Professional Documents

Culture Documents

Uploads Downloads Files Li Ion Vs Lead Acid WEB 1

Uploads Downloads Files Li Ion Vs Lead Acid WEB 1

Uploaded by

JorenStevenMadriagaSaclotOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uploads Downloads Files Li Ion Vs Lead Acid WEB 1

Uploads Downloads Files Li Ion Vs Lead Acid WEB 1

Uploaded by

JorenStevenMadriagaSaclotCopyright:

Available Formats

Li-Ion vs.

Lead Acid

Summary of Li-Ion advantages compared to Lead Acid

Li-Ion Advantages

Higher voltage in Lithium Ion over Lead Acid 3.7v vs 2.0v (almost 2x)

Greater Energy Density per unit Weight (3x), Volume (6x)

Lighter / smaller providing more portability, less storage space, could even eliminate storage boxes

Tolerates Higher Temp (140F vs 80F), No Air Conditioning required (vs spending 10% of capacity)

Faster recharge time, and More time between recharges (26 wks vs continuous or max 2 wks)

Higher turnaround charge efficiency (97% vs 75%)

More Discharge Cycles (2x)

Deeper Discharge Tolerance (95% vs 50%) Can offset cost due to shallow Lead Acid discharge

State of Health and State of Charge can be readily and remotely monitored

Longer time between service (24-36+ mos vs 6 mos)

Replacement timeframe

Li-Ion 5-7 years

Lead Acid 1.5 - 2 years

Li-Ion Disadvantages

Li-Ion

Protection Circuitry is custom & expensive

Lead Acid

Overall Circuitry is Commercial off the Shelf (COTS) & inexpensive

Li-Ion volatility must be closely managed and addresses with safety considerations in design

Individual Cell cost ROM Li-Ion $300-$400 / kWhr vs Lead Acid $80-$100 / kWhr

Sys Cost (with circuitry) ROM

$500 / kWhr

$125 / kWhr

Ultralife Corporation

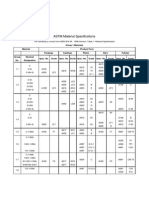

Details of Comparison: Lead Acid - Li-Ion

Lead Acid

Energy Density

Nominal Cell voltage

Voltage operating range

Wh/kg

Wh/liter

2.0v

1.8-2.1v

35-40

70

3.7v

3.2-4.1v

140-150

400

Size of a

14 Liters

2.5 Liters

873 cubic inches

153 cubic inches

1 kWh battery

Weight of a 1 kWh battery

25kg, 55lbs

6.7kg, 14.8 lbs

Size of a

14,285 Liters,

2,500 Liters,

1 MWh battery

504 cubic feet

(1/2 of a 20 shipping container)

Weight of a 1 MWh battery

Ultralife Corporation

20 Ft Shipping container

40 Ft Shipping container

88 cubic feet

25,000kg,

6,700kg,

55,115 lbs

14,770 lbs

Reference sizes and weights

Li-Ion (Cobalt)

1160 cu ft, 4928 lbs

2360 cu ft, 7392 lbs

Details of Comparison: Lead Acid - Li-Ion

Lead Acid

Temperature

Li-Ion (Cobalt)

Requires Air temp Control >75F

Loses 50% every 10F >77F

High temp Survival / Life Reduction

OK to 25C (77F)

Life % remaining at Disch Temp 100% at 77F

50% at 87F

25% at 97F

12% at 107F

6% at 117F

3% at 127F

0% at 137F (60C)

Low Temp (Partial Functionality)

To -40C

Charging

Over-chargeability

Protection Circuitry

(Overvoltage and Discharge)

Constant Charging rate in terms of C

Recharging time duration

Recharge interval

Turnaround Charge Efficiency

Temp range of Charge

Cost to recharge (as % of capacity)

Self Discharge %/month or year

Ultralife Corporation

OK to 60C (140F)

100%

100%

100%

100%

100%

100%

100%

To -25C

Tolerant (forms H2 gas)

COTS, inexpensive

Intolerant - Vents

Custom, expensive

0.07C rate

10 x the capacity

needs recharge weekly

75%

-40C (-40F) +27C (80F)

C rate (10x faster)

1x the capacity

needs recharge every 6 mos

97%

-20C (-4F) + 55C(131F)

8%/month, 63%/year

1.5%/month, 17%/year

Details of Comparison: Lead Acid - Li-Ion

Lead Acid

Operation

Voltage profile (during discharge)

Failure mode

(assumes traditional control circuits)

Cycles

State of charge measured by

Costs

Cell cost

Assembled Sys Cost (with circuitry)

Maintenance costs and frequency

Operating costs

Air conditioning

Service Interval

Replacement timeframe

At 10% discharge

At 50% discharge

At 95% discharge

Ultralife Corporation

Li-Ion (Cobalt)

Sloping

Flat

will not accept charge predictive based on cycles

and efficiency

1750

500

250

4000+

1000

500

Voltage level

Rough

Coulombs transferred

Exact

$80-$100 / kWhr

$125 / kWhr

SLA = 2%

VRLA=10%

$300-$400 / kWhr

$500 / kWhr

None

8% of capacity

6 mos

None required

12 mos

2 years

5-7 years

Assumes life is not limited by number of discharge cycles, instead by time

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DR 4000 User ManualDocument116 pagesDR 4000 User ManualJovan Agatonović StraussNo ratings yet

- Kashmiri Rituals Kah-NaetherDocument1 pageKashmiri Rituals Kah-NaetherdchattaNo ratings yet

- Tonight I Can Write (The Saddest Lines) : Pablo NerudaDocument2 pagesTonight I Can Write (The Saddest Lines) : Pablo NerudadchattaNo ratings yet

- ASTM Material SpecificationsDocument1 pageASTM Material SpecificationsdchattaNo ratings yet

- PoetryDocument3 pagesPoetrydchattaNo ratings yet

- Machhail MataDocument2 pagesMachhail MatadchattaNo ratings yet

- 46.innovative Congestion Control System For Ambulance Using ZigbeeDocument4 pages46.innovative Congestion Control System For Ambulance Using ZigbeebalabooksNo ratings yet

- CD4094BCDocument4 pagesCD4094BCcafumanashopNo ratings yet

- P225 PDFDocument12 pagesP225 PDFdave chaudhuryNo ratings yet

- Training Material of MS82CT ChassisDocument36 pagesTraining Material of MS82CT Chassisبوند بوندNo ratings yet

- Tutorial 3 (Cable and Sizing of Conductors) ESB S2 2013 Student VersionDocument5 pagesTutorial 3 (Cable and Sizing of Conductors) ESB S2 2013 Student VersionNajiyah SalehNo ratings yet

- Power Wave Advanced Module & Advanced Module Aluminum: Operator'S ManualDocument34 pagesPower Wave Advanced Module & Advanced Module Aluminum: Operator'S ManualnikolovskidareNo ratings yet

- Kenwood TM v71 Programming GuideDocument2 pagesKenwood TM v71 Programming GuidePurevsambuu BatbilegNo ratings yet

- Physics 30 Diploma ReviewDocument7 pagesPhysics 30 Diploma ReviewRahulNo ratings yet

- F321 Module 1 Practice 3Document7 pagesF321 Module 1 Practice 311pearcerNo ratings yet

- Electronics and Communication Ece Formula Book For Gate Ies and PsuDocument56 pagesElectronics and Communication Ece Formula Book For Gate Ies and PsuThomas James88% (16)

- Basics of ElectrochemistryDocument7 pagesBasics of Electrochemistryaman pandeyNo ratings yet

- Study On Grounding System and Safety PracticesDocument29 pagesStudy On Grounding System and Safety PracticesFaiz MangalasseryNo ratings yet

- Cqa SuspensionDocument78 pagesCqa SuspensionSanjay MehrishiNo ratings yet

- AWG To Square MM Wire Gauge ConversionDocument2 pagesAWG To Square MM Wire Gauge Conversionsteve_yNo ratings yet

- Wireless Broadband With Wimax: Hype and Reality: Dr. Jeffrey G. AndrewsDocument25 pagesWireless Broadband With Wimax: Hype and Reality: Dr. Jeffrey G. AndrewsKarthik SharmaNo ratings yet

- Model 5190-C Temperature/Humidity Probe User's ManualDocument8 pagesModel 5190-C Temperature/Humidity Probe User's ManualNguyễn Văn TrungNo ratings yet

- Mecanismo Radio Avh x2750btDocument55 pagesMecanismo Radio Avh x2750btmarcoaguNo ratings yet

- List of Melaka CompaniesDocument3 pagesList of Melaka CompaniesNasrul SalmanNo ratings yet

- Bluespec Systemverilog Reference GuideDocument474 pagesBluespec Systemverilog Reference GuideSHIBU M RNo ratings yet

- FFT Computation and Generation of SpectrogramDocument32 pagesFFT Computation and Generation of Spectrogramps1188No ratings yet

- 3 Course StudiesDocument16 pages3 Course Studiestaz_taz3No ratings yet

- UM3481Document4 pagesUM3481mungos967No ratings yet

- Helium Neon LaserDocument13 pagesHelium Neon LaserJose GalvanNo ratings yet

- (Amphenol 10 Port) Type 3B 6898408G SZXDocument5 pages(Amphenol 10 Port) Type 3B 6898408G SZXyusufapwNo ratings yet

- Lec. (7) - Generator ProtectionDocument64 pagesLec. (7) - Generator ProtectionSalmi Nour E'ddineNo ratings yet

- ATS48 User ManualDocument85 pagesATS48 User Manualkythuat04 nteNo ratings yet

- Lockdown DDocument19 pagesLockdown DGeorge MihailaNo ratings yet

- F01T100 Cabinet Datasheet 01Document1 pageF01T100 Cabinet Datasheet 01Itthiphol RattanachoteNo ratings yet

- PhilipsDocument8 pagesPhilipseduardoquijadaNo ratings yet