Professional Documents

Culture Documents

CS Gate-20141222-122249871

Uploaded by

adilmkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS Gate-20141222-122249871

Uploaded by

adilmkCopyright:

Available Formats

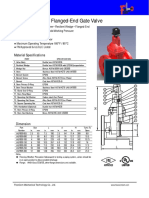

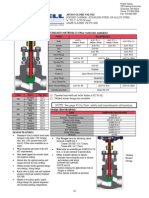

Cast Steel Gate Valve

16

MATERIAL

SL

No.

15

14

1.

19

L-CLOSED HEIGHT (APP)

13

12

11

18

10

9

8

CARBON STEEL

PART NAME

STAINLESS STEEL

WCB

BODY

CF8

ASTM A 216 Gr. WCB

2.

BODY SEAT

CS with 13% Cr. FACING

3.

WEDGE

ASTM A 216 Gr. WCB

4.

WEDGE SEAT

13% Cr. S.S. DEPOSIT

CF8

CF8M

CF8M

INTEGRAL

CF8

CF8M

INTEGRAL

5.

GASKET

SPIRAL WOUND AISI-304 / CAF

6.

BONNET

ASTM A 216 Gr. WCB

7.

BONNET BUSH

AISI-410

8.

GLAND PACKING

CF8

CF8M

INTEGRAL

BRAIDED GRAPHITE

TEFLON

WITH WIRE REINFORCE

IMPREGNATED

9.

GLAND BUSH

AISI-410

AISI-304

AISI-316

17

10.

GLAND FLANGE

CARBON STEEL

CF8

CF8M

11.

YOKE

ASTM A 216 Gr. WCB

CF8

CF8M

12.

STEM

AISI-410

AISI-304

AISI-316

NB

D

13.

YOKE SLEEVE

AL BRONZE / SG IRON / NI RESIST

14.

SLEEVE LOCK NUT

CARBON STEEL

15.

HAND WHEEL

CARBON STEEL / (FABRICATE) MI

AISI-316

16.

HAND WHEEL NUT

CARBON STEEL

17.

STUD

A 193 Gr. B7

A 193-B8 A193-B8M

NUTS

A 194 Gr. 2H

A 194-8

A 194-8M

18.

EYE BOLTS & NUTS

ASTM A 307 Gr. B / 2H

19.

GREASE NIPPLE

STEEL

STEEL

STEEL

2

1

AISI-304

Fig. 1

CLASS

TEST PRESSURE

HYDROSTATIC

150

300

600

AIR

SEAT &

BACK SEAT

BODY

2

32 Kg/cm

2

79 Kg/cm

158 Kg/cm2

DESIGN FEATURES :

MANUFACTURING STANDARD - API-600 / BS:1414 / API 6D

FACE TO FACE AS PER ANSI B16.10

ENDS - FLANGED & DRILLED AS PER ANSI B16.5 R.F.

BUTT-WELDING ENDS AS PER ANSI B16.25

CLASS 300 & ABOVE SHALL HAVE CIRCULAR BODY-BONNET FLANGE.

TESTING STANDARD : API -598 / BS 6755 PART I

ALSO AVAILABLE IN CAST ALLOY STEEL (Gr. WC 6 / WC 9)

& STAINLESS STEEL (Gr. CF 3 / CF 3 M)

GEAR OPERATED, ACTUATOR OPERATOR OPTIONAL

BY-PASS & BODY BLEED ARRANGEMENT OPTIONAL

22 Kg/cm

2

58 Kg/cm

116 Kg/cm2

SEAT

2

6 Kg/cm

2

6 Kg/cm

6 Kg/cm2

CLASS 150

SIZE 'NB'

1"/40

2"/50

2"/65

3"/80

4"/100

5"/125

6"/150

8"/200

10"/250

12"/300

14"/350

16"/400

18"/450

20"/500

24"/600

A

165

178

190.5

203

229

254

267

292

330

356

381

406.5

432

457

508

D

125

150

180

190

230

255

280

345

405

485

535

595

635

700

815

CLASS 300

T

14.7

16.3

17.9

19.5

24.3

24.3

25.9

29.0

30.6

32.2

35.4

37.0

40.1

43.3

48.1

L

330

360

415

425

510

595

685

770

940

1030

1270

1450

1600

1810

2170

A

190.5

216

241.5

282.5

305

381

403.5

419

457

502

762

838.5

914.5

991

1143

D

155

165

190

210

255

280

320

380

445

520

585

650

710

775

915

FOR END FLANGE DETAILS REFER PAGE NO. 30 & 31

T

21.1

22.7

25.9

29.0

32.2

35.4

37.0

41.7

48.1

51.3

54.4

57.6

60.8

64.0

70.3

CLASS 600

L

390

370

440

445

520

570

740

910

1100

1200

1415

1540

1670

1910

GOP

A

241.5

292

330

356

432

508

559

660.5

787.5

838.5

889

991

1092

1194

1397

D

155

165

190

210

275

330

355

420

510

560

605

685

745

815

940

T

28.6

32.4

35.6

38.8

45.1

51.5

54.7

62.6

70.5

73.7

76.9

83.2

89.6

95.9

108.6

L

380

445

475

490

615

765

840

950

1290

GOP

GOP

GOP

GOP

GOP

GOP

You might also like

- Bellow Gate ValvesDocument1 pageBellow Gate ValvesmotalebyNo ratings yet

- FMC GGCDocument8 pagesFMC GGCsheshidharrajubNo ratings yet

- Flowcom - Bridada y BridadaDocument1 pageFlowcom - Bridada y BridadaErickNo ratings yet

- Gate Valve 150Document2 pagesGate Valve 150Masih BelajarNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- How To Order Alfa ValveDocument0 pagesHow To Order Alfa ValveZoebairNo ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12.1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12.1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Jorge ValenciaNo ratings yet

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocument20 pagesBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNo ratings yet

- IFRVT1Document2 pagesIFRVT1Shilpa SinghNo ratings yet

- Air Release Valve - Double FloatDocument1 pageAir Release Valve - Double FloatNikhil RajanNo ratings yet

- Lug & W Afer Style Butter Fly V AlvesDocument4 pagesLug & W Afer Style Butter Fly V AlvesMalissa ClarkNo ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)kasoseiNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Flowcom - Ranurada y RanuradaDocument1 pageFlowcom - Ranurada y RanuradaErickNo ratings yet

- FSV01Document22 pagesFSV01shiva_ssk17No ratings yet

- Flowcom - NRS - BridadaDocument1 pageFlowcom - NRS - BridadaErickNo ratings yet

- Materials List: Bronze Ball Valve Two-Piece, Full-Port 600 Psig Wog / 150 Psig SWP Threaded EndsDocument1 pageMaterials List: Bronze Ball Valve Two-Piece, Full-Port 600 Psig Wog / 150 Psig SWP Threaded Endsa100acomNo ratings yet

- JC-FIG. 800 Series Rev 3 ForgedDocument4 pagesJC-FIG. 800 Series Rev 3 ForgedindikumaNo ratings yet

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- 4-6 Balon Ball ValvesDocument2 pages4-6 Balon Ball ValvesSam WeberNo ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- 150-600 Gate ValveDocument4 pages150-600 Gate ValveSaquib NishatNo ratings yet

- Globe Valve-Bolted BonnetDocument3 pagesGlobe Valve-Bolted Bonnetxaaabbb_550464353No ratings yet

- Ball Valve 150 - GODocument1 pageBall Valve 150 - GOJohnNo ratings yet

- Valvula de Tres ViasDocument1 pageValvula de Tres Viasjhoger2012No ratings yet

- Bill of Material: Amco Industrial ValvesDocument1 pageBill of Material: Amco Industrial ValvesFrancis NelsonNo ratings yet

- Rex BF-Series Ball Float Steam Traps BFH-10 25NB Drg. No. RSP-GTD-BFH-10!25!002Document1 pageRex BF-Series Ball Float Steam Traps BFH-10 25NB Drg. No. RSP-GTD-BFH-10!25!002cnaren67No ratings yet

- Powell Gate ValvesDocument3 pagesPowell Gate Valveszguy360No ratings yet

- 13.date Sheet For Gate ValveDocument2 pages13.date Sheet For Gate ValveMrinal Kanti BhaduriNo ratings yet

- Basket Strainer Bf150qrDocument1 pageBasket Strainer Bf150qrSantiago MenaNo ratings yet

- FSV03Document24 pagesFSV03elangopi89No ratings yet

- Bronze Valves PDFDocument10 pagesBronze Valves PDFashish_pradhan75No ratings yet

- Class 125 3% Nickel Iron Body Gate ValvesDocument1 pageClass 125 3% Nickel Iron Body Gate ValvesBureau VeritasNo ratings yet

- Valve Cast Steel Gate Globe PDFDocument58 pagesValve Cast Steel Gate Globe PDFjua666nNo ratings yet

- Firsa Catalog 2009Document53 pagesFirsa Catalog 2009alankar2050No ratings yet

- FCS BLV SC RB 800# 15 20Document1 pageFCS BLV SC RB 800# 15 20Francis NelsonNo ratings yet

- Outet: 6.25" X 3.8" (159mm X 98mm) Length X Width Item Description MaterialDocument4 pagesOutet: 6.25" X 3.8" (159mm X 98mm) Length X Width Item Description Materialraj@siri7567No ratings yet

- DI Bend FittingDocument16 pagesDI Bend Fittingewanz89No ratings yet

- 30.99.12.1624 Appendix3Document3 pages30.99.12.1624 Appendix3Mallela Sampath KumarNo ratings yet

- Inventory Item List (YARD)Document12 pagesInventory Item List (YARD)sirjamlesNo ratings yet

- Class 150 Ductile Iron Body Gate ValvesDocument1 pageClass 150 Ductile Iron Body Gate Valveshijitus_80No ratings yet

- Klinger Valve DetailsDocument2 pagesKlinger Valve DetailsDular PatelNo ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Glove Valve API 602Document1 pageGlove Valve API 602Tran NguyenNo ratings yet

- Valvula Globo Ang Nibco - 230614 - 100826Document2 pagesValvula Globo Ang Nibco - 230614 - 100826Pedro Jose Garces AlarconNo ratings yet

- Kitz Gate ValveDocument28 pagesKitz Gate ValvemohamedfirozNo ratings yet

- Kit 11011Document28 pagesKit 11011Reza VakilNo ratings yet

- Contromatics Tri-Seal Quarter-Flex HP Butterfly ValvesDocument16 pagesContromatics Tri-Seal Quarter-Flex HP Butterfly ValvesFilipe Simoes OliveiraNo ratings yet

- Wafer Type Butterfly Valves SpecsDocument2 pagesWafer Type Butterfly Valves SpecsRavi Sankar VenkatesanNo ratings yet

- Literature Force Floating Ball Valve CatalogDocument16 pagesLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- 600.0 Temp Ambient Strength Design StrengthDocument2 pages600.0 Temp Ambient Strength Design StrengthBashu PoudelNo ratings yet

- Meridian Gate Globe CheckDocument4 pagesMeridian Gate Globe Checkkresimir.mikoc9765No ratings yet

- Bill of Materials 11: Valve ViewDocument1 pageBill of Materials 11: Valve ViewmarpadanNo ratings yet

- Api 602Document4 pagesApi 602kreyson77750% (2)

- Gate ValveDocument4 pagesGate ValveOwais AhmedNo ratings yet

- Filtro Tipo y BridadoDocument1 pageFiltro Tipo y BridadoPaulo MaresNo ratings yet

- 300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureDocument1 page300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureayaNo ratings yet

- Valtech Catalogue-1Document44 pagesValtech Catalogue-1Bashir AliNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Spiral Wound LadderDocument1 pageSpiral Wound LadderadilmkNo ratings yet

- Aero Academy FlightDocument35 pagesAero Academy FlightIssac BennyNo ratings yet

- CBSE Sample Papers Class 10 Maths SA II Solved 1Document16 pagesCBSE Sample Papers Class 10 Maths SA II Solved 1gyanpubNo ratings yet

- Pipe Dimensions Weights ChartDocument1 pagePipe Dimensions Weights ChartSaid Ahmed SalemNo ratings yet

- Method Work Statement Pipe Welding WorksDocument17 pagesMethod Work Statement Pipe Welding WorksSanjana AhujaNo ratings yet

- BSD-Steel Guide 2011 2Document112 pagesBSD-Steel Guide 2011 2Kiran Kumar K T0% (1)

- Ateco Catalog 2014 - R0-20141222-110334102Document32 pagesAteco Catalog 2014 - R0-20141222-110334102adilmkNo ratings yet

- Material List TihamaDocument2 pagesMaterial List TihamaadilmkNo ratings yet

- TNT 10-2Document12 pagesTNT 10-2Welkin SkyNo ratings yet

- No: Description Qty Price Amount: Total 4,488.00Document1 pageNo: Description Qty Price Amount: Total 4,488.00adilmkNo ratings yet

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- GB FarbtonfarbtonkDocument6 pagesGB FarbtonfarbtonkadilmkNo ratings yet