Professional Documents

Culture Documents

Certified Solidworks Associate (Cswa) : Sample Exam Questions

Certified Solidworks Associate (Cswa) : Sample Exam Questions

Uploaded by

fhfhbfhgcbfghdhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certified Solidworks Associate (Cswa) : Sample Exam Questions

Certified Solidworks Associate (Cswa) : Sample Exam Questions

Uploaded by

fhfhbfhgcbfghdhCopyright:

Available Formats

CSWASampleExamQuestions

CertifiedSolidWorksAssociate(CSWA)

SampleExamQuestions

ThequestionsbelowrepresentsampleCSWAExamquestions.Partmodelingand

assemblymodelingquestionsthatrequireyoutobuildmodelshouldbecorrectly

answeredin45minutesorless.Question2andQuestion3shouldbecorrectly

answeredin5minutesorless.

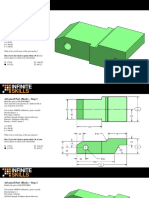

Question1.

BuildthispartinSolidWorks.

Unitsystem:MMGS(millimeter,gram,second)

Decimalplaces:2.Partorigin:Arbitrary

A=63mm,B=50mm,C=100mm.Allholesthroughall.

Partmaterial:CopperDensity=0.0089g/mm^3

PAGE1

CSWASampleExamQuestions

Whatisthe

overallmassof

thepartingrams?

a)1205

b)1280

c)144

d)1108

PAGE2

CSWASampleExamQuestions

Question2.

COSMOSXPressallowschangestomeshsettings.Whichofthefollowing

statementsisnotTrue?

a)Afinemeshsettingproducesmoreaccurateresultsthanacoursemesh.

b)Acoarsemeshsettingproduceslessaccurateresultsthanafinemesh.

c)Afinemeshsettingcanbeappliedtoaspecificfaceinsteadoftheentire

model.

d)Alloftheabove

Question3.

Tocreatedrawing

view,Bitisnecessary

tosketchaspline(as

shown)ondrawing

viewAandinsert

whichSolidWorksview

type?

a) Brokenout Section

b) Aligned Section

c) Section

d) Detail

PAGE3

CSWASampleExamQuestions

Question4.

Buildthisassembly

inSolidWorks.

Itcontains3

machinedbrackets

and2pins.

Brackets:2mm

thickness,andequalsize(holesthroughall).Material:6061Alloy,Density

=0.0027g/mm^3.Thetopedgeofthenotchislocated20mmfromthetop

edgeoftheMachinedBracket.

Pins:5mmlengthandequalindiameter,Material:Titanium,Density=

0.0046g/mm^3.Pinsarematedconcentrictobracketholes(noclearance).

Pinendfacesarecoincidenttobracketouterfaces.Thereisa1mmgap

betweenthebrackets.Bracketsarepositionedwithequalanglemates(45

degrees).

Unitsystem:MMGS(millimeter,gram,second)

Decimalplaces:2

Assemblyorigin:Asshown.

Whatisthecenterofmassoftheassembly?

a)

X=11.05 Y=24.08

b)

X=11.05 Y=24.08 Z=40.19

c)

X=40.24 Y=24.33

Z=20.75

d)

X=20.75

Z=40.24

Y=24.33

Z=40.19

PAGE4

CSWASampleExamQuestions

Question5.

Buildthisassemblyin

SolidWorks.Itcontains3

components:Base,Yoke,

AdjustingPin.ApplytheMMGS

unitsystem.

Material:1060Alloyforall

components.Density=

0.0027g/mm^3

Base:Thedistancebetweenthe

frontfaceoftheBaseandthe

frontfaceoftheYoke=60mm.

Yoke:TheYokefitsinsidethe

leftandrightsquarechannelsof

theBasecomponent,(no

clearance).Thetopfaceofthe

Yokecontainsa12mm

throughallhole.

AdjustingPin:Thebottomface

oftheAdjustingPinheadis

located40mmfromthetopfaceoftheYokecomponent.TheAdjustingPin

componentcontainsa5mmthoughallhole.

Whatisthecenterofmassoftheassemblywithrespecttotheillustrated

coordinatesystem?

a)

X=30.00

Y=40.16 Z=40.16

b)

X=30.00

Y=40.16

Z=43.82

c)

X=30.00

Y=40.16

Z=50.20

d)

X=30.00

Y=40.16

Z=53.82

PAGE5

CSWASampleExamQuestions

Question6.

Buildthispartin

SolidWorks.

Material:6061

Alloy.Density=

0.0027g/mm^3

Unitsystem:

MMGS

(millimeter,gram,

second)

Decimalplaces:2.

Partorigin:

Arbitrary

A=100.

Allholesthrough

all,unlessotherwisespecified

Whatistheoverallmassofthepartingrams?

a)2040.57

b)2004.57

c)102.63

d)1561.23

PAGE6

CSWASampleExamQuestions

For further preparation, please complete the SolidWorks tutorials, located in

SolidWorks under the Help Menu, before taking the CSWA Exam. Review the

About the CSWA Exam document located at www.solidworks.com/cswa.

Good Luck,

Certification Program Manager, SolidWorks Corporation

Correctanswers:

1. b

2. c

3. a

4. c

5. d

6. a

PAGE7

You might also like

- Computerised Learner's Licence Final PDFDocument26 pagesComputerised Learner's Licence Final PDFJannie71% (7)

- Assessment in Counseling PDFDocument16 pagesAssessment in Counseling PDFWong Chew Nie0% (3)

- CSWP Examen de EjemploDocument3 pagesCSWP Examen de EjemploJoa Molina100% (8)

- 3-Practice Drawing Ebook - Revision 1Document91 pages3-Practice Drawing Ebook - Revision 120-MCE-63 SYED HASSAN KUMAIL100% (1)

- UIDAHO Exam 1.1Document6 pagesUIDAHO Exam 1.1dgm929No ratings yet

- Test Questions: Part 1: Drafting CompetenciesDocument11 pagesTest Questions: Part 1: Drafting Competencies4112 - Subhash NNo ratings yet

- Edu Cswa Sample Exam 2013 EngDocument10 pagesEdu Cswa Sample Exam 2013 Engtigerman_nr10% (1)

- SolidWize CSWP Sample Exam 2 Segment 3Document16 pagesSolidWize CSWP Sample Exam 2 Segment 3Kamel Bousnina100% (1)

- Cert Cswpcdessample2008Document7 pagesCert Cswpcdessample2008Gustavo Reaño PulacheNo ratings yet

- Certifiedsolidworksassociate (Cswa) : SampleexamquestionsDocument2 pagesCertifiedsolidworksassociate (Cswa) : SampleexamquestionsRahmadiNo ratings yet

- CsWa Sample Exam QuestionsDocument6 pagesCsWa Sample Exam QuestionsgurisNo ratings yet

- CSWP-WLDM Sample ExamDocument12 pagesCSWP-WLDM Sample Examtito36bcnNo ratings yet

- PE-D-CO-PRO-001-00 Project Commissioning, Start - Up and Handover ProcedureDocument38 pagesPE-D-CO-PRO-001-00 Project Commissioning, Start - Up and Handover Proceduremarin cristian0% (1)

- Part Modeling: The Following Images Are To Be Used To Answer Questions #3 - 4Document8 pagesPart Modeling: The Following Images Are To Be Used To Answer Questions #3 - 4AliNo ratings yet

- CSWASample Exam 2010Document14 pagesCSWASample Exam 2010Rich Mack100% (1)

- CSWP Sample Exam 2009Document9 pagesCSWP Sample Exam 2009Yassine BziouiNo ratings yet

- CSWP-WLDM Sample ExamDocument12 pagesCSWP-WLDM Sample ExamJose CuevasNo ratings yet

- Q1 11Document5 pagesQ1 11SeymurH-vNo ratings yet

- CSWP Core Sample Exam 2009Document9 pagesCSWP Core Sample Exam 2009Jose Luis AtaullucoNo ratings yet

- Segment 1 ExerciseDocument16 pagesSegment 1 ExerciseCarlos MillanNo ratings yet

- 60 AutoCAD 2D & 3D PracticeDocument65 pages60 AutoCAD 2D & 3D PracticeAkash MahmudNo ratings yet

- Quiz Basic Gear Concepts and CalculationsDocument4 pagesQuiz Basic Gear Concepts and CalculationsLister NambatacNo ratings yet

- SW Tips - CSWP - Weldments ReviewDocument66 pagesSW Tips - CSWP - Weldments ReviewWill FongNo ratings yet

- Knuckle JointDocument10 pagesKnuckle JointRajat MathurNo ratings yet

- Finite Element AnalysisDocument113 pagesFinite Element AnalysisBruno CoelhoNo ratings yet

- CAD Contest QuestionDocument37 pagesCAD Contest QuestionFahad AbdullahtNo ratings yet

- Official Guide To Certified Solidworks Associate Exams: Cswa, Csda, Cswsa-FeaDocument22 pagesOfficial Guide To Certified Solidworks Associate Exams: Cswa, Csda, Cswsa-FeaShafier KhanNo ratings yet

- CSWP MBD SampleexamDocument24 pagesCSWP MBD SampleexamUfficio TecnicoNo ratings yet

- Creating Motion in SolidWorks-Motion DriversDocument58 pagesCreating Motion in SolidWorks-Motion DriversManuj AroraNo ratings yet

- Cswp-Surf Exam: GuidelinesDocument5 pagesCswp-Surf Exam: GuidelinesGustavo Reaño PulacheNo ratings yet

- CSWP Book - Segment3 - SamplesDocument30 pagesCSWP Book - Segment3 - SamplesMohamed ShafeekNo ratings yet

- Solidwize: Online Solidworks TrainingDocument9 pagesSolidwize: Online Solidworks Trainingjuanito pipas0% (1)

- Advanced PartDocument6 pagesAdvanced PartMatnSambu100% (1)

- Wireframe and Surface Design: CATIA TrainingDocument55 pagesWireframe and Surface Design: CATIA Trainingkishore99939No ratings yet

- Autodesk Inventor Professional Courses Contents by - SerbocadDocument8 pagesAutodesk Inventor Professional Courses Contents by - SerbocadNikola ŠererNo ratings yet

- Ejercicio1 CSWADocument2 pagesEjercicio1 CSWAjorgeriver7No ratings yet

- Autodesk Inventor 2015 Courses Contents by Serer N - Anglocad.Document9 pagesAutodesk Inventor 2015 Courses Contents by Serer N - Anglocad.Nikola ŠererNo ratings yet

- Certification Exam Insights: Lars Christensen CadimensionsDocument13 pagesCertification Exam Insights: Lars Christensen CadimensionsazharscarNo ratings yet

- SOLIDWORKS Certification Exam Guide & Practice Test: CSWPA-MM: Certified SOLIDWORKS Professional Advanced Mold MakingDocument31 pagesSOLIDWORKS Certification Exam Guide & Practice Test: CSWPA-MM: Certified SOLIDWORKS Professional Advanced Mold MakingjesusNo ratings yet

- EDU Motion Student 2013 ENGDocument20 pagesEDU Motion Student 2013 ENGcbr6000No ratings yet

- Autodesk Inventor 2012 For Machine DesignDocument2 pagesAutodesk Inventor 2012 For Machine DesignDreamtech PressNo ratings yet

- Solid Works Training Files PDFDocument1 pageSolid Works Training Files PDFdanxl007No ratings yet

- A Certified SOLIDWORKS Professional Is An Individual Who Has Successfully Passed Our Advanced Skills ExaminationDocument3 pagesA Certified SOLIDWORKS Professional Is An Individual Who Has Successfully Passed Our Advanced Skills ExaminationsravanNo ratings yet

- SWW2018 ZenSurfacingDocument121 pagesSWW2018 ZenSurfacinghang sangNo ratings yet

- SolidWize CSWA Practice SolutionsDocument1 pageSolidWize CSWA Practice SolutionsAntonio JambrešićNo ratings yet

- Commands Guide Tutorial For Solidworks 2013: A Comprehensive Reference Guide With Over 240 TutorialsDocument69 pagesCommands Guide Tutorial For Solidworks 2013: A Comprehensive Reference Guide With Over 240 Tutorialskishor mNo ratings yet

- CSWP WeldmentDocument32 pagesCSWP Weldmentsssf-dobojNo ratings yet

- Certified Solidworks Associate (Cswa) : Sample Exam QuestionsDocument7 pagesCertified Solidworks Associate (Cswa) : Sample Exam Questionsagus fikri rosjadi100% (10)

- Certified Solidworks Associate (Cswa) : Sample Exam QuestionsDocument3 pagesCertified Solidworks Associate (Cswa) : Sample Exam QuestionsMeme BohNo ratings yet

- Cs Was Ample Exam 2010Document14 pagesCs Was Ample Exam 2010El FilyNo ratings yet

- Solidworks Corporation: Cswa Sample ExamDocument14 pagesSolidworks Corporation: Cswa Sample ExamReena MoisesNo ratings yet

- CSWASample Exam2010Document11 pagesCSWASample Exam2010Elmika TrầnNo ratings yet

- Solidworks Corporation: Cswa Sample ExamDocument12 pagesSolidworks Corporation: Cswa Sample Examboussaid nejlaNo ratings yet

- Solidworks Corporation: CSWP Sample ExamDocument3 pagesSolidworks Corporation: CSWP Sample ExamlevannuNo ratings yet

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document62 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)bontrager1306100% (1)

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- CSWP Advanced Sheet Metal Sample ExamDocument7 pagesCSWP Advanced Sheet Metal Sample Examroberto1793No ratings yet

- EXO3Document19 pagesEXO3Douaa GhazouaniNo ratings yet

- Solidworks Corporation: CSWP Advanced Sheet Metal Sample ExamDocument7 pagesSolidworks Corporation: CSWP Advanced Sheet Metal Sample ExamKamal GifariNo ratings yet

- Pieza AvanzadaDocument9 pagesPieza AvanzadaLuis PNo ratings yet

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document8 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Klever MoralesNo ratings yet

- CSWA Practice 2013Document24 pagesCSWA Practice 2013pacomermela69No ratings yet

- Coaching Culture in IndiaDocument23 pagesCoaching Culture in IndiaPratik RajNo ratings yet

- Cambridge IGCSE™: First Language English 0500/22 May/June 2020Document11 pagesCambridge IGCSE™: First Language English 0500/22 May/June 2020Jonathan ChuNo ratings yet

- HRM Assignment 2.2Document14 pagesHRM Assignment 2.2Vaibhav TodkarNo ratings yet

- Server Information SK0-004Document14 pagesServer Information SK0-004tallknight50% (2)

- Minutes of Placement MeetingDocument2 pagesMinutes of Placement MeetingD Y Patil Institute of MCA and MBANo ratings yet

- Tour Guide CurriculumDocument21 pagesTour Guide CurriculumSiti Zulaiha Zabidin0% (2)

- 20140327Document24 pages20140327Kristy ElliottNo ratings yet

- Seneca College of Applied Arts Technology Practical Nursing Diploma ProgramDocument20 pagesSeneca College of Applied Arts Technology Practical Nursing Diploma ProgramMaggie LiNo ratings yet

- IBUS 5716 D: Management of International Business Fall 1 - 2017, Tuesdays 11:35am - 2:25pmDocument6 pagesIBUS 5716 D: Management of International Business Fall 1 - 2017, Tuesdays 11:35am - 2:25pmMdshaffiSiddu Hina2019No ratings yet

- 1 SRM BDocument7 pages1 SRM Bbiswa217No ratings yet

- Course CatalogueDocument84 pagesCourse CataloguebafhiNo ratings yet

- Ccnav7 Enterprise Networking, Security, and Automation (Ensa) Release NotesDocument4 pagesCcnav7 Enterprise Networking, Security, and Automation (Ensa) Release NotesHồngPhúcNo ratings yet

- Common Management Admission Test Admit CardDocument1 pageCommon Management Admission Test Admit CardJyothi. K.N.No ratings yet

- Rule 1: Learn It in The First PlaceDocument8 pagesRule 1: Learn It in The First PlaceAlice ParkNo ratings yet

- IbpsDocument112 pagesIbpsLakshmi NagurNo ratings yet

- Institutional SyllabusDocument9 pagesInstitutional SyllabusAngelou Quinagoran100% (1)

- Ocr 33981 PP 09 Jan L Gce 2813 03Document8 pagesOcr 33981 PP 09 Jan L Gce 2813 03Philip_830No ratings yet

- Module 2 in EL106Document23 pagesModule 2 in EL106Gretchen TajaranNo ratings yet

- How To Prepare For The TOEFL Test The Right WayDocument1 pageHow To Prepare For The TOEFL Test The Right WayRaquel EchalarNo ratings yet

- Master Rigger - ITI Course Ebook 012218Document14 pagesMaster Rigger - ITI Course Ebook 012218Asad AwanNo ratings yet

- PROF ED Assessment and Evaluation of Learning 3Document4 pagesPROF ED Assessment and Evaluation of Learning 3Joni Czarina AmoraNo ratings yet

- Gs 101 ExamDocument5 pagesGs 101 Examchristie_aureliaNo ratings yet

- Annual Examination Report Card Grade 9 Kilari Dhanush Sanjay Rahul 2022-06!09!052203Document6 pagesAnnual Examination Report Card Grade 9 Kilari Dhanush Sanjay Rahul 2022-06!09!052203Dhanush KilariNo ratings yet

- S19 Syllabus - AIS 100Document11 pagesS19 Syllabus - AIS 100SPENCER HIKADENo ratings yet

- Pearson VUE - Checkout - Step 5 - ReceiptDocument2 pagesPearson VUE - Checkout - Step 5 - ReceiptAnurag SinghNo ratings yet

- Civil Works - InspectionsDocument47 pagesCivil Works - Inspectionsamer_arauf83% (6)

- Minutes of First English Panitia Meeting 2014Document2 pagesMinutes of First English Panitia Meeting 2014Abd Hakim ZakariaNo ratings yet