Professional Documents

Culture Documents

Gold Tron

Uploaded by

JavierMamaniVelasquez0 ratings0% found this document useful (0 votes)

7 views2 pagesconcentrator

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentconcentrator

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesGold Tron

Uploaded by

JavierMamaniVelasquezconcentrator

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

GOLDTRON

What to do with all the concentrate is a constant

complaint at the minesite. Until now, no commercial system could

separate both the minus 200 mesh gold and nuggets at the same

time. Clean-up involved hours of tedious, time-consuming labor.

With the Goldtron, GOLDFIELD ENGINEERING introduces a single

machine which will process concentrates from jigs, sluices, and

other concentrators into clean gold. The Goldtron eliminates all

the tedious, time-consuming labor necessary with other final

clean-up devices by separating the minus 200 mesh gold as well as

nuggets in one continuous automatic process. The Goldtron is the

fastest, most efficient system that does not rely on chemicals or

amalgamation to separate your fine gold.

The Goldtron is an integrated system consisting of a

variable feed-rate hopper whose auger meters out the concentrates

in a steady disbursement onto a wet vibrating screen. The

double-deck screen sizes the gold into three size fractions. The

large material is automatically routed to a carpeted nugget trap.

The two remaining classified concentrates are diverted to

opposite sides of a highly specialized fiberglass table for final

separation. The table, constructed of steel and molded fiberglass, is designed for optimal fine gold recovery - which meets

or exceeds that of any other table on the market. Our tests show

gold recovery down to minus 400 mesh.

The Goldtron is a carefully engineered and quality

constructed piece of machinery. Every Goldtron is tested, tuned,

and adjusted in our lab before shipment. We are so confident

that no other product even approaches the Goldtron when it comes

to gold clean-up that we will refund your purchase in full if you

find a better machine on the market. We will be happy to show

you this amazing machine in action at our Lindon plant.

Reports from the GPAA Project in Nome, Alaska indicate that

the Goldtron, built by Goldfield Engineering, is a great success

and that it recovers micro fine gold particles quickly and

efficiently. The built-in screening and feeding system makes the

unit unique and easy to use.

Quoted from the Newsworthy column of the November 1989

issue of the GOLD PROSPECTOR magazine.

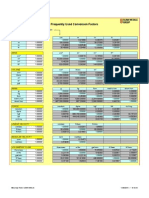

GOLDTRON SPECIFICATIONS

CAPACITY:

DIMENSIONS:

150 lbs. of concentrate per hour

Length

72"

Width

39"

Height

54"

TABLE DIMENSIONS:

52" long by 39" wide

WEIGHT:

450lbs

WATER REQUIREMENTS: 5 - 10 gallons per minute at 30 - 50 psi

POWER:

110/220 volts, single phase, 50/60 hertz

SCREENS:

Equipped with 16 and 35 mesh screens. Other

screens available

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Evalucación de Molino de BolasDocument26 pagesEvalucación de Molino de BolasCeferino Avalos EsquivelNo ratings yet

- Evalucación de Molino de BolasDocument26 pagesEvalucación de Molino de BolasCeferino Avalos EsquivelNo ratings yet

- Heavy-Medium: and Gravity Separation at Iscor's Tin-Ore and Iron-Ore MinesDocument7 pagesHeavy-Medium: and Gravity Separation at Iscor's Tin-Ore and Iron-Ore MinesJavierMamaniVelasquezNo ratings yet

- Dec OddsDocument113 pagesDec OddsRolando Flores IngalaNo ratings yet

- Introducción A Los JigsDocument13 pagesIntroducción A Los JigsPepirito GonzalesNo ratings yet

- Utilities Conv FactorsDocument4 pagesUtilities Conv FactorsJavierMamaniVelasquezNo ratings yet

- Gekko Hardware EmailDocument5 pagesGekko Hardware EmailJavierMamaniVelasquezNo ratings yet

- Duplex Jig BrochureDocument2 pagesDuplex Jig BrochureJavierMamaniVelasquezNo ratings yet

- Robin Grayson Gold Recovery Method14Document1 pageRobin Grayson Gold Recovery Method14JavierMamaniVelasquezNo ratings yet

- About ... Moly-Cop ToolsDocument4 pagesAbout ... Moly-Cop ToolssergiodiazsandivariNo ratings yet

- Savana Mining Pan-American Mineral JigDocument1 pageSavana Mining Pan-American Mineral JigWyattYeagerNo ratings yet

- About ... Moly-Cop ToolsDocument4 pagesAbout ... Moly-Cop ToolssergiodiazsandivariNo ratings yet

- Example 8: M C S: Problem DescriptionDocument12 pagesExample 8: M C S: Problem DescriptionZoebairNo ratings yet