Professional Documents

Culture Documents

Hydrostatic Vs Pneumatic Test

Hydrostatic Vs Pneumatic Test

Uploaded by

Aitazaz Ahsan0 ratings0% found this document useful (0 votes)

8 views1 pageHydraulic Pressure Test

Original Title

Hydrostatic vs Pneumatic Test

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHydraulic Pressure Test

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageHydrostatic Vs Pneumatic Test

Hydrostatic Vs Pneumatic Test

Uploaded by

Aitazaz AhsanHydraulic Pressure Test

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

ae Mego Lat OG

ENGINEERING CASE HISTORIES )

an.

244

Case 34: Hydrotesting

or pneumatic testing?

"There is a big difference in safety between the two

T. SOFRONAS, Consulting Engineer, Houston, Texas

ally the vessel foundation has not been designed for a water

load or the process doesn't allow contamination with water.

Projece management's argument is thatthe vessel was designed for

4 gas pressure so a pneumatic test over pressurization, to verify the

soundness of the modification, shouldnt be a concern.

‘This analysis was done to help explain why vessels should be

fully hydrotcsted, localized hydrotested with blinds, or other

‘nondestructive inspection plans used, such as ultrasonic or X-ray

instead of a pneumatic test, when possible. The discussion has to

do with safety and the high energy involved when pneumatic pres-

sure testing. Hydrocesting has other advantages over pneumatic

testing, but these are not discussed here.

For simplicity, consider a pressurized pipe with an end cap.

‘The end cap can also be thought of as a vessel wall section that

breaks out and is acted on by the compressed water or gas pressure

within, Well examine a pipe pressured up to p = 150 Ib/in2, using

water and then compare this to it being pressured up with ait.

Fig, 1 shows a volume that is compressed 8 amount and can be

used to calculate the energy available.

First the pressurized water potential energy is calculated:

‘Compressbilcy of water can be presented as the bulk modulus or

B= Ap/AVIV, where B = 3.12 x 10° Ibvin2.

T: question comes up often during vessel modifications. Usu-

From Fig. 1, V=Ah, AV= AB pur

Baocer= AplB

‘Therefore, the potential energy of the waters:

PE. = APB caer

‘Next, using the ideal gas laws the potential energy of the com-

pressed energy of the ai is

Buy = Bll Pan! (PtP)

PE = AB,

In real-life terms, i is far more effective to show how fast and

how fara broken-out chunk will “ly” chrough the plant before it

lands, then to just say pneumatic testing is dangerous.

By equating potential cnergy to the kinetic energy we can

solve for the velocity and use this velocity ina trajectory caleula-

tion.! Units are inch, pound, second, ¢ = 386 in./sec? and for this

example W= 25 Ibs.

Condition Velosity,flsec Distance traveled, S ft,

from hivgne = 24

‘Water pressured 5 2

Air pressured 75, 76

Veg = (2gpAg)W), in.fsec

Hete @ = Bue for water and 8 i for ait

S= Vas (Deg i,

‘We see that the 25-pound fragment or end cap will just drop a

couple of feet from where it was attached when pressurized with

‘water. However, when pressurized with air it will eravel at 215

filsec (147 mph) until it comes to rest 76 fe away. Visions of a

25-pound projectile rocketing through a plant will usually receive

the decision makers’ attention.

‘Often pneumatic resting cannot be avoided. When this is

specified, safety and rigorous risk evaluations are required. Even

with such plans in place, all involved should be standing far away

and well protected during such testing.

BIBLIOGRAPHY

Solfonas, A Anaya! Toableonting

"a Word Cae Sa, Jon Wey

Pras Machinery and PsueVeele:Incuding

me tSBN. OE ISBIT PD

Tony Sofronas, PLE., is» consulting engineer located in

Houston, Texas. Dr. Soonas was lead mechanical engineer for

sonldcbil before his reiement. information on his books, sei=

fats and consulting are avaiable at http iva mechanicaleng

eernghelp com,

HYDROCAREON PROCESSING SEPTEMBER 2006 | 119

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- GAT Analytical ReasoningDocument272 pagesGAT Analytical ReasoningMuzaffar Iqbal90% (10)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ecat 2011Document5 pagesEcat 2011Aitazaz AhsanNo ratings yet

- Ecat 2014Document12 pagesEcat 2014Aitazaz AhsanNo ratings yet

- Ecat 2013 FinalDocument7 pagesEcat 2013 FinalAitazaz AhsanNo ratings yet

- 4 SimplificationDocument9 pages4 SimplificationsrinivasmicNo ratings yet

- 2Document6 pages2bestread67No ratings yet

- Profit Loss Problems SolutionsDocument7 pagesProfit Loss Problems SolutionsAitazaz AhsanNo ratings yet

- GAT 5th JanDocument22 pagesGAT 5th JanAitazaz Ahsan100% (2)

- Physics: © The PreceptorDocument10 pagesPhysics: © The PreceptorAitazaz AhsanNo ratings yet

- © The Preceptor: PhysicsDocument10 pages© The Preceptor: PhysicsAitazaz AhsanNo ratings yet

- Tips For ProbabilityDocument2 pagesTips For ProbabilityAitazaz AhsanNo ratings yet

- Clocks Problem SolutionsDocument16 pagesClocks Problem SolutionsAitazaz AhsanNo ratings yet

- Final Thesis, Solar Dish Engine System 1 Uet TaxilaDocument114 pagesFinal Thesis, Solar Dish Engine System 1 Uet TaxilaAitazaz Ahsan100% (6)

- Previous GAT QuestionsDocument8 pagesPrevious GAT QuestionsAhmad NaumanNo ratings yet

- NDocument14 pagesNAitazaz Ahsan100% (1)

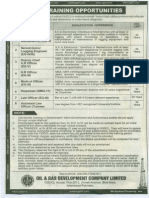

- Jobs at OGDCL Jan15Document1 pageJobs at OGDCL Jan15Aitazaz AhsanNo ratings yet

- Aberration: Frequently Used Vocabulary in GAT GeneralDocument10 pagesAberration: Frequently Used Vocabulary in GAT GeneralAitazaz Ahsan0% (1)

- P4 High Frequency WordsDocument86 pagesP4 High Frequency WordsAitazaz AhsanNo ratings yet

- SPC CR UR 510 3 (Important)Document35 pagesSPC CR UR 510 3 (Important)Aitazaz AhsanNo ratings yet

- FastenersDocument46 pagesFastenerser_lalitgargNo ratings yet

- Sample Paper Sse Paper PDocument8 pagesSample Paper Sse Paper PAitazaz AhsanNo ratings yet

- Semester II: Discipline: Information Technology Stream: IT1Document188 pagesSemester II: Discipline: Information Technology Stream: IT1Jassim RafeekNo ratings yet

- Geotechnical Engineering-I: BSC Civil Engineering - 4 SemesterDocument14 pagesGeotechnical Engineering-I: BSC Civil Engineering - 4 SemesterSudin PradhanNo ratings yet

- PTTT Intermediate Level Look InsideDocument37 pagesPTTT Intermediate Level Look InsideKhánh TrangNo ratings yet

- Human Resource Management 13Th Edition Gary Dessler Solutions Manual Full Chapter PDFDocument33 pagesHuman Resource Management 13Th Edition Gary Dessler Solutions Manual Full Chapter PDFumbarasanayab100% (10)

- Good GovernanceDocument15 pagesGood GovernanceilhamNo ratings yet

- Lossna-Board: Heat-Resistant Material SeriesDocument14 pagesLossna-Board: Heat-Resistant Material SeriesLord VarioNo ratings yet

- Practice Test 8 Math Level 2: Answer SheetDocument13 pagesPractice Test 8 Math Level 2: Answer SheetKai Chung TamNo ratings yet

- NUR 4837 Chapter 9 PowerPoint Ethical and Bioethical Issues in Nursing and Health CareChapter - 09Document42 pagesNUR 4837 Chapter 9 PowerPoint Ethical and Bioethical Issues in Nursing and Health CareChapter - 09Clarisse Suan100% (1)

- Bond (2013) - Implementation and Evolution of Eurocode 7Document12 pagesBond (2013) - Implementation and Evolution of Eurocode 7Andrew BondNo ratings yet

- Detalles de Un Termorreactor para Análisis de AguaDocument2 pagesDetalles de Un Termorreactor para Análisis de AguaDexi BadilloNo ratings yet

- Topic 1 AdditionDocument2 pagesTopic 1 AdditionAbbie WanyiiNo ratings yet

- 4th Summative Test Q1-11 WEEK 7&8Document5 pages4th Summative Test Q1-11 WEEK 7&8Lalaine De Guzman CanoNo ratings yet

- The Role of Syntax in Forensic LinguisticsDocument5 pagesThe Role of Syntax in Forensic LinguisticssarahmelgamilNo ratings yet

- Clack EI Programming ManualDocument16 pagesClack EI Programming ManualAndres GarciaNo ratings yet

- Seismic Design of Bridges South East Asia Part 1Document173 pagesSeismic Design of Bridges South East Asia Part 1Mike2322No ratings yet

- Organization of LifeDocument1 pageOrganization of LifeSiraj ShaikNo ratings yet

- Nature Based PlayDocument56 pagesNature Based PlayIdelma SicolinNo ratings yet

- Quantum: Etymology and DiscoveryDocument3 pagesQuantum: Etymology and DiscoveryDexterNo ratings yet

- PTG Conceptual FoundtnsDocument18 pagesPTG Conceptual FoundtnsGiulia AtanasiuNo ratings yet

- Quantities, Measurements, and VectorsDocument34 pagesQuantities, Measurements, and VectorsDiane RosarioNo ratings yet

- Course 3 Unit 1Document102 pagesCourse 3 Unit 1Sripriya KanigantiNo ratings yet

- TDS Fosroc Solvent 102 Saudi ArabiaDocument2 pagesTDS Fosroc Solvent 102 Saudi ArabiaShaikhRizwanNo ratings yet

- 1ST Term J1 MathematicsDocument49 pages1ST Term J1 MathematicsPeter Omovigho Dugbo100% (1)

- Moanassar,+4878 14648 1 LEDocument10 pagesMoanassar,+4878 14648 1 LEMichel M.No ratings yet

- Perdev q2 Module 29Document24 pagesPerdev q2 Module 29Dhusty Jane100% (1)

- AGU - IPoster Printed v8 FINAL Presented at ConferenceDocument16 pagesAGU - IPoster Printed v8 FINAL Presented at ConferenceLeopoldoNo ratings yet

- Abo Clinical Exam Study GuideDocument15 pagesAbo Clinical Exam Study GuidealrowdhidentalNo ratings yet

- Welding InspectionDocument139 pagesWelding Inspectionvanchai sapaNo ratings yet

- A Activated Carbon Vapor Filter ElementsDocument2 pagesA Activated Carbon Vapor Filter ElementsMohsenNo ratings yet

- A New Approach To Stability and Stabilization Analysis For Continuous Time Takagi Sugeno Fuzzy Systems With Time Delay TFS 2017 0269 R1 Two ColumnsDocument7 pagesA New Approach To Stability and Stabilization Analysis For Continuous Time Takagi Sugeno Fuzzy Systems With Time Delay TFS 2017 0269 R1 Two ColumnsSujacka RetnoNo ratings yet