Professional Documents

Culture Documents

2140 Inert Buffer Gas

Uploaded by

ronny_fernandes363Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2140 Inert Buffer Gas

Uploaded by

ronny_fernandes363Copyright:

Available Formats

Inert Buffer Gas

Control System

Designed to Reduce Fugitive Emissions

The inert buffer gas control

system is available in standard

designs, or Dresser-Rand can

custom engineer a system to

meet your specifications.

Purging with inert buffer gas is an effective way to control and virtually eliminate

fugitive gas emissions from reciprocating compressors. Dresser-Rand offers an

inert buffer gas control system that will reliably distribute, control, and monitor

buffer gas at all points on your reciprocating compressor. Instrumentation allows

operators to simply and easily monitor buffer gas pressures as well as the condition

of buffered and seal packings. Automated alarm and/or shutdown capability also is

an option with this system.

Two types of pressure control are available manual and automatic. Manual pressure control is used when venting to a constant pressure disposal (flare) or vapor

recovery system. Automatic pressure control is used when its necessary to maintain a buffer gas pressure 15 psig higher than a variable pressure disposal (flare)

or vapor recovery system, as recommended by API 618.

Features

Benefits

Central distribution

Controls and monitors all reciprocating compressor

buffer gas purge requirements from one location

Automatic pressure control

Maintains buffer gas purge pressure 15 psig above

plant gas disposal (flare) or vapor recovery system pressure as recommended by API 618

Automated monitoring

Activates alarm and/or shutdown in the event of a buffer

gas supply loss

Instrumentation

Enables simple and easy monitoring

Flow meters

Displays buffer gas flow rates to buffered packings

and distance pieces (changes in flow rates indicate an

increase in wear of the buffered and seal packings)

Compact design

Requires minimal space on compressor operating deck

Fully tested before delivery

Ensures Dresser-Rand quality and reliability

Control SystemTypical for One Compressor Cylinder

For a complete list of D-R products

and services, visit us at

www.dresser-rand.com or

contact one of the following locations:

Dresser-Rand

Corporate Headquarters

West8 Tower Suite 1000

10205 Westheimer Road

Houston, TX 77042 USA

Tel: (Intl +1) 713-354-6100

Fax: (Intl +1) 713-354-6110

email: info@dresser-rand.com

PI

4

PI

1

PDI

1

INERT

BUFFER

GAS

SUPPLY

ON/OFF

PCV

1

DPCV

1

PSL

1

PRV

1

PI

3

FI

1

FI

2

FI

3

FI

4

TO OIL

WIPING

PACKING

(1)

TO CYLINDER

PRESSURE

PACKING

(2)

TO CYLINDER

UNLOADER

(FRAME END)

(3)

TO CYLINDER

UNLOADER

(OUTER END)

(4)

CHECK

VALVE

(TYPICAL)

PANEL BOUNDARY

The Americas

Dresser-Rand

PI

2

FILTER

112, Avenue Kleber

75784 Paris Cedex 16

Tel: (Intl +33) 156 26 71 71

Fax: (Intl +33) 156 26 71 72

email: info@dresser-rand.com

Regional Headquarters

SENSING

PRESSURE

FROM DISPOSAL

(FLARE) OR

VAPOR

RECOVERY

SYSTEM

UNNECESSARY FOR A CONSTANT PRESSURE (FLARE)

OR VAPOR RECOVERY SYSTEM

Typical Compressor Cylinder Inert Buffer Gas Arrangement

DISTANCE PIECE VENT

West8 Tower Suite 1000

10205 Westheimer Road

Houston, TX 77042 USA

Tel: (Intl +1) 713-354-6100

Fax: (Intl +1) 713-354-6110

UNLOADER VENTS

(1)

(2)

TO DISPOSAL (FLARE)

OR VAPOR RECOVERY

SYSTEM

(4)

(3)

EMEA

(Europe, Middle East, Africa)

Dresser-Rand S.A.

31 Boulevard Winston Churchill

Cedex 7013

Le Havre 76080 France

Tel: (Intl +33) 2-35-25-5225

Fax: (Intl +33) 2-35-25-5366 / 5367

CYLINDER

UNLOADER

(FRAME END)

OIL WIPER PACKING

COMPRESSOR

FRAME

CYLINDER

UNLOADER

(OUTER END)

ACCESS OPENING

(SOLID COVER)

PRESSURE

PACKING

PISTON ROD

CROSSHEAD

GUIDE

Asia-Pacific

Dresser-Rand Asia Pacific Sdn Bhd

Unit 9-4, 9th Floor

Bangunan Malaysian Re

17 Lorong Dungun, Damansara Heights

50490 Kuala Lumpur, Malaysia

Tel: (Intl +60) 3-2093-6633

Fax: (Intl +60) 3-2093-2622

OIL SLINGER

INBOARD

DISTANCE PIECE

ACCESS OPENING

(SOLID COVER)

OUTBOARD

DISTANCE PIECE

PISTON

CYLINDER

COMBINED PACKING VENT AND DRAIN

INBOARD

DISTANCE PIECE

DRAIN

TO DISPOSAL (FLARE)

OR VAPOR RECOVERY

SYSTEM

OUTBOARD

DISTANCE PIECE

DRAIN

Key

DPCV-1

FI-1

FI-2

FI-3

2007 Dresser-Rand.

FI-4

PCV-1

This document comprises a general overview

PDI-1

of the products described herein. It is solely for

informational purposes, does not represent a war- PI-1

ranty or guarantee of the information contained

PI-2

herein and is not to be construed as an offer to

sell or a solicitation to buy. Contact Dresser-Rand PI-3

for detailed design and engineering information

PI-4

suitable to your specific applications. DresserRand reserves the right to modify its products and PRV-1

related product information at any time without

PSL-1

prior notice.

Form 2140

Differential Pressure Control Valve - Maintains buffer gas pressure at a minimum of 15 psig above a

variable pressure disposal (flare) or vapor recovery system

Flow Indicator - Displays buffer gas flow rate to oil wiper packing

Flow Indicator - Displays buffer gas flow rate to pressure packing

Flow Indicator - Displays buffer gas flow rate to cylinder unloader (frame end)

Flow Indicator - Displays buffer gas flow rate to cylinder unloader (outer end)

Pressure Control Valve - Reduces buffer gas supply pressure to the required system pressure

Pressure Differential Indicator - Displays condition of buffer gas filter

Pressure Gauge - Displays buffer gas supply pressure into buffer gas control system

Pressure Gauge - Displays pressure control valve buffer gas outlet pressure

Pressure Gauge - Displays differential pressure control valve buffer gas outlet pressure

Pressure Gauge - Displays disposal (flare) or vapor recovery gas line pressure

Pressure Relief Valve - Protects buffer control system components from over pressure

Low Pressure Switch - Identifies loss of buffer gas pressure and generates alarm (or shutdown)

You might also like

- Operation of Rotary Screw Compressors RWF 270Document14 pagesOperation of Rotary Screw Compressors RWF 270Bayol SemprolNo ratings yet

- Vilter SOPDocument9 pagesVilter SOPAnonymous ffje1rpaNo ratings yet

- Oil-Free Rotary Screw Parts and AccessoriesDocument2 pagesOil-Free Rotary Screw Parts and AccessoriesSharad KokateNo ratings yet

- BE SG RWF Frick II RotaryDocument8 pagesBE SG RWF Frick II RotarygamunozdNo ratings yet

- 7000 Flow Control ValvesDocument51 pages7000 Flow Control Valvesadyro12100% (1)

- Curso PDFDocument185 pagesCurso PDFJose VidalNo ratings yet

- Compressor Anti-Surge ValveDocument2 pagesCompressor Anti-Surge ValveMoralba SeijasNo ratings yet

- Program Information Mobile Hydraulics, Mobile Electronics, GearsDocument27 pagesProgram Information Mobile Hydraulics, Mobile Electronics, GearsCem KoçakNo ratings yet

- Bendix® AD-IS® EverFlow™ AssemblyDocument10 pagesBendix® AD-IS® EverFlow™ Assemblyjgomez30No ratings yet

- 0700P-E - B Global Air PreparationDocument89 pages0700P-E - B Global Air PreparationJosé Luis De la ONo ratings yet

- Operating Manual Manual de Instrucciones Manuel D'utilisationDocument16 pagesOperating Manual Manual de Instrucciones Manuel D'utilisationCarlos EscalonaNo ratings yet

- Ec210 160B Eng 7Document22 pagesEc210 160B Eng 7Mohamed Yousif Hamad94% (32)

- Turboexpansor. Manual Detallado LATDocument52 pagesTurboexpansor. Manual Detallado LATCamilo Ernesto Nardez Martinez100% (2)

- DRESSER Regulators FlowgridDocument12 pagesDRESSER Regulators Flowgridzalziza100% (1)

- MANN Filters For LiquidsDocument48 pagesMANN Filters For LiquidsRoccinanteNo ratings yet

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocument8 pagesOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1No ratings yet

- QGB25Document48 pagesQGB25Nelia ShkutNo ratings yet

- 27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFDocument20 pages27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFLungisaniNo ratings yet

- Book LayoutDocument8 pagesBook LayoutaamenaNo ratings yet

- Codigos de Limpieza Segun VickerDocument6 pagesCodigos de Limpieza Segun VickerFelipe Alexis Aros Sánchez100% (1)

- Sanden Compressor Service GuideDocument30 pagesSanden Compressor Service Guideantony.petro100% (1)

- Parker Valves Pdn1000us Brass-Poppet Sliding-SealDocument20 pagesParker Valves Pdn1000us Brass-Poppet Sliding-SealEric Figueroa UribeNo ratings yet

- Belgen150 & 200 - MAY 2006 - 65084-1BDocument42 pagesBelgen150 & 200 - MAY 2006 - 65084-1BdavidNo ratings yet

- HPG Range: Direct High-Pressure Gas ActuatorsDocument8 pagesHPG Range: Direct High-Pressure Gas ActuatorsLuan HuynhNo ratings yet

- Advanced Troubleshooting Guide For Air Brake Compressors: IndexDocument24 pagesAdvanced Troubleshooting Guide For Air Brake Compressors: IndexCanaan MoxamNo ratings yet

- Indigenous Development of Imported Components Used To Build The Light Combat Aircraft LCA TejasDocument4 pagesIndigenous Development of Imported Components Used To Build The Light Combat Aircraft LCA TejasLuptongaNo ratings yet

- Air Compressors and Pneumatic Control SystemsDocument7 pagesAir Compressors and Pneumatic Control SystemsBader Shrbaji100% (2)

- Operator'S Manual: Split SystemDocument19 pagesOperator'S Manual: Split SystemchevyllNo ratings yet

- PFvalveDocument4 pagesPFvalveJose Luis RattiaNo ratings yet

- Dosing Product Price List by GrundfosDocument36 pagesDosing Product Price List by Grundfossantosh kumar50% (2)

- Heavy Duty ManualDocument26 pagesHeavy Duty ManualErnesto Andres Guevara MalaveNo ratings yet

- Copeland Semi-Hermetic Compressor GatalogueDocument70 pagesCopeland Semi-Hermetic Compressor GatalogueMoon Choon-GeunNo ratings yet

- 769D 07 Aire y FrenosDocument57 pages769D 07 Aire y Frenosrigoberto123456789100% (1)

- Elgi Screw CompressorDocument12 pagesElgi Screw CompressorRAVINDER DHINGRANo ratings yet

- Recips YesWeCanDocument9 pagesRecips YesWeCanho-faNo ratings yet

- VW RetrofitDocument9 pagesVW Retrofitisuntxo0% (1)

- Senator LSV Series With Mam-660 ControllerDocument64 pagesSenator LSV Series With Mam-660 ControllerRomanCHubaNo ratings yet

- Surge Control: Compressor Surge and MeasurementDocument4 pagesSurge Control: Compressor Surge and Measurementmtrj59100% (1)

- Lubrication Equipment CatalogDocument60 pagesLubrication Equipment Catalogjairo269No ratings yet

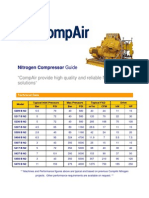

- Nitrogen Compressor Guide: "Compair Provide High Quality and Reliable Nitrogen SolutionsDocument5 pagesNitrogen Compressor Guide: "Compair Provide High Quality and Reliable Nitrogen Solutionskalpesh_1588No ratings yet

- 2013 Champion Advantage Series PDFDocument4 pages2013 Champion Advantage Series PDFputra_quezeeNo ratings yet

- 301 12 PDFDocument13 pages301 12 PDFEduardo VillatoroNo ratings yet

- Why An Air Filtration System Is So ImportantDocument8 pagesWhy An Air Filtration System Is So ImportantSujoy BanikNo ratings yet

- Parts Manual: Belt Drive Air CompressorDocument57 pagesParts Manual: Belt Drive Air CompressorestebanNo ratings yet

- QGB 40-50-60 Parts ManualDocument56 pagesQGB 40-50-60 Parts ManualPing KSomsupNo ratings yet

- D, H, V-Pak and V-Pak Low Profile Series HY28-2661-CD-USDocument50 pagesD, H, V-Pak and V-Pak Low Profile Series HY28-2661-CD-USmecambNo ratings yet

- +FlowgridSlamShut Bro - 111Document8 pages+FlowgridSlamShut Bro - 111Carlos TarquinoNo ratings yet

- WABCO Buses2008 8150101563 PDFDocument79 pagesWABCO Buses2008 8150101563 PDFPapuciev Ivan100% (5)

- Gorter r200Document6 pagesGorter r200Manish SaraswatNo ratings yet

- Csa NewDocument8 pagesCsa Newpeterpunk75No ratings yet

- Sg10 Sizing & Selection ManualDocument104 pagesSg10 Sizing & Selection ManualiaintNo ratings yet

- © 2002 Caterpillar IncDocument60 pages© 2002 Caterpillar Incrigoberto123456789100% (1)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Kaydon Dry Gas SealDocument12 pagesKaydon Dry Gas Sealxsi666No ratings yet

- 8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)Document22 pages8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)LongTuanNo ratings yet

- 31290034Document45 pages31290034fraihafraihaNo ratings yet

- Company Profile & Catalogue PDFDocument24 pagesCompany Profile & Catalogue PDFhbookNo ratings yet

- S 28AT XP EXP EngDocument6 pagesS 28AT XP EXP EngpramodtryNo ratings yet

- Compressor ManturboDocument6 pagesCompressor ManturboSubhasish MitraNo ratings yet

- 2140 Inert Buffer GasDocument2 pages2140 Inert Buffer GasNikola HodakNo ratings yet

- 1992 - Sdorra-Basic Investigations For Laser MicroanalysisDocument9 pages1992 - Sdorra-Basic Investigations For Laser MicroanalysisVincent PiscitelliNo ratings yet

- Compressor Dry Gas Seal TrainingDocument10 pagesCompressor Dry Gas Seal TrainingTg TarroNo ratings yet