Professional Documents

Culture Documents

ULC Z 805 W Columns

Uploaded by

TPOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ULC Z 805 W Columns

Uploaded by

TPCopyright:

Available Formats

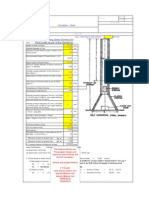

ULC Design No.

Z805

March 23, 2004

Rating - See Table Below

Steel Building Column - W150x22, Minimum Size

1(a). Spray-Applied Fire-Resistive Material - (Guide No. 40 U18.6). Applied to column surfaces to

thickness as shown in Table. Minimum average dry density of 165 kg/m3 with no individual value

less than 148 kg/m 3. For method of density determination, refer to General Information Section

under heading "Fire Resistance Ratings". Steel surfaces must be clean and free of dirt, loose

scale and oily deposits.

A/D FIRE PROTECTION SYSTEMS INC

Rating, h

Min Required Thickness of

Spray-Applied Fire-Resistive Material, mm

32

1-1/2

41

46

59

72

Page 1 of 2

ULC Design Z805 continued

Alternatively, the required thickness may be determined by the equation:

T/PV = 0.215 (M/D) + 7.25

or

t=

Tx1000

dx{0.215(M/D)+7.25}

Where:

t = required thickness, mm (Equation applicable for calculated thickness not greater than

127 mm.)

T = rating period, minutes (240 minutes maximum)

PV = protection values, kg/m2

M = mass of column section, kg/m with M/D > 24.4

d = density, kg/m3 (125 kg/m3 < d < 285 kg/m3)

Thickness should not be reduced below the lesser of 13 mm or the thickness indicated in

the particular design. Surfaces may be oversprayed with "TC-55 Sealer" per design

requirements.

OR

1(b). Spray-Applied Fire-Resistive Material - (see table below) - (Guide No. 40 U18.6). A/D "Type 5"

spray-applied fire-resistive material for application to steel surfaces in thicknesses indicated in the

following table. Mixture to have a minimum average dry density of 272 kg/m3 with minimum

individual density measurements no less than 248 kg/m 3. For method of density measurements,

refer to General Information Section under heading "Fire Resistance Ratings". Steel surfaces

must be clean and free of dirt, loose scale and oily deposits.

A/D FIRE PROTECTION SYSTEMS INC

Rating, h

Min Required Thickness, mm

32

1-1/2

41

46

59

72

You might also like

- Api 5l PDFDocument2 pagesApi 5l PDFtomj9104No ratings yet

- API 650 10th Edition ErrataDocument6 pagesAPI 650 10th Edition ErrataJosé Ramón GutierrezNo ratings yet

- Agenda Item: 650-569: Title: Shell Design VDP Method, Variable Corrosion Date: ContactDocument4 pagesAgenda Item: 650-569: Title: Shell Design VDP Method, Variable Corrosion Date: ContactMuhammad ChairulNo ratings yet

- 1.choosing Steel Sub GradeDocument7 pages1.choosing Steel Sub GradeFlorin MatisNo ratings yet

- Lecture 6 - Design of RC SlabsDocument21 pagesLecture 6 - Design of RC SlabsTuan Jalai100% (1)

- Beam design parameters and calculationsDocument33 pagesBeam design parameters and calculationsAudarya Chaitanya DasNo ratings yet

- ASME B31.4 Design Minimum Wall ThicknessDocument6 pagesASME B31.4 Design Minimum Wall ThicknessAlfredo BravoNo ratings yet

- Floating Floors InstallationDocument6 pagesFloating Floors Installationrt_belmonte5019No ratings yet

- CSSBI S2-2008:: Criteria For The Testing of Composite SlabsDocument4 pagesCSSBI S2-2008:: Criteria For The Testing of Composite SlabsPhablo GustavoNo ratings yet

- 2.CALENBERG Vibration Insulation Bearings Bi-Trapez Bearing enDocument12 pages2.CALENBERG Vibration Insulation Bearings Bi-Trapez Bearing enAlexandra SanduNo ratings yet

- Iso 10683Document7 pagesIso 10683Permeshwara Nand BhattNo ratings yet

- Section Design For Crack WidthDocument8 pagesSection Design For Crack WidthYou TubeNo ratings yet

- Pipeline Wall Thickness Calculation With Example (With PDFDocument21 pagesPipeline Wall Thickness Calculation With Example (With PDFALINo ratings yet

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaNo ratings yet

- Reduced Wear and Higher Corrosion Resistance by Combined Heat-Treatment and Coating Procedures Using Plasma-Assisted ProcessesDocument3 pagesReduced Wear and Higher Corrosion Resistance by Combined Heat-Treatment and Coating Procedures Using Plasma-Assisted Processesmp87_ingNo ratings yet

- Variable Design Point Method.Document56 pagesVariable Design Point Method.jwochNo ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Topdek 700 Concealed Clip RoofingDocument16 pagesTopdek 700 Concealed Clip RoofingctaciutNo ratings yet

- Evaluate strength classes of wood beams under uniform and concentrated loadsDocument10 pagesEvaluate strength classes of wood beams under uniform and concentrated loadsAma DavidescuNo ratings yet

- Ul BondingDocument2 pagesUl BondingMehman NasibovNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGARNo ratings yet

- Rectangular Splitter Attenuators Splitters: Type MSA100 and MSA200Document12 pagesRectangular Splitter Attenuators Splitters: Type MSA100 and MSA200Fabian RomeoNo ratings yet

- Strutural Design Data SNVDocument8 pagesStrutural Design Data SNVGoran VišnjarićNo ratings yet

- Accidental DamageDocument29 pagesAccidental Damagestan80No ratings yet

- Multideck 60-V2: - Concrete Volume SavingsDocument18 pagesMultideck 60-V2: - Concrete Volume Savingsdexterbox1No ratings yet

- MMA Cold PlasticDocument2 pagesMMA Cold PlasticjmasiglatNo ratings yet

- C660 - Estimation of Drying Shrinkage According To EN1992-1-1Document3 pagesC660 - Estimation of Drying Shrinkage According To EN1992-1-1Madhusudan MandalNo ratings yet

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Document12 pagesDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- Guide To ICBO Evaluation Reports For Monokote MK6Document8 pagesGuide To ICBO Evaluation Reports For Monokote MK6Eric SoNo ratings yet

- Requirements Concerning PIPES AND PRESSURE VESSELSDocument60 pagesRequirements Concerning PIPES AND PRESSURE VESSELSCostinRotaruNo ratings yet

- Astm C90Document7 pagesAstm C90Jairo MendezNo ratings yet

- PS 8956 NDocument7 pagesPS 8956 N林坤緯No ratings yet

- Din 2413-1Document13 pagesDin 2413-1A.ANo ratings yet

- LTA and Dryer Cylinders - Applying Mandatory Appendix 32Document2 pagesLTA and Dryer Cylinders - Applying Mandatory Appendix 32GTpianomanNo ratings yet

- Concrete Design To AS3600-2018Document8 pagesConcrete Design To AS3600-2018dongsheng100% (1)

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Method of Test ForDocument8 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Method of Test ForYago MendozaNo ratings yet

- Joint Venture Production C4TTM PanelsDocument12 pagesJoint Venture Production C4TTM PanelstrambolinaNo ratings yet

- Raised access floors technical solutionsDocument33 pagesRaised access floors technical solutionsGhenoiu PaulNo ratings yet

- International Codes and Standards for High-Pressure Vessel DesignDocument6 pagesInternational Codes and Standards for High-Pressure Vessel DesignkylenilsenNo ratings yet

- Impact Requirements For Low Temperature ApplicationsDocument3 pagesImpact Requirements For Low Temperature ApplicationsNguyen03No ratings yet

- Pressure Vessel Design ManualDocument6 pagesPressure Vessel Design ManualJasmine Eliza EspejoNo ratings yet

- RC Beam Design CCAA - Revised 1.2 JWWDocument12 pagesRC Beam Design CCAA - Revised 1.2 JWWFerdie TolosaNo ratings yet

- Designing A Cable TrayDocument20 pagesDesigning A Cable TrayTimothy LeonardNo ratings yet

- Slab Design CombinedDocument28 pagesSlab Design CombinedEr. Rajendra Acharaya0% (1)

- The Development of Dry Film Thickness Requirements For Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP801Document6 pagesThe Development of Dry Film Thickness Requirements For Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP801Samer BayatiNo ratings yet

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Climaver Plus R IngDocument4 pagesClimaver Plus R IngjosekinNo ratings yet

- IACS Req Pipes Pressure VesselDocument69 pagesIACS Req Pipes Pressure VesselFrancesco CauzNo ratings yet

- UNIT Dfty57Document8 pagesUNIT Dfty57JPDGLNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Design Development Quality Management Phase ChecklistDocument8 pagesDesign Development Quality Management Phase ChecklistWunNaNo ratings yet

- Material Lift SpecificationsDocument4 pagesMaterial Lift SpecificationsTPNo ratings yet

- Sikafloor Morritex Self-Levelling Broadcast SystemDocument4 pagesSikafloor Morritex Self-Levelling Broadcast SystemTPNo ratings yet

- Tds CPD Sikalastic 621 TC UsDocument3 pagesTds CPD Sikalastic 621 TC UsTPNo ratings yet

- Design Development Quality Management Phase ChecklistDocument8 pagesDesign Development Quality Management Phase ChecklistWunNaNo ratings yet

- Lap Sealant: Experience The Carlisle DifferenceDocument2 pagesLap Sealant: Experience The Carlisle DifferenceTPNo ratings yet

- Acrylic ColourDocument9 pagesAcrylic Colouralmstick2076No ratings yet

- Design Development Quality Management Phase ChecklistDocument8 pagesDesign Development Quality Management Phase ChecklistWunNaNo ratings yet

- Wall Air Barrier To Roof Tie-In DetailDocument6 pagesWall Air Barrier To Roof Tie-In DetailTPNo ratings yet

- Storage and Control of Flammable and Combustible LiquidsDocument4 pagesStorage and Control of Flammable and Combustible Liquidskenoly123No ratings yet

- Sikafloor261sys1 PdsDocument4 pagesSikafloor261sys1 PdsTPNo ratings yet

- Gfa HandbookDocument132 pagesGfa HandbookCheng Gi NiNo ratings yet

- 811Document65 pages811TPNo ratings yet

- Two (2) YearsDocument18 pagesTwo (2) YearsTPNo ratings yet

- Two (2) YearsDocument18 pagesTwo (2) YearsTPNo ratings yet