Professional Documents

Culture Documents

Popular Mechanics - Replacing Front-Drive Axles

Popular Mechanics - Replacing Front-Drive Axles

Uploaded by

mmaleniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Popular Mechanics - Replacing Front-Drive Axles

Popular Mechanics - Replacing Front-Drive Axles

Uploaded by

mmaleniCopyright:

Available Formats

PM: Saturday Mechanic - Replacing Front-Drive Axles

1 of 4

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=P...

SAVE THIS | EMAIL THIS | Close

Replacing Front-Drive Axles

BY MIKE ALLEN

Photography by Monte Isom

Shop facilities courtesy of Bargain Auto Service, Linden, N.J.

Published in the June, 2005 issue.

That clicking noise that your front-wheel-drive car makes as you

accelerate around low-speed righthand corners has been getting a

little louder for weeks. One afternoon, just as you pull out of the

parking lot, there's a loud banging noise and a series of crunches.

Then all forward thrust drops off, punctuated by vibration and the

occasional ping of tortured metal. Your CV joint has failed.

THEY DON'T MAKE THEM LIKE THAT ANYMORE

The wheels of your front-drive vehicle are connected to the

transaxle via axles that have constant-velocity-type universal joints

at each end. There is an inner and outer joint on the left and right

29/08/2006 12:33 PM

PM: Saturday Mechanic - Replacing Front-Drive Axles

2 of 4

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=P...

axles. All else being equal, the outer joints fail first because they

run with the highest angularity--when the wheel is turned, the joint

has to redirect the torque from the engine around a corner. The

more angle, the more strain. And it's usually the right side that goes

first because here in the lefthand-drive US of A, we turn sharper

around righthand corners than lefthand ones. Sometimes the rubber

boots covering the joints fail from age or are torn by road debris,

letting the grease out and dirt and water in. As recently as 10 years

ago, the repair meant removing the pertinent axle and taking out

the failed CV. You'd then replace it and the boot, lubricate the new

and old joint with fresh grease, reinstall and go.

A failed boot requires immediate disassembly and

cleaning, fresh lube and a new boot.

Nowadays it's difficult to find a CV joint for sale at a parts store.

The industry has made it standard procedure to swap in a complete

new or remanufactured axle, with the boots installed and

prelubricated. No mess, no fuss--which is good because the

molysulfide-doped grease specified for CV joints is the blackest,

nastiest, most thixotropic (you know, sticky) goop you can

imagine, and it will stain your cuticles, your tools and your work

clothes worse than printer's ink. You'd never get the stuff out of the

washing machine.

You can save some money by buying a remanufactured axle, which

will be virtually as good as new. The refurbishing process involves

regrinding all the grooves in the inner and outer halves of the joint

to a standard oversize, and replacing the cage and ball bearings

with new oversize ones.

This joint shows minor wear. Balls and grooves will

show wear before the joint fails completely.

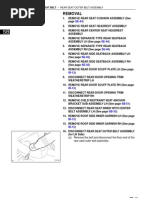

GET DOWN

Replacing a front-wheel-drive axle is straightforward, although physically

demanding. Get the replacement axle before you start, as well as a new

spindle nut and a cotter pin or two. The counterman at the auto parts store

will be able to tell you what you need and if the spindle nut needs to be

replaced every time it's removed. There may be a new spindle nut in the box

with the axle assembly.

Start by loosening all the lug nuts on the wheel that you'll be working on

with the car on the ground. Jack up the car and set the whole front end on

proper safety stands, as high as you can. You'll need both wheels off the

ground to allow enough suspension droop.

You'll need a big socket to remove the spindle nut. A large crescent wrench

or pipe wrench is not an acceptable substitute. Borrow, rent or buy the right

socket and a flex handle with at least an 18-in. handle, because that nut may

be torqued to as much as 300 lb.-ft. You can use an air wrench to loosen it if

you have compressed air available.

Start by removing the ball joint's pinch

clamp bolt and tie rod end from the

suspension upright.

At this point procedures may vary slightly, depending on your vehicle's

29/08/2006 12:33 PM

PM: Saturday Mechanic - Replacing Front-Drive Axles

3 of 4

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=P...

suspension. Consult your shop manual for specifics, but for the most part

you'll need to do the following.

Remove the cotter pin from the tie rod end, and pop the tie rod end out of the

steering arm. If it's frozen, don't whack the end of the threaded shank with a

hammer; you'll probably just ding the threads. Leave the castellated nut a

few threads on, and use a big screwdriver or pry bar to lift the steering arm

up. Then, smack the rod end a good shot with a hammer and it should pop

right out. An alternative is to use two ball-peen hammers and hit both sides

of the steering arm simultaneously. There are also threaded pullers for really

stubborn cases. If you don't mind destroying the rubber boot on the rod end,

you can use a crowbar or a "pickle fork" puller.

Disconnect the ball joint from the suspension upright. You probably can do

this by loosening and then removing the pinch bolt at the bottom of the

shock. Pull the lower control arm down until the ball joint separates from the

steering upright.

Pry the inner joint free of the

transmission. Check a manual for

specifics for your vehicle.

This is where it gets tricky. On some vehicles you're in a position to pull the

suspension upright and outward enough to let the spindle shaft fall free of its

bearing. On many vehicles the suspension arm won't droop far enough.

You'll need to disconnect the sway bar and perhaps another suspension

piece. Try disconnecting the sway bar, and using a big pry bar and a helper

to get the ball joint to clear.

POPPING THE AXLE OUT

Methods of attaching the axle at the transmission end vary. Our

example vehicle uses a spring ring that snaps into a groove. We

simply used a big pry bar to pop it out. On other vehicles, there's a

snap ring that needs to be removed with snap ring pliers to allow

the axle to clear the transmission. Check beforehand because using

a pry bar until one of these came loose probably would be a bad

idea.

Warning: Some vehicles will spill transmission fluid as soon as the

inner axle stub clears the seal. Be ready with a drain pan.

Use a big pry bar to drop the ball joint far enough to

allow the suspension to clear the spindle shaft.

Some European vehicles use a ring of bolts to hold the inner CV to

the inner stub axle, and the stub axle stays in the transmission case.

These bolts probably use a 12-point Allen-type wrench. They are

notorious for stripping. Be sure to clean any road grime out of the

Allen bolt heads, and seat the Allen wrench into the bolt head with

a light hammer tap to prevent this.

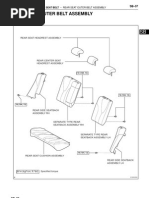

POPPING THE AXLE IN

Give the pair of axles, new and old, a critical look to be sure they

are identical. For instance, ABS- and non-ABS-equipped cars may

use axles that look almost exactly the same, but have differing

29/08/2006 12:33 PM

PM: Saturday Mechanic - Replacing Front-Drive Axles

4 of 4

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=P...

numbers of splines.

Clean the inner end splines of the new axle to keep from

introducing any dirt into your transmission. Slide the new axle

home until it's seated, being sure the snap or spring rings are seated

in their grooves. Now it's simply a matter of reassembling the ball

joint--which will probably require a helper to lean on the pry bar

while you stuff the ball joint stud back into its hole in the bottom of

the upright.

Reinstall the tie rod end with a fresh cotter pin, button up the sway

bar and any other parts you've removed or loosened, and you're

ready to torque the spindle nut, reattach the wheel and take the car

off the safety stands.

Use pliers to install the tie rod end with a fresh cotter

pin. Don't reuse the old pin.

He Ain't Heavy, He's My ...

That spindle nut needs to be torqued properly, but few shade-tree

mechanics have a torque wrench capable of the 200 to 300 lb.-ft.

required. Put Archimedes to work. Say the nut is supposed to be

tightened to 225 lb.-ft. (Check the shop manual.) If the flex

handle you have is 18 in. long, simply put 150 pounds of weight

on the end of the handle: 150 pounds x 1.5 ft. = 225 lb.-ft. You

may need to find someone who weighs the right amount, or

measure out a slightly different place to stand on the wrench. Do

the math. And don't bounce up and down--just let your weight do

the work.

Links referenced within this article

Find this article at:

http://www.popularmechanics.com/automotive/how_to_central/powertrain_drivetrain/1715877.html

SAVE THIS | EMAIL THIS | Close

Uncheck the box to remove the list of links referenced in the article.

29/08/2006 12:33 PM

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Automotive Emails KuwaitDocument40 pagesAutomotive Emails KuwaitnazirsayyedNo ratings yet

- M.atelIER-Model NC 1996-Electrical & Ignition - Pages.1 20Document20 pagesM.atelIER-Model NC 1996-Electrical & Ignition - Pages.1 20Anonymous M0OEZEKoGi100% (1)

- A Project Report ON: Bachelor of Commerce'Document52 pagesA Project Report ON: Bachelor of Commerce'Aryan Jain100% (6)

- Motor Cat C7-AcertDocument2 pagesMotor Cat C7-Acertcarlucido247970100% (2)

- Financial Analysis Bajaj Auto LTDDocument45 pagesFinancial Analysis Bajaj Auto LTDRajat Gulati83% (6)

- Terberg Magazine 2020 GBDocument52 pagesTerberg Magazine 2020 GBAbdelhadi HoussinNo ratings yet

- Database Sponsor Oil Mining and Gas Warna KuningDocument24 pagesDatabase Sponsor Oil Mining and Gas Warna KuningJesus MartinezNo ratings yet

- Pumps & SystemsDocument76 pagesPumps & Systemsquiqueton100% (1)

- FRONT SEAT ASSEMBLY (For Power Seat) : ComponentsDocument4 pagesFRONT SEAT ASSEMBLY (For Power Seat) : ComponentsdiemnganNo ratings yet

- Installation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHDocument3 pagesInstallation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHdiemnganNo ratings yet

- FRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsDocument3 pagesFRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsdiemnganNo ratings yet

- Rear Seat Assembly: ComponentsDocument6 pagesRear Seat Assembly: ComponentsdiemnganNo ratings yet

- Seat Heater Switch: ComponentsDocument4 pagesSeat Heater Switch: ComponentsdiemnganNo ratings yet

- Reassembly: Seat - Front Seat Assembly (For Power Seat)Document5 pagesReassembly: Seat - Front Seat Assembly (For Power Seat)diemnganNo ratings yet

- Removal: Seat Belt - Rear Seat Outer Belt AssemblyDocument4 pagesRemoval: Seat Belt - Rear Seat Outer Belt AssemblydiemnganNo ratings yet

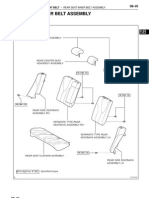

- Rear Seat Outer Belt Assembly: ComponentsDocument3 pagesRear Seat Outer Belt Assembly: ComponentsdiemnganNo ratings yet

- Disposal: Seat Belt - Front Seat Outer Belt AssemblyDocument5 pagesDisposal: Seat Belt - Front Seat Outer Belt AssemblydiemnganNo ratings yet

- Front Seatback Heater: ComponentsDocument2 pagesFront Seatback Heater: ComponentsdiemnganNo ratings yet

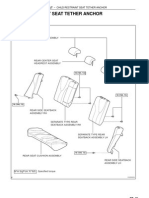

- Child Restraint Seat Tether Anchor: ComponentsDocument3 pagesChild Restraint Seat Tether Anchor: ComponentsdiemnganNo ratings yet

- Rear Seat Inner Belt Assembly: ComponentsDocument3 pagesRear Seat Inner Belt Assembly: ComponentsdiemnganNo ratings yet

- Removal: Seat Belt - Rear Seat Inner Belt AssemblyDocument2 pagesRemoval: Seat Belt - Rear Seat Inner Belt AssemblydiemnganNo ratings yet

- Removal: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchDocument4 pagesRemoval: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchdiemnganNo ratings yet

- Removal: Seat - Front Power Seat Lumbar SwitchDocument2 pagesRemoval: Seat - Front Power Seat Lumbar SwitchdiemnganNo ratings yet

- Seat Heater System: PrecautionDocument2 pagesSeat Heater System: PrecautiondiemnganNo ratings yet

- Lumbar Support Adjuster Assembly: ComponentsDocument2 pagesLumbar Support Adjuster Assembly: ComponentsdiemnganNo ratings yet

- Child Restraint Seat Anchor Bracket: ComponentsDocument2 pagesChild Restraint Seat Anchor Bracket: ComponentsdiemnganNo ratings yet

- Front Seat Cushion Heater: ComponentsDocument2 pagesFront Seat Cushion Heater: ComponentsdiemnganNo ratings yet

- Removal: Seat - Front Seat Assembly (For Power Seat)Document2 pagesRemoval: Seat - Front Seat Assembly (For Power Seat)diemnganNo ratings yet

- Removal: Seat - Front Seat Assembly (For Manual Seat)Document2 pagesRemoval: Seat - Front Seat Assembly (For Manual Seat)diemnganNo ratings yet

- Removal: Seat - Front Seatback HeaterDocument2 pagesRemoval: Seat - Front Seatback HeaterdiemnganNo ratings yet

- Front Power Seat Lumbar Switch: ComponentsDocument2 pagesFront Power Seat Lumbar Switch: ComponentsdiemnganNo ratings yet

- Power Seat Switch: ComponentsDocument2 pagesPower Seat Switch: ComponentsdiemnganNo ratings yet

- Seat Belt Warning System: PrecautionDocument2 pagesSeat Belt Warning System: PrecautiondiemnganNo ratings yet

- Removal: Seat - Front Seat Cushion HeaterDocument2 pagesRemoval: Seat - Front Seat Cushion HeaterdiemnganNo ratings yet

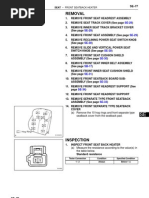

- Front Seat Frame With Adjuster: InspectionDocument2 pagesFront Seat Frame With Adjuster: InspectiondiemnganNo ratings yet

- System Diagram: Driver SideDocument2 pagesSystem Diagram: Driver SidediemnganNo ratings yet

- Diagnosis System: CG SG SIL CanhDocument2 pagesDiagnosis System: CG SG SIL CanhdiemnganNo ratings yet

- System Diagram: E55 Seat Heater SwitchDocument2 pagesSystem Diagram: E55 Seat Heater SwitchdiemnganNo ratings yet

- Partnership Directory 0405Document59 pagesPartnership Directory 0405Anna LaClair100% (1)

- Progress ReportDocument3 pagesProgress Reportapi-490394587No ratings yet

- Form 25Document2 pagesForm 25Akash SNo ratings yet

- Automated Guided VehiclesDocument22 pagesAutomated Guided VehiclessurajNo ratings yet

- Project On Maruti Suzuki ModifiedDocument83 pagesProject On Maruti Suzuki ModifiedSumit Kumar100% (1)

- The Patent OfficeDocument341 pagesThe Patent OfficeVirendra KumarNo ratings yet

- LepelletierDocument4 pagesLepelletierSaveli Paul FlorinNo ratings yet

- TESLA International Business StrategiesDocument28 pagesTESLA International Business StrategiesBeauty Of NatureNo ratings yet

- Brake04 Disc Brake PDFDocument0 pagesBrake04 Disc Brake PDFPushkar NathNo ratings yet

- Friction Clutches mmc1 April 20 2011Document24 pagesFriction Clutches mmc1 April 20 2011Shyam GupthaNo ratings yet

- Castrol Transmax Multivehicle ATF SpecificationDocument2 pagesCastrol Transmax Multivehicle ATF SpecificationArief SuprayogoNo ratings yet

- ZF 6HP26 Elektrozawory, Gdzie DmuchaćDocument8 pagesZF 6HP26 Elektrozawory, Gdzie DmuchaćGrzegorz DaniłowiczNo ratings yet

- 2017 Airline EM Alton Fleet Trends 19oct2017Document16 pages2017 Airline EM Alton Fleet Trends 19oct2017Omar A TavarezNo ratings yet

- Adjusting Headlamps Multiple ModelsDocument5 pagesAdjusting Headlamps Multiple ModelsHussein AkilNo ratings yet

- Kimmel Excersice 9Document11 pagesKimmel Excersice 9Jay LazaroNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word Documentrajmv7No ratings yet

- MB0052 SLM Unit 10Document30 pagesMB0052 SLM Unit 10SarlaJaiswalNo ratings yet

- Operations Management-Teaching Plan - Class of 2015Document2 pagesOperations Management-Teaching Plan - Class of 2015Aakash MehtaNo ratings yet

- 07Document34 pages07LuisTocoraNo ratings yet

- VCDDocument0 pagesVCDomarsosa#747No ratings yet

- Luk Repset Emerging Flyer en LowresDocument6 pagesLuk Repset Emerging Flyer en LowresMariusNo ratings yet

- Consumer Behavior For Small Cars: An Empirical Study: AbhinavDocument6 pagesConsumer Behavior For Small Cars: An Empirical Study: AbhinavdeeepanshulNo ratings yet