Professional Documents

Culture Documents

AGIP STD - Valves Specification Sheet

Uploaded by

halim_kaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGIP STD - Valves Specification Sheet

Uploaded by

halim_kaCopyright:

Available Formats

AGIP

04039.PIP.MEC.SDS

INTERNAL NORMALIZATION

Revisions

PIPING PROJECT SPECIFICATION

SERVICE : NON CORROSIVE HYDROCARBONS - GLYCOL BLOW DOWN - VENTS - DRAINS (T > 120C)

Sheet

of

B 10

ITEM

300 # RF

125 Ra

MAT.

CODES - Design : ASME B 31.3

Dimensions : ASME B 16.5 / B 16.34

PIPING CLASS

20367.PIP.MEC.FUN

RED. S.O. FLG.S

15017

---

WELDS EXAMINATION

20377.PIP.MEC.FUN

DRIP RINGS

15011

A 105

MATERIALS (if not otherw.stated)

ASTM STANDARDS

SPECTACLE BLINDS

15038

A 105

T - C

150

P - bar

45,2

15039

A 105

200

43,8

----

----

AISI 316

250

41,7

----

----

300

37,8

----

----

350

375

37,0

36,5

-------

-------

14380 A 105 / 3000# SW

--

SPACERS & BLINDS

THDD FITTINGS

14381 A 105 / 3000# NPT (3)

--

TEMP. STRAINERS 15050-15007

NORMAL (from pipe)

14383 API 5L Gr.B / SMLS (3)

--

SWAGES (from pipe)

14382 API 5L Gr.B / SMLS (3)

NIPPLES

S.W. FITTINGS

THICKNESS

mm

PIPES

INCH

WALL THK.

mm

SCHEDULE

MATERIAL

FLANGES

14355

SOCKET WELD

14356

THREADED

14357

SLIP ON

14358

LAP JOINT

14359

BLIND

14360

STUD BOLTS & NUTS

14368

VALVES

14365

ON / OFF

15801

MANUAL CONTROL

15801

CHECK

15801

STSW

STSW

STEE

HEADER SIZE

DN"

1/2" 3/4"

1"

1"

2"

2"

3"

4"

6"

8"

10" 12"

14"

3,73 3,91 4,55 5,08 3,91 5,16 5,49 6,02 7,11 8,18 7,80 8,38

80

80

80

80

40

40

40

40

40

40

30

16" 18" 20" 24" 30" 36"

9,52 11,13 11,13 12,70 14,27

30

30

P - bar

----

---

30

30

30

---

---

---

---

A 105 / 600# RF 125 Ra

A 105 / 300# - RF125 Ra

A 105 / 600# RF 125 Ra

32 C 28

A 193 Gr.B7 / A 194 Gr.2H (ZINC COATING) (1)

VS 113 AG A01 - RF 125 Ra

VS 235 AG E24 - SW

VS 115 AG B25 - RF125 Ra

VD 435 AG 7R1 - SW

VD 313 AG A01 - RF 125 Ra

VDR 713 AG 6C1 - RF 125 Ra (WAFER)

VDR 835 AG 3R1 - SW

VS 235 AG E24 - NPT (3)

STSW

4,78 5,56 6,35 7,14 8,74

T - C

----

SMLS

A 105 / 300# - RF125 Ra

FT 935 AG 5R1 - SW

15701

STSW

RTSW

DESIGN CONDITIONS

API 5L Gr.B

GASKETS

14350

WELDING NECK

3/4

FT 913 AG 2C4 - RF 125 Ra

90-45 ELBOWS

14370

CONC.REDUCTIONS

14372

A 234 Gr.WPB

A 234 Gr.WPB

ECC.REDUCTIONS

14372

A 234 Gr.WPB

ELLIPT.CAPS

14374

A 234 Gr.WPB

LJ STUB ENDS

14375

PIPE BENDS

15023

METER ELBWS

STEE

15020

15021

STEE

Mark

STEE

INTERSECTIONS

STEE

10

STEE

12

SLET

NLET

14

SWLT

RTEE

STEE

Components

Material

STEE STRAIGHT BW TEE

14371

A 234 Gr.WPB

RTEE REDUCTION BW TEE

14371

A 234 Gr.WPB

STSC STRAIGHT THDD TEE

14381

RTSC REDUCTION THDD TEE

14381

STSW STRAIGHT SW TEE

14380

A 105

RTSW REDUCTION SW TEE

14380

A 105

SWLT SWEEPOLETS

15003

A 105

WLET WELDOLETS

15004

30

TLET THREDOLETS

14381

36

SLET SOCKOLETS

14380

A 105

NLET NIPOLETS THDD

14381

A 105

PTOP PIPE TO PIPE

15012

STEE

16

STEE

18

STEE

20

24

STEE

STEE

1/2 3/4 1 1 2

1 mm

A 105

1/2

F

G

CORR.ALLOWANCE

15016

SPECIAL USE

0

0

2

Date

RED. THDD FLG.S

" Y " STRAINERS

T

U

B

20368.PIP.MEC.FUN

MANIFACTURE

M

E

C

WELDING AND HEAT TREATMENT

NOMINAL SIZE

M

O

D

COMPONENTS

06--97

Rating & Facing

REFERENCE SPECIFICATIONS

Compiled

6

DN"

10

12

14

16

BRANCH SIZE

18

20

24

30

36

NOTES:

1) All carbon steel bolting on flanges, valves & "Y" strainers shall be zinc coating

(hot-dip) to ASTM A-153.

3) Threaded Ends and connections are allowed for instrument taps only (15801).

Company's sole property document . Company will protect his right by law.

You might also like

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- A09Document1 pageA09liviu_dovaNo ratings yet

- Specification for weakly corrosive hydrocarbon piping systemDocument1 pageSpecification for weakly corrosive hydrocarbon piping systemhalim_ka100% (1)

- AGIP 04061.PIP.MEC.SDS INTERNAL NORMALIZATION PIPING PROJECT SPECIFICATIONDocument1 pageAGIP 04061.PIP.MEC.SDS INTERNAL NORMALIZATION PIPING PROJECT SPECIFICATIONhalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Internal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water SystemsDocument1 pageInternal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water Systemsliviu_dovaNo ratings yet

- Internal Normalization Piping Project Specification for Weakly Corrosive HydrocarbonsDocument1 pageInternal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbonsliviu_dovaNo ratings yet

- Piping Project Specification for Non-Corrosive Hydrocarbon ServiceDocument1 pagePiping Project Specification for Non-Corrosive Hydrocarbon Servicehalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- D11Document1 pageD11liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°CDocument1 pageAGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°Chalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Piping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain SystemsDocument1 pagePiping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain Systemshalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- Piping Shortage MaterialDocument12 pagesPiping Shortage MaterialAnonymous i3lI9MNo ratings yet

- 094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1Document80 pages094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1thongNo ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- Piping Project Specification for Mean Pressure Steam and Steam Condensate ServiceDocument1 pagePiping Project Specification for Mean Pressure Steam and Steam Condensate Servicehalim_kaNo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- Ep31492 PDFDocument11 pagesEp31492 PDFJilJilNo ratings yet

- 15CSTL NaDocument3 pages15CSTL NaVipin NairNo ratings yet

- Class A1D1Document8 pagesClass A1D1SalimNo ratings yet

- rc61180 b09Document9 pagesrc61180 b09eww08No ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- SEQ REV NOTE - Item and Material Listing for Piping SystemDocument6 pagesSEQ REV NOTE - Item and Material Listing for Piping SystemMuhsen KhanNo ratings yet

- Material EquivalentsDocument25 pagesMaterial EquivalentsAditya B. Ryanto100% (6)

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- GID-1630-ME-LD-ds-5214: SL - No Description Material OD MM Length MM Weith MM THK MMDocument3 pagesGID-1630-ME-LD-ds-5214: SL - No Description Material OD MM Length MM Weith MM THK MMManikandanNo ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Bohler Bestseller Engl NTDocument28 pagesBohler Bestseller Engl NTClaudia MmsNo ratings yet

- Valve Description Code PagesDocument13 pagesValve Description Code PagesAdrian GallegosNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingganeshNo ratings yet

- STD PipingDocument51 pagesSTD PipingRodrigo Iván Latorre AlmirallNo ratings yet

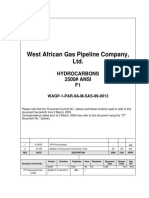

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Document5 pagesWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- Abu Dhabi Oil Refining Company Testing Laboratory SpecificationDocument17 pagesAbu Dhabi Oil Refining Company Testing Laboratory Specificationhalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaNo ratings yet

- 15378E01Document1 page15378E01halim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- Appendix B. Sample Problem: Chevron Corporation B-1 March 1991Document2 pagesAppendix B. Sample Problem: Chevron Corporation B-1 March 1991halim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaNo ratings yet

- 15378E01Document1 page15378E01halim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet