sampling time of 5 Hz. Data

obtained from the miniature pressure sensor were

calculated using a sensor interface (PCD-300A; Kyowa

Electronic Instruments Co) and then recorded on

a personal computer (VAIO PCG-FX77; Sony Co,

Tokyo, Japan) (Fig. 3). The maximum value immediately after the initial pressure and the value after 120

seconds (end pressure), which allowed the impression

pressure to settle after compression, were determined.

572

No spacer

(NS)

Sheet wax

spacer (SS)

Base plate wax

spacer (BS)

No hole

(NH)

0.5-mm

hole

(05H)

1.0-mm

hole

(10H)

2.0-mm

hole

(20H)

NSNH

NS05H

NS10H

NS20H

SSNH

SS05H

SS10H

SS20H

BSNH

BS05H

BS10H

BS20H

Statistical analysis

The mean values and SD of impression pressure in

each tray were calculated. The effects of the spacers,

escape holes, and measuring points on impression

pressure were analyzed using 3-way analysis of variance

(ANOVA). Simple main effect and multiple comparisons (Bonferroni) were used to test the difference

between the values by analysis of 3-way interaction effect

(a=.05). All analyses were conducted using a computer

software package (SPSS 11.0 for Windows; SPSS,

Chicago, Ill).

RESULTS

Figure 4 indicates the typical pressure changes using

the NSNH and BS20H tray. Immediately after the start

of compression, impression pressure increased rapidly,

and gradually decreased thereafter. The maximum value

immediately after compression (initial pressure) and the

value after 120 seconds (end pressure), which allowed

the impression pressure to settle after compression, were

determined by obtaining continuous data.

VOLUME 91 NUMBER 6

KOMIYAMA ET AL

THE JOURNAL OF PROSTHETIC DENTISTRY

Fig. 3. Measuring system. Edentulous cast was isotonically compressed by tray with impression material using rheometer.

Impression pressure was detected by pressure sensor embedded into edentulous cast.

Initial pressure

Fig. 4. Typical pressure changes using the NSNH and BS20H

tray. Immediately after start of compression, impression

pressure increased rapidly, and gradually decreased thereafter. Maximum value immediately after compression (initial

pressure) and value after 120 seconds (end pressure), which

allowed the impression pressure to settle after compression,

were determined by obtaining continuous data.

Figure 5, Table II, and Table III show the results of

data from each tray design and relief combination at

point-P and point-R. Tables IV and V show the results

of the ANOVA test. There were significant 3-way

interactions between both initial and end pressure, and

these data were analyzed by using simple main effect and

multiple comparisons (Bonferroni) to test the difference.

JUNE 2004

The data obtained at point-P showed significantly

higher values for NSNH, NS05H, SSNH, and SS05H

(29.96 6 1.41 kPa , 25.90 6 0.59 kPa , 26.22 6 1.09

kPa, and 22.29 6 1.58 kPa, respectively) than corresponding values at point-R (22.72 6 2.12 kPa, 21.22 6

1.99 kPa, 21.49 6 1.48 kPa, and 18.61 6 1.12 kPa,

respectively) (P\.001). However, similar values were

obtained for the other conditions.

By altering the escape hole at point-P from NH to

05H, and further to 10H, the impression pressure

significantly decreased from 29.96 6 1.41 kPa to

25.90 6 0.59 kPa and 20.10 6 0.69 kPa, respectively,

in the NS group, and from 26.22 6 1.09 kPa to

22.29 6 1.58 kPa and 17.31 6 1.28 kPa, respectively,

in the SS group (P\.001). However, there was no

significant reduction between 10H and 20H, and no

significant effect of the escape hole in the BS series. In

NH, by altering the spacer from NS to SS, and further

to BS, the impression pressure was significantly reduced

from 29.96 6 1.41 kPa to 26.22 6 1.09 kPa and 18.76

kPa, respectively (P\.001). A similar tendency was

observed in the 05H series; however, in the 10H and

20H series, there was no significant difference in

pressure associated with altering the spacer. At pointR, no significant reduction in pressure was associated

with changes made to the escape hole and spacers.

End pressure

The data obtained from NSNH at point P showed

a significantly higher pressure value (25.36 6 1.69 kPa)

than that of point-R (15.36 6 0.99 kPa) (P\.001),

whereas data from NS10H and NS20H specimens at

point-P showed a significantly lower pressure value

(6.32 6 0.84 kPa and 4.50 6 0.42 kPa) than point-R

(15.50 6 0.49 kPa and 14.98 6 0.88 kPa) (P\.001).

573

THE JOURNAL OF PROSTHETIC DENTISTRY

KOMIYAMA ET AL

Fig. 5. Measurements data in each tray at point-P and point-R: A, initial pressure, B, end pressure. Initially, impression pressure at

point-P (mid-palatal) was higher than or similar to that of point-R (ridge crest). However, end pressure at point-P of tray with

escape hole 1.0 or 2.0 mm in diameter and without spacer, tray with escape hole 0.5 mm or greater in diameter with sheet wax

spacer, and tray with base plate wax spacer were significantly lower than that at point-R. (*P\.05, ANOVA).

Table II. Mean and 95% confidence interval (lower, upper) of initial pressure (kPa) measurements (n=5) from each tray

design and relief combination at sagittal mid-point (point-P) of mid-palatal suture and at left first molar point of crest on

edentulous residual ridge (point-R)

Hole

Point

Spacer

NS

SS

BS

NS

SS

BS

NH

29.96

26.22

18.76

22.72

21.49

18.91

(28.66,

(24.93,

(17.46,

(21.43,

(20.20,

(17.62,

05H

31.25)

27.52)

20.05)

24.01)

22.79)

20.21)

25.90

22.29

17.72

21.22

18.61

18.79

(24.61,

(21.00,

(16.43,

(19.93,

(17.32,

(17.50,

The data obtained from SS05H, SS10H, and NS20H

specimens at point-P showed significantly lower values

than those at point-R (P\.001). Moreover, the data

obtained from BSNH, BS05H, BS10H, and BS20H at

point-P showed significantly lower pressure values than

those of point-R (P\.001).

By altering the escape hole at point-P from NH, 05H,

and further to 10H, impression pressure significantly

decreased from 25.36 6 1.69 kPa to 14.13 6 1.19 kPa

and 6.33 6 0.84 kPa, respectively, in the NS groups,

and from 13.77 6 1.28 kPa to 9.10 6 0.26 kPa and

5.78 6 1.15 kPa, respectively, in the SS groups

(P\.001). However, there was no significant reduction

from 10H to 20H. In the BS groups, a significant

decrease was observed when changed from 05H to

10H (P\.001). Moreover, in NH, by altering the

574

10H

27.18)

23.58)

19.02)

22.51)

19.90)

20.08)

20.10

17.31

17.86

18.66

16.54

17.92

(18.81,

(16.02,

(16.57,

(17.37,

(15.25,

(16.63,

20H

21.39)

18.60)

19.15)

19.95)

17.83)

19.21)

18.08

15.74

14.95

18.14

16.39

14.75

(16.79,

(14.44,

(13.66,

(16.85,

(15.09,

(13.46,

19.37)

17.03)

16.24)

19.43)

17.68)

16.05)

spacer from NS to SS, and further to BS, the impression

pressure was significantly reduced from 25.36 6 1.69

kPa to 13.77 6 1.28 kPa and 10.20 6 1.84 kPa, respectively (P\.001). In 05H, a significant reduction

was observed from NS to SS (P\.001); however, in the

10H and 20H series, there was no significant difference

as a result of altering the spacer. As for point-R, no

significant reductions were observed associated with any

escape hole and spacer changes.

DISCUSSION

Frank21 simulated and measured impression pressure

using trays with 5 escape holes placed equidistant from

each other and 0.25 inches from the center of each

pressure gauge with a round bur (number 6) along with

VOLUME 91 NUMBER 6

KOMIYAMA ET AL

THE JOURNAL OF PROSTHETIC DENTISTRY

Table III. Mean and 95% confidence interval (lower, upper) of end pressure (kPa) measurements (n =5) from each tray

design and relief combination at sagittal mid-point (point-P) of mid-palatal suture and at left first molar point of crest on

edentulous residual ridge (point-R)

Hole

Point

P

Spacer

NH

NS

SS

BS

NS

SS

BS

25.36

13.77

10.20

15.36

14.81

13.96

05H

(24.28, 26.45)

(12.68, 14.85)

(9.12, 11.29)

(14.27, 16.45)

(13.73, 15.90)

(12.88, 15.05)

14.13

9.10

7.94

14.62

14.40

13.95

(13.05, 15.22)

(8.02, 10.19)

(6.85, 9.02)

(13.54, 15.71)

(13.31, 15.48)

(12.86, 15.03)

Source

Point

89.666

Spacer

388.157

Hole

777.773

Point*Spacer

67.244

Point*Hole

74.904

Spacer*Hole

130.928

Point*Spacer*Hole

54.478

Model

1583.151a

Error

203.661

Degree

of

freedom

1

2

3

2

3

6

6

23

96

Mean

square

6.33

5.78

4.66

15.50

14.40

14.04

20H

(5.24, 7.41)

(4.69, 6.86)

(3.58, 5.75)

(14.42, 16.59)

(13.32, 15.49)

(12.95, 15.12)

4.50

3.72

3.24

14.98

13.40

11.69

(3.41, 5.58)

(2.63, 4.81)

(2.15, 4.32)

(13.90, 16.07)

(12.32, 14.49)

(10.60, 12.77)

Table V. ANOVA table of end pressure

Table IV. ANOVA table of initial pressure

Type III

sum of

square

10H

F value

89.666 42.266

194.079 91.483

259.258 122.206

33.622 15.848

24.968 11.769

21.821 10.286

9.080

4.280

68.833 32.446

2.121

P value

.001

.001

.001

.001

.001

.001

.001

.001

a 2

R = 0.886.

Source

Type III

sum of

square

Point

810.836

Spacer

316.717

Hole

829.673

Point*Spacer

109.036

Point*Hole

625.464

Spacer*Hole

153.573

Point*Spacer*

207.722

Hole

Model

3053.022a

Error

143.633

Degree of

freedom

Mean

square

F value

P value

1

2

3

2

3

6

6

810.836

158.358

276.558

54.518

208.488

25.596

34.620

541.937

105.842

184.842

36.438

139.347

17.107

23.139

.001

.001

.001

.001

.001

.001

.001

23

96

132.740

1.496

88.719

.001

a 2

R = 0.955.

relief provided by a base plate wax spacer. That tray

design produced a pressure of 15 to 16 kPa, compared

with approximately 29 kPa for trays without holes and

relief. The values of the present experiment are similar,

in that initial pressure ranged from 14 to 30 kPa, and

end pressure ranged from 3 to 25 kPa, when similar

conditions were used. Therefore, it is the authors

opinion that loading force and compression speed used

in the present experimental system was reasonable.

In the present study, it was found that impression

pressure was higher at point-P than at point-R, located

on the ridge crest, when the tray was completely fitted to

the edentulous maxilla. Clinically, attempts to decrease

or release the pressure include using a spacer or placing

escape holes.1 For the trays without a hole or spacer in

the present study, both initial pressure and end pressure

at point-P were higher than those recorded at point-R.

Accordingly, such a tray may not be recommended for

making an impression of the edentulous maxilla. As

Boucher1 suggested, if it is necessary to apply pressure to

the edentulous ridge crest while applying minimal

pressure to the palate, a tray with an escape hole of 1.0

mm or larger, or that with a base plate wax-like spacer in

the palatal area, should be used. If it is necessary to apply

even less pressure to the palate, the concomitant use of

JUNE 2004

a spacer and hole, or an increased number of escape

holes, may be solutions.

With regard to end pressure, pressure concentration

at point-P and point-R was reversed by the effects of

escape holes and spacers. When impression material is

placed in a tray and the cast is compressed, the highest

pressure is located in the central area, and pressure

gradually decreases in the direction of the periphery.22

This is due to the rheological properties of the impression material, as the internal pressure of the material

decreases in the direction of the peripheral area where

pressure escapes. The pressure in the center area was

decreased by the use of escape holes in the present

experiment because the impression material was able to

flow out of the center area, and pressure decreased in the

direction of the peripheral area and also at the escape

hole. Furthermore, the pressure in the central area

also decreased by the use of spacers because the impression material flowed in the direction of not only the

peripheral area but also the space created by the use of

the spacer.

In the present study, the impression was simulated

using silicone impression materials with a standard

edentulous cast. However, clinically, the variability of

the condition of the residual ridge and impression

575

THE JOURNAL OF PROSTHETIC DENTISTRY

material should also be considered. Furthermore, a rigid

acrylic cast is not movable and is different from compressible moist mucosa. The authors speculate that,

intraorally, initial pressure is absorbed by the elasticity

of the mucosa, producing lower pressure, whereas end

pressure may be higher due to the elastic recovery of the

mucosa. Although the impression material was mechanically compressed in this experiment, it is questionable whether clinicians make impressions sensing

differences between 20 and 30 kPa. Furthermore, the

authors speculate that pressure is sufficiently applied in

the early stage by the use of the hand and fingers,

whereas almost no hand pressure is applied in the final

stage. Only 2 sensors were used in this experiment.

By increasing the number of sensors, it would be

possible to investigate the distribution of impression

pressure influenced by the use of escape holes and

spacers. Nevertheless, it appears that a hole placed in

the mid-palatal portion of the tray may significantly alter

impression pressure, with a more ideal result. Future

studies are needed to investigate how impression pressures vary in accordance with the height and hardness of

the edentulous ridge, as well as to investigate a variety of

impression materials and impression-making methods.

CONCLUSIONS

Within the limitations of this in vitro study, it was

found that initially, mid-palatal impression pressure

using a tray with no spacer, a sheet wax spacer and no

hole, or an escape hole 0.5 mm in diameter, was

significantly higher (P\.001) than or similar to the

pressure at the ridge crest. However, a tray with an

escape hole 1.0 or 2.0 mm in diameter and without

a spacer, a tray with an escape hole 0.5 mm in diameter

with a sheet wax spacer, or a tray with a base plate wax

spacer at each mid-palatal point produced end pressures

that were significantly lower than that at the ridge crest

(P\.001). Therefore, it is suggested that an escape hole

1.0 mm or larger, or a spacer with the thickness of a sheet

of base plate wax, may be used to selectively reduce

palatal impression pressure when making an impression

of an edentulous maxilla.

REFERENCES

1. Zarb GA, Bolender CL, Eckert SE, Jacob RF, Fenton AH, Mericske-Stern R.

Prosthodontic treatment for edentulous patients. 12th ed. St. Louis: Elsevier

Science; 2003. p. 211-31.

2. Nanci A, Cate T. Oral Histology. Development, structure, and fundamentals. 5th ed. St. Louis: Mosby; 1998. p. 104-27.

576

KOMIYAMA ET AL

3. Mohl ND, Drinnan AJ. Anatomy and physiology of the edentulous mouth.

Dent Clin North Am 1977;21:199-217.

4. Tomlin HR, Wilson HJ, Osborne J. The thickness and hardness of soft

tissues. A preliminary clinical survey. Br Dent J 1968;124:223-6.

5. Picton DC, Wills DJ. Viscoelastic properties of the periodontal ligament

and mucous membrane. J Prosthet Dent 1978;40:263-72.

6. Inoue K, Wilson HJ. Viscoelastic properties of elastomeric impression

materials. I. A method of measuring shear modulus and rigidity during

setting. J Oral Rehabil 1978;5:89-94.

7. DuBrul EL. Sicher and DuBruls Oral Anatomy. 8th ed. St. Louis: Ishiyaka

EuroAmerica; 1988. p. 161-78.

8. Lytle RB. Soft tissue displacement beneath removable partial and

complete denture. J Prosthet Dent 1962;12:34-43.

9. Kydd WL, Daly CH, Nansen D. Variation in the response to mechanical

stress of human soft tissues as related to age. J Prosthet Dent 1974;32:

493-500.

10. Watson IB, MacDonald DG. Regional variations in the palatal mucosa of

the edentulous mouth. J Prosthet Dent 1983;50:853-9.

11. Atwood DA. Some clinical factors related to rate of resorption of residual

ridges. J Prosthet Dent 1962;12:441-50.

12. Ortman HR. Factors of born resorption of the residual ridge. J Prosthet

Dent 1962;12:429-40.

13. Felton DA, Cooper LF, Scurria MS. Predictable impression procedures for

complete dentures. Dent Clin North Am 1996;40:39-51.

14. Klein IE, Broner AS. Complete denture secondary impression technique to

minimize distortion of ridge and border tissues. J Prosthet Dent 1985;54:

660-4.

15. Denen HE. Negative pressure impressions for full dentures. J Am Dent

Assoc 1944;31:888-94.

16. Newton JP, Quinn DM, Sturrock KC. An impression procedure for the

mobile maxillary residual ridge. Int J Prosthodont 1988;1:245-7.

17. Osborne J. Two impression methods for mobile fibrous ridges. Br Dent J

1964;117:392-4.

18. Tilton GE. Minimum pressure complete denture impression technique. J

Prosthet Dent 1956;6:6-23.

19. Frechette AR. Masticatory forces associated with the use of various types

of artificial teeth. J Prosthet Dent 1955;5:252-67.

20. Lindan O. Etiology of decubitus ulcers: an experimental study. Arch Phys

Med Rehabil 1961;42:774-83.

21. Frank RP. Analysis of pressures produced during maxillary edentulous

impression procedures. J Prosthet Dent 1969;22:400-13.

22. Rihani A. Pressures involved in making upper edentulous impressions. J

Prosthet Dent 1981;46:610-4.

Reprint requests to:

DR OSAMU KOMIYAMA

DEPARTMENT OF COMPREHENSIVE CLINICAL DENTISTRY

NIHON UNIVERSITY SCHOOL OF DENTISTRY AT MATSUDO

2-870-1 SAKAECHO-NISHI, MATSUDO

CHIBA 271-8587

JAPAN

FAX: 81-47-360-9615

E-MAIL: komiyama@mascat.nihon-u.ac.jp

0022-3913/$30.00

Copyright 2004 by The Editorial Council of The Journal of Prosthetic

Dentistry

doi:10.1016/j.prosdent.2004.03.020

VOLUME 91 NUMBER 6

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Pin Out ToyotaDocument60 pagesPin Out Toyotaariboro100% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Attachment and Development: A Perspective, Longitudinal Study From Birth and AdulthoodDocument19 pagesAttachment and Development: A Perspective, Longitudinal Study From Birth and Adulthooddelfinius65100% (1)

- The Tell Tale Heart QuestionsDocument8 pagesThe Tell Tale Heart QuestionsAmina SalahNo ratings yet

- F31 Measurement 2 PDFDocument348 pagesF31 Measurement 2 PDFJoseph WarNo ratings yet

- Chapter 08 - Ion Exchange, Water Demineralization & Resin TestingDocument23 pagesChapter 08 - Ion Exchange, Water Demineralization & Resin TestingMohamed ElbehlilNo ratings yet

- Biological Science PreboardDocument19 pagesBiological Science PreboardMark de Jesus0% (2)

- Module Tests: Expert PTEA Testmaster B2 Answer KeyDocument5 pagesModule Tests: Expert PTEA Testmaster B2 Answer KeyRyan MathProNo ratings yet

- Anil Ghom - Textbook of Oral Radiology - 2nd Ed - WWW - Thedentalhub.org - inDocument928 pagesAnil Ghom - Textbook of Oral Radiology - 2nd Ed - WWW - Thedentalhub.org - inSatavisha MohapatraNo ratings yet

- Pess Work PlanDocument1 pagePess Work PlanRESTTIE DAGUIO100% (2)

- Bio 11.1 LE 2 NotesDocument7 pagesBio 11.1 LE 2 NotesCode BlueNo ratings yet

- Neki-Dent KATALOGU FINAL - CompressedDocument73 pagesNeki-Dent KATALOGU FINAL - CompressedStefan PutnikNo ratings yet

- 2018 - Shiau - Evaluation of A Flipped Classroom Approach To Learning Introductory EpidemiologyDocument9 pages2018 - Shiau - Evaluation of A Flipped Classroom Approach To Learning Introductory EpidemiologySocorro Moreno LunaNo ratings yet

- Ix. Answers To Study QuestionsDocument6 pagesIx. Answers To Study Questionsyessa gamuedaNo ratings yet

- Introduction To Chemical BondingDocument5 pagesIntroduction To Chemical BondingMini PGNo ratings yet

- Supply, Elasticity of SupplyDocument4 pagesSupply, Elasticity of SupplySaurabhNo ratings yet

- The Complete Aqueous Hydrochloric Acid Solutions Density-Concentration CalculatorDocument2 pagesThe Complete Aqueous Hydrochloric Acid Solutions Density-Concentration CalculatorEngr. Md. Tipu SultanNo ratings yet

- SDD 048 ML 12xx DocumentDocument12 pagesSDD 048 ML 12xx DocumentRomiNo ratings yet

- 4099 0002Document4 pages4099 0002kikeecpNo ratings yet

- Family Fitness Challenge ScriptDocument2 pagesFamily Fitness Challenge ScriptXyrille GuevarraNo ratings yet

- Barriers To Delivering Trauma Focused Interventions For People With PsychosisDocument20 pagesBarriers To Delivering Trauma Focused Interventions For People With Psychosissamira6alvarado6zebaNo ratings yet

- Airo WaterDocument27 pagesAiro WaterAhana SahaNo ratings yet

- Water ProofingDocument5 pagesWater ProofingMalith De SilvaNo ratings yet

- "MacFarlane and Another V Tayside Health Board (2000) 2 AC 59Document8 pages"MacFarlane and Another V Tayside Health Board (2000) 2 AC 59LAW MANTRA100% (1)

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor JumperDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor Jumpermohammed tofiqNo ratings yet

- MSDS Hemolok GelDocument5 pagesMSDS Hemolok GelReniNo ratings yet

- Envicool AC AIRCON MC30HDNC1ADocument7 pagesEnvicool AC AIRCON MC30HDNC1ABores ModearNo ratings yet

- SHDH2040 Lecture 5Document83 pagesSHDH2040 Lecture 5123 HahahaNo ratings yet

- Bipolar Disorder - Case studyTSAD2015Document37 pagesBipolar Disorder - Case studyTSAD2015Eldruga PabloNo ratings yet

- Transition Metal ChemistryDocument15 pagesTransition Metal Chemistryswc306No ratings yet

- HT 800 Medium Cellular SiliconeDocument2 pagesHT 800 Medium Cellular SiliconeDarwinPowChonLongNo ratings yet