Professional Documents

Culture Documents

Heavy PTFE Seat Split Body Concentric Butterfly Valve Series

Uploaded by

shashikanth79Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heavy PTFE Seat Split Body Concentric Butterfly Valve Series

Uploaded by

shashikanth79Copyright:

Available Formats

Heavy PTFE Seat Split Body Concentric Butterfly Valve

Type:

Face to Face:

Flange:

Mounting Flange:

Wafer, Lugged

API609, BS EN 558, DIN3202,

ISO 5752

DIN, BS, UNI, ISO, ANSI,

AS, JIS

ISO5211

Bushings (4)

Shaft bushings reduce torque

and isolate the shaft from the

valve body, preventing seizure

of the shaft due to corrosion in

the shaft journal.

Shaft

The shaft which consist of

lower and upper shaft

connection by screw thread,

ensures dependability and

positive disc positioning.

Series 450

Working Pressure:

PN10 (150PSI)

Application:

Chemical/Petrochemical/Processing,

Power and Utilities, Paper and Pulp,

Food & Beverage, Pharmaceutical

Mounting Flange

ISO 5211 mounting flange

accommodates direct

mounting of all types of

actuators, including:

handles, gear operators,

electric and pneumatic.

O-Ring (1)

Shaft seal provides further

assurance against shaft

leakage.

Flats & Groove Seal

PTFE Seat

Pure PTFE seat min . 5mm

thickness can resist heavy

corrosive flow media .

Disc and

Shaft Connection

The square connection

eliminates shaft retention

components being exposed to

the line media . Maximum flow

is achieved.

Smooth finished disc flats

mate with seat flats and a

raised ring on disc top and

bottom tightly inserted to a

groove on the seat which

prevents leakage into the

shaft area.

Two Piece Body

Two piece body allows for

ease of assembly and

maintenance.

Disc

Stainless steel or stainless

steel PTFE (min . Thickness

6mm) coated disc prevents

chemical corrosion from flow

media. Precision profile

provides bubble-tight shutoff, assures minimum torque

and longer seat life.

11

Heavy PTFE Seat Split Body Concentric Butterfly Valve

Series 450

LUG TYPE

Series 450L

WAFER TYPE

Series 450W

d0

D1

n- M

n-

d1

C

LEVER STANDARD

FOR 1-1/2"-6"

GEAR STANDARD

FOR 8" & LARGER

P

K

z- d

STANDARD MATERIALS OF MAIN PARTS

ITEM

1

2

3

4

5

6

7

8

MATERIAL

Ductile Iron, Carbon Steel, Stainless Steel

Stainless Steel 316

PTFE

CF8M+PTFE

Viton

Stainless Steel 316

Malleable Iron

Component

PART NAME

Body

Lower Shaft

Seat

Disc

O Ring

Upper Shaft

Lever

Gear

DIMENSIONS AND WEIGHTS

SIZE

in

1-1/2

2

2-1/2

3

4

5

6

8

10

12

DN

40

50

65

80

100

125

150

200

250

300

d0

33

43

46

46

52

56

56

60

68

78

73

73

80

90

116

130

148

180

220

255

128

135

135

138

158

175

188

230

270

300

270

270

270

270

270

270

270

300

300

300

32

32

32

32

32

32

32

45

45

45

12.6

14.3

14.3

14.3

15.77

18.92

18.92

22.1

28.45

31.6

9

11

11

11

11

14

14

17

22

22

UPPER FLANGE

K

77

90

90

90

90

90

90

125

125

140

E

50

70

70

70

70

70

70

102

102

102

z-d

4-7

4-9

4-9

4-9

4-9

4-9

4-9

4-12

4-12

4-12

ANSI 150

D1

n-d1

98.5 4-15

120.5 4-19

139.5 4-19

152.5 4-19

190.5 8-19

216 8-22

241.5 8-22

298.5 8-22

362 12-25

432 12-25

DIN PN10/16

Weight (kg)

n-d1

Wafer

M

D1

M

4-18

2.2

1/2"

110

M16

4-18

3.0

5/8"

M16

125

4-18

3.0

5/8"

M16

145

4/8-18

3.5

5/8"

M16

160

8-18

4.8

5/8"

M16

180

8-18

6.8

3/4"

M16

210

8-23

8.0

3/4"

M20

240

8/12-23

24.8

3/4"

M20

295

7/8" 350/355 12-23/27 M24/M24 30.8

7/8" 400/410 12-23/27 M24/M24 44.0

Lug

3.7

4.2

4.2

4.5

7.8

10.8

13.8

32.5

43.2

55.0

NOTE: 1. Standard actuation is 1-1/2"- 6" with lever , 8-12" with gear.

2. Shaft head types of double D head and round with key are optional.

12

You might also like

- Butterfly 400Document2 pagesButterfly 400shashikanth79No ratings yet

- High Performance ButterflyDocument19 pagesHigh Performance ButterflyEmily NguyenNo ratings yet

- Pin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting FlangeDocument4 pagesPin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting Flangeshashikanth79No ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- FlowTek Ball Valve DesignDocument0 pagesFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNo ratings yet

- T4E Brochure PDFDocument6 pagesT4E Brochure PDFgullenariNo ratings yet

- Two BallDocument5 pagesTwo Ballchartwithsam0041653No ratings yet

- BV : 1 : 1 : 13 - Concise for Ball Valve DocumentDocument16 pagesBV : 1 : 1 : 13 - Concise for Ball Valve DocumentRamaswamy Neelakantan NNo ratings yet

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- F-2306 - S19 - 2015-09 Flow TekDocument8 pagesF-2306 - S19 - 2015-09 Flow Tekel ronisNo ratings yet

- Dezurik High Performance Butterfly Valves BHP Sales 45-00-1Document8 pagesDezurik High Performance Butterfly Valves BHP Sales 45-00-1yg89No ratings yet

- Shaffer ShpericalDocument11 pagesShaffer Shpericaljeinerdt100% (1)

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilNo ratings yet

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDocument8 pagesW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999No ratings yet

- Chi CharraDocument6 pagesChi CharraMax PawerNo ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- AVK Valvula Borboleta Com Flanges Iso5752 Concentric A Corpo Longo Serie 7542Document2 pagesAVK Valvula Borboleta Com Flanges Iso5752 Concentric A Corpo Longo Serie 7542PkKhakeNo ratings yet

- Tyco Fig.110-190 Ball Valves DatasheetDocument24 pagesTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- Valve0114 PDFDocument14 pagesValve0114 PDFbinhjukiNo ratings yet

- Butterfly Flu01 Omb 04 11Document16 pagesButterfly Flu01 Omb 04 11ila_368684492No ratings yet

- High-Tech Block & Bleed ValvesDocument20 pagesHigh-Tech Block & Bleed ValvesMayur PatelNo ratings yet

- PCC Technova Series CPL Cylindrical ValvesDocument5 pagesPCC Technova Series CPL Cylindrical ValvesAnju VijayanNo ratings yet

- Literature Force Floating Ball Valve CatalogDocument16 pagesLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionAyman RiyadhNo ratings yet

- Prochem Ball ValvesDocument5 pagesProchem Ball Valvesmd_taheriNo ratings yet

- FMC - Knife Edge Gate ValveDocument5 pagesFMC - Knife Edge Gate ValvesheshidharrajubNo ratings yet

- High Performance Butterfly Valve Series: Mounting FlangeDocument2 pagesHigh Performance Butterfly Valve Series: Mounting Flangeshashikanth79No ratings yet

- High End Technology Tight Shutoff: EFLO Eccentric PlugDocument4 pagesHigh End Technology Tight Shutoff: EFLO Eccentric Plugابزار دقیقNo ratings yet

- Datasheet Vetec TY005.030Document16 pagesDatasheet Vetec TY005.030Ali Abdul MannanNo ratings yet

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanNo ratings yet

- Naf Pocket ValveDocument4 pagesNaf Pocket ValveAlfredo Silvi MellaNo ratings yet

- Flanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignDocument9 pagesFlanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignSaleh EttehadiNo ratings yet

- Series 7400Document22 pagesSeries 7400zekha87No ratings yet

- EJ Series Butterfly ValvesDocument12 pagesEJ Series Butterfly ValvesGia Minh Tieu TuNo ratings yet

- High Performance Butterfly ValvesDocument8 pagesHigh Performance Butterfly ValvesTejas JasaniNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- Flowserve Vlatb001Document20 pagesFlowserve Vlatb001Selva KumarNo ratings yet

- Block and Bleed ValvesDocument25 pagesBlock and Bleed ValvesVidyasenNo ratings yet

- Ball Valve Design FeatureDocument6 pagesBall Valve Design FeaturebbmokshNo ratings yet

- ISO Sovereign Parts ListDocument17 pagesISO Sovereign Parts ListTiago PortanskyNo ratings yet

- Rotork 300 Quarter TurnDocument4 pagesRotork 300 Quarter TurngullenariNo ratings yet

- Ball Valve GuideDocument22 pagesBall Valve GuideBalakrishna BisoyiNo ratings yet

- Direct-Acting Pressure Reducing Valve For Air: ModelDocument2 pagesDirect-Acting Pressure Reducing Valve For Air: ModelAmerico WaxNo ratings yet

- Arita KatalogDocument58 pagesArita KatalogAhmed Beaet83% (6)

- DIN3202 F4 Gate Valve Specs & DimensionsDocument1 pageDIN3202 F4 Gate Valve Specs & Dimensionsstignz50% (2)

- Williams - Válvulas Tipo Bola API 608 API 6dDocument15 pagesWilliams - Válvulas Tipo Bola API 608 API 6despanolasaNo ratings yet

- Vintrol Ball ValveDocument8 pagesVintrol Ball ValvechadNo ratings yet

- Product Data Sheet Product Data Sheet B6F Type Ball Valve B6F Type Ball ValveDocument1 pageProduct Data Sheet Product Data Sheet B6F Type Ball Valve B6F Type Ball ValveArunNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzNo ratings yet

- Heavy Duty Actuator - BrochureDocument16 pagesHeavy Duty Actuator - BrochureRedzaNo ratings yet

- CTT Pot BearingsDocument16 pagesCTT Pot BearingswpchengNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Gate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12Document1 pageGate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12shashikanth79No ratings yet

- Ball Check Valve Dimensions and SpecificationsDocument1 pageBall Check Valve Dimensions and Specificationsshashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- PN 16 Flanged Ball Valve with ISO Top FlangeDocument1 pagePN 16 Flanged Ball Valve with ISO Top Flangeshashikanth79No ratings yet

- Ball Check Valve: 4740 47401 PN 16 PN 10Document1 pageBall Check Valve: 4740 47401 PN 16 PN 10shashikanth79No ratings yet

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79No ratings yet

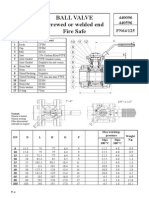

- Ball Valve Full Bore - Flanged End: 1 Body No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 Body No Materialshashikanth79No ratings yet

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Document1 pageGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79No ratings yet

- Ball Valve Full Bore - Compact: No MaterialDocument1 pageBall Valve Full Bore - Compact: No Materialshashikanth79No ratings yet

- Ball Valve Parts & SpecsDocument1 pageBall Valve Parts & Specsshashikanth79No ratings yet

- Full Bore Flanged Ball ValveDocument1 pageFull Bore Flanged Ball Valveshashikanth79No ratings yet

- Resilient Seated Gate Valve: 620302 620301 PN 16 PN 10Document1 pageResilient Seated Gate Valve: 620302 620301 PN 16 PN 10shashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: No MaterialDocument1 pageBall Valve Full Bore - Flanged End: No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocument1 pageBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79No ratings yet

- Screwed End Stainless Steel Ball Valve Technical SpecificationsDocument1 pageScrewed End Stainless Steel Ball Valve Technical Specificationsshashikanth79No ratings yet

- Full Bore Butt Weld Ball ValveDocument1 pageFull Bore Butt Weld Ball Valveshashikanth79No ratings yet

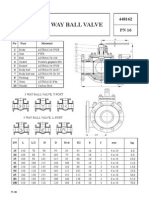

- 3-Way Ball Valve Full Bore - Screwed End: No MaterialDocument1 page3-Way Ball Valve Full Bore - Screwed End: No Materialshashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- Ball Valve Full Bore - Butt Weld End: 1 No MaterialDocument1 pageBall Valve Full Bore - Butt Weld End: 1 No Materialshashikanth79No ratings yet

- Brass Full Bore Screwed End Ball ValveDocument1 pageBrass Full Bore Screwed End Ball Valveshashikanth79No ratings yet

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocument1 pageBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79No ratings yet

- 3-Way Gland Cock: No Material 1Document1 page3-Way Gland Cock: No Material 1shashikanth79No ratings yet

- 3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- 3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10Document1 page3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79No ratings yet

- 3-Way Gland Cock: 1 No MaterialDocument1 page3-Way Gland Cock: 1 No Materialshashikanth79No ratings yet

- 3-Way Ball Valve Flanged ISO PN16 Stainless SteelDocument1 page3-Way Ball Valve Flanged ISO PN16 Stainless Steelshashikanth79No ratings yet