Professional Documents

Culture Documents

Patent

Uploaded by

toxicwind0 ratings0% found this document useful (0 votes)

11 views10 pagesPatent

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPatent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views10 pagesPatent

Uploaded by

toxicwindPatent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

2) United States Patent

Wiebe et al.

(54) SYSTEM TO HARVEST ENERGY IN A

WELLBORE

(71) Applicant: Focus Tools Colorado, LLC, Deaver

cows)

(72) Inveators: Durey L, Wiebe, Denver, CO (

Rene M. Rey, Denver, CO (U

)

Focus Tools Colorado, LLC, Denver,

cows)

(73) Assignee:

(4) Notice: Subject to any disclaimer, the term of this

patent is extended ot adjusted under 35

USC. 154(b) by O days

(21) Appl. Nos 14494463

(22) Filed: Sep. 23,2014

(1) Inc

E21B 7724 (2006.01)

Ho2N 218 (2006.01)

E21B 41/00 (2006.01)

(32)

1 41/0085 (2013.01)

175/56, 175/93; 175/105; 310/339

tion Search

175/56, 93, 106: 101339, 319

See pplication ile far complete search history.

68)

S008925649B1

US 8,925,649 B1

jan. 6, 2015

U

(10) Patent No.

4s) Date of Patent:

66) References Cited

US. PATENT DOCUMENTS

SOME A * 811999 Olney ctl sm

yom B2* 7201 Wang eal Sina

Sat0.s67 B2* 43013 Rasteparet a 3101339

SSott7e B2* 102013 Havetal 310339

2ons003tias ALS '2200) Garcia-Oauna 15340

* cited by examiner

Primary Examiner — Kenneth [Thompson

Assistant. Wei Wang

(74) Attorney, Agent, o Firm

Wendy Buskop

Buskop Law Group, PC:

on ABSTRACT

A systemo harvest mechanical energy ina wellbore, wherein

‘the mechanical energy comes from motion. The system ses

‘mechanical energy coming from at lest one of: motion of @

Grill bit, motion of a drill sting, motion of Mowing air or

rilling md down the dil string tothe drill bit and up an

‘annulis between the dil string and he wellbore. motion ofa

bottom hole assembly connected tothe dil string. The sys-

tem can include a plurality of piezoelectric stand bundles,

‘wherein cach individual piezoelectric strand ean vibrate as

the pressure hosing moves inthe wellhore, thereby prone

ing electricity

15 Claims, § Drawing Sheets

U.S. Patent Jan. 6, 2015 Sheet 1 of 5 US 8,925,649 B1

102 | Hoan TE {DRILLING MUD ‘ FIGURE 1

103a

i

2

I

Le

ye

a

U.S. Patent Jan. 6, 2015 Sheet 2 of 5 US 8,925,649 B1

FIGURE 2

US 8,925,649 BL

Sheet 3 of 5

Jan. 6, 2015

U.S, Patent

eze

o—s—_

HOLIOVAY BAY |

apt 31800 duAloLos73| | Taosnas

‘SUN IWHadINL HOIH BOVLIOA i t

epp“L U9 SOVEOIS DUANE | gay

: wossz00ud =F #8

98

Eresirceuy ee) | STE

gee| HILHIANOD

SUNLMEANL HOH | ~[B0¥LI0A a7 Haven

gop" 30IN30 30VUOLS ADHANE 0s

AINDYID

pee SNINOLLIGNOD H3MOd

WOLIOVAYO BAAYT i

ep! F18NOd QUAIOWL III YOSN3S

SUNLVHSdINSL HOIH JOVIIOA, aig

gp JIAO SOVEOIS AOWANA ais

ae

€Fungld

US 8,925,649 BL

Sheet 4 of 5

Jan. 6, 2015

U.S, Patent

288

8s

ania

‘snoynanad 341 Wows SONVHLS 9181071307314

GNIS D1gL93190¢aid FHL 40 SHOW HO 3NO

41 3NINU3L30 01 S35¥L10A NMON 40 ALITY Id

3HL O1 119419 SNINOLIONOS YaMOd 3H OL,

S300WL912 40 ALMVHMTd 3H Ad CaLLivuSNeL

S39¥LIOA aevdN09 OL SNOUIAYISNI B3LNaNO9|

iL ‘S3OVIIOA NMIOND

‘SNOLIVOIsIO3dS NIHLIM ONIIVeAdO TeV $3010

SOVYOLS AHANS HL al ANINUSL0 OL SANA

NLvHAI¥9 40 ALrveflid 3HL OL ST¥NOIS 39vLI0A|

SHI 3dvaINOO O1 SNOLONUISNI ¥3LNAIOD

SaTTTVA NOUWUSNVD

SUT 39VUO1S ADURN

0vSS3IN V AOIAOYG O1 SNOMOMLLSNI UALNAIIOD

FOUN30_INANO ONY AMTASIO 3HL 40 3N0 ISvaT IY.

jy NO dolAad 29 vHO1S AgHNa Hv 40 GOVLION HOV

LAW 1dSI GN OLINOW Ol SNOLINULSNI WaLNdMIO9|

SLUT 3OVUOLS ADURNG

OvUOLS VIVO 30vsuNS

1W0SS300Ud JOVIUNS

—— eee

OvSSaN

‘AMASIO

WSLS HIWSH 3OWNOA IOVIUTS

£9

a9

ee

969

v JuNdld

U.S. Patent Jan. 6, 2015 Sheet 5 of 5 US 8,925,649 B1

US 8,925,649 BI

1

SYSTEM TO HARVEST ENERGY INA.

WELLBORE

FIELD

‘The present embodiments generally relate to a system to

harvest energy ina wellbore containing adil string ompris-

ing interconnected tubulars

BACKGROUND

Power foruse in a downhole environment has generally in

the past been either stored in a battery and conveyed down-

holeorthe power as been transmitted va conductors. sacha

wireline, from the space or another remote location Batter-

Jeshave the capability of storing only afiniteamountof poser

therein and have environmental limits, such as temperanre,

‘on thei use,

Electrical conductors, suchasthoseina conventional wire

Tine, provide a practically unlimited amount of power, but

rexire special facilities tthe surface for deployment. These

‘ales typically block the production low path (ie, Himit

ing the flow rate of fds through the flow path) while the

‘conductors are inthe flow path. Thus, wireline operations are

‘ypicallyearied out prior othe production phase ofa well or

«during remedial operations after the well hasbeen placed into

producto

Inwellbore dilling operations, oe or moreeflicient power

sources are desirable to power dexenhole instrumentation. A

‘wide variety of devices can se mechanical energy inorder to

perform work downhole. Those devices may be subject t0 @

‘variety of forces and can release energy ina number of ways.

"A nced exists fora system of harvesting mechanical energy

‘downhole and generating electrical power therefrom. A need,

‘exists fora system to harvest energy ina wellbore containing

‘adil string

“The present embodiments mut these needs

BRIEF DESCRIPTION OF THE DRAWINGS.

“The detailed description will be beter understood in con-

junction withthe accompanying drawings as follows

FIG. 1 depict a dil string ina wellbore sccording one oF

more embodiments.

FIG, 2 depicts a cross sectional view of the portion ofthe

system that harvests mechanical motion from movement

While drilling acconting one or more embodiment.

FIG. 3 depicis a block diagram of the electrical system

acconting one or more embodiments

TIG. 4 depicts diggram ofa surface voltage health meter

usable at the surface and outside of the wellbore according

‘one oF more embodiments,

FIG. 5 depicts. piezoelectric stand bundle witha plurality

‘of piesoelectrc strands according one or more embodiments

The preseat embodiments ae detailed below with refer.

‘ence tothe listed Figures.

DETAILED DESCRIPTION OF THE

EMBODIMENTS.

Before explaining the present system in detail, it is to be

understood thatthe system is not limited to the particular

‘embodiments and that it ean be practiced of carried out in

various ways,

“The present cibodiments relate to systems to harvest

energy in a wellbore containing a drill string using an

0

o

2

enclosed waterproof hermetic pressure housing, connected

between drilling collar and a universal bottom hole orien-

‘ation (UBHO) sub assembly

"The pressure hosing ean be adapted to sustain an extemal

pressure of at Jest 20,000 ps and maintain an internal pres-

Se of about I stm. The pressure housing ca he an enclosed

Waterproof hermetie pressure housing.

‘The internal chamber ofthe pressure housing can contain

pendulous member. One or more piezeectre strand bundles

‘an cach be secured to the pendslous member These piezo-

clecizc stand bundles can vibrate and produce elececiy as

thepressure housing moves in the wellboreas wcomponest of

she drill sting,

letredes can be connected to the piezoeletric strand

bunes and receive electricity prodvced from the piezoelee-

‘we stand bundles, Each electzade can flow poster from the

piezoelectric strand bundles to 2 power conditioning cecuit

"A power conditioning circuit is wed to normalize the eloc-

tricity eevived by the electrodes to within predetermined

range. This power conditioning cicuit can be eleccically

‘snneeted tone oF more energy stomige devices

‘The energy storage deviees ean be connected in series and

cccve the power fom the power conditioning circuit within

1 predetermined range. Fach energy storage device can eon-

‘ain a high temperature electrofytic double layer capacitor.

Fach high temperature electrolytic double layer eapacitorcan

be adapted 10 susisin operating temperatures from ~40

degrees Celsius to 300 degrees Celsius without damage,

thereby forming a magnet fre system for harvesting eletric™

ity while operating ina wellbore,

‘A benefit of the present cinbodimentsis tht the power is

produced on site, thereby bypassing the transportation

Frictions of fuel cells and lithium batteries. Further, the

present embodiments provide power during quiet times of the

bottom hole assembly

A benefit of the present embodiments is that no liduium

‘batteries, which can explode, are needed. Lithium batteries

can case Inge fies at a dil site, oF another work over

Tction, and the present embodiments prevent sch explo-

sions, Futher, when the tool is being tested, there is no

possibility of explosion bya ithium hater. asthe tool has

Tihium battery

‘A benefit othe present embodiments is that itis usable for

‘operating messure-while-dlling equipment while deillingin

‘wellbore.

A benefit of the present embodiments is that it prevents

eat ata del site by enabling fewer trips out of the hole

thereby creating a safer environment for field hands at dil

site. A benefit of the present embodiments s that it prevents

broken bones and other serious injuries by avoiding explo-

‘The embodied systems are directed at harvesting energy’ in.

wellbore, A pressure housing, iypically waterproot and

hermetically senfed, can be eonnected between a drilling col-

Jar and a sub assembly. Within the internal chamber of the

pressure housing, « pendulows member ean be anchored. The

pendulous member can swing ina pendulum motion as the

pressure housing moves inthe wellbore.

Dezoeletric strand bundles, which can be comprised of

individual piezoclectric strands of various lengths, ean be

secured tothe pendulous member by an anchor. The piezo-

cleciric strand bundles can swing frely in parallel with the

pendulous member. The individual piezoelectric strands can

vibrate as the pressure housing moves in the wellbore,

thereby producing electricity. The electricity can low to elec”

trodes galvanically connccted to the pieroelectric strand

bundles and then to enemy storage devices.

US 8,925,649 BI

3

The systems ean include a power conditioning circuit con

nected between the electrodes and the eneray storage devices.

The power conditioning circuit normalizes electricity from

the electrodes and provides a voltage to the energy slonage

‘device within predetermined range. A buck boos! converter

‘can beaded o accept a ringe af input voltage levels less than

8 preset range and more than a preset range, and provide &

voltage output within a predetermined output voltage range.

“Turning now tothe Figures, FIG. I depietsa drill string Sin

wellbore 100 accordingly fo one or more embodiments

“The drill string S canbe made up ofinterconnected tubulars

1037 aod 103 In embodiments, the del string canbe from

fw feet to several miles in length

‘A pressure housing 10 can be located within « deiling

collar 12 and secured toa sib assembly 13 of a bottom hole

assembly 6. The bottom hole assembly 6 can be connected 10

the drill string § proximate the drill bit 1. The sub assembly

‘ean be a universal bottom hole orientation (UBHO) sub

assembly.

TInembodiments the pressure housing can be from 2 feet 10

6.5 feet. The pressure housing ean havea diameter from 1 87S

‘inches to slightly less than the diameter ofthe tubulars used

{or the drill string. The pressure housing ean be made from

‘copper beryllium, such as TOUGHMET™, a copper alloy

made by Materion of Michigan and Ilinois. The pressure

housing ean be comprised of any suitable non-magnetic

material. In embodiments, the pressure housing can have &

‘coating disposed on the outside. The pressure howsing 10,

‘which ean be waterproof and hermetically sealed, can Be

adapted to sustain external pressures of at least 20,000 psi

‘hile simultaneously maintaining an intemal chamber pres

sure of around I stmosphere (atm) ar ancter normal stmo-

spheric pressure.

The dail string § can rotate and have @ motion 2 of a dill

string, Air3 can low into the dell ting. Their can bean

sirand foam mixture used for air drilling. Diling mud 4 ean

also flow into the drill ting §. The air and the drilling mud,

‘can flow down the connccted tbls to adil it 1 and up ac

‘annulus 102 between the drill string Sand the wellbore 100,

TIG. 2 depicts a cross sectional view of the portion ofthe

system that havests the mechanical motion from movement

‘while drilling acconlingly to one or more embodiments

“The stem harvests themechsical energy coming from at

least one of a motion ofa dail bit, a motion ofa dri sting, @

‘mation of flowing air or driling mud dawn the dil string to

the dail bitand up an annulus between the del string and the

‘wellbore, and a motion of bottom hole assembly connected

to the drill sting

The pressure housing 10 ean have an internal chamber 1.

‘he pressure housing 10 can be inside a drilling collar 12

and connected 1 a sub assembly. In embodiments the pres-

‘ure housing ean connest Io a bulkbead 18 which attaches to

the sub assembly 13.

TInembodiments, the pressure housing 10 can havea diam-

‘eter fom 20 percent to 95 percent less than 3 diameter ofthe

‘it voltage signals tothe power conditioning eirui.

'5, The system of claim 1, further comprising. surface

voltage health meter comprising a surface processor con-

nected 10-2 strface data storage, wherein the surface data

storage comprises:

a. preset energy storage limits;

', computer instnictions to insiruet the processor io moni

{orand display each voltage of the atleast one energy

Storage device on a least one of at least one display, at

Teast one cient device, or the at leastone display and the

atleast one cleat devioe: and

«-computeriastructions to jnstructthe processor‘o provide

‘a message to at east one ofthe a least one display the

at least one client device, or both theat least one display

‘and the at least oneclieat device when the energy storage

ddovioe exceeds one of the preset energy storage limit.

8

6. The system of claim §, wherein the surface voltage

Dealth meter i in communication with 9 network and with a

splay ofthe at last one client device, providing a message

to the display of the at least one client device through the

ework,

7. The system of claim 5, wherein the surface data storage

comprises a plurality of calibration values for the energy

storage device and computer instrections to instruct the sur-

face processor to compare the voltage signal othe plurality

‘ofealibraton values to determine if the energy storage device

is operating within specifications

8. The system of claim §, wherein the surface data storage

comprises:

a plurality of known voltages foreach ofthe piezoelec-

tee strands and

+. compute instructions to instruct the surface processor to

‘compare Voliages irasenitted by the plurality of elee-

‘rods toa power conditioning circuit to the plurality of

[known voltages to determine ifone or more ofthe piezo-

the pendulous member, and

to increase the evellcient of transfer of energy from

‘cach of the piezoelectric strands to the plurality of

‘lecirades,

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Experimental EconophysicsDocument204 pagesExperimental Econophysicstoxicwind100% (1)

- Crimbonade Spading LIVES!Document72 pagesCrimbonade Spading LIVES!toxicwindNo ratings yet

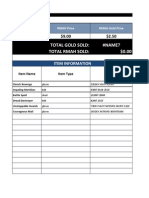

- Profit Tracking: Total Gold Sold: Total Rmah Sold: Item InformationDocument206 pagesProfit Tracking: Total Gold Sold: Total Rmah Sold: Item InformationtoxicwindNo ratings yet

- Quick Calculator: Item InformationDocument204 pagesQuick Calculator: Item InformationtoxicwindNo ratings yet

- Quick Calculator: Total Gold Sold: Total Rmah Sold: Item InformationDocument204 pagesQuick Calculator: Total Gold Sold: Total Rmah Sold: Item InformationtoxicwindNo ratings yet

- Discourse Community EssayDocument5 pagesDiscourse Community EssaytoxicwindNo ratings yet

- GW2-Xpadder-Reference GuideDocument3 pagesGW2-Xpadder-Reference GuidetoxicwindNo ratings yet

- Quick Calculator: Item InformationDocument138 pagesQuick Calculator: Item InformationtoxicwindNo ratings yet

- Quick Calculator: Item Information GoldDocument138 pagesQuick Calculator: Item Information GoldtoxicwindNo ratings yet

- Quick Calculator: Item InformationDocument170 pagesQuick Calculator: Item InformationtoxicwindNo ratings yet

- International Glass Art Retail DirectoryDocument82 pagesInternational Glass Art Retail DirectorytoxicwindNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)