Professional Documents

Culture Documents

Ve Dual 721 Service PDF

Uploaded by

Onet Dorel0 ratings0% found this document useful (0 votes)

250 views26 pagesOriginal Title

ve_dual_721_service.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

250 views26 pagesVe Dual 721 Service PDF

Uploaded by

Onet DorelCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

The home of the turntable

THE VINYL énGiné

For more turntable manuals and setup information

please visit www.vinylengine.com

‘August 1976 Edition

Service Manual

Dual Gebriider Steidinger - 7742 St. GeorgeniSchwarzwald

Specification

Current Type

AC 50 - 60 Hz, without motor changeover

Line voltages

110 — 130 Volt, 220 — 240 Volt

Drive

Electronically controlled direct drive system Dual

EDS 1000-2

Power Consumption

approx. 2.5 Watt

Motor during play <50 mW

Current Consumption

with 220 V 50 Hz:

on start-up 60 mA,

with 110 V 60 Hz:

on start-up 110 mA

during play 20mA

during play app. 38 mA

Run-up Time (until nominal speed is reached)

2-25 sec. on 33 1/3 rpm

Platter

Non-magnetic, dynamically balanced, detachable, 1.5 kg

305 mm ¢

Total rotating mass of drive system (rotor with platter)

3.0 kg, moment of inertia 250 kp cm2

Platter:

33 1/3 and 46 rpm, electronically switchable, automatic

‘tonearm lowering coupled to speed change.

Pitch Control

Separate for both speeds, adjustable in each case with

variable resistor, with setting scales, range of adjustment

10%,

‘Speed Check

with light stroboscope for platter speed 23 1/3 rpm.

Sensitivity of Light Stroboscope for 0.1 % Speed Deviation

3 graduations per minute at 50 Hz

3.6 graduations per minute at 60 Hz

‘Overall Speed Variation

(assessed in accordance with DIN 45 507) <+0.03%

‘Signal-to-Noise Ratio (in accordance with DIN 45 500)

Rumble unweighted signal-to-noise ratio >50d8

Rumble weighted signal-to-noise ratio > 7008

Tonearm

Torsion resistant, extra long tubular aluminum tonearm

in super flat universal four-point gimbal suspension, tone-

‘arm balance weight with double acting vibration damping

(2 anti-resonators)

Effective Tonearm Lenght

222 mm

Offset Angle

250 20°

‘Tangential Track Error Angle

0.169 /em

Tonearm Bearing Friction

{related to stylus point)

Vertical <0.07 mN (0.007 6)

Horizontal <0.15 mN (0.015)

Tracking Force

0-30 mN (0-3 grams) infinitely variable with 1 mN

(0.1 g) calibrations from 0 to 15 mN (0 to 1.54}, operable

from 2.5 mN (0.25 g) stylus pressure up.

0-3g.continuously variable, with 1/10 calibration in the

range from 0 - 1.5 g, reliable as from 0.25 g tracking force

Pick-up Head

Detachable, suitable for all pick up cartridges with 1/2"

mounting and @ deadweight of 2- 10 g (including moun-

ting material)

Adjustable Overhang

5mm

Pick-up Cartridge

See separate data sheet

Weight

7.8 kg

Dimensions and Cutout Required

refer to Installation instructions

R

\Cc

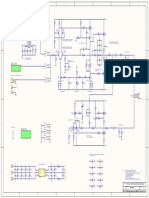

. 1 Circuit diagram

Strommetbriicke

Current measuring bridge

Pont de mesure de courant

Leertaufstrom ca, 55 mA

Idle current

Courant a vide

‘Anlautstrom

Initial current

Courant de démarrage

6

R22

100k

(33 1/3 Upm)

255mA *10mA

Anderungen vorbehalten,

Alterations reserved

‘Sous réserve de modifications

33:13 Upm

EDS 1000-2

0,15 w+ 10%

cA

6

‘J001

Fou

oe oe

470 |

Drehzahischalter

Platter speed switch

Commutateur de vitesse B

co

ut 10%

Spannungen gemessen mit MeBinstrument (7 — 10 MOhm Eingangswiderstand) gegen Masse

Voltages measured with measuring instrument (7 — 10 MOhm input resistance) to ground

Tensions mesurées avec instrument de mesure (7 — 10 MOhm résistance d’entrée) contre masse

1

Von der Bestiickungsseite gesehen

As seen from the top side

Vu du cété elements

110/130

220/249 y 50-60 Hz

Transistoren von der Anschluseite gesehen

Transistors as seen from the connecting side

Transistors vus du c6té des connexions

Contents

Specification

Circuit Diagram

Dual EDS 1000-2 Electronic Direct Drive System

Description of Function

Speed Regulation

Assembly Instructions for Dual EDS 1000-2

Stroboscope

Pitch Control

Adjustment of nominal speeds

Tonearm and Tonearm Suspension

Removal of tonearm from bearing frame

Removal of tonearm assembly with tonearm bearing

Replacement of spring housing

Adjustment of tonearm suspension

Vertical Tonearm Controt

Aatiskating Control

Tonearm Control

Cue Control

Replacement of cue control assembly

Starting

Manual Start

Stopping

Muting switch

Continuous Play

Pick-up head not parallel to platter

Shutoff

Stylus slips out of playing groove

Tonearm does not set down at the edge of the record

Tonearm does not set down or lowers onto record too quickly

Vertical movement of tonearm dragging

Tonearm returns to rest immediately

Tonearm moves with dials in zero position

During automatic operation of tonearm disturbing noises are perceptible

Motor does not shut-off

Acoustic feed back

Pick-up Connection Diagrarn

Spare Parts

Exploded view - Parts above chassis

Exploded view - Parts below chassis

Spare Parts

Lubricating Instructions

Note: The reference numbers inthe instructions refer to the spare parts lists and exploded views.

Page

3,4

67

8,9

10

10,11

"

uN

12

12

12

13

13

13

13

4

14

“4

16

16

16

16

16

16

”7

7

18

18

18

18

18

18

18

18

19

21

22

23-25

26

Fig. 2 Dual £08 1000-2 Electronic Direct Drive System

‘turntable center plate centering pin

steel plate

7 a ee

|/ conductor

fps

field coils hedded Hall generator

coil support

Dual EDS 1000-2 Electron Direct Drive System

The EDS 1000-2 motor especially designed

for the Qual 721 ie a slou-running no-commu~

tator DC electronic motor which draus its

pover supply from a stabilized pouer pack.

The electro-mechanical commutation normally

carried out on OC motores by the conmutator

is electronically controlled in the case of

the Dual €08 1000-2 motor by tuo Hell gonera~

tors. These tuo Hell generators ~ dependent

Gn the rotor position = control four suitch=

ing tranaistors uhich in turn have the

effect of a rotating magnetic field occurring

in the field coile of the motor by means of

uhich the four paire of magnets of the rotor

re continuously attracted or repelled. By

means of the torque thue oxerted, uniform

Totation is induced in the rotor’- and uith

it the platter.

A speed-dependent voltage (tacho voltage)

induced in the motor windings not suitched

‘on is coupled out and controls the slectro-

fic regulator circuit. This ensures that

nthe slightest devietions from the nomi~

fal speed are corrected in fractions of 3

Second by a change in the motor current.

Speed fluctuations are, therefore, practi~

cally eliminated.

joining centring

for turntable

angular bearing

Absolute maintenance of the nominal speed

no longer presents any problem with thi:

control system.

The above-mentioned Hall generator is a nag-

netically controllable semi-conductor oli

mont named after the physicist €. Hall. Uith

the Hal, ct as a result of the action

of a magnetic ficld on the Hall generator a

Voltage approximately proportionate to the

atrength of the magnetic field is genera

ite polarity being dependent on the direc-

tion of the magnetic flux.

A control current flous through the Hall ge~

herator. If nou s magnetic field become:

effective at right angles to the area of the

Hell generator, the so-called Hall voltage

occurs. Uith constant control current this

Hall voltage is dependent on the direction

and strength of the magnetic field. If the

polarity of the magnetic field is reversed

the polarity of the Hall voltage changes a:

uell. In the absence of a magnetic field the

Hall voltage is zero. This effect is utili-

zed to control the Dual EDS 1000-2 motor.

Ae the motor is operated on DC from a stabi-

lized pouer pack it operated independently

of line voltage and Frequency fluctuations

The motor is of 8-pole disk rotor design.

The rotor has a barium ferrite annular mag~

net ineide which hee B-pole magnotizetion

on its louer face,

A slotiess steel disk connected to the rotor

acts as magnetic return.

The Field vindings of the motor are ironless

and are embedded in @ plastic support. The

field windings consist of 16 double uounc

coile uhich are arranged in tuo planes above

ne another. The & coils of the lover plane

are 22,50 offect in relation to the top pla~

Ne. Ineach plane there is a Hall gonerator

in'the center of one coil. The tuo Hall go~

Nerators are also offset by 22.59 in rele-

tion to one another.

The individual uindings ~ 32 in all - are

connected tagether so that four all round

phage windings sre produced.

Conpered with other cirectly-driven record

players in the cese of the Dual c0S 1000 no

tor’no form of magnetic drag or restoring

force 19 prasent {ole Jerk ete.) aa. can

Sly "be datectec by tuening the tator: A

lit" of the Sronless field soils no hye

Storesis or eddy current losses or inverts

Ting slotoripple frequencies cccut

This results in completely vibration-tree

motor running together with a low pover con=

Sumption of Less than 50 al during play (the

electronic system is not taken into account).

By virtue of this vibration-free running the

motor can be rigidly connected to the chas~

sis. The electronic system itself is divided

into the guitch, commutation and control

sections (see block diagram).

Fig. 4 Block Diagram

Fig.

3

Line Board (Equipment Side)

Drshzahtum

ghaltang und

Fetnregulerung

Speed change ot

fine tuning

Changement de

vite ot occord

price

Description of Function

‘The 4 phase windings are each in the collec-

tor circuit of the 4 euitching transistors

T 4 to 1 7 (Fig, 5) and are connected to~

gether in etar form at one point. This point

is connected to the minus pole of the supply

voltage.

The position of the rotor illustrated in

Fig. 5 has the effect that the magnetic

field of the south pole of a pair of poles

at connection 11 of the Hell generator H 1

gives rise to @ Hall voltage maxinun of ne=

gative polarity.

Transistor T 4 whose base is joined to con

nection 11 of the Hall generator therefore

receives a negative base omitter voltage and

is fully connected through whereby the cur

Fig. 5

rent flous through the phase winding U1 lo-

catod in the collector section or it ie

suitched on,

Transistor 1 5 uhose base is joined to con-

nection 9 of Hall transistor it 1 is blocked

by the positive Hall voltage potential.

Ae Hall generator H 2 ie in the neutral zo~

ne of the pair of magnetic poles during

this period, no Hall voltages occur at its

connsctions’7 and , The transistore T 6

‘and T 7 joined to these connections ere,

therefore, blocked as uel.

The suitched on phase uinding W 1 (Fig. 7 a)

produces clockuise rotation of the rotor

through 22 1/29. This cycle takes place

displaced electrically in each case by 909,

in sequanca in all four phase windings.

Thus the following sequence of movement ta~

kes place:

After the 1. rotation phase (Fig. 7 b) the

Hall generator K 1 is located in’ the neutral

zono of a pair of magnetic poles. One south

pole is nou directly above Hall generator

H 2 end now also produces at its connection

7 a Hell voltage maximum of negative polar-

ity uhich suitches on phase vinding U3 via

transistor T 6. All other transistors are

ked. The rotor nou rotates again through

221/20 through the magnetic fields genera=

ted in phase winding U3.

After elapse of the second rotation phai

(Fig. 7 c) tho Hall generator H 2 is now in

the heutral zone of a pair of magnetic po-

los. Hall generator H 1 is now directly un-

deraeath a north pole anda Hall voltage of

Feversed polarity occurs, i. 2. the negative

polarity Hall voltage maximum is nou present

at connection 9 uhich connects through phaso

Uinding U 2 via transistor T 5.

The other transistors are blocked. The rotor

again advances by 22 1/29,

After this 3, rotation phase (Fig. 7 ¢) Hall

generator M i is in the neutral zone. A

Rorth pole ie above Hall generator #2 and

produces a negative Hall voltage at ite con=

hoction § uhish suitches on phase winding

U'é via transistor 1 7, The rotor advences

by a further 22 1/29,

After conclusion of this 4. rotation phase

the process starts again. Thus, a continuous

rotating field occurs uhich drives the rotor

at an uniform rate.

If the rotor is, for exemple, betueen two

phase windings, @ partial flux of a peir of

magnetic poles passes through both Hall ge-

heratore and thus tuo suitehing transistors

are partly opened. The current is divided

accordingly betueen tuo phase windings. Both

phase windings participate simultaneously

in the torque formation and together produce

the torque of a fully-connected phase uin~

ding. The torque is, therefore, almost con=

stant in any position of the rotor,

‘Speed Regulation

As a result of the rotery movement of the

rotor, voltages are induced in the phase

windings not connected through uhich are

coupled out via diodes 0.9 to 0 12, Thus, a

tacho voltage proportionate to the speed is,

obtained.

The tacho voltage passes via a voltage divi-

dar to connection 4 of the operation empli-

fier in the control section and counteracts

the voltage present there. A stabilized vol-

tage is present at connection 5 of the ope-

ration amplifier.

On start-up and during run-up of the motor

the potential at connection 4 of the opera~

tion amplifier is more or less positive in

relation to connection 5. In this condition

the operation amplifier fully drives tren-

8

or 1 7. T 7 is present as variable ro

istance in the common emitter circuit of

the four suitching transistors through which

practically the full suitching current can

Flow in sequence.

Fig. 7

The nominal or controlled speed is reached

when the sane potentiel is present at con-

ection 4 of the operation amplifier as at

connection 5, because at this moment the

operation anplifier clases transistor T 7.

Re uLt the motor current drops and ti

speed cannot, therefore, increase any fur~

ther.

®y switching over or altering the voltage

divider in the control circuit the controlled

‘apeed can be preselected or altered. Uith

Eeducing speed the potential et connaction

4 of the operation amplifier would change

30 that transistor T 7 yould be fully driven.

T 7 would thus become of low resistance, the

result vould be a sharp rise in the motor

current and thus of the speed.

Ag this control process takes place even at

minor deviations from the nominal speed, a

constant speed independent of load fluctua:

tione is obtained.

‘Assembly Instructions for Dual EDS 1000.2

For repair of the Qual €0S 1000-2 special

toole and measuring meene are required.

Uork on the motor or motor electronic ay~

stem should, therefore, only be carried cut

by an authorized Dual service station. Ex-

penees arising from unsuthorized interferen-

Ge will be charged to the consignor.

Removal

Lift off platter (4). Remove housing of po~

wer pack (123) after removing scrous (117)+

@

10

Attention! Unsolder leads for operating vol-

je on pover board (125), Do not remove

le on motor eid

Unsolder connections on rotary knob (192)

and potentiomotor (191/R 33). Pull off in~

sulating tube.

Unscreu conplete bearing pillar (147) and

remove togothor with uasher (148), Remove

cam uheel (144), Se careful uith bell (136)

in'gtop bar (164). Remove internediete pla-

te (137).

Undo hex nuts (75) and the three machine

screus. Lift motor (5) and make sure that

‘the cofnacting leads and the thernistor are

routed in the chassis recessed. Remove the

motor. Slide the insulating tube over the

connecting leads. Place motor in origina:

carton for return shipment.

Remove motor from packing, pull off insulat=

ing tube. Uhen inserting the motor on the

mounting board (21) eneure that the lead

outlet hole faces the pouer pack (123).

Now, refit motor and other dieassombled

parts in reverse order to that described

Under "Removal",

Attention: To prevent deformation of the

‘Shorting springs the camuneel (144) should

not be Fitted in 0 position, Make eure that

the pin of main lever (154) 18 engaged in

the Quideuay of the camuheal (144),

Arter assembly fit knob (44) complete with

Pin in midposition. Suitch on unit and check

current consumption on operation.

220 U/S0 Hz approx. 18 ma

417 V/60 Hz approx. 35 ma

Using control (R 21) eet nominal speed

45 xpm (check by means of a strobe disk),

using control (# 22) set nominal speed

33, 1/3 rpm. Run in for approximately 5 mi~

nutes and, if necessary, correct speed.

Hote: It is advisable subsequently to carry

aut brief check of all unit Tunctions

Stroboscope

Accurate setting of the platter speeds

38 1/3 and 45 rpm can be checked during

play with the aid of the strobescope.

Uben the platter (3) ie rotating at exactly

331/53 or 45 rpm the lines of the strovos~

cope appear to stand otill. If the lines

move in the direction of rotation of the

platter, the platter speed is too high. IF

the 1ings nove backwards, the platter is

rotating nore slouly than ths nominal speed.

Adjustmant of platter speods 33 1/3 and

45 rpm is carried out seperately with the

"patch" knobe (44),

It can happen that the etroboscope lince

appear to move slightly although the exact

peed setting with straboscope lines sta-

tionary has not been altered. This apparent

contradiction is explained by the fact that

the electronic central drive motor operates

fully independently of line frequency uhilst

the only relatively accurete line frequency

of the AC current supply is used for spead

measurement with the light stroboscops. The

constantly detectable fluctuations of line

frequency by + 2 % (according to the infor~

mation of the electricity supply companies)

brief frequency Fluctuations up to 1 % are

possible ~ only effect the strabascope in.

dication and can causo the lines to "ender"

though the platter speed is as constant

and absolutely accurate as before.

Strobe markings are provided on the outer

edge of the platter ‘or 50 and 60 Hz line

Frequencies.

To replace glow Lemp (103) remove machine:

serous (105) and renova strobe cover (104).

Pitch Controt

Each of the tuo standerd speeds 33 1/3 and

45 rpm can be varied by approximately 10 %.

The variable speed control (R 33) located

in tho voltage divider ie adjusted by turn=

ing the pitch control knob (44). By this

means the oporation amplifier is altered

and the motor speed accordingly.

‘Adjusting the nominal speed

Using knob (44) bring the variable speed

control (191) into midposition.

Nominal speed 33 1/3 rpm using R 22 control

Nominal speed 45 "rpm using R 21 control

Check uith strobe disk:

"

Fig.

10

Pitch control

Tonearm suspension

a

‘Tonearm and Tanearm Suspension

The feather-Light, extremely torsion resi-

stant all-metal tonoarn is suspended in e

gimbal. Suspension is by means of 4 hardened

and precision polished stool pointe unich

rest in precision ball bearings. Tonearn

bearing Friction is thus reduced ta a mini-

Bearing friction vertical = 0.007 p

Bearing friction horizontal = 0.015 p

as related to stylus point

As a result, it ensures most favourable

pick-up conditions. Before adjusting the

pick-up force to suit the built-in pick-up

Cartridge the tonearm is balenced with the

scale set to zero. Coarse adjustment is

carried eut by moving the ueight uith the

stem (51), the subsequent fine adjustment

by turning the weight

The balance weight is designed so that pick

up cartridges having a deadueight of 4.5 ~

10 g can be balanced. It takes the form of

@ double anti-resonator thus absorbing the

vibration energy in the range of tonearm and

chassis resonance. For this purpose, the

inner part weight is matched to the tonearm

2

rosonance and thue acts ae anti-resonator

by means of antiphase vibration. The outer

part of the belence weight taking the form

Of a higher balanced anti-resonator pravents

transmission of partially occurring chassis

resonance to the tonearm,

The tracking force is adjusted by turning

the graduated spring housing (S58) incor-

poraling «coil spring, The scale hes. mar

Linge fer-a°eonge’ of adjustnent, trom 0" to

30'an (0 to 3p) hich permit accurate ade

JOstmost of the tracking Forces One gred=

dation inthe rangerof 2-78 aN (Bed. =

1.5 p) corresponds to 1 mN (0.1 p), in the

Tange of 152 30 ma (tes So) e208 aw

(6°85 8).

flomoval_of tonesen (50

fron bearing frame

1, Secure unit in repair jig. Remove ueight

(51) unscrew fixing screu (54), Sot

tracking force scale to zero,

2. Move unit into head position. Remove

screening plate (133), Unsolder tonearm

fon muting suitch (131).

3. Move unit into normal position. Turn

both mounting scrous ~ SU 4.5 - (55)

counterclockwise to the stop of the bear-

ing frame (53).

Attention! Observe the bayonet mounting.

Sige tonearm (50) rearvarde and remove it

Upuards fron the bearing frame.

For installation proceed in the reverse or-

der.

Renovel of tonearm assembly vith tonearn

Bearing

Proceed as follous:

1, Secure unit in repair jig. Set graduated

spring housing (58) to zero, Arrest tono~

arm (50). Remove weight (51).

2. Loosen tension lever (62) and bring tone-

arm (50) in its highest position using

knob (64). Fasten tension lever (62).

Bring knurled ring (66) in position "3",

3. Turn unit upside doun. Remove acreening

plate (133). Unsolder tonearm leads on

the muting auitch.

4, Remove machine screu (217), hex nut (218)

and fillister head screu (70). Also re-

move transition plate (268) and guard

plate (219

5. Unscrew machine screw (232) and holding

spring (231).

6. Hold tonearm (50) and unscrew pin (214).

Untock tonearm ($0) and remove it car

fully.

Uhen installing the tonearm complete usth

suspension, proceed in reverse order con=

sidering the follouing points:

Place presoure spring (39) on axle of frane

(38). Both axles of bearing (56) should

align segment (230) accurately. Trane (36)

should not contact cover (73) after tighten=

ing bolt (214). Mount holding spring so that

it'does not contact the setting plate uhen

moving the tonearm (50).

Replacing spring housing (58)

Remove tonearm (50) from bearing frame (53)

te dosctibed above, Loosen Lock nut, (48) and

threaded pin (43). Unscreu_beering screw

(60), Lire bearing franc (53). Remove. spring

housing (58) and washer. (59). Unen install

ing note that the helical. spring. catches tho

bearing frame, Slide in ueaher (59) and

tighten bearing screu. (60). Reinstall tone

ate (50), Set Searing play as described be=

fog veing threaded pin’ (48) and tack nut

‘Adjusting the Tonearm Bearing

Firet balance tonearm exactly. Soth bearings

must have slight, just perceptible play. The

horizontel tonearm bearing is correctly ad

justed uhen at anti-skating settings "0.

and being touched it slides in without 5

sistance. The Vertical tonearm bearing is

correctly adjusted uhen it evings in after

being touches. The play of the horizontal

tonearm bearing should be adjusted uith

threaded pin (37), the play ef the vertical

tonearm bearing with threaded pin (49).

Vertical Tonearm Controt

After Loosening the tension Lever (62) the

tonearm can bo shifted vertically uithin the

Fange of approximately & nn by tdening knob,

(ea). Uhen’ turning kno (e4) the pivoe com

(223) is moved thus shifting the cue con-

trol aasembly (210) and the tonearm bearing

(58) vertically. this device is used to main=

tain the vertical tzecking angie of the pick=

Up cartridge independent fronite height

(istence betueen the mounting level sf the

cartridge and stylue tip). the vertical

tacking angle is properly adjusted ~ vith

the etylue tip on the recerd chen the tone

arn is’exactly paralleled to it. To check

for correct edjustaent proceed as follow

Disconnect unit plug from pouer Line. cor~

Pectly balance tonesrm and adjust tracking

force: Put a 30 cm record on tho platter.

Nou, lover tho stylue on the run-out groove

Using the cue contro.

Check setting, correct if necessary, Tighten

tension lever (62) clockwise. Operate cue

control ( 2 ) and bring back tonearm manuel-

ly on the rest. Lower cue control ( £ ).

Eénnact unit piug to power lino, For automa

tie edjustnont of the mechonical gear and

the shuteof? mechanism the unit should be

started for the fizet tine uith tho tonearm

locked.

13

Adjustment Points

Knob (64) should not be movable uhen ten=

Sion lever (62) is tightened, Adjustment

Gan be made after Loosening machine screw

(225)" ane siiding or shifting adjustment

plate (229).

Fig. 13

‘Anti Skating Device

To compensate for skating force use the

knurled ring (65). Tho asymmetric cam plate

(68) displaces the skating lever (237) from

the tonearm pivoting point. The anti-skating

force is transmitted to the segment (230)

and to the tonearm (50).

Optimum adjustment is carried out at the

yorks for atyli uith a tip radius of 15

(conical), 5/6 and 18/22 um (elliptical),

and CO 4-cartridges.

Any alteration can only be carried out with

the aid of a Oual-Skate-O-Meter and a test

record and should only be done by an autho

rized service station.

Recheck as follows:

Balance tonearm (50) correctly. Set knurled

ring to 0, The tonearm should remain at any

desired point uithin its turning range. the

hole of the skating lever (237) should be in

alignment ith the center line of the tone-

ares Adjustment ts nade by the eccentric

puliey {E) uhich is accessible through the

hole in the installation plate (21) betueen

the knurled ring (66) and tho tonearm mount=

ing plate (71). See fig. 14.

The set knurled ring to "0.5". The tonearm

should now smoothly rotate from the platter

center to its rest.

Tonearm Control

Automatic movement of the tonearm is ini-

tiated by the control cams on the inside of

the cam wheel (144) on rotating through

3609. The control elements for raising ané

Louering are the control Lever (184), the

main lever (156) and the lift pin (47), For

horizontal movement of the tonearm control

Lover (154), tha main lover (156), the

coupling plate (233) and the spring pin of

the’ segnent (238),

The automatic set-doun point is designed for

30'cm and 17 om records and coupled to the

platter speed changeover.

Fig. 15 Cus control

i

133° 162 13 BS BO _230

Limitation of the horizontal movement (set-

Goun point) of tha tonearm is produced by

the pin of segment (230) contacting the stop

(saa) attached to the side ber (246).

Only during set~doun does main lever (156)

Tift the elide bar (24s) and the stop (383)

attached to it unich, ase result, moves. ine

to the suivel range of the stop pin ritted

on segment (230). On completion of set-doun

(ousting of the tonearn onto the record)

slide bar (246) Teleased again and re~

tune to ite neutral positions Ae a roault,

stop (189) moves out of the suivel renge of

the stop pin (F) a0 that unimpeded movement

of the tonearm is possible for playing.

14

(Cue Controt

By moving the lever (201) foruard ( 2) litt

can (203) rotates. The slide bar (246) con

ected to it trananits thie movement to the

Lift"pin (213) (via the componsating can)

uhich’ then raises the tonearn.

As a result, the cue control pormits set-

doun of the’ tongarm at any desired point.

The slide bar (245) is released by moving

the cue control lever rearuards (2). Ae a

result of the action of compression spring

(212) iirt pin (213) is returned to neutral

position and thus lovere the tonaarn. Lover

{ing of the tonearm is danped by silicone oi]

invthe 1ift tube. The height of the etylue

above the record can be varied by turning

adjusting acreu (44). Tuning bush (207) to

"DM reduces the louering speed, turning the

bush to "25>" increases the louering speed.

The distance between the record and the sty=

1us can be variod by sot scrou (40). It

should be approx. 3 to 5 mm,

Replacement of Cue Control Pate

Replace cue control plate (210) as follous:

1. Fix unit on repair Jig and lock tonearm,

Ranove eight (50). Turn unit upeide doun.

Loosen tension lever (62), bring tonearm

in its lowest position using knob (64).

3. Set knurled ring (65) of the antivskat~

ing device to position "3".

4, Remove machine scrou (217), pox-nut (218)

anc fillister head screw (0). Remove

teangition slate (268) and guard plate

(213),

S, Remove safety ueeher (152) and axle (161).

Also renova main lever (156) and com=

pression spring (155).

Remove countersunk acreus (234) and coup-

Lig plate (233).

Loosen safety uasher (222), then turn

t sereu (40) until slide’bar ie ro-

eased. Place slide bar (245) complete

vith bearing (211) beside the bearing

pin.

©. Remove compensating cam (226) and com

pression spring (225).

9. Undo pin (214), Turn bush (207) to" *.

Remove cue control plate (210) from cam

(223). The turn until the bush (207) fite

the recesa of the mounting plate (128) s0

that the cue control plete (210) can be

removed,

For installation proceed in reverse order.

Adiustment points

8) Disconnect unit plus from pouer Line

(raine)s ove Lover (74) to, "atazt™ po

sition, Rotate platter (4) until. the to~

near hes reached its, highest position.

The distance betueen the lover edge of

the pick-up head” (2?) and the rest (41)

should be approxinately 3mm. Adjust by

turning bush (206) (Lg. 17).

b) Disconnect unit plug from pouer Line.

Lock tonearm (50). Move Lever (74) 80

Netart" position, Rotate platter (4) and

observe shaft pin (258) of the coupling

plate (233); The ouide lever (258) on the

Bain lever (156) should just tousn the

chart pin or just move if by 0.1 mn (ad

justable by satting machine sctau (130)

(igre):

Starting

Change lever (174) is rotated uhen the left

control lever is turned to "start", This

results in the folloving function being ini~

tiated.

The control arm (170) connected to change

lever (174) operates the pouer switch uhich

starts the motor (5) rotating. Simultencous-

ly, paul coupled to the change lever (178)

bya tension spring engages and retains it

in this position.

The change lover (178) presses the shut-off

lever (142) touard the dogs on the motor

pinion and thue cauera the camuhsel (144)

to rotate. The paul then moves daflection

Tever (139) into eterting position.

After fitment and each time after transport

the unit should be started once with the to-

nearm locked for automatic adjustment of the

mechanical gear.

Adjustment points:

4) Place unit upside doun. Disconnect pouer

Line plug until detent (164) 18 secured.

Slightly move cam (144) out of position,

The play betueen the detent (164) and pin

(8) should be about 0.3 mm (see Fig. 21).

Correct getting by bending suitch arm

section (L5).

b) Disconnect unit plug from power line.

Place unit upside doun. Operate control

lever (74), Rotate motor. The pousr

suitch (105) shoule operate shortly be~

fore the change lever (178) catches. Ad~

justment should be made by turning

eccentric pulley "E".

©) Tonearm (50) should louer the stylus

exactly on the lead-in groove. The ad—

justment screu is accessible through the

hole betueen control lever (74) and the

cus control. The adjustment screv should

be either turned clockuise of counter

clockwise,

15

[a er 187 169 233 235

153152

4) The change lever (174) should bring de~

flection lever (139) into the start po-

sition.

Adjustment can be made by alight bending

of change lever section (u).

3

gaa

Manual Start

The detent (164) coupled to control ern

(170) engages the pin in the chassis uhen

the tonearm is moved inuards by hand and req

tains the tonearm in this position (Fig. 21).

The power suitch is operated by the control

arm and thus the platter starts to rote

After reaching the run out groove of the

played record return of the tonearm and

Shutcorf of the unit take place autonatical~

ly. If, on the other, the tonearm is lifted

off the record before playing is comple

and is moved onto the rest by hand, the pin

Of the segment disengages the detent (164)

So that the control arn is returned to its

Starting position. As a result, the pouer

suitch shute off the pouer supply.

Adjustment point

Extract pover plug. Turn unit upside doun.

fove tonearn inuards. Pouer suiten shoula

Doluch safely. Correct. adjustment by bending

Control arm (i)

‘topping

Uhen control lever (74) is set to "atop" po~

Sition the change Lever (174) is turned an-

fi-clockuise. The deflection lever (139) re:

maing in its stop position.

Muting switch

To prevent disturbing noises during automa-

tic operation of the tonearm the unit is

fitted uith e muting ouitch. Control of the

suitch springs for both channels is effected

by the camsheel. With the unit in neutral

state the short circuit of the pick-up leads

is eliminated.

Adjustment point

In neutral position the distance betueen

contact springs should be about 0.3 nm.

Correct by elightly bending contact springs

Continuous automatic play

The continuous aytomatic play is operated

by turning knob (72) to "CO". Suitch bracked

242) is actuated by knob (72). Suitch rod

241) keeps change lever (174) in start po-

sition, After playing the record the tone

Fig. 20 Muting Suitch

ZESSS

A=

XN

arm returne automatically to the lead-in

groove of the record. The record will be

Blayec again, This procedure will be repeated

Until cancelled by pushing control lever

'gtop" or turning knob (72) to po-

A join:

@ring turning knob (72) to "oo" position,

The play between the eccentric pulley (E)

ang charge Lever (174) shoula be 0.1 to

O13 mm, Adjust by bending the suitch rod

(241) (rig: 19).

Fig. 21

—170

184

Defect

Tonearm head not parallel to platter.

couse

Seat of tonearm head on the tonearm tube

hee changed during transit,

Remedy

Renove platter. Insert screudriver through

the hole in the cheseis mounting plate.

Blign tonearn head end retighten screw

(Fig. 22).

Fig. 22

16

Shutoff Operation

The Functions of autonatic set-doun and

shuteotf are determined by the position of

the deflection Laver (139), The deflection

lever (139) is only moved out of stop po-

sition during starting by the change’ Lever

(i745, Initiation of shutaort artes playing

the record is brought about by the doo (MH)

Gf the notor pinion and eho stutrort foves

(442),

The shut~oft Lever (142) is guided onto the

dog by the movement of the toneace unen

Playing the record uith the aid oF the shut=

oft baz (182) propertionats to tho groove

ited, The eccentricaliyemauntad Joo forces

the nuteof? lover (142) back vith each se

volution es long ae the advance of the, tos

neazm only amounts to the Uisth of ons

groove (rig 20a).

Only the run-out groove vith ite increased

Toad guides the shutsoft Lover (142) onto

the 9j ato higher Fate oo that tne shue=

oft lever ts piekec up and moved slong

(rig. 242). The cenuhecl (448) is thus no-

ved Gut of zero position into engagement

uith the motor pinion (rig. 18 cf.

Adjustment point

Uith the eccentric pully "S" on segment

(230) ‘the shut-off point can be varied.

Fig. 23 Shut-off operation

Detect Cause

Stylus slips out of a) Tonearm is not bo~

playing groove lancea

b) Tonearm tracking

force is too lou

©) Anti-akating

getting incorrect

4) Stylus tip uorm

or chipped

@) Excessive bearing

Friction in tone=

arm bearing

P) Steet ball (136)

of shut-off bar

(182) missing

9) Friction of dog

of segment (230)

in guide piece

(215). (Segment

shifting uhen to-

noarm is in stop

position for 30 om

records.)

7

MR OM 142 143: 182

Remedy

a)

»)

e)

f)

a)

Balance tonearm

Adjust tracking force to the value stated

by the cartridge manufacturer

Correct anti-skating settin:

Renew atylus °

Check tonearm b

necessary

rings and re-adjust if

Renew steel ball (136),

Bend holding spring (231) or check ad~

justment points "b* (Fig, 18, page 15).

Detect

Tonearn does not sot

doun at the edge of

the record

Tonearn does not set=

gown or sets-doun

too quickly after

operating cue con~

trol lever (201)

Vertical tonearm mo~

vament shous resi-

stance during set-

doun

Tonsara returns to

rest after manual

aat-doun innediately

after the platter

starts to turn

Tonearm moves uith

tracking force and

anti-skating scale

ip 0 position

a) outuards

b) invards

During automatic

operation tonearm

disturbing noises

are perceptible

No reproduction. The

short circuit of the

pick-up leads is no

Longer being elinix

nated

Motor does not shut-

off uhen tonearm

sets doun on rest

Acoustic feedback

Cause

a) Record size set-

ting incorrect

b) Tonearm set-doun

point is incor=

Fectly set.

e) Set ecreu (40)

maladjusted.

b) Damping excessive

or toa lou by

contamination of

the silicone oil

Excessive friction

of Lift pin (213)

in guide tube

Position of shut=

orf has altered dur-

ing transport of the

unit

a) Anti-skating 4

vice out of ad=

justment

b) Excessively tight

tonearm leads

produce @ torque

Muting suitch out

of adjustment. The

distances between

the slide springs

and the short cir-

cuit strips on the

muting suitch are

excessive.

Distance betuaen the

slide springs and

the short circuit

stripe on the muting

euiteh is absent or

insufficient

Suppression capaci~

tor (111) in pouer

guitch is defective

(short circuit)

a) Chassis comp

nonts (2, g. also

connecting leads)

b) Connecting leads

are too tight

18

Remedy

a) Carry out necessary adjustment uith the

control lever (74).

b) Set control lever (74) to "33". The ad-

justment screu becomes visible through.

the hole detueen the control lever (74)

and the cue cantral. Turn adjustment.

sereu either clockuise or anti-clockuis:

) Adjust set screw (40) for 3 - 5 mm cue

control height.

b) Using turning bush set for (35) or (>).

If necessary, remove cue control plate

{210};"ae déccribec on page 14 and also

Fonove shaft pin (204) onthe Lift pin

1278)> Gaanoc’ (205), adjustment slosve,

{ho aécond seshor (205): Remove Litt pin.

Clean lift tube and lift pin. Smear lift

pin evenly vith “Uecker Silicone O12

Rx"360 000"

Roaasomble components.

See above (b)

After fitment and auch time after transport

the unit should be started once with tone-

arn secured for automatic adjustment of au-

tomatic shut-off.

a) Adjust skating lever (see p. 13/14)

b) Slacken tonoarm leads

By bonding the short circuit strips. Adjust-

mont ie correct uhen, with the camuheel in

neutral position, the distance betueen the

slige springs and the short circuit strips

fan the muting suitch is approx. 0.3 mm.

Spray contact springs uith preservative

(e.g. Kontakt 61) and check adjustment of

short circuit strips.

By adjusting the short circuit strips. Ad~

GUstmant is correct hen, uith the camuh

in neutral position, tha’ distance betueen

the slida eprings and the short-circuit

gtrips on the muting suitch is epprox.

0.3 an,

a

Feneu suppression capacitor in pouer suitch

(10,000 pF/700 Vv)

2) Line up cutout in accordance uith data in

fitting instructions. Move loads.

b) Slacken or lengthen cable

Fig. 25 Pick-up Connection Diagran

fight channel

4) with miniature plug 5-pin

rant channel

Q, red loos

!

1 tet chanoet

| wit ead

connection Hl

plate I

' 1) with phono plug

1 I I |

4k

} bck sahite

(ved) (yellow)

bck

‘ht channel lot channel

ves white

Moss right channel Mas ltt channe

seen bie

‘Tonearm hesd

‘Spring contacts berween

plug-in cartridge

head and tonearm

ica

vw tne ve seot gone

ce a Gy er ieatae

19

Replacement Parts

Pos. | Part. No. Discreption aty.

1 220 213 | Centering disc

2 238 434 | Washer seette

3 239 409 | Turntable mat compl:

4 239 410 | Turntable complete uith mat.

5 239 411 | Electronic direct drive system £05 1

7 210 516 | Machine scroyM 4x8 ceeeeeeeeeeee

8 239 350 | Washer 4.2/7/1 ....-.0ttes

9 237 844 | Supporting poot

10 237 795, P:

un 330 S06 | Uesner'3,2/7/008. ss mn :

12 227 402 | Flat head scrou N34 UII :

13 237 668 | Special scrov

14 239 413 | Oual emblem .

15 200 444 | Spring uasher

16 239 414 | Shipping screw complet

” 210 145 | Lock uasher 3.2

18 201 632 | Rubber washer ..

19 237 117 | Vasher ......

20 237 118 | Lock uasher

21 239 415 | Chassis complete -

22 234 432 | Spring mount comp): {fonoase aida}")

259 416 | Spring mount compl: (Sapply unit side)

23 230 529 | Threaded piece ....... ey

24 232 842 | Compression spring (Tonearm aide) ...+

238 556 | Compression spring (Sapply unit side).

28 200 723 | Rubber damping block ...-...

28 200 722 | Steel cup -.eeeeeeeeceee eee

27 239 417 | Tonearm head compl. er

28 234 611 | Hancle Bt

29 210 182 | Boued to

30 210 630 | Uasher 4.2/8/0.5 .

a 210 197 | "c" clip Gaxs .

32 236 242 | TK 24 cartridge mount cc...

33 236 895 | Contact plate compl. ......ss

34 237 671 | Pointer “s..seeeeeceneeee

35, 237 672 | Pin 2x6 LI

36 234 635 | Lock nut.

37 230 063 | Grub crow

38 239 418 | Frame compl.

39 237 481 | Tension spring...

40 237 623 | Turning knob

a4 236 911 | Tonearm rest compl.

42 210 362 | Hex nut 6M 3 so...

43 218 321 | Hex nut M10 2...

48 237 530 | Turning knob compl.

45 237 661 | Grub sereu M3 x 4

46, 239 419 | Cover front compl. °.

47 200 44a | Spring washer .....+.

48 234 635 | Lock nut ..

4 217 438 | Grub screv..

50 239 188 | Tonearm compl.

51 239 420 | Weight compl.

52 236 160 | Supporting plate

53 239 421 | Bearing rack

54 236 051 | Clanp bolt ...1

55 234 617 | Fixing screw”.

56 239 422 | Bearing compl... 1.02 nt

87 210 475 | Machine scrou AN 3°x 5 :

38 236 907 | Saring housing compl.

59 237 363 hers... :

60 237 564 | Bearing screu an

61 237 471 | Shaft “.eeeee ee tlltlt

62 237 581 | Tension lever 2...

63. 234 303 | Compression spring

64 237 577 | Turning knob compl.

6s 210 361 | Hex nut M3 eeeeecee

66 237 618 | Knurled ring "-

67 216 867 | Boued lock washer 5.32/10" "111

68 225 176 | Curve uasher seseeseeee

69 210 361 | fiex nut HS.

70, 237 737 | Fillister head “Countersunk M3740" "t

n 239 423 | TA-Plate ..eeeeeeseeee oe

2 237 544 | Turning knob compl. +. In

73 239 424 | Cover complete veseecssesececeseee

7% 237 $37 | Suitch lover : nn

75 210 366 | Hex nut oma | :

16 237 738 | Fillister head ecrou countersunk m 3x 8

20

view, above chassis

Fig. 26 Exploded

==.

@OOE

@

6 o=—4)

2

Fig. 27 Exploded view,

@OQHHOD 5 OOOO

©

© © ©6©606HH5550 © ©

OOOO _ Qe: cane,

Ja. 62D©\\8 ‘

sdoood

@®

©00®

@®

Pos. | Part. No. Description oty,

101 | 237 678 | deftecting prism . : 1

102 | 237 677 | Case, lower pare n 1

103 | 225 321 | Tublar glimn Lamp ..2222222 1

104 | 237 679 | Strobe cover seeeessciiiiee 1

wos | 210 472 | Machine scrou Am’3°x 4° °2 2

10s | 233 009 | Power switch compl. . 1

107 | 200 aaa | Spring washer... sss. 1

10a | 236 335 | Slide - SIS 1

os | 233 012 | Suitch piate compl. “2222202 1

110 | 230 148 | Suitch slide ....... : 1

111 | 209 805 | Capacitor 10 nf /i000'U/10"% 1

142 | 230 296 | Tension spring s.sesseeee 1

113 | 219 200 | Snap spring SIS 1

114 | 233 010 | Cover compl. BL 1

115 | 210 498 | machine acrau W3°x 28°"! 1

116 | 210 480 | Machine scrou AN3 x 6 1. 4

117 | 213 a71 | Machine acrau self-tapping 2

118 | 210 515 | Machine acreu AN a xO vs 2

119 | 227 189 | Joining nuEM 4 .ee....ce 2

120 | 209 939 | Sleeving ....sessssssssee 2

121 | 209934 | Sleeving * i 4

122 | 223 611 | Sieoving with strain relict 2

3123 | 239 425 | Supply unit compl. ...... 1

124 | 225 058 | Pover tranarormer compl. i

125 | 229073 | Pover plate compl. .-. 1

126 209 719 | Fuse 0.125 a/250 v . 1

c si | 228 322 | Foii capacitor 68 nf/400 v/10 ¢ 1

© §2 | 224 eae | Feil Sopacttor a? nr/2s0 V/t0 ¥ 1

0 s1 | 225 247 | Silicon diode ey 183/300 ..... 1

a 51 | 225 916 | Carbon resistor 22 kohms/0,25 U/S x . 1

R 52 | 225 916 | Cerbon resistor 2.7 kohms/0.125 U/5 % 1

128 | 239 415 | Chessic complete ..... 1

129 | 210 361 | Hex nut M3) seweeeeeese 3

130 | 210 472 | Machine scrov AN 3'x 4 2

131 | 239 426 | muting Suitch ....eeee 4

132 | 227 450 | Hex nut M 2.6 : 1

433, | 227 101 | Shiela ...ce..0000 1

134 | 227 100 | Sleeve 2.222220) 1

135 | 231 979 | Coble noidar compi 4

136 | 209 358 | Ball 4.0. 1

137. | 237 511 | Internadiata p. 1

138 | 200 650 | Rubber sleave 2

139 | 237 515 | cam follover lever 1

140 | 200 522 | Toggle apring ws... 1

447 | 210 142 | Lock washer ss ..se: 1

142 | 232 608 | Shutt-orr lever’ “21! 1

143 | 232 606 | Friction plate .... 1

144 | 230 427 | Cam wheel complote 4

345 | 234 026 | Grub screv "2.5 x 4.0 1

tas | 210 145 | Lock washer .se..ee 8

147 | 227 092 | Searing pillar’ 1... 1

148 | 210 148 | Lock uashor 5... 1

149 | 210 361 | Hex nut M3 ost 3

150 210 586 | Washer 3.2/7/0 6

181 | 227 076 | Bearing bolt. 1. 1

152 | 210 145 | Lock washer 2.3 S| 8

153 | 227 080 | Searing support compiate mn 4

154 | 239 428 | Control lever complate . Bp 4

155 | 227 037 | Compression spring DD pa

186 | 237 507 | Main lover v..es Ba pa

157 | 237 555 | Tension spring. Bp oa

18a | 227 303 | Special screuN3 x 6 11.) a

159 | 237 510 | Guide lever ......... 4

veo | 210 145 | Lock washer 2.3 8

61 | 216 asa | Share... : 2

162 | 210 146 | Lock washer 3.2 5

163 | 210 352 | Hex nut BM 3"... 2

ea | 237 519 | detent ......022 1

165 | 210 536 | Uacher 31/7/0158 6

165 | 210 536 | Washer 3.2/7/0.5 6

187 | 237 439 | Grooved shart". 1

168 | 237 490 | Grooved bolt. 1

169 | 210 145 | Lock washer 2.3 8

170 | 237 491 | Suitch arm comal. 1

171 | 237 668 | Tension spring + 4

172 | 200 650 | Rubber sleeve ufo2

23

Pos. | Part. Now Devcription aty.

17s | 210 147 | Lock washer 6 sees eeeses 3

ita | 237 493 | Gonteal lover asgembiy’: :

17s | #39 44a | Seneion spring’ sss. -s--! 1

176 | 200 103 | Tension spring liclo202: 1

177 | Bio tar | lock washer @ nn 3

ie | 237 aor | Stece“Teves NE tf 4

173 | 227 aa3 | Tension spring’ 2222.2 tf 4

iso | 340 47 | Lock weshes @ tf 3

tat | d4e tar | Cock uasnes 4 t] 3

faz | 237 tz | Smutorr ber 1220200001 f) 4

185 | 201 te7 | Stiding vashee 220202001 f]4

tes | 240 145 | Lock useher 2.3 f] oa

tas | 239 $20 | Lock uscnes In r] 4

tae | 237 863 | Buen“ al

ta1| 237 64 | Compression’ apzing’ 7.2.2! f]4

130 | 221 av2 | Tension spring f] 4

tay | 231 503 | Stop comps tf 4

130 | 231 182 | Potentioneter’ nut ;

431 | 231 100 | Fine speed sonezo2 1

132 | 337 ter | Turning kno "ss 1

133 | 237 626 | Bearing piste": 1

134 | 231 017 | Tension Spring 1

tas | 237 536 | Hennut me xt 2

13¢ | 237 370 | Start lover i

137 | 210 596 | Ussher 5.2/7/0.5 &

tae | 219 362 | Hox'nut On 3. 3

tas | 219 av2 | facnine screw ;

200 | 327 030 | Suiten mentor compl: 1

201 | 237 S61 | Lover compl ;

for | 210 353 | Hex'nut on 2 ;

bos | 237 300 | Litt’cem ;

zoe | 237 60 | Guide s-.ti2s2 1

20s | 210 463 | Lock veahor 4.5 2

doe | 219 310 | Aejustment bush ;

zor | 237 S24 | Turning bush... 1

zoe | 237 61 | Lock ussher” 21. 1

30s | 237 460 | Aajustmont con HEE [4

Bio | 235 423 | Cite tube sssemiy i

211 | 237 459 | Hajustmont piste mp4

Ziz_ | 237 450 | Conprecaion epring INEEEEE | 4

21s | 237 dey | Gite pins IEEE] 4

fie | 231 46g | bin : t) 4

Bis | 237 ara | tulae f]o4

zis | 237 ozt | Machi ff 4

Zit | 237 21 | machine screu an 3 f] 4

3ia | 210 361 | Hox out ars f] 3

213. | 237 aso | Shiela ores. :] 4

220, | 237 499 | Conpzessian opting f]o4

251 | 237 490 | pivot searing f] 4

222 | 240 14s | Lock vesner 2.3 t] 8

223 | 2ar 451 | Bivocing cam eetl0) f] 4

22a | 237 450 | Boaring’ousm 12000021 al

225 | 237 477 | Conpression spring ff 4

228 | 231 arn | Compensating can fa

zer_| 231 400 | Intermediate goer fla

223 | 237 4a2 | Adjustment piste tf 4

223 | 210 400 | Machine screu AM 3°x 1

350 | 239 622 | Sognent cols, oes. i

231 | 237 475 | Holeing spring’. ;

B32 | 210 472 | Machine scrouan’3'x°4 ;

233 | 239 23 | Coupling plate essonnly i

Z3e | 210 331 | Countersunk sereu 2

23s | 237 47a | Gules verses i

336 | 229 cae | Veopsing 2200002 i

337 | 237 aes | Skating tower’ 2.2.2 i

235 | 218 $51 | Tension epring “<2: ;

335 | Zor tea | Adjusting washers: ;

3io | 210 tae | Cock vasner 3.2.01) $

Bar| 259 der | Uinting rover. i

gaz | 231 302 | Suitonvelice 1: 1

343 | 230 363 | Coat spring. 222002 :

24a | 210 S49 | Uasnar 2.1/5/0.5 2.021 1

Bas | 210 363 | Hex nut on 2 te. 2 0000 my 4

zac | 237 S00 | Rajustment resi” 200% 1

gar | 231 S36 | Hox nue ext sc 2

zea | 231 316 | Contact piece oc ;

Bas | Zar aes | Fonsion spring “22:2 ;

330 | 210 446 | Lock ueshor 2:2 3

24

Pos. Part. tio. Discrap| aty

281 justment plate toa

252 pining nut - i 1

253 Pouer cable : 1

254 ANB compactor +} 2

255 Pouer cable : 1

256 Cyneh plug black’. D]2

Cynch plug unite <. DIDI [2

258 Pick-up lead compl. with’ Cynch’ plug i

239 Pick-up lead compl. sssessessenseses 1

260 Flat connector slecve Inn 3

261 Miniature plug 1

262 Hox nut M3. 2

263 Foothed uasher 2

264 hield o i

268 RCA-type sack i

266 Machine screu MS x 6 2

267 Rubber oleove seeeeeeessee 3

268 Intermediate shim i

269 Vasher 3.2/7/0.5.

a Hardyare for cartridge moun

eee Mounting instructions... +

wee Operating instructions

oe Operating instructions UAP

ae Packing carton 721 complete

oe Packing carton CS 721 ws.+

n reserved!

Lubricating Instructions

All bearing and friction

pointe of the unit are ade-

quately lubricated at the

dorks. Replenishment of oil

and Fea: only necessary

after aproximately 2 yaars

of normal use of the record

player as the most important

bearing paints (motor bea~

Tings) have sintered matal

bushes.

Bearing paints and friction

faces should be lubricated

sparingly rather than gene-

Uhen using different Lubri-

cante, chemical decomposi-

tion can often take pl:

To prevent lubrication fai-

lure we recommend using the

original lubricants stated

below. The follouing Lubri-

eante should be used for

Subsequent lubrication:

AX Saker Silicone 011

WN ak 300 G00

AX Bigg scone

BX oreo

Dual Gebriider Steidinger - 7742 St.Georgen/Schwarzwald

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Carcasa SG12Document44 pagesCarcasa SG12romanbunNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 1978 Phono PDFDocument16 pages1978 Phono PDFOnet DorelNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Dual 1219 1229 Diy Service GuideDocument34 pagesDual 1219 1229 Diy Service Guidekkrouw568100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Azur 640P User Manual - English PDFDocument8 pagesAzur 640P User Manual - English PDFOnet DorelNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Feb 77 ArticleDocument13 pagesFeb 77 ArticleOnet DorelNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Pricesne Colinde 17mai2010 v14Document16 pagesPricesne Colinde 17mai2010 v14Onet DorelNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Dual 1219 1229 Diy Service GuideDocument34 pagesDual 1219 1229 Diy Service Guidekkrouw568100% (1)

- Dual 1219 1229 Diy Service GuideDocument34 pagesDual 1219 1229 Diy Service Guidekkrouw568100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hfe Pioneer ct-777 Service PDFDocument31 pagesHfe Pioneer ct-777 Service PDFOnet DorelNo ratings yet

- Pap - RM-Phono C-Load & Balance PDFDocument10 pagesPap - RM-Phono C-Load & Balance PDFOnet DorelNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elpumps Catalog 2014 enDocument64 pagesElpumps Catalog 2014 enOnet DorelNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Ve Linsleyhood Phono PDFDocument5 pagesVe Linsleyhood Phono PDFOnet DorelNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Moving Magnet Rev 3Document1 pageMoving Magnet Rev 3Onet DorelNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Salas Riaa v1102f0Document8 pagesSalas Riaa v1102f0Onet DorelNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- GR HK 2012 IFA International LRDocument35 pagesGR HK 2012 IFA International LROnet DorelNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Avr3808e2a Addendum Im 007Document16 pagesAvr3808e2a Addendum Im 007Onet DorelNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BG-GP 1355 N: Garden PumpDocument1 pageBG-GP 1355 N: Garden PumpOnet DorelNo ratings yet

- BG-GP 1355 N: Garden PumpDocument1 pageBG-GP 1355 N: Garden PumpOnet DorelNo ratings yet

- Avr 3808Document2 pagesAvr 3808Onet DorelNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Avr 3808Document2 pagesAvr 3808Onet DorelNo ratings yet

- Avr 3808Document2 pagesAvr 3808Onet DorelNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)