Professional Documents

Culture Documents

Me6311 Manual Mt-I 27 - 08-2014.0018 PDF

Uploaded by

pcelumalai0 ratings0% found this document useful (0 votes)

16 views1 pageDrill bit is fed into work by turning tail stock hand wheel up to required path. Then Boring tool is fitted on the tool post and fed parallel to the axis of lathe. 11. Compound rest is swiveled by calculated half-taper angle and taper is generated on the work piece.

Original Description:

Original Title

ME6311 MANUAL MT-I 27 -08-2014.0018.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDrill bit is fed into work by turning tail stock hand wheel up to required path. Then Boring tool is fitted on the tool post and fed parallel to the axis of lathe. 11. Compound rest is swiveled by calculated half-taper angle and taper is generated on the work piece.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageMe6311 Manual Mt-I 27 - 08-2014.0018 PDF

Uploaded by

pcelumalaiDrill bit is fed into work by turning tail stock hand wheel up to required path. Then Boring tool is fitted on the tool post and fed parallel to the axis of lathe. 11. Compound rest is swiveled by calculated half-taper angle and taper is generated on the work piece.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

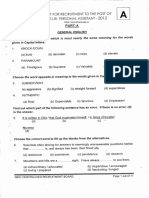

II YEAR, MECH A SEC

ME6311 MANUFACTURING TECHNOLOGY LABORATORY-I

6. The drill is fitted in the tail stock spindle

7. The tail stock is moved over the bed and chambered near the work piece

8. When the job rotates, the drill bit is fed into work by turning tail stock hand wheel up

to required path

9. Then Boring tool is fitted on the tool post and fed parallel to the axis of lathe.

10. Boring the work piece to 30mm diameter.

11. Compound rest is swiveled by calculated half taper angle and taper is generated on the

work piece.

12. Rotation of the compound slide screw will cause the tool to be fed at the half-taper

angle.

PRECAUTIONS:

1. Operate the machine at optimal speeds.

2. Coolant has to be sued while drilling.

3. Care should be taken to obtain the required accuracy.

RESULT:

Required specimen successfully obtained according to specified operations (Step

turning, Taper turning and Knurling) with given dimensions.

DEPT. OF MECHANICAL ENG INEERING

18

VELAMMAL ENGINEERING COLLEGE

You might also like

- ISRO URSC Technical Assistant Previous Paper 2010p2Document14 pagesISRO URSC Technical Assistant Previous Paper 2010p2pcelumalaiNo ratings yet

- Ak 20 Electrical and Electronics Engineering CompressedDocument51 pagesAk 20 Electrical and Electronics Engineering CompressedpcelumalaiNo ratings yet

- Post Doctoral Fellow Position: Synthesis and Characterization of Self-Assembling Polymers For Applications in Water Remediation (Code: PDF-STAR)Document2 pagesPost Doctoral Fellow Position: Synthesis and Characterization of Self-Assembling Polymers For Applications in Water Remediation (Code: PDF-STAR)pcelumalaiNo ratings yet

- Ak 19 M.tech Production Engineering and Engineering Design CompressedDocument56 pagesAk 19 M.tech Production Engineering and Engineering Design CompressedpcelumalaiNo ratings yet

- ISRO URSC Technical Assistant Previous Year Question PaperDocument17 pagesISRO URSC Technical Assistant Previous Year Question PaperpcelumalaiNo ratings yet

- MDF BoardDocument10 pagesMDF BoardpcelumalaiNo ratings yet

- TestingCharges CATERSDocument4 pagesTestingCharges CATERSpcelumalaiNo ratings yet

- IISc Facility Manager Post NotificationDocument4 pagesIISc Facility Manager Post NotificationpcelumalaiNo ratings yet

- Flyer FamiliarizationWorkshopDocument1 pageFlyer FamiliarizationWorkshoppcelumalaiNo ratings yet

- All Universites WebnoteDocument1 pageAll Universites WebnotepcelumalaiNo ratings yet

- DOTE Revised June Schedule 2022Document1 pageDOTE Revised June Schedule 2022pcelumalaiNo ratings yet

- Adhoc Faculty Recrutiement Notification - AY - 2022-23Document4 pagesAdhoc Faculty Recrutiement Notification - AY - 2022-23pcelumalaiNo ratings yet

- ADVT-NO.2-May 2022-LComDocument1 pageADVT-NO.2-May 2022-LCompcelumalaiNo ratings yet

- Web Note - 30072018Document1 pageWeb Note - 30072018pcelumalaiNo ratings yet

- I, II and III Year Assessment - Schedule - Ugpg - Ot8 - Ot10 PDFDocument1 pageI, II and III Year Assessment - Schedule - Ugpg - Ot8 - Ot10 PDFbalajivnrNo ratings yet

- Andhra Pradesh Public Service Commission::Vijayawada Assistant Professors in Various Universities of Ap Web NoteDocument1 pageAndhra Pradesh Public Service Commission::Vijayawada Assistant Professors in Various Universities of Ap Web NotepcelumalaiNo ratings yet

- I Ii EeeDocument23 pagesI Ii EeepcelumalaiNo ratings yet

- I BT II-sem 2021-22-Autonomous CompressedDocument1 pageI BT II-sem 2021-22-Autonomous CompressedpcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0022 PDFDocument1 pageMe6311 Manual Mt-I 27 - 08-2014.0022 PDFpcelumalaiNo ratings yet

- Marks Secured by Candidates in Screening Test of Assistant Professors in A.P. Universities Mechanical EngineeringDocument18 pagesMarks Secured by Candidates in Screening Test of Assistant Professors in A.P. Universities Mechanical EngineeringpcelumalaiNo ratings yet

- International Journal of Research in Engineering and Science (IJRES)Document1 pageInternational Journal of Research in Engineering and Science (IJRES)pcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0009Document1 pageMe6311 Manual Mt-I 27 - 08-2014.0009pcelumalaiNo ratings yet

- Awjm 1Document2 pagesAwjm 1pcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0008Document1 pageMe6311 Manual Mt-I 27 - 08-2014.0008pcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0019 PDFDocument1 pageMe6311 Manual Mt-I 27 - 08-2014.0019 PDFpcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0017 PDFDocument1 pageMe6311 Manual Mt-I 27 - 08-2014.0017 PDFpcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0020 PDFDocument1 pageMe6311 Manual Mt-I 27 - 08-2014.0020 PDFpcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0021 PDFDocument1 pageMe6311 Manual Mt-I 27 - 08-2014.0021 PDFpcelumalaiNo ratings yet

- Me6311 Manual Mt-I 27 - 08-2014.0016 PDFDocument1 pageMe6311 Manual Mt-I 27 - 08-2014.0016 PDFpcelumalaiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)