Professional Documents

Culture Documents

IFI Manual

IFI Manual

Uploaded by

budygmoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IFI Manual

IFI Manual

Uploaded by

budygmoodCopyright:

Available Formats

INDUSTRIAL FASTENERS INSTITUTE

6363 Oak Tree Boulevard Independence, Ohio 44131 USA, www.indfast.org

What is the Proper Torque to Use on a Given Bolt?

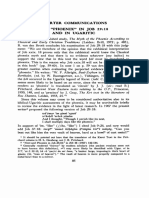

What torque should I use to tighten my bolts? is a question suppliers of bolts are frequently asked by end

user customers. Many times I have been asked if a chart is published on the recommended tightening torque for

various bolt grades and sizes. I do not know of any. This article provides such a chart for Initial Target Tightening

Torque. See Figure 1. The formula for generating these values is explained below.

The widely recognized engineering formula, T= K x D x P (to be explained later in this article), was used

to provide the charts values, but it must be understood that every bolted joint is unique and the optimum tightening

torque should be determined for each application by careful experimentation.

A properly tightened bolt is one that is stretched such that it acts like a very ridged spring pulling mating surfaces together. The rotation of a bolt (torque) at some point causes it to stretch (tension). Several factors affect how

much tension occurs when a given amount of tightening torque is applied.

The first factor is the bolts diameter. It takes more force to tighten a 3/4-10 bolt than to tighten a 3/8-16 bolt

because it is larger in diameter. The second factor is the bolts grade. It takes more force to stretch an SAE Grade

8 bolt than it does to stretch an SAE Grade 5 bolt because of the greater material strength. The third factor is the

coefficient of friction, frequently referred to as the nut factor. The value of this factor indicates that harder, smoother,

and/or slicker bolting surfaces, such as threads and bearing surfaces, require less rotational force (torque) to stretch

(tension) a bolt than do softer, rougher, and stickier surfaces.

The basic formula T = K x D x P stated earlier takes these factors into account and provides users with a

starting point for establishing an initial target tightening torque.

T = target tighten torque (the result of this formula is in inch pounds, dividing by 12 yields foot pounds)

K = coefficient of friction (nut factor), always an estimation in this formula

D = bolts nominal diameter in inches

P = bolts desired tensile load in pounds (generally 75% of yield strength)

The reason all applications should be evaluated to determine the optimum tightening torque is that the K factor in this formula is always an estimate. The most commonly used bolting K factors are 0.20 for plain finished bolts,

0.22 for zinc plated bolts, and 0.10 for waxed or highly lubricated bolts.

The only way to properly determine the optimum tightening torque for a given application is to simulate the

exact application. This should be done with a tension indicating device of some type on the bolt in the application.

The bolt is tightened until the desired P (load) is indicated by the tension indicating device. The tightening torque

required to achieve the desired tension is the actual tightening torque that should be used for that given application.

It is extremely important to realize that this tightening value is valid only so long as all of the aspects of the

application remain constant. Bolt suppliers sometimes have customers say that their bolts are no good because they

have started breaking while being installed. Thorough investigation commonly reveals that the customer has started

lubricating the bolts to make assembly easier, but maintained to same torque as was used when the were plain finished.

The table in this article shows that by using this formula a 1/2-13 Grade 5 plain bolt should be tightened to

82 foot pounds, but the same bolt that is waxed only requires 41 foot pounds to tighten the same tension. A perfect

1/2-13 Grade 5 waxed bolt will break if it is tightened to 81 foot pounds because the K factor is drastically lower. The

bolts are fine, but the application changed. Suppliers need to understand this and be able to educate their customers

to resolve this common customer complaint about breaking bolts.

IFI

Technical Bulletin

Published and issued by the

Industrial Fasteners Institute

of Independence, OH

What is the Proper Torque to

Use on a Given Bolt?

IFI

Page 1 of 2

Issued: Sept., 1994

All standards and specifications are advisory only. Their use by anyone is entirely voluntary. Reliance thereon for any purpose by anyone is at the sole risk of that person or the

user of the product, and the IFI is not responsible for any loss, claim, or damage arising therefrom. In formulating and approving standards and specifications, the IFI has not

investigated and will not investigate patents which may apply to the subject matter. Prospective users of the standards and specifications are responsible for advising themselves

of and protecting themselves against any patent infringement liability which may arise out of such use. INDUSTRIAL FASTENERS INSTITUTE 2008

INDUSTRIAL FASTENERS INSTITUTE

6363 Oak Tree Boulevard Independence, Ohio 44131 USA, www.indfast.org

The chart is provided for quick reference by fastener suppliers and users for selecting an initial target tightening torque. This chart was derived by using the formula shown earlier. An example of the calculation is as follows:

Product: 3/4-10 Grade 5 zinc plated bolt

Formula: T = KxDxP

K = 0.22 (zinc plated)

D = .750 (3/4-10 nominal diameter)

P = 23,046 pounds

Note: P = 75% of yield strength (92,000 PSI) times the tensile stress area of the thread (0.3340)

T = (0.22 x .750 x 23,046) /12 = 317 foot pounds

Hopefully the chart will help suppliers with an initial answer to the customers question, What torque should

I use to tighten my bolts? Keep in mind this is only an estimated value. It may provide satisfactory performance, but

it also may not. Every application should be evaluated on its own to determine the optimum torque value for each application. Major bolt suppliers should have tension indicating equipment necessary to help their customers determine

the appropriate tightening values for their specific applications. Keep in mind that if the lubricant on a bolt and nut

combination is changed, the tightening torque value must be altered to achieve the desired amount of bolt tension.

Thread

Size

Tensile Stress

Area

TSA

SAE Grade 2

SAE Grade 5

SAE Grade 8

75% Yield Strength (PSI) = 43000

75% Yield Strength (PSI) = 69000

75% Yield Strength (PSI) = 98000

Plain

Zinc

Plated

Waxed

Plain

Zinc

Plated

Waxed

Plain

Zinc

Plated

Waxed

Square Inches

Ft. Lb.

Ft. Lb.

Ft. Lb.

Ft. Lb.

Ft. Lb.

Ft. Lb.

Ft. Lb.

Ft. Lb.

R. Lb.

1/4-20.

0.0318

10

13

14

1/4-28.

0.0364

10

12

15

16

5/16-18.

0.0524

12

13

19

21

27

29

13

5/16-24.

0.0580

13

14

21

23

10

30

33

15

3/8-16.

0.0775

21

23

10

33

37

17

47

52

24

3/8-24.

0.0878

24

26

12

38

42

19

54

59

27

7/16-14.

0.1063

33

37

17

53

59

27

76

83

38

7/16-24.

0.1187

37

41

19

60

66

30

85

93

42

1/2-13.

0.1419

51

56

25

82

90

41

116

127

58

1/2-20.

0.1599

57

63

29

92

101

46

131

144

65

9/16-12.

0.1820

73

81

37

118

129

59

167

184

84

9/16-18.

0.2030

82

90

41

131

144

66

186

205

93

5/8-11.

0.2260

101

111

51

162

179

81

231

254

115

5/8-14.

0.2560

115

126

57

184

202

92

261

287

131

3/4-10.

0.3340

180

197

90

288

317

144

409

450

205

3/4-16.

0.3730

200

221

100

322

354

161

457

503

228

Figure 1. Initial Target Tightening Torque. (Formula: T = K x D x P)

Disclaimer: All information provided in this document and/or presentation is based on data the Industrial Fasteners

Institute believes to be reliable and accurate. Such information is intended for use by persons at their own discretion

and risk. The information here in is based on industry standards and recognized practices. The Industrial Fasteners

Institute and the representatives providing this material assume no responsibility for the content.

IFI

Technical Bulletin

Published and issued by the

Industrial Fasteners Institute

of Independence, OH

What is the Proper Torque to

Use on a Given Bolt?

IFI

Page 2 of 2

Issued: Sept., 1994

All standards and specifications are advisory only. Their use by anyone is entirely voluntary. Reliance thereon for any purpose by anyone is at the sole risk of that person or the

user of the product, and the IFI is not responsible for any loss, claim, or damage arising therefrom. In formulating and approving standards and specifications, the IFI has not

investigated and will not investigate patents which may apply to the subject matter. Prospective users of the standards and specifications are responsible for advising themselves

of and protecting themselves against any patent infringement liability which may arise out of such use. INDUSTRIAL FASTENERS INSTITUTE 2008

You might also like

- Smooth Seduction 2Document17 pagesSmooth Seduction 2Serrano Jimenez Joseph50% (12)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- The Orthodox Church in The Byzantine Empire (J. M. Hussey)Document132 pagesThe Orthodox Church in The Byzantine Empire (J. M. Hussey)theseus11100% (1)

- GB962B Maturity Model R13.5Document16 pagesGB962B Maturity Model R13.5leniadz2No ratings yet

- Design of Pressure Vessels For Low-Cycle Fatigue PDFDocument11 pagesDesign of Pressure Vessels For Low-Cycle Fatigue PDFLeonardo TerraNo ratings yet

- IADC/SPE 74488 Advanced Slip Crushing Considerations For Deepwater DrillingDocument15 pagesIADC/SPE 74488 Advanced Slip Crushing Considerations For Deepwater DrillingJaaTa Da shaanNo ratings yet

- Discussion - Design Concepts For Jib CranesDocument2 pagesDiscussion - Design Concepts For Jib Cranesheitor29No ratings yet

- Swagelok-Thread and End Connection Identification Guide-MS-13-77 PDFDocument56 pagesSwagelok-Thread and End Connection Identification Guide-MS-13-77 PDFmac9papNo ratings yet

- DS47 - (1971) Evaluations of The Elevated Temperature Tensilde and Creep-Rupture Properties of C-Mo, Mn-Mo and Mn-Mo-Ni Steels PDFDocument102 pagesDS47 - (1971) Evaluations of The Elevated Temperature Tensilde and Creep-Rupture Properties of C-Mo, Mn-Mo and Mn-Mo-Ni Steels PDFJacques BlueqNo ratings yet

- Trademark PDFDocument54 pagesTrademark PDFSaket RaoNo ratings yet

- Angry Birds Comics #1 PreviewDocument6 pagesAngry Birds Comics #1 PreviewGraphic Policy50% (2)

- Guideline For Bolted Joint Design and Analysis VerDocument48 pagesGuideline For Bolted Joint Design and Analysis Verminh thi lương trầnNo ratings yet

- WRC Nozzle LoadsDocument3 pagesWRC Nozzle LoadsGovindan KrishnamoorthybashyamNo ratings yet

- Code Design and Evaluation For Cyclic Loading - Section III and VIIIDocument34 pagesCode Design and Evaluation For Cyclic Loading - Section III and VIIIMatthieu100% (1)

- Bursting Pressure of Mild Steel Cylindrical VesselsDocument4 pagesBursting Pressure of Mild Steel Cylindrical VesselsAris FauziNo ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Altemp X-750 PDFDocument2 pagesAltemp X-750 PDFeugenio.gutenbertNo ratings yet

- Ansi A250 - 13Document34 pagesAnsi A250 - 13maikelc1No ratings yet

- Astm D1525 PDFDocument10 pagesAstm D1525 PDFCristian Culqui PerezNo ratings yet

- Evaluation of Flanged Connections Due To Piping L.oaoDocument9 pagesEvaluation of Flanged Connections Due To Piping L.oaoSJNo ratings yet

- Asme Viii Div.2Document16 pagesAsme Viii Div.2rps1977100% (1)

- Aerospace Standard: Hose Assemblies, Metal, Medium Pressure, High TemperatureDocument3 pagesAerospace Standard: Hose Assemblies, Metal, Medium Pressure, High TemperatureRangaNo ratings yet

- Fatigue Stress AnalysisDocument5 pagesFatigue Stress AnalysisnareniviNo ratings yet

- Ch6 Thermal Stress Analysis Sp16Document34 pagesCh6 Thermal Stress Analysis Sp16Haidar YafieNo ratings yet

- 4.2 Registration of Fittings 4.2.1: Definition Per CSA B51 FittingDocument2 pages4.2 Registration of Fittings 4.2.1: Definition Per CSA B51 FittingniranjanreddykNo ratings yet

- FEA 107 Validation ExperimentDocument7 pagesFEA 107 Validation ExperimentMas Arman TewoNo ratings yet

- Escoa Fintube Corporation, An Oklahoma Corporation v. Tranter, Inc., A Michigan Corporation, 631 F.2d 682, 10th Cir. (1980)Document22 pagesEscoa Fintube Corporation, An Oklahoma Corporation v. Tranter, Inc., A Michigan Corporation, 631 F.2d 682, 10th Cir. (1980)Scribd Government DocsNo ratings yet

- ASME VIII-1 UG-101 Burst Test CalculationDocument1 pageASME VIII-1 UG-101 Burst Test CalculationcorreenNo ratings yet

- Threaded Fasteners For FSAE PDFDocument27 pagesThreaded Fasteners For FSAE PDFMarcelo Delgado100% (1)

- CAESAR II-Applications GuideDocument302 pagesCAESAR II-Applications GuideTakChi_LamNo ratings yet

- Schaeffler Diagram PDFDocument16 pagesSchaeffler Diagram PDFrajesh_14No ratings yet

- WRC Load AnalysisDocument5 pagesWRC Load Analysisyogacruise100% (1)

- Auto-Refrigeration / Brittle Fracture: Prevention and Process Safety MitigationDocument2 pagesAuto-Refrigeration / Brittle Fracture: Prevention and Process Safety MitigationAli VarmazyarNo ratings yet

- Hardness Conversion TableDocument3 pagesHardness Conversion TableNisarg PandyaNo ratings yet

- Bellow Design GuideDocument14 pagesBellow Design Guidelokeshraja007100% (2)

- ASME B16.03 - Malleable Iron Threaded Fittings PDFDocument54 pagesASME B16.03 - Malleable Iron Threaded Fittings PDFGrzegorz UrantówkaNo ratings yet

- Zimmerlin PDFDocument87 pagesZimmerlin PDFАндрей ИнгельбергNo ratings yet

- Bolt Head Fillet Stress Concentration Factors in Cylindrical Pressure VesselsDocument6 pagesBolt Head Fillet Stress Concentration Factors in Cylindrical Pressure Vesselsacadjournals. comNo ratings yet

- BARNES Associated Spring Raymond 2010Document260 pagesBARNES Associated Spring Raymond 2010Francois LaroucheNo ratings yet

- Asme Ccase - 2046Document2 pagesAsme Ccase - 2046ADAMJSRAONo ratings yet

- Comparison of The ASME, BS and CEN Fatigue Design Rules For Pressure Vessels (October 2003)Document2 pagesComparison of The ASME, BS and CEN Fatigue Design Rules For Pressure Vessels (October 2003)sagar1503No ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet

- Preview PTB-5 2019Document12 pagesPreview PTB-5 2019muhammad0umar-4No ratings yet

- Fea SR CouplingsDocument67 pagesFea SR CouplingsAna Isabel Aguilar ReyesNo ratings yet

- Fan ParameterDocument40 pagesFan ParametervrgohilNo ratings yet

- Elastic Stability of Plates With Circular and Rectangular Holes Subjected To Axial Compression and Bending MomentDocument39 pagesElastic Stability of Plates With Circular and Rectangular Holes Subjected To Axial Compression and Bending Momenthunter111No ratings yet

- Gusset Plate Connection To Round HSS Tension MembersDocument7 pagesGusset Plate Connection To Round HSS Tension Membersglav1309No ratings yet

- Analysis of The Behaviour of Stainless Steel Bolted ConnectionsDocument11 pagesAnalysis of The Behaviour of Stainless Steel Bolted ConnectionsSam SamouraNo ratings yet

- Acoples TB Wood SDocument100 pagesAcoples TB Wood SLuis CastrovillariNo ratings yet

- Calculation of Fin Efficiency For Wet and Dry Fins.Document16 pagesCalculation of Fin Efficiency For Wet and Dry Fins.Wilfredo Ruiz100% (1)

- Shell Analysis ManualDocument848 pagesShell Analysis ManualIon ClipaciNo ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- DS6S1 - (1966) Supplemental Report On The Elevated-Temperature Properties of Chromium-Molybdenum SteelsDocument148 pagesDS6S1 - (1966) Supplemental Report On The Elevated-Temperature Properties of Chromium-Molybdenum SteelsJacques StrappeNo ratings yet

- Elliptical Pressure Vesel Stress AnalysisDocument36 pagesElliptical Pressure Vesel Stress Analysisliviu333nt6132No ratings yet

- Burke's Speech On Conciliation With America by Burke, Edmund, 1729-1797Document59 pagesBurke's Speech On Conciliation With America by Burke, Edmund, 1729-1797Gutenberg.orgNo ratings yet

- External Pressure - Pressure Vessel EngineeringDocument15 pagesExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- Modern Developments in the Mechanics of ContinuaFrom EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziNo ratings yet

- Proper Bolt TorqueDocument2 pagesProper Bolt TorqueDarmawan PutrantoNo ratings yet

- Bolt Tensioning: This Document Is A Summary Of..Document12 pagesBolt Tensioning: This Document Is A Summary Of..Hari Kumar D.No ratings yet

- Bolt Preload CalculationDocument3 pagesBolt Preload Calculationmihai90No ratings yet

- Bolt Torq 0309Document3 pagesBolt Torq 0309jakkakiransNo ratings yet

- Analysis of Bolt TorquingDocument7 pagesAnalysis of Bolt TorquingAlessandro Serafini100% (1)

- Bolt Torque ChartDocument7 pagesBolt Torque ChartMarco BacianNo ratings yet

- Bolt Torquing AnalysisDocument7 pagesBolt Torquing AnalysisEleonor MaderazoNo ratings yet

- Connections For Steel Structures by John Mark (CISC - ICCA)Document32 pagesConnections For Steel Structures by John Mark (CISC - ICCA)prabhu81100% (2)

- Arabic Language - Easy Arabic GrammarDocument156 pagesArabic Language - Easy Arabic Grammardvfilmspk100% (1)

- The Enigma Unlawful Men Book 2 by Malpas JodiDocument402 pagesThe Enigma Unlawful Men Book 2 by Malpas JodibgkxgvmzcrNo ratings yet

- Rules and Guidelines - GSD Musabaka 2017Document4 pagesRules and Guidelines - GSD Musabaka 2017Anas AsifNo ratings yet

- Advent RisingDocument16 pagesAdvent RisingKleets123No ratings yet

- 8765 Butlerdidi Script SampleDocument18 pages8765 Butlerdidi Script SampleAnnette kuklaNo ratings yet

- Group 1 Vrts 111 Truth Vs False ActivityDocument7 pagesGroup 1 Vrts 111 Truth Vs False ActivityDane Yron VIcenteNo ratings yet

- An Account of The Manner of Inoculating For The Small Pox in The East IndiesDocument34 pagesAn Account of The Manner of Inoculating For The Small Pox in The East IndieskkNo ratings yet

- Mostro - Special K - Unlimited LicenseDocument6 pagesMostro - Special K - Unlimited Licenseswagydevil0786No ratings yet

- C595Document6 pagesC595Duyanh NguyenNo ratings yet

- Downloading Hobbii - PagijgyDocument8 pagesDownloading Hobbii - PagijgyAxialexandrinaNo ratings yet

- US7525004 New EditedDocument11 pagesUS7525004 New EditedFahreza HidayatullahNo ratings yet

- DAHOOD 1974-Hol 'Phoenix' in Job 29,18 and in UgariticDocument5 pagesDAHOOD 1974-Hol 'Phoenix' in Job 29,18 and in UgariticCharles-Antoine FogielmanNo ratings yet

- Run Length Encoding and DecodingDocument3 pagesRun Length Encoding and DecodingDaniel SimanjuntakNo ratings yet

- The Value House, A Corporation v. Phillips Mercantile Company, D/B/A Value House, 523 F.2d 424, 10th Cir. (1975)Document12 pagesThe Value House, A Corporation v. Phillips Mercantile Company, D/B/A Value House, 523 F.2d 424, 10th Cir. (1975)Scribd Government DocsNo ratings yet

- (2012) 12 SCC 581 PDFDocument19 pages(2012) 12 SCC 581 PDFRadha SundarNo ratings yet

- Biomerieux Bact-Alert 3D-60 - User ManualDocument254 pagesBiomerieux Bact-Alert 3D-60 - User ManualVinsmoke SanjiNo ratings yet

- Datafly Commerce v. WellaX Gear - ComplaintDocument20 pagesDatafly Commerce v. WellaX Gear - ComplaintSarah BursteinNo ratings yet

- Grade 8 Laws of Indices WorksheetDocument2 pagesGrade 8 Laws of Indices WorksheetLatona Oladipupo OlawaleNo ratings yet

- Nadoa 2017 Ejournal PDFDocument979 pagesNadoa 2017 Ejournal PDFMathew LoveNo ratings yet

- Micronpiles Brochure Draft 2-1Document2 pagesMicronpiles Brochure Draft 2-1Hi kosokoNo ratings yet

- Astm A455 A455m-90 (1996)Document2 pagesAstm A455 A455m-90 (1996)FeteneNo ratings yet

- HSK Flashcards 6 1Document64 pagesHSK Flashcards 6 1Fredy NandaNo ratings yet

- (Download pdf) Practice Makes Perfect Basic French Premium Third Edition Kurbegov full chapter pdf docxDocument69 pages(Download pdf) Practice Makes Perfect Basic French Premium Third Edition Kurbegov full chapter pdf docxmirvilodiles100% (5)

- 38wknm18 Week38 2018 PDFDocument121 pages38wknm18 Week38 2018 PDFAnand HemnathNo ratings yet

- Big Data ManagementDocument21 pagesBig Data ManagementThatapudi ThomasNo ratings yet